Calibration Quality Control . Let us attempt to explain what calibration is, why it is important, what is required by iso 9001:2015 and some common pitfalls while implementing this requirement. Instrument calibration is the process of comparing the instrument’s readings to the readings on a calibrator or reference instrument. Why is calibration important to understand? A calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment. At its core, calibration involves comparing measurements of an instrument or device against a known and. Calibration plays a pivotal role in quality control processes across various industries. It's an essential step for every type of laboratory, whether its focus is research and development, quality control, or testing. Tool calibration in mechanics and engineering is vital, ensuring that tools and instruments achieve the necessary standards of accuracy and precision (e.g. Torque analysers) for manufacturing, safety, and quality control. Calibration is the key to quality and quality is something customers will recognize.

from www.alamy.com

Let us attempt to explain what calibration is, why it is important, what is required by iso 9001:2015 and some common pitfalls while implementing this requirement. It's an essential step for every type of laboratory, whether its focus is research and development, quality control, or testing. Why is calibration important to understand? Instrument calibration is the process of comparing the instrument’s readings to the readings on a calibrator or reference instrument. Tool calibration in mechanics and engineering is vital, ensuring that tools and instruments achieve the necessary standards of accuracy and precision (e.g. Torque analysers) for manufacturing, safety, and quality control. Calibration plays a pivotal role in quality control processes across various industries. At its core, calibration involves comparing measurements of an instrument or device against a known and. Calibration is the key to quality and quality is something customers will recognize. A calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment.

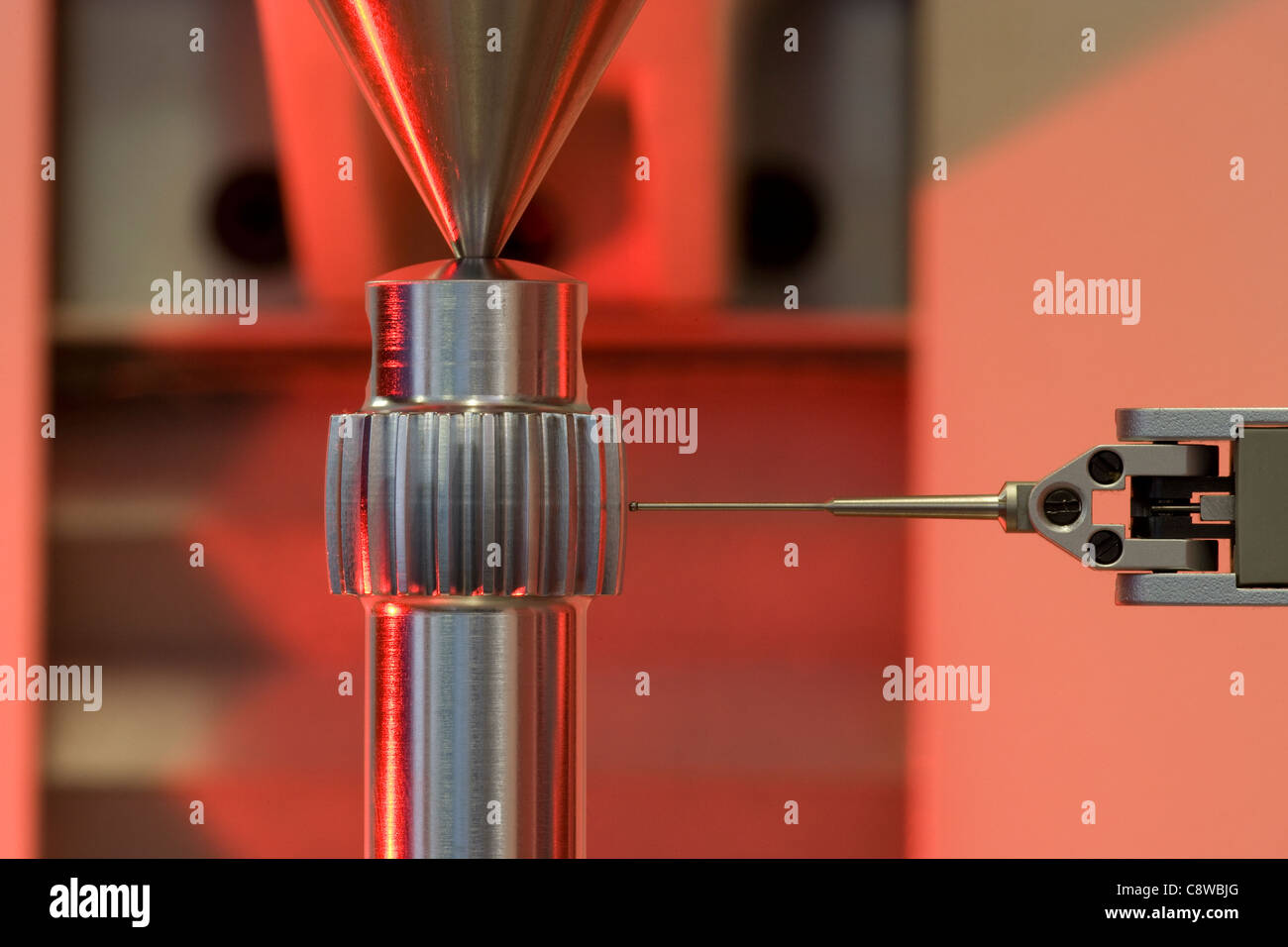

precision engineering probe calibration device for quality control

Calibration Quality Control At its core, calibration involves comparing measurements of an instrument or device against a known and. Why is calibration important to understand? Calibration is the key to quality and quality is something customers will recognize. A calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment. Let us attempt to explain what calibration is, why it is important, what is required by iso 9001:2015 and some common pitfalls while implementing this requirement. Calibration plays a pivotal role in quality control processes across various industries. At its core, calibration involves comparing measurements of an instrument or device against a known and. It's an essential step for every type of laboratory, whether its focus is research and development, quality control, or testing. Torque analysers) for manufacturing, safety, and quality control. Instrument calibration is the process of comparing the instrument’s readings to the readings on a calibrator or reference instrument. Tool calibration in mechanics and engineering is vital, ensuring that tools and instruments achieve the necessary standards of accuracy and precision (e.g.

From www.slideshare.net

Calibration and Quality controls of automated hematology analyzer Calibration Quality Control Calibration is the key to quality and quality is something customers will recognize. Torque analysers) for manufacturing, safety, and quality control. Instrument calibration is the process of comparing the instrument’s readings to the readings on a calibrator or reference instrument. At its core, calibration involves comparing measurements of an instrument or device against a known and. Let us attempt to. Calibration Quality Control.

From www.creativesafetysupply.com

Quality Control Check Calibration Before Use Rectangular Floor Sign Calibration Quality Control Calibration plays a pivotal role in quality control processes across various industries. At its core, calibration involves comparing measurements of an instrument or device against a known and. A calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment. Torque analysers) for manufacturing, safety, and quality control. Instrument calibration is the. Calibration Quality Control.

From slideplayer.com

Chapter 5 Quality Assurance and Calibration Methods ppt download Calibration Quality Control Why is calibration important to understand? At its core, calibration involves comparing measurements of an instrument or device against a known and. Torque analysers) for manufacturing, safety, and quality control. It's an essential step for every type of laboratory, whether its focus is research and development, quality control, or testing. Calibration is the key to quality and quality is something. Calibration Quality Control.

From tech-publish.com

SOP For Calibration Of Quality Control Instruments Techpublish Calibration Quality Control Calibration is the key to quality and quality is something customers will recognize. Calibration plays a pivotal role in quality control processes across various industries. It's an essential step for every type of laboratory, whether its focus is research and development, quality control, or testing. Why is calibration important to understand? Torque analysers) for manufacturing, safety, and quality control. A. Calibration Quality Control.

From www.alamy.com

precision engineering probe calibration device for quality control Calibration Quality Control Instrument calibration is the process of comparing the instrument’s readings to the readings on a calibrator or reference instrument. Why is calibration important to understand? Let us attempt to explain what calibration is, why it is important, what is required by iso 9001:2015 and some common pitfalls while implementing this requirement. It's an essential step for every type of laboratory,. Calibration Quality Control.

From www.slideserve.com

PPT Process Control Quality Control for Quantitative Tests Calibration Quality Control Calibration plays a pivotal role in quality control processes across various industries. Torque analysers) for manufacturing, safety, and quality control. At its core, calibration involves comparing measurements of an instrument or device against a known and. It's an essential step for every type of laboratory, whether its focus is research and development, quality control, or testing. Tool calibration in mechanics. Calibration Quality Control.

From www.slideserve.com

PPT Quality Assurance/ Quality Control PowerPoint Presentation, free Calibration Quality Control Torque analysers) for manufacturing, safety, and quality control. Calibration is the key to quality and quality is something customers will recognize. Instrument calibration is the process of comparing the instrument’s readings to the readings on a calibrator or reference instrument. A calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment.. Calibration Quality Control.

From www.creativesafetysupply.com

Quality Control Calibration Due Landscape Wall Sign Calibration Quality Control Calibration plays a pivotal role in quality control processes across various industries. Tool calibration in mechanics and engineering is vital, ensuring that tools and instruments achieve the necessary standards of accuracy and precision (e.g. A calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment. Let us attempt to explain what. Calibration Quality Control.

From www.creativesafetysupply.com

Quality Control Calibrate Before Use Rectangular Floor Sign Calibration Quality Control It's an essential step for every type of laboratory, whether its focus is research and development, quality control, or testing. Instrument calibration is the process of comparing the instrument’s readings to the readings on a calibrator or reference instrument. Why is calibration important to understand? Calibration is the key to quality and quality is something customers will recognize. Let us. Calibration Quality Control.

From www.youtube.com

What is Calibration of Quality Instruments? Calibration Plan Quality Calibration Quality Control Why is calibration important to understand? Tool calibration in mechanics and engineering is vital, ensuring that tools and instruments achieve the necessary standards of accuracy and precision (e.g. Let us attempt to explain what calibration is, why it is important, what is required by iso 9001:2015 and some common pitfalls while implementing this requirement. Torque analysers) for manufacturing, safety, and. Calibration Quality Control.

From multiplex-eng.ie

The Role of Calibration in Quality Control Multiplex Engineering Ltd. Calibration Quality Control Tool calibration in mechanics and engineering is vital, ensuring that tools and instruments achieve the necessary standards of accuracy and precision (e.g. At its core, calibration involves comparing measurements of an instrument or device against a known and. A calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment. It's an. Calibration Quality Control.

From www.anyrgb.com

International Organization Of Legal Metrology, sartorius Ag Calibration Quality Control Torque analysers) for manufacturing, safety, and quality control. It's an essential step for every type of laboratory, whether its focus is research and development, quality control, or testing. Let us attempt to explain what calibration is, why it is important, what is required by iso 9001:2015 and some common pitfalls while implementing this requirement. Why is calibration important to understand?. Calibration Quality Control.

From dokumen.tips

(PDF) Calibration & Quality Control Standards SCP SCIENCE Literature Calibration Quality Control It's an essential step for every type of laboratory, whether its focus is research and development, quality control, or testing. Calibration is the key to quality and quality is something customers will recognize. Tool calibration in mechanics and engineering is vital, ensuring that tools and instruments achieve the necessary standards of accuracy and precision (e.g. Why is calibration important to. Calibration Quality Control.

From www.creativesafetysupply.com

Quality Control Critical Calibration Portrait Wall Sign Calibration Quality Control Torque analysers) for manufacturing, safety, and quality control. Let us attempt to explain what calibration is, why it is important, what is required by iso 9001:2015 and some common pitfalls while implementing this requirement. Calibration is the key to quality and quality is something customers will recognize. Tool calibration in mechanics and engineering is vital, ensuring that tools and instruments. Calibration Quality Control.

From lemproductsinc.com

Quality Control Labels QC Labels LEM Products, Inc. Calibration Quality Control Torque analysers) for manufacturing, safety, and quality control. Instrument calibration is the process of comparing the instrument’s readings to the readings on a calibrator or reference instrument. Tool calibration in mechanics and engineering is vital, ensuring that tools and instruments achieve the necessary standards of accuracy and precision (e.g. At its core, calibration involves comparing measurements of an instrument or. Calibration Quality Control.

From instrumentationtools.com

How to Create Calibration Records? Instrumentation and Control Calibration Quality Control Calibration plays a pivotal role in quality control processes across various industries. Let us attempt to explain what calibration is, why it is important, what is required by iso 9001:2015 and some common pitfalls while implementing this requirement. Tool calibration in mechanics and engineering is vital, ensuring that tools and instruments achieve the necessary standards of accuracy and precision (e.g.. Calibration Quality Control.

From www.dreamstime.com

Automated Calibration and Quality Control System Stock Photo Image of Calibration Quality Control Instrument calibration is the process of comparing the instrument’s readings to the readings on a calibrator or reference instrument. Tool calibration in mechanics and engineering is vital, ensuring that tools and instruments achieve the necessary standards of accuracy and precision (e.g. It's an essential step for every type of laboratory, whether its focus is research and development, quality control, or. Calibration Quality Control.

From www.pharmaexcipients.com

5 Advantages of Calibrating Your Equipment At An Accredited Lab Calibration Quality Control A calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment. Tool calibration in mechanics and engineering is vital, ensuring that tools and instruments achieve the necessary standards of accuracy and precision (e.g. It's an essential step for every type of laboratory, whether its focus is research and development, quality control,. Calibration Quality Control.

From www.zalkincapping.com

Control & Calibration Quality Control Equipment to Help with Line Calibration Quality Control A calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment. Torque analysers) for manufacturing, safety, and quality control. At its core, calibration involves comparing measurements of an instrument or device against a known and. Why is calibration important to understand? It's an essential step for every type of laboratory, whether. Calibration Quality Control.

From www.caq.de

Calibration Management Software Calibration Quality Control At its core, calibration involves comparing measurements of an instrument or device against a known and. Tool calibration in mechanics and engineering is vital, ensuring that tools and instruments achieve the necessary standards of accuracy and precision (e.g. Instrument calibration is the process of comparing the instrument’s readings to the readings on a calibrator or reference instrument. Torque analysers) for. Calibration Quality Control.

From www.quality-assurance-solutions.com

Tool Calibration and Control System Calibration Quality Control Torque analysers) for manufacturing, safety, and quality control. Calibration plays a pivotal role in quality control processes across various industries. At its core, calibration involves comparing measurements of an instrument or device against a known and. Let us attempt to explain what calibration is, why it is important, what is required by iso 9001:2015 and some common pitfalls while implementing. Calibration Quality Control.

From www.creativesafetysupply.com

Quality Control Critical Calibration Rectangular Floor Sign Calibration Quality Control Torque analysers) for manufacturing, safety, and quality control. Calibration plays a pivotal role in quality control processes across various industries. Why is calibration important to understand? Let us attempt to explain what calibration is, why it is important, what is required by iso 9001:2015 and some common pitfalls while implementing this requirement. A calibrated equipment procedure describes the process that. Calibration Quality Control.

From www.complianceonline.com

cGMP and GLP Regulations for Quality Control Labs An overview Calibration Quality Control Why is calibration important to understand? At its core, calibration involves comparing measurements of an instrument or device against a known and. Instrument calibration is the process of comparing the instrument’s readings to the readings on a calibrator or reference instrument. It's an essential step for every type of laboratory, whether its focus is research and development, quality control, or. Calibration Quality Control.

From www.slideserve.com

PPT Internal Quality Control PowerPoint Presentation, free download Calibration Quality Control Instrument calibration is the process of comparing the instrument’s readings to the readings on a calibrator or reference instrument. Torque analysers) for manufacturing, safety, and quality control. It's an essential step for every type of laboratory, whether its focus is research and development, quality control, or testing. At its core, calibration involves comparing measurements of an instrument or device against. Calibration Quality Control.

From www.assurx.com

Calibration Management Software AssurX QMS Calibration Quality Control Torque analysers) for manufacturing, safety, and quality control. Instrument calibration is the process of comparing the instrument’s readings to the readings on a calibrator or reference instrument. Tool calibration in mechanics and engineering is vital, ensuring that tools and instruments achieve the necessary standards of accuracy and precision (e.g. At its core, calibration involves comparing measurements of an instrument or. Calibration Quality Control.

From www.desertcart.ph

Buy Self Laminating Calibration Labels 1x2 Inch Writeon Calibration Calibration Quality Control Let us attempt to explain what calibration is, why it is important, what is required by iso 9001:2015 and some common pitfalls while implementing this requirement. Instrument calibration is the process of comparing the instrument’s readings to the readings on a calibrator or reference instrument. It's an essential step for every type of laboratory, whether its focus is research and. Calibration Quality Control.

From www.yumpu.com

Instrument Calibration Quality Control and Inspection Report Form Calibration Quality Control Why is calibration important to understand? A calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment. At its core, calibration involves comparing measurements of an instrument or device against a known and. Let us attempt to explain what calibration is, why it is important, what is required by iso 9001:2015. Calibration Quality Control.

From www.alamy.com

precision engineering probe calibration device for quality control Calibration Quality Control At its core, calibration involves comparing measurements of an instrument or device against a known and. A calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment. Why is calibration important to understand? Calibration plays a pivotal role in quality control processes across various industries. Instrument calibration is the process of. Calibration Quality Control.

From www.isixsigma.com

Why Calibration is Essential for Quality Control Calibration Quality Control A calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment. Instrument calibration is the process of comparing the instrument’s readings to the readings on a calibrator or reference instrument. Tool calibration in mechanics and engineering is vital, ensuring that tools and instruments achieve the necessary standards of accuracy and precision. Calibration Quality Control.

From www.academia.edu

(PDF) Calibration & Quality Control Log Date Time Test Strip Calibration Quality Control Why is calibration important to understand? Let us attempt to explain what calibration is, why it is important, what is required by iso 9001:2015 and some common pitfalls while implementing this requirement. Instrument calibration is the process of comparing the instrument’s readings to the readings on a calibrator or reference instrument. At its core, calibration involves comparing measurements of an. Calibration Quality Control.

From www.creativesafetysupply.com

Quality Control Calibration Due Landscape Wall Sign Calibration Quality Control It's an essential step for every type of laboratory, whether its focus is research and development, quality control, or testing. Why is calibration important to understand? Calibration is the key to quality and quality is something customers will recognize. At its core, calibration involves comparing measurements of an instrument or device against a known and. Instrument calibration is the process. Calibration Quality Control.

From www.landauer.eu

Calibration and quality control kits Landauer Calibration Quality Control A calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment. Torque analysers) for manufacturing, safety, and quality control. At its core, calibration involves comparing measurements of an instrument or device against a known and. Why is calibration important to understand? It's an essential step for every type of laboratory, whether. Calibration Quality Control.

From www.slideserve.com

PPT EQUIPMENT/INSTRUMENT CALIBRATION PowerPoint Presentation, free Calibration Quality Control It's an essential step for every type of laboratory, whether its focus is research and development, quality control, or testing. Let us attempt to explain what calibration is, why it is important, what is required by iso 9001:2015 and some common pitfalls while implementing this requirement. Instrument calibration is the process of comparing the instrument’s readings to the readings on. Calibration Quality Control.

From www.quality-assurance-solutions.com

Quality Assurance vs Quality Control Calibration Quality Control Let us attempt to explain what calibration is, why it is important, what is required by iso 9001:2015 and some common pitfalls while implementing this requirement. Why is calibration important to understand? Calibration plays a pivotal role in quality control processes across various industries. At its core, calibration involves comparing measurements of an instrument or device against a known and.. Calibration Quality Control.

From iconic.com.bd

Importance of Quality Assurance and Quality Control in Medical Device Calibration Quality Control Instrument calibration is the process of comparing the instrument’s readings to the readings on a calibrator or reference instrument. Torque analysers) for manufacturing, safety, and quality control. Why is calibration important to understand? Tool calibration in mechanics and engineering is vital, ensuring that tools and instruments achieve the necessary standards of accuracy and precision (e.g. It's an essential step for. Calibration Quality Control.