Loading Ramp Standards . The maximum grade percentage from the loading dock to the vehicle is determined by the height of the dock (discussed in detail in set the dock. Loading ramps and forcing yards are the most hazardous areas in livestock handling, posing risks such as crushing, lacerations, and falls. The best internal width between rails for loading is 750mm. Side panels should be at least 1.5 metres high. By properly positioning, using, and maintaining your loading ramp, it can help you maintain efficiency in your warehouse for years. When designing a loading dock ramp, make sure the slope is. Knowing the risks, as well as osha and state requirements, and maintaining a safe zone around loading docks is an important first step in preventing injuries and fatalities. If the slope of a ramp or a walkway is steeper than one (1) vertical in eight (8) horizontal, the ramp or walkway shall have cleats not more than.

from gbu-presnenskij.ru

Knowing the risks, as well as osha and state requirements, and maintaining a safe zone around loading docks is an important first step in preventing injuries and fatalities. By properly positioning, using, and maintaining your loading ramp, it can help you maintain efficiency in your warehouse for years. The maximum grade percentage from the loading dock to the vehicle is determined by the height of the dock (discussed in detail in set the dock. The best internal width between rails for loading is 750mm. Loading ramps and forcing yards are the most hazardous areas in livestock handling, posing risks such as crushing, lacerations, and falls. Side panels should be at least 1.5 metres high. If the slope of a ramp or a walkway is steeper than one (1) vertical in eight (8) horizontal, the ramp or walkway shall have cleats not more than. When designing a loading dock ramp, make sure the slope is.

Ramp Straight Run Dimensions Drawings, 42 OFF

Loading Ramp Standards If the slope of a ramp or a walkway is steeper than one (1) vertical in eight (8) horizontal, the ramp or walkway shall have cleats not more than. Side panels should be at least 1.5 metres high. When designing a loading dock ramp, make sure the slope is. If the slope of a ramp or a walkway is steeper than one (1) vertical in eight (8) horizontal, the ramp or walkway shall have cleats not more than. By properly positioning, using, and maintaining your loading ramp, it can help you maintain efficiency in your warehouse for years. Knowing the risks, as well as osha and state requirements, and maintaining a safe zone around loading docks is an important first step in preventing injuries and fatalities. The maximum grade percentage from the loading dock to the vehicle is determined by the height of the dock (discussed in detail in set the dock. The best internal width between rails for loading is 750mm. Loading ramps and forcing yards are the most hazardous areas in livestock handling, posing risks such as crushing, lacerations, and falls.

From www.duraramp.com

How to Properly Set Up Your Loading Ramp DuraRamp Loading Ramp Standards When designing a loading dock ramp, make sure the slope is. Loading ramps and forcing yards are the most hazardous areas in livestock handling, posing risks such as crushing, lacerations, and falls. By properly positioning, using, and maintaining your loading ramp, it can help you maintain efficiency in your warehouse for years. The maximum grade percentage from the loading dock. Loading Ramp Standards.

From www.agwarehouse.com.au

Norton Cattle Loading Ramp Standard Adjustable AG Warehouse Loading Ramp Standards Side panels should be at least 1.5 metres high. Loading ramps and forcing yards are the most hazardous areas in livestock handling, posing risks such as crushing, lacerations, and falls. The maximum grade percentage from the loading dock to the vehicle is determined by the height of the dock (discussed in detail in set the dock. When designing a loading. Loading Ramp Standards.

From www.duraramp.com

DuraRamp Solutions Truck Loading Ramp Solutions Loading Ramp Standards When designing a loading dock ramp, make sure the slope is. Knowing the risks, as well as osha and state requirements, and maintaining a safe zone around loading docks is an important first step in preventing injuries and fatalities. By properly positioning, using, and maintaining your loading ramp, it can help you maintain efficiency in your warehouse for years. If. Loading Ramp Standards.

From www.sheepcentral.com

Loading ramp changes must be guidelines only, say livestock bodies Loading Ramp Standards If the slope of a ramp or a walkway is steeper than one (1) vertical in eight (8) horizontal, the ramp or walkway shall have cleats not more than. Knowing the risks, as well as osha and state requirements, and maintaining a safe zone around loading docks is an important first step in preventing injuries and fatalities. The maximum grade. Loading Ramp Standards.

From alsafriksteel.com

How to choose the right Loading Ramp? Al Safrik Steel Loading Ramp Standards Side panels should be at least 1.5 metres high. The maximum grade percentage from the loading dock to the vehicle is determined by the height of the dock (discussed in detail in set the dock. When designing a loading dock ramp, make sure the slope is. Loading ramps and forcing yards are the most hazardous areas in livestock handling, posing. Loading Ramp Standards.

From feedingtrends.com

Types of Loading Ramps Which One Is the Best? Loading Ramp Standards The maximum grade percentage from the loading dock to the vehicle is determined by the height of the dock (discussed in detail in set the dock. Knowing the risks, as well as osha and state requirements, and maintaining a safe zone around loading docks is an important first step in preventing injuries and fatalities. When designing a loading dock ramp,. Loading Ramp Standards.

From maintco.com

ADA Curb Ramp Requirements Maintco Corp. Loading Ramp Standards The best internal width between rails for loading is 750mm. The maximum grade percentage from the loading dock to the vehicle is determined by the height of the dock (discussed in detail in set the dock. Loading ramps and forcing yards are the most hazardous areas in livestock handling, posing risks such as crushing, lacerations, and falls. When designing a. Loading Ramp Standards.

From www.diggawest.com.au

Aluminium Loading Ramps Digga West Loading Ramp Standards Side panels should be at least 1.5 metres high. Knowing the risks, as well as osha and state requirements, and maintaining a safe zone around loading docks is an important first step in preventing injuries and fatalities. The best internal width between rails for loading is 750mm. When designing a loading dock ramp, make sure the slope is. If the. Loading Ramp Standards.

From jnjxlift.en.made-in-china.com

China Wholesale Loading Dock Ramp Slope 6t 8t 10t 12t 15t European Loading Ramp Standards If the slope of a ramp or a walkway is steeper than one (1) vertical in eight (8) horizontal, the ramp or walkway shall have cleats not more than. Loading ramps and forcing yards are the most hazardous areas in livestock handling, posing risks such as crushing, lacerations, and falls. The best internal width between rails for loading is 750mm.. Loading Ramp Standards.

From www.duraramp.com

Railcar Loading Ramp Safety Tips DuraRamp Loading Ramp Standards Knowing the risks, as well as osha and state requirements, and maintaining a safe zone around loading docks is an important first step in preventing injuries and fatalities. Side panels should be at least 1.5 metres high. The maximum grade percentage from the loading dock to the vehicle is determined by the height of the dock (discussed in detail in. Loading Ramp Standards.

From www.storetogo.ae

Steel Loading Ramps Heavy Duty Loading Ramps in UAE StoreToGoUAE Loading Ramp Standards By properly positioning, using, and maintaining your loading ramp, it can help you maintain efficiency in your warehouse for years. If the slope of a ramp or a walkway is steeper than one (1) vertical in eight (8) horizontal, the ramp or walkway shall have cleats not more than. The best internal width between rails for loading is 750mm. Knowing. Loading Ramp Standards.

From www.bigrentz.com

Forklift Ramp Slope Incline Requirements & Safety Guidelines Bigrentz Loading Ramp Standards Side panels should be at least 1.5 metres high. If the slope of a ramp or a walkway is steeper than one (1) vertical in eight (8) horizontal, the ramp or walkway shall have cleats not more than. Knowing the risks, as well as osha and state requirements, and maintaining a safe zone around loading docks is an important first. Loading Ramp Standards.

From www.phl.co.uk

Easyramps Container Loading Ramps Forklift Ramps Loading Ramp Standards Side panels should be at least 1.5 metres high. When designing a loading dock ramp, make sure the slope is. Loading ramps and forcing yards are the most hazardous areas in livestock handling, posing risks such as crushing, lacerations, and falls. If the slope of a ramp or a walkway is steeper than one (1) vertical in eight (8) horizontal,. Loading Ramp Standards.

From www.beefcentral.com

Loading ramp changes should be 'guidelines', not standards livestock Loading Ramp Standards Knowing the risks, as well as osha and state requirements, and maintaining a safe zone around loading docks is an important first step in preventing injuries and fatalities. Loading ramps and forcing yards are the most hazardous areas in livestock handling, posing risks such as crushing, lacerations, and falls. When designing a loading dock ramp, make sure the slope is.. Loading Ramp Standards.

From gbu-presnenskij.ru

Ramp Straight Run Dimensions Drawings, 42 OFF Loading Ramp Standards Knowing the risks, as well as osha and state requirements, and maintaining a safe zone around loading docks is an important first step in preventing injuries and fatalities. Side panels should be at least 1.5 metres high. If the slope of a ramp or a walkway is steeper than one (1) vertical in eight (8) horizontal, the ramp or walkway. Loading Ramp Standards.

From www.rpmrural.com

Cattle Loading Ramps Cattle Yards Australia RPM Rural Loading Ramp Standards By properly positioning, using, and maintaining your loading ramp, it can help you maintain efficiency in your warehouse for years. If the slope of a ramp or a walkway is steeper than one (1) vertical in eight (8) horizontal, the ramp or walkway shall have cleats not more than. Loading ramps and forcing yards are the most hazardous areas in. Loading Ramp Standards.

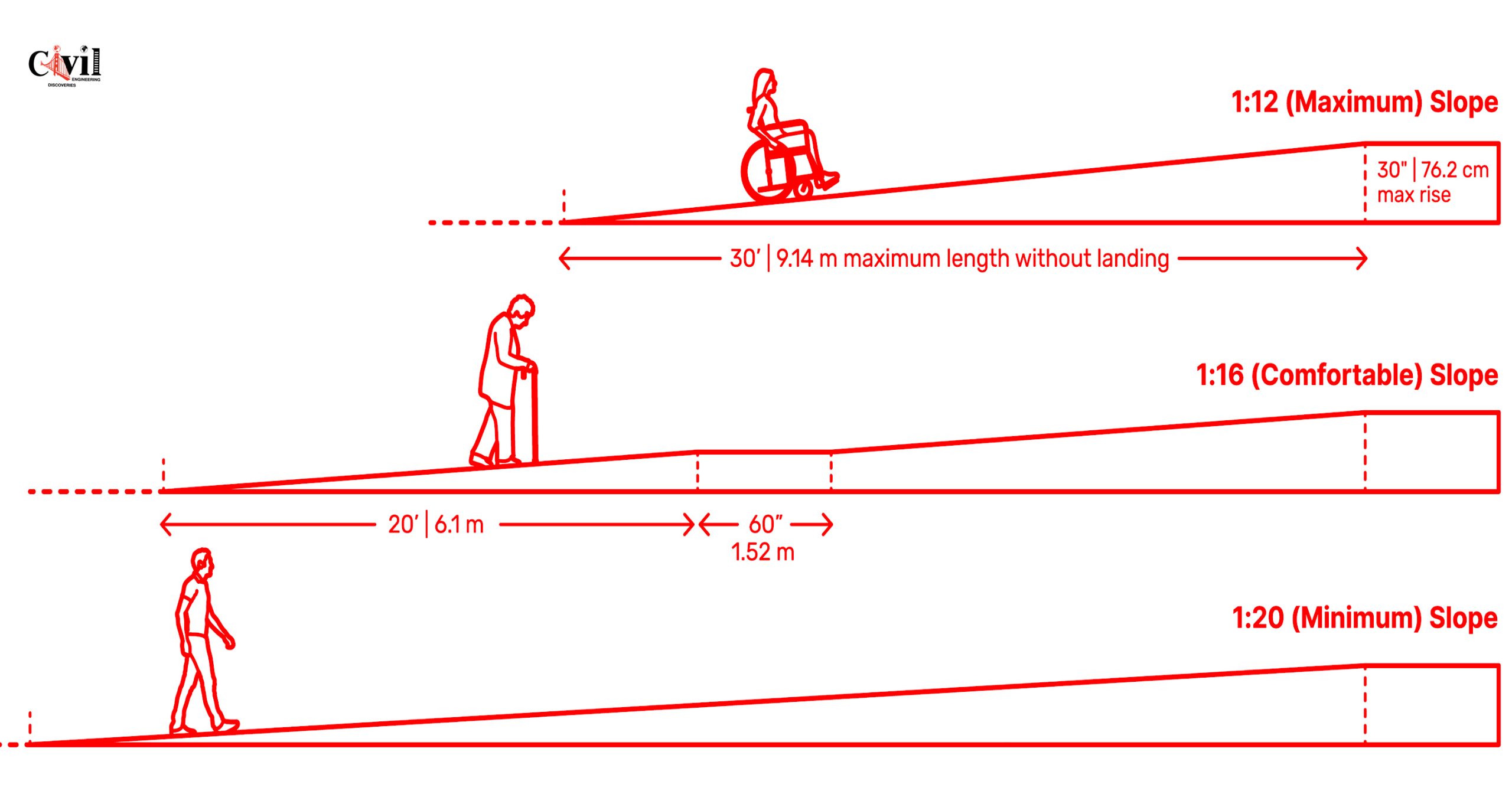

From www.engineeringdiscoveries.net

How To Design A Ramp Engineering Discoveries Loading Ramp Standards Loading ramps and forcing yards are the most hazardous areas in livestock handling, posing risks such as crushing, lacerations, and falls. The maximum grade percentage from the loading dock to the vehicle is determined by the height of the dock (discussed in detail in set the dock. The best internal width between rails for loading is 750mm. By properly positioning,. Loading Ramp Standards.

From ecoplanthire.ie

Steel Loading Ramp Extends to 13M Foldable & Adjustable Eco Plant Loading Ramp Standards When designing a loading dock ramp, make sure the slope is. Knowing the risks, as well as osha and state requirements, and maintaining a safe zone around loading docks is an important first step in preventing injuries and fatalities. The maximum grade percentage from the loading dock to the vehicle is determined by the height of the dock (discussed in. Loading Ramp Standards.

From www.rpmrural.com

Cattle Loading Ramps Cattle Yards Australia RPM Rural Loading Ramp Standards By properly positioning, using, and maintaining your loading ramp, it can help you maintain efficiency in your warehouse for years. When designing a loading dock ramp, make sure the slope is. If the slope of a ramp or a walkway is steeper than one (1) vertical in eight (8) horizontal, the ramp or walkway shall have cleats not more than.. Loading Ramp Standards.

From www.prweb.com

Copperloy Improves Freight Loading/Unloading Production with their New Loading Ramp Standards The maximum grade percentage from the loading dock to the vehicle is determined by the height of the dock (discussed in detail in set the dock. Side panels should be at least 1.5 metres high. By properly positioning, using, and maintaining your loading ramp, it can help you maintain efficiency in your warehouse for years. The best internal width between. Loading Ramp Standards.

From www.jewelbeat.com

Aluminum Loading Ramps 101 A Guide to HassleFree Machinery Transport Loading Ramp Standards Loading ramps and forcing yards are the most hazardous areas in livestock handling, posing risks such as crushing, lacerations, and falls. Knowing the risks, as well as osha and state requirements, and maintaining a safe zone around loading docks is an important first step in preventing injuries and fatalities. The best internal width between rails for loading is 750mm. When. Loading Ramp Standards.

From www.nationalstockyards.com.au

Loading Ramps National Stockyard Systems Loading Ramp Standards If the slope of a ramp or a walkway is steeper than one (1) vertical in eight (8) horizontal, the ramp or walkway shall have cleats not more than. By properly positioning, using, and maintaining your loading ramp, it can help you maintain efficiency in your warehouse for years. Loading ramps and forcing yards are the most hazardous areas in. Loading Ramp Standards.

From www.beefcentral.com

Loading ramp changes should be 'guidelines', not standards livestock Loading Ramp Standards Side panels should be at least 1.5 metres high. The best internal width between rails for loading is 750mm. If the slope of a ramp or a walkway is steeper than one (1) vertical in eight (8) horizontal, the ramp or walkway shall have cleats not more than. When designing a loading dock ramp, make sure the slope is. Knowing. Loading Ramp Standards.

From www.duraramp.com

Loading Dock Ramp Slope Requirements DuraRamp Loading Ramp Standards Loading ramps and forcing yards are the most hazardous areas in livestock handling, posing risks such as crushing, lacerations, and falls. The maximum grade percentage from the loading dock to the vehicle is determined by the height of the dock (discussed in detail in set the dock. If the slope of a ramp or a walkway is steeper than one. Loading Ramp Standards.

From www.spaldings.co.uk

Straight 3.5m H/duty Aluminium Loading Ramps C125.35.410, 1 pair (3 Loading Ramp Standards Side panels should be at least 1.5 metres high. The maximum grade percentage from the loading dock to the vehicle is determined by the height of the dock (discussed in detail in set the dock. If the slope of a ramp or a walkway is steeper than one (1) vertical in eight (8) horizontal, the ramp or walkway shall have. Loading Ramp Standards.

From www.forkliftrivews.com

22+ Forklift Ramp Design Images Forklift Reviews Loading Ramp Standards Loading ramps and forcing yards are the most hazardous areas in livestock handling, posing risks such as crushing, lacerations, and falls. By properly positioning, using, and maintaining your loading ramp, it can help you maintain efficiency in your warehouse for years. The best internal width between rails for loading is 750mm. When designing a loading dock ramp, make sure the. Loading Ramp Standards.

From www.duraramp.com

LightDuty Portable Loading Ramp DuraRamp LT Ramp Loading Ramp Standards By properly positioning, using, and maintaining your loading ramp, it can help you maintain efficiency in your warehouse for years. The maximum grade percentage from the loading dock to the vehicle is determined by the height of the dock (discussed in detail in set the dock. When designing a loading dock ramp, make sure the slope is. Knowing the risks,. Loading Ramp Standards.

From inspectapedia.com

Accessible Design ADA & Best Practices for Accessible Buildings Loading Ramp Standards If the slope of a ramp or a walkway is steeper than one (1) vertical in eight (8) horizontal, the ramp or walkway shall have cleats not more than. Loading ramps and forcing yards are the most hazardous areas in livestock handling, posing risks such as crushing, lacerations, and falls. When designing a loading dock ramp, make sure the slope. Loading Ramp Standards.

From www.bigrentz.com

Forklift Ramp Slope Incline Requirements & Safety Guidelines Bigrentz Loading Ramp Standards When designing a loading dock ramp, make sure the slope is. Side panels should be at least 1.5 metres high. Loading ramps and forcing yards are the most hazardous areas in livestock handling, posing risks such as crushing, lacerations, and falls. By properly positioning, using, and maintaining your loading ramp, it can help you maintain efficiency in your warehouse for. Loading Ramp Standards.

From nationramps.com

Ground to Dock Ramp Toronto Warehouse Loading Ramp Loading Ramp Standards Side panels should be at least 1.5 metres high. By properly positioning, using, and maintaining your loading ramp, it can help you maintain efficiency in your warehouse for years. The maximum grade percentage from the loading dock to the vehicle is determined by the height of the dock (discussed in detail in set the dock. The best internal width between. Loading Ramp Standards.

From www7.mississauga.ca

City of Mississauga Facility Accessibility Design Standards Loading Ramp Standards By properly positioning, using, and maintaining your loading ramp, it can help you maintain efficiency in your warehouse for years. If the slope of a ramp or a walkway is steeper than one (1) vertical in eight (8) horizontal, the ramp or walkway shall have cleats not more than. The maximum grade percentage from the loading dock to the vehicle. Loading Ramp Standards.

From www.duraramp.com

Loading Ramp Maintenance Requirements DuraRamp Loading Ramp Standards By properly positioning, using, and maintaining your loading ramp, it can help you maintain efficiency in your warehouse for years. If the slope of a ramp or a walkway is steeper than one (1) vertical in eight (8) horizontal, the ramp or walkway shall have cleats not more than. When designing a loading dock ramp, make sure the slope is.. Loading Ramp Standards.

From www.duraramp.com

Heavy Duty Portable Loading Ramps & Forklift Ramps Loading Ramp Standards Loading ramps and forcing yards are the most hazardous areas in livestock handling, posing risks such as crushing, lacerations, and falls. If the slope of a ramp or a walkway is steeper than one (1) vertical in eight (8) horizontal, the ramp or walkway shall have cleats not more than. Side panels should be at least 1.5 metres high. By. Loading Ramp Standards.

From seedstockcentral.com.au

New loading ramp standards to improve worker safety Seedstock Central Loading Ramp Standards The maximum grade percentage from the loading dock to the vehicle is determined by the height of the dock (discussed in detail in set the dock. If the slope of a ramp or a walkway is steeper than one (1) vertical in eight (8) horizontal, the ramp or walkway shall have cleats not more than. Knowing the risks, as well. Loading Ramp Standards.

From bordinbros.com.au

Standard 4.8 meter ramps Bordin Bros Loading Ramp Standards The maximum grade percentage from the loading dock to the vehicle is determined by the height of the dock (discussed in detail in set the dock. By properly positioning, using, and maintaining your loading ramp, it can help you maintain efficiency in your warehouse for years. Knowing the risks, as well as osha and state requirements, and maintaining a safe. Loading Ramp Standards.