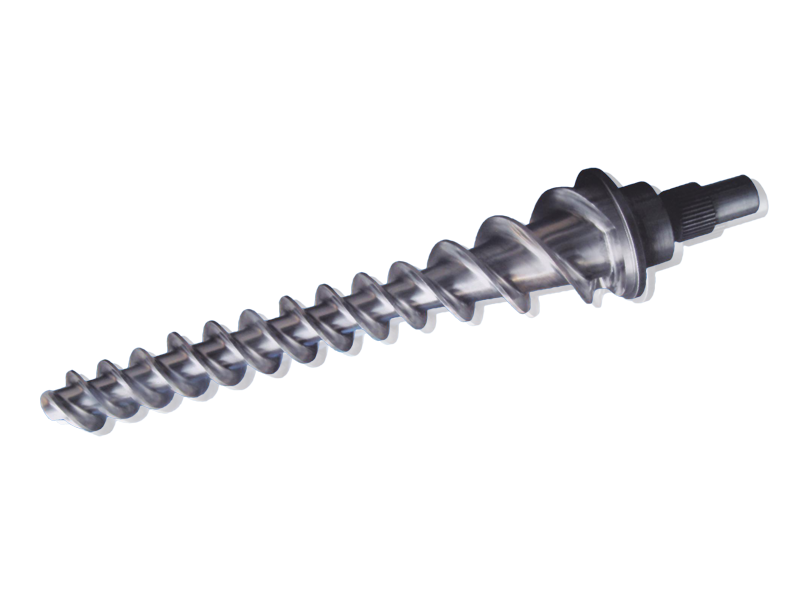

Extruder Feed Screw . The screw’s feed section starts by pushing materials into the compression zone, where they get compacted and begin melting due to heat and pressure. In the middle is the compression zone, walls close in on the melt/pellet mix, drive air backward and make up for slipping and rolling of pellets in the feed zone. Feed screws are essential in the extrusion process as they convey the raw material from the hopper to the barrel. Constant depth, takes up 15 to 30% of length. They can be located at the feed end or at a partially filled. The screw starts with a feed zone: For over, 27years tir manufactures and designs quality feed screws, barrels, and relined feed throats for extrusion/injection molding compounding machines. They are used to feed solid material into the extruder by a conveying screw. • pp screw would have a shallower metering section to help in. • ldpe screw would have shorter feed and faster transition.

from www.chinafudesi.com

They can be located at the feed end or at a partially filled. • ldpe screw would have shorter feed and faster transition. • pp screw would have a shallower metering section to help in. Constant depth, takes up 15 to 30% of length. The screw’s feed section starts by pushing materials into the compression zone, where they get compacted and begin melting due to heat and pressure. The screw starts with a feed zone: They are used to feed solid material into the extruder by a conveying screw. Feed screws are essential in the extrusion process as they convey the raw material from the hopper to the barrel. In the middle is the compression zone, walls close in on the melt/pellet mix, drive air backward and make up for slipping and rolling of pellets in the feed zone. For over, 27years tir manufactures and designs quality feed screws, barrels, and relined feed throats for extrusion/injection molding compounding machines.

Hot Feed Rubber Extruder Screws ZHOUSHAN FUDES MACHINERY CO., LTD.

Extruder Feed Screw Constant depth, takes up 15 to 30% of length. The screw starts with a feed zone: Constant depth, takes up 15 to 30% of length. They are used to feed solid material into the extruder by a conveying screw. The screw’s feed section starts by pushing materials into the compression zone, where they get compacted and begin melting due to heat and pressure. They can be located at the feed end or at a partially filled. In the middle is the compression zone, walls close in on the melt/pellet mix, drive air backward and make up for slipping and rolling of pellets in the feed zone. • ldpe screw would have shorter feed and faster transition. Feed screws are essential in the extrusion process as they convey the raw material from the hopper to the barrel. • pp screw would have a shallower metering section to help in. For over, 27years tir manufactures and designs quality feed screws, barrels, and relined feed throats for extrusion/injection molding compounding machines.

From www.chinafudesi.com

Hot Feed Rubber Extruder Screws ZHOUSHAN FUDES MACHINERY CO., LTD. Extruder Feed Screw • pp screw would have a shallower metering section to help in. They are used to feed solid material into the extruder by a conveying screw. • ldpe screw would have shorter feed and faster transition. In the middle is the compression zone, walls close in on the melt/pellet mix, drive air backward and make up for slipping and rolling. Extruder Feed Screw.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process Extruder Feed Screw They are used to feed solid material into the extruder by a conveying screw. • ldpe screw would have shorter feed and faster transition. Feed screws are essential in the extrusion process as they convey the raw material from the hopper to the barrel. The screw starts with a feed zone: The screw’s feed section starts by pushing materials into. Extruder Feed Screw.

From www.cpshzy.com

China Professional manufacturer Twin Screw Extruder for Feed industry Extruder Feed Screw For over, 27years tir manufactures and designs quality feed screws, barrels, and relined feed throats for extrusion/injection molding compounding machines. • pp screw would have a shallower metering section to help in. Feed screws are essential in the extrusion process as they convey the raw material from the hopper to the barrel. They are used to feed solid material into. Extruder Feed Screw.

From www.ejsscrewbarrel.com

Factory For China Extrusion Feed Screws manufacturers and suppliers EJS Extruder Feed Screw They can be located at the feed end or at a partially filled. The screw’s feed section starts by pushing materials into the compression zone, where they get compacted and begin melting due to heat and pressure. In the middle is the compression zone, walls close in on the melt/pellet mix, drive air backward and make up for slipping and. Extruder Feed Screw.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process Extruder Feed Screw Constant depth, takes up 15 to 30% of length. They are used to feed solid material into the extruder by a conveying screw. • pp screw would have a shallower metering section to help in. They can be located at the feed end or at a partially filled. For over, 27years tir manufactures and designs quality feed screws, barrels, and. Extruder Feed Screw.

From qbchannel.en.made-in-china.com

Extruder Feed Screw Barrel Rubber Screw Barrel for Plastic Extruder Extruder Feed Screw Feed screws are essential in the extrusion process as they convey the raw material from the hopper to the barrel. • ldpe screw would have shorter feed and faster transition. For over, 27years tir manufactures and designs quality feed screws, barrels, and relined feed throats for extrusion/injection molding compounding machines. The screw starts with a feed zone: They can be. Extruder Feed Screw.

From www.youtube.com

Feed Screw Manufacturing Process. Singlescrew & Twins Extruder Extruder Feed Screw In the middle is the compression zone, walls close in on the melt/pellet mix, drive air backward and make up for slipping and rolling of pellets in the feed zone. Constant depth, takes up 15 to 30% of length. • pp screw would have a shallower metering section to help in. The screw’s feed section starts by pushing materials into. Extruder Feed Screw.

From extruder-screw.com

Extrusion screw Extruder Feed Screw & Barrel Extruder Feed Screw • pp screw would have a shallower metering section to help in. The screw’s feed section starts by pushing materials into the compression zone, where they get compacted and begin melting due to heat and pressure. The screw starts with a feed zone: They can be located at the feed end or at a partially filled. • ldpe screw would. Extruder Feed Screw.

From www.fareastnetwork.co.jp

What is an extruder? Structure and mechanism detailed explanation Extruder Feed Screw They are used to feed solid material into the extruder by a conveying screw. The screw’s feed section starts by pushing materials into the compression zone, where they get compacted and begin melting due to heat and pressure. For over, 27years tir manufactures and designs quality feed screws, barrels, and relined feed throats for extrusion/injection molding compounding machines. • pp. Extruder Feed Screw.

From extruder-screw.com

Products Extruder Feed Screw & Barrel Extruder Feed Screw They can be located at the feed end or at a partially filled. • pp screw would have a shallower metering section to help in. Constant depth, takes up 15 to 30% of length. • ldpe screw would have shorter feed and faster transition. They are used to feed solid material into the extruder by a conveying screw. The screw. Extruder Feed Screw.

From www.cowinextrusion.com

5 minutes to understand the extruder Cowin Extrusion Extruder Feed Screw Constant depth, takes up 15 to 30% of length. In the middle is the compression zone, walls close in on the melt/pellet mix, drive air backward and make up for slipping and rolling of pellets in the feed zone. Feed screws are essential in the extrusion process as they convey the raw material from the hopper to the barrel. •. Extruder Feed Screw.

From www.twinscrewextruder-parts.com

PP ABS Twin Screw Extruder Side Feeder KY75 Type 300rpm Output Screw Speed Extruder Feed Screw For over, 27years tir manufactures and designs quality feed screws, barrels, and relined feed throats for extrusion/injection molding compounding machines. The screw’s feed section starts by pushing materials into the compression zone, where they get compacted and begin melting due to heat and pressure. Feed screws are essential in the extrusion process as they convey the raw material from the. Extruder Feed Screw.

From www.fish-feed-extruder.com

Qualified Fish Feed Extruders and Feed Production Line by Expert Extruder Feed Screw • pp screw would have a shallower metering section to help in. • ldpe screw would have shorter feed and faster transition. They are used to feed solid material into the extruder by a conveying screw. Feed screws are essential in the extrusion process as they convey the raw material from the hopper to the barrel. In the middle is. Extruder Feed Screw.

From extruder-screw.com

Single Screw Barrel Extruder Feed Screw & Barrel Extruder Feed Screw • pp screw would have a shallower metering section to help in. For over, 27years tir manufactures and designs quality feed screws, barrels, and relined feed throats for extrusion/injection molding compounding machines. • ldpe screw would have shorter feed and faster transition. They are used to feed solid material into the extruder by a conveying screw. Constant depth, takes up. Extruder Feed Screw.

From idah.com

High Quality Extruder Single Screw Extruder (for Aqua Feed and Pet Extruder Feed Screw They are used to feed solid material into the extruder by a conveying screw. • ldpe screw would have shorter feed and faster transition. The screw starts with a feed zone: Constant depth, takes up 15 to 30% of length. In the middle is the compression zone, walls close in on the melt/pellet mix, drive air backward and make up. Extruder Feed Screw.

From www.rbplasticsmachinery.com

Plastic Extrusion Screws R&B Plastics Machinery Extruder Feed Screw For over, 27years tir manufactures and designs quality feed screws, barrels, and relined feed throats for extrusion/injection molding compounding machines. Feed screws are essential in the extrusion process as they convey the raw material from the hopper to the barrel. • ldpe screw would have shorter feed and faster transition. In the middle is the compression zone, walls close in. Extruder Feed Screw.

From www.indiamart.com

Twin Screw Floating Fish Feed Extruder, 500 kg per hr at Rs 1750000 in Pune Extruder Feed Screw • ldpe screw would have shorter feed and faster transition. Feed screws are essential in the extrusion process as they convey the raw material from the hopper to the barrel. They can be located at the feed end or at a partially filled. They are used to feed solid material into the extruder by a conveying screw. The screw starts. Extruder Feed Screw.

From www.youtube.com

Extruder Feed Screw Manufacturing, Rebuilding, and Design Glycon Corp Extruder Feed Screw They can be located at the feed end or at a partially filled. • pp screw would have a shallower metering section to help in. They are used to feed solid material into the extruder by a conveying screw. In the middle is the compression zone, walls close in on the melt/pellet mix, drive air backward and make up for. Extruder Feed Screw.

From mungfali.com

Single Screw Extruder Diagram Extruder Feed Screw • pp screw would have a shallower metering section to help in. For over, 27years tir manufactures and designs quality feed screws, barrels, and relined feed throats for extrusion/injection molding compounding machines. Constant depth, takes up 15 to 30% of length. Feed screws are essential in the extrusion process as they convey the raw material from the hopper to the. Extruder Feed Screw.

From idah.com

Patented Extruder Technology Counterrotating Twin Screw Extruder Extruder Feed Screw For over, 27years tir manufactures and designs quality feed screws, barrels, and relined feed throats for extrusion/injection molding compounding machines. The screw starts with a feed zone: Constant depth, takes up 15 to 30% of length. The screw’s feed section starts by pushing materials into the compression zone, where they get compacted and begin melting due to heat and pressure.. Extruder Feed Screw.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process Extruder Feed Screw Constant depth, takes up 15 to 30% of length. • ldpe screw would have shorter feed and faster transition. • pp screw would have a shallower metering section to help in. Feed screws are essential in the extrusion process as they convey the raw material from the hopper to the barrel. The screw starts with a feed zone: They can. Extruder Feed Screw.

From www.chinafudesi.com

Hot Feed Rubber Extruder Screws ZHOUSHAN FUDES MACHINERY CO., LTD. Extruder Feed Screw They are used to feed solid material into the extruder by a conveying screw. • pp screw would have a shallower metering section to help in. In the middle is the compression zone, walls close in on the melt/pellet mix, drive air backward and make up for slipping and rolling of pellets in the feed zone. • ldpe screw would. Extruder Feed Screw.

From www.chinafudesi.com

Hot Feed Rubber Extruder Screws ZHOUSHAN FUDES MACHINERY CO., LTD. Extruder Feed Screw The screw’s feed section starts by pushing materials into the compression zone, where they get compacted and begin melting due to heat and pressure. They can be located at the feed end or at a partially filled. They are used to feed solid material into the extruder by a conveying screw. For over, 27years tir manufactures and designs quality feed. Extruder Feed Screw.

From fish-feed-extruder.com

Feed Pellet Extruder for Kinds of Aquafeed Extruder Feed Screw The screw’s feed section starts by pushing materials into the compression zone, where they get compacted and begin melting due to heat and pressure. • pp screw would have a shallower metering section to help in. Constant depth, takes up 15 to 30% of length. They can be located at the feed end or at a partially filled. In the. Extruder Feed Screw.

From www.youtube.com

Single screw fish feed extruder YouTube Extruder Feed Screw For over, 27years tir manufactures and designs quality feed screws, barrels, and relined feed throats for extrusion/injection molding compounding machines. Feed screws are essential in the extrusion process as they convey the raw material from the hopper to the barrel. They are used to feed solid material into the extruder by a conveying screw. They can be located at the. Extruder Feed Screw.

From www.haisiextrusion.com

PP + Glass Fibre Twin Screw Extruder with Feeding Platform Buy twin Extruder Feed Screw Feed screws are essential in the extrusion process as they convey the raw material from the hopper to the barrel. They are used to feed solid material into the extruder by a conveying screw. For over, 27years tir manufactures and designs quality feed screws, barrels, and relined feed throats for extrusion/injection molding compounding machines. • ldpe screw would have shorter. Extruder Feed Screw.

From www.concortool.com

Concor Tool and Machine Screws, Barrels, Tips, and Endcaps, for Extruder Feed Screw They can be located at the feed end or at a partially filled. • ldpe screw would have shorter feed and faster transition. The screw’s feed section starts by pushing materials into the compression zone, where they get compacted and begin melting due to heat and pressure. • pp screw would have a shallower metering section to help in. They. Extruder Feed Screw.

From www.indiamart.com

Extruder Feed Screw at Rs 15000/piece Extruder Feed Screw in Extruder Feed Screw • ldpe screw would have shorter feed and faster transition. Constant depth, takes up 15 to 30% of length. The screw starts with a feed zone: The screw’s feed section starts by pushing materials into the compression zone, where they get compacted and begin melting due to heat and pressure. They are used to feed solid material into the extruder. Extruder Feed Screw.

From www.chinafudesi.com

Hot Feed Rubber Extruder Screws ZHOUSHAN FUDES MACHINERY CO., LTD. Extruder Feed Screw Constant depth, takes up 15 to 30% of length. Feed screws are essential in the extrusion process as they convey the raw material from the hopper to the barrel. They are used to feed solid material into the extruder by a conveying screw. The screw starts with a feed zone: For over, 27years tir manufactures and designs quality feed screws,. Extruder Feed Screw.

From www.rbplasticsmachinery.com

Plastic Extrusion Screws R&B Plastics Machinery Extruder Feed Screw • ldpe screw would have shorter feed and faster transition. • pp screw would have a shallower metering section to help in. Constant depth, takes up 15 to 30% of length. Feed screws are essential in the extrusion process as they convey the raw material from the hopper to the barrel. They can be located at the feed end or. Extruder Feed Screw.

From extruder-screw.com

Extruder Twin Screw Extruder Feed Screw & Barrel Extruder Feed Screw They are used to feed solid material into the extruder by a conveying screw. They can be located at the feed end or at a partially filled. The screw starts with a feed zone: • pp screw would have a shallower metering section to help in. For over, 27years tir manufactures and designs quality feed screws, barrels, and relined feed. Extruder Feed Screw.

From www.rbplasticsmachinery.com

Plastic Extrusion Screws R&B Plastics Machinery Extruder Feed Screw The screw starts with a feed zone: They can be located at the feed end or at a partially filled. In the middle is the compression zone, walls close in on the melt/pellet mix, drive air backward and make up for slipping and rolling of pellets in the feed zone. For over, 27years tir manufactures and designs quality feed screws,. Extruder Feed Screw.

From arrowextrusion.en.made-in-china.com

Twin Screw Extruder Dry Type Fish Feed Extruder China Feed Pellet Extruder Feed Screw They can be located at the feed end or at a partially filled. The screw starts with a feed zone: In the middle is the compression zone, walls close in on the melt/pellet mix, drive air backward and make up for slipping and rolling of pellets in the feed zone. They are used to feed solid material into the extruder. Extruder Feed Screw.

From www.chinafudesi.com

Hot Feed Rubber Extruder Screws ZHOUSHAN FUDES MACHINERY CO., LTD. Extruder Feed Screw • pp screw would have a shallower metering section to help in. For over, 27years tir manufactures and designs quality feed screws, barrels, and relined feed throats for extrusion/injection molding compounding machines. The screw’s feed section starts by pushing materials into the compression zone, where they get compacted and begin melting due to heat and pressure. Constant depth, takes up. Extruder Feed Screw.

From popexup.en.made-in-china.com

Screw Type Hot Feed Cold Feed Rubber Extruder Rubber Machine Extruder Extruder Feed Screw • pp screw would have a shallower metering section to help in. The screw’s feed section starts by pushing materials into the compression zone, where they get compacted and begin melting due to heat and pressure. Feed screws are essential in the extrusion process as they convey the raw material from the hopper to the barrel. They are used to. Extruder Feed Screw.