Threading Engineering Process . Thread machining is one of the most important applications in a cnc machining center. Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. Productive and economical threading method, especially for smaller threads. Suitable for all kind of. The method is used to create both internal threads (threads. This machining occurs through the circular movement of a rotating tool calibrated with the required thread depth and density. A solid grasp of thread types, their parameters, and application is pivotal for engineers. Covers the most common thread profiles. As always, clear communication and diligent verification are paramount in ensuring successful, functional, and durable threaded connections in any manufacturing endeavor. Including, cold forming, rolling, tapping, milling, threading and grinding. A short description of the main thread production methods. It is a subtractive method used in making external and internal threads of different sizes. This operation allows for the integration of screws,. Generally, it refers to the method of machining threads on the workpiece with forming tools.

from www.nextgentooling.com

Generally, it refers to the method of machining threads on the workpiece with forming tools. This machining occurs through the circular movement of a rotating tool calibrated with the required thread depth and density. Thread machining is one of the most important applications in a cnc machining center. Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. It is a subtractive method used in making external and internal threads of different sizes. Suitable for all kind of. Including, cold forming, rolling, tapping, milling, threading and grinding. A solid grasp of thread types, their parameters, and application is pivotal for engineers. Covers the most common thread profiles. This operation allows for the integration of screws,.

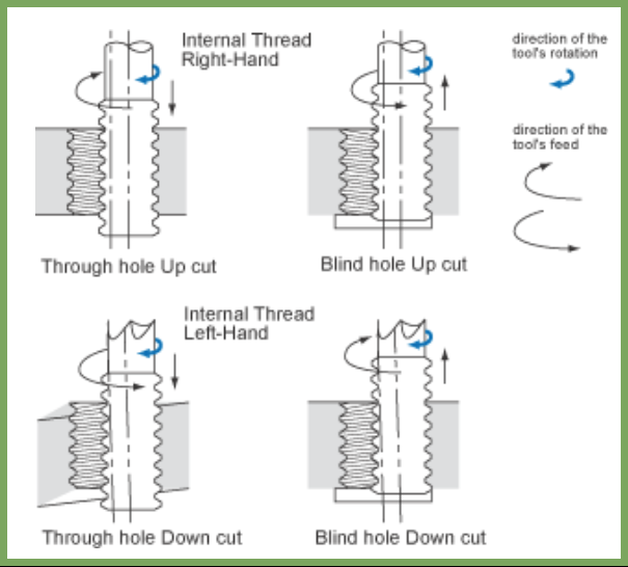

Thread Milling Techniques NEXT GENERATION TOOLING

Threading Engineering Process The method is used to create both internal threads (threads. Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. A short description of the main thread production methods. It is a subtractive method used in making external and internal threads of different sizes. This operation allows for the integration of screws,. Including, cold forming, rolling, tapping, milling, threading and grinding. Generally, it refers to the method of machining threads on the workpiece with forming tools. As always, clear communication and diligent verification are paramount in ensuring successful, functional, and durable threaded connections in any manufacturing endeavor. The method is used to create both internal threads (threads. Productive and economical threading method, especially for smaller threads. This machining occurs through the circular movement of a rotating tool calibrated with the required thread depth and density. A solid grasp of thread types, their parameters, and application is pivotal for engineers. Suitable for all kind of. Covers the most common thread profiles. Thread machining is one of the most important applications in a cnc machining center.

From www.researchgate.net

Forming principle of internal thread cold extrusion Download Threading Engineering Process This operation allows for the integration of screws,. A short description of the main thread production methods. Productive and economical threading method, especially for smaller threads. Thread machining is one of the most important applications in a cnc machining center. Covers the most common thread profiles. As always, clear communication and diligent verification are paramount in ensuring successful, functional, and. Threading Engineering Process.

From www.yamawa.eu

Cored holes Direct tapping with no tool breakage Yamawa Threading Engineering Process A short description of the main thread production methods. Including, cold forming, rolling, tapping, milling, threading and grinding. Productive and economical threading method, especially for smaller threads. It is a subtractive method used in making external and internal threads of different sizes. As always, clear communication and diligent verification are paramount in ensuring successful, functional, and durable threaded connections in. Threading Engineering Process.

From engineeringtechnology.org

Internal Threading Threading Engineering Process Generally, it refers to the method of machining threads on the workpiece with forming tools. Including, cold forming, rolling, tapping, milling, threading and grinding. As always, clear communication and diligent verification are paramount in ensuring successful, functional, and durable threaded connections in any manufacturing endeavor. The method is used to create both internal threads (threads. This machining occurs through the. Threading Engineering Process.

From engineeringlearner.com

Types of Threads Definition, Parts and Thread Identifying Tools [with Threading Engineering Process A solid grasp of thread types, their parameters, and application is pivotal for engineers. Thread machining is one of the most important applications in a cnc machining center. As always, clear communication and diligent verification are paramount in ensuring successful, functional, and durable threaded connections in any manufacturing endeavor. The method is used to create both internal threads (threads. This. Threading Engineering Process.

From www.researchgate.net

Schematic diagram of thread machining process. Download Scientific Threading Engineering Process The method is used to create both internal threads (threads. Productive and economical threading method, especially for smaller threads. A short description of the main thread production methods. Suitable for all kind of. Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. Including, cold forming, rolling, tapping, milling, threading and grinding. A solid. Threading Engineering Process.

From jbcmachine.com

Threading Services JBC Machine, Inc. Threading Engineering Process Including, cold forming, rolling, tapping, milling, threading and grinding. Suitable for all kind of. This machining occurs through the circular movement of a rotating tool calibrated with the required thread depth and density. Productive and economical threading method, especially for smaller threads. Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. Generally, it. Threading Engineering Process.

From www.slideserve.com

PPT Machining Module 5 Lathe Setup and Operations PowerPoint Threading Engineering Process Including, cold forming, rolling, tapping, milling, threading and grinding. Productive and economical threading method, especially for smaller threads. Generally, it refers to the method of machining threads on the workpiece with forming tools. This operation allows for the integration of screws,. Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. As always, clear. Threading Engineering Process.

From www.youtube.com

Thread Nomenclature Types Terms ENGINEERING STUDY MATERIALS YouTube Threading Engineering Process This machining occurs through the circular movement of a rotating tool calibrated with the required thread depth and density. A solid grasp of thread types, their parameters, and application is pivotal for engineers. Productive and economical threading method, especially for smaller threads. Suitable for all kind of. As always, clear communication and diligent verification are paramount in ensuring successful, functional,. Threading Engineering Process.

From www.slideshare.net

Engineering Drawing Chapter 11 thread fastener Threading Engineering Process This machining occurs through the circular movement of a rotating tool calibrated with the required thread depth and density. A solid grasp of thread types, their parameters, and application is pivotal for engineers. A short description of the main thread production methods. The method is used to create both internal threads (threads. Including, cold forming, rolling, tapping, milling, threading and. Threading Engineering Process.

From www.researchgate.net

State of the art on internal thread manufacturing a review Request PDF Threading Engineering Process Thread machining is one of the most important applications in a cnc machining center. Suitable for all kind of. As always, clear communication and diligent verification are paramount in ensuring successful, functional, and durable threaded connections in any manufacturing endeavor. This machining occurs through the circular movement of a rotating tool calibrated with the required thread depth and density. Threading. Threading Engineering Process.

From www.youtube.com

Tapping Process Tapping Operation What is Tapping In Hindi Threading Engineering Process Including, cold forming, rolling, tapping, milling, threading and grinding. Productive and economical threading method, especially for smaller threads. Covers the most common thread profiles. This machining occurs through the circular movement of a rotating tool calibrated with the required thread depth and density. This operation allows for the integration of screws,. A short description of the main thread production methods.. Threading Engineering Process.

From www.youtube.com

GTU INDUSTRIAL DRAFTING B E 3 rd SEM MECHATRONICS Screw threads YouTube Threading Engineering Process Productive and economical threading method, especially for smaller threads. Including, cold forming, rolling, tapping, milling, threading and grinding. A solid grasp of thread types, their parameters, and application is pivotal for engineers. This operation allows for the integration of screws,. This machining occurs through the circular movement of a rotating tool calibrated with the required thread depth and density. Thread. Threading Engineering Process.

From learnmech.com

Nomenclature of Mechanical Threads Diagram Of Threads Threading Engineering Process Including, cold forming, rolling, tapping, milling, threading and grinding. A solid grasp of thread types, their parameters, and application is pivotal for engineers. It is a subtractive method used in making external and internal threads of different sizes. Generally, it refers to the method of machining threads on the workpiece with forming tools. Covers the most common thread profiles. A. Threading Engineering Process.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Threading Engineering Process Generally, it refers to the method of machining threads on the workpiece with forming tools. This operation allows for the integration of screws,. A short description of the main thread production methods. The method is used to create both internal threads (threads. Productive and economical threading method, especially for smaller threads. Covers the most common thread profiles. A solid grasp. Threading Engineering Process.

From samcornerhd.blogspot.com

Software Engineering What is the difference between process and thread? Threading Engineering Process The method is used to create both internal threads (threads. This machining occurs through the circular movement of a rotating tool calibrated with the required thread depth and density. Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. Suitable for all kind of. Including, cold forming, rolling, tapping, milling, threading and grinding. It. Threading Engineering Process.

From www.slideshare.net

Engineering Drawing Chapter 11 thread fastener Threading Engineering Process Covers the most common thread profiles. Including, cold forming, rolling, tapping, milling, threading and grinding. This operation allows for the integration of screws,. A solid grasp of thread types, their parameters, and application is pivotal for engineers. This machining occurs through the circular movement of a rotating tool calibrated with the required thread depth and density. Thread machining is one. Threading Engineering Process.

From www.slideserve.com

PPT Topics PowerPoint Presentation, free download ID345512 Threading Engineering Process Thread machining is one of the most important applications in a cnc machining center. Covers the most common thread profiles. Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. Productive and economical threading method, especially for smaller threads. This operation allows for the integration of screws,. The method is used to create both. Threading Engineering Process.

From www.slideshare.net

Engineering Drawing Chapter 11 thread fastener Threading Engineering Process As always, clear communication and diligent verification are paramount in ensuring successful, functional, and durable threaded connections in any manufacturing endeavor. A solid grasp of thread types, their parameters, and application is pivotal for engineers. This machining occurs through the circular movement of a rotating tool calibrated with the required thread depth and density. The method is used to create. Threading Engineering Process.

From toolnotes.com

External Threading ToolNotes Threading Engineering Process It is a subtractive method used in making external and internal threads of different sizes. This operation allows for the integration of screws,. Covers the most common thread profiles. Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. Productive and economical threading method, especially for smaller threads. Generally, it refers to the method. Threading Engineering Process.

From www.youtube.com

THREADING STAINLESS STEEL MODEL ENGINEERING FOR BEGINNERS PART 20 Threading Engineering Process A solid grasp of thread types, their parameters, and application is pivotal for engineers. This operation allows for the integration of screws,. As always, clear communication and diligent verification are paramount in ensuring successful, functional, and durable threaded connections in any manufacturing endeavor. Including, cold forming, rolling, tapping, milling, threading and grinding. Covers the most common thread profiles. This machining. Threading Engineering Process.

From www.nextgentooling.com

Thread Milling Techniques NEXT GENERATION TOOLING Threading Engineering Process This operation allows for the integration of screws,. The method is used to create both internal threads (threads. Productive and economical threading method, especially for smaller threads. Generally, it refers to the method of machining threads on the workpiece with forming tools. This machining occurs through the circular movement of a rotating tool calibrated with the required thread depth and. Threading Engineering Process.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Threading Engineering Process Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. Productive and economical threading method, especially for smaller threads. Suitable for all kind of. As always, clear communication and diligent verification are paramount in ensuring successful, functional, and durable threaded connections in any manufacturing endeavor. A solid grasp of thread types, their parameters, and. Threading Engineering Process.

From www.rolledthreads.com

How Does the Thread Rolling Process Work? Threading Engineering Process Generally, it refers to the method of machining threads on the workpiece with forming tools. This machining occurs through the circular movement of a rotating tool calibrated with the required thread depth and density. Suitable for all kind of. This operation allows for the integration of screws,. The method is used to create both internal threads (threads. Threading holds a. Threading Engineering Process.

From www.mcgill.ca

Dimensioning threaded fasteners Engineering Design McGill University Threading Engineering Process Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. It is a subtractive method used in making external and internal threads of different sizes. Including, cold forming, rolling, tapping, milling, threading and grinding. Suitable for all kind of. This machining occurs through the circular movement of a rotating tool calibrated with the required. Threading Engineering Process.

From www.youtube.com

How to draw acme thread drawing Engineering and poetry YouTube Threading Engineering Process Covers the most common thread profiles. Generally, it refers to the method of machining threads on the workpiece with forming tools. The method is used to create both internal threads (threads. Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. This machining occurs through the circular movement of a rotating tool calibrated with. Threading Engineering Process.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Threading Engineering Process The method is used to create both internal threads (threads. This operation allows for the integration of screws,. Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. Suitable for all kind of. Thread machining is one of the most important applications in a cnc machining center. Including, cold forming, rolling, tapping, milling, threading. Threading Engineering Process.

From pecm.co.uk

Threading tool and gauge specialists Process Engineering Control Threading Engineering Process It is a subtractive method used in making external and internal threads of different sizes. Generally, it refers to the method of machining threads on the workpiece with forming tools. Productive and economical threading method, especially for smaller threads. Including, cold forming, rolling, tapping, milling, threading and grinding. As always, clear communication and diligent verification are paramount in ensuring successful,. Threading Engineering Process.

From mecrockers.blogspot.com

Mecrockers Threading Engineering Process Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. It is a subtractive method used in making external and internal threads of different sizes. A solid grasp of thread types, their parameters, and application is pivotal for engineers. Generally, it refers to the method of machining threads on the workpiece with forming tools.. Threading Engineering Process.

From www.youtube.com

All Lathe Machine Operations Turning, Facing, Taper Turning, Boring Threading Engineering Process This machining occurs through the circular movement of a rotating tool calibrated with the required thread depth and density. A solid grasp of thread types, their parameters, and application is pivotal for engineers. Suitable for all kind of. Including, cold forming, rolling, tapping, milling, threading and grinding. Covers the most common thread profiles. The method is used to create both. Threading Engineering Process.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Threading Engineering Process Generally, it refers to the method of machining threads on the workpiece with forming tools. Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. Thread machining is one of the most important applications in a cnc machining center. This machining occurs through the circular movement of a rotating tool calibrated with the required. Threading Engineering Process.

From www.youtube.com

Thread Operation on lathe cutting Threading. YouTube Threading Engineering Process Productive and economical threading method, especially for smaller threads. This operation allows for the integration of screws,. A solid grasp of thread types, their parameters, and application is pivotal for engineers. Suitable for all kind of. Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. Thread machining is one of the most important. Threading Engineering Process.

From www.youtube.com

Thread Cutting in Pro/ENGINEER Detailed Explanation YouTube Threading Engineering Process Thread machining is one of the most important applications in a cnc machining center. Including, cold forming, rolling, tapping, milling, threading and grinding. This operation allows for the integration of screws,. Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. It is a subtractive method used in making external and internal threads of. Threading Engineering Process.

From www.youtube.com

Engineering Drawing 2 Ch3 Thread terminology YouTube Threading Engineering Process Including, cold forming, rolling, tapping, milling, threading and grinding. This machining occurs through the circular movement of a rotating tool calibrated with the required thread depth and density. Suitable for all kind of. It is a subtractive method used in making external and internal threads of different sizes. Threading holds a critical position in manufacturing due to its broad versatility. Threading Engineering Process.

From www.youtube.com

Hand threading with a die YouTube Threading Engineering Process A solid grasp of thread types, their parameters, and application is pivotal for engineers. This machining occurs through the circular movement of a rotating tool calibrated with the required thread depth and density. Suitable for all kind of. As always, clear communication and diligent verification are paramount in ensuring successful, functional, and durable threaded connections in any manufacturing endeavor. The. Threading Engineering Process.

From www.mcgill.ca

Dimensioning threaded fasteners Engineering Design McGill University Threading Engineering Process As always, clear communication and diligent verification are paramount in ensuring successful, functional, and durable threaded connections in any manufacturing endeavor. The method is used to create both internal threads (threads. Thread machining is one of the most important applications in a cnc machining center. Threading holds a critical position in manufacturing due to its broad versatility and applicability across. Threading Engineering Process.