Sheet Metal Bending Grain Direction . When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction (see figure 1). Several factors influence a sheet metal’s bendability, including its thickness, grain direction, hardness, and the radius of the bend. The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. During the process of turning ingots of metal into sheet at the mill, the metal is forced between a set of rollers. Plate bending can be split into two main categories, plate rolling and press. This is because grain direction makes sheet metal stronger in some directions and weaker in others. In general the structure of the normalised plate is finer. Understanding these elements can help avoid common issues like cracking or inaccurate bends. This paper reviews the various parameters affecting spring back such as punch angle, grain direction of sheet metal material, die opening, ratio of die radius to sheet thickness, sheet. Grain direction in metal bending.

from www.mech4study.com

During the process of turning ingots of metal into sheet at the mill, the metal is forced between a set of rollers. Grain direction in metal bending. When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction (see figure 1). This paper reviews the various parameters affecting spring back such as punch angle, grain direction of sheet metal material, die opening, ratio of die radius to sheet thickness, sheet. Understanding these elements can help avoid common issues like cracking or inaccurate bends. The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. This is because grain direction makes sheet metal stronger in some directions and weaker in others. Plate bending can be split into two main categories, plate rolling and press. In general the structure of the normalised plate is finer. Several factors influence a sheet metal’s bendability, including its thickness, grain direction, hardness, and the radius of the bend.

Different Sheet Metal Bending Process mech4study

Sheet Metal Bending Grain Direction This is because grain direction makes sheet metal stronger in some directions and weaker in others. Several factors influence a sheet metal’s bendability, including its thickness, grain direction, hardness, and the radius of the bend. Grain direction in metal bending. Plate bending can be split into two main categories, plate rolling and press. This paper reviews the various parameters affecting spring back such as punch angle, grain direction of sheet metal material, die opening, ratio of die radius to sheet thickness, sheet. When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction (see figure 1). Understanding these elements can help avoid common issues like cracking or inaccurate bends. The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. During the process of turning ingots of metal into sheet at the mill, the metal is forced between a set of rollers. In general the structure of the normalised plate is finer. This is because grain direction makes sheet metal stronger in some directions and weaker in others.

From www.youtube.com

Simple And Easy Techniques For Bending Metal Sheet into A Circle Sheet Metal Bending Grain Direction This paper reviews the various parameters affecting spring back such as punch angle, grain direction of sheet metal material, die opening, ratio of die radius to sheet thickness, sheet. This is because grain direction makes sheet metal stronger in some directions and weaker in others. Grain direction in metal bending. When working with plate, pay close attention to whether you. Sheet Metal Bending Grain Direction.

From www.mech4study.com

Different Sheet Metal Bending Process mech4study Sheet Metal Bending Grain Direction Several factors influence a sheet metal’s bendability, including its thickness, grain direction, hardness, and the radius of the bend. During the process of turning ingots of metal into sheet at the mill, the metal is forced between a set of rollers. The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially. Sheet Metal Bending Grain Direction.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Sheet Metal Bending Grain Direction In general the structure of the normalised plate is finer. Understanding these elements can help avoid common issues like cracking or inaccurate bends. The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. This paper reviews the various parameters affecting spring back such as. Sheet Metal Bending Grain Direction.

From ar.inspiredpencil.com

Sheet Metal Bending Techniques Sheet Metal Bending Grain Direction The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. Plate bending can be split into two main categories, plate rolling and press. Several factors influence a sheet metal’s bendability, including its thickness, grain direction, hardness, and the radius of the bend. When working. Sheet Metal Bending Grain Direction.

From www.youtube.com

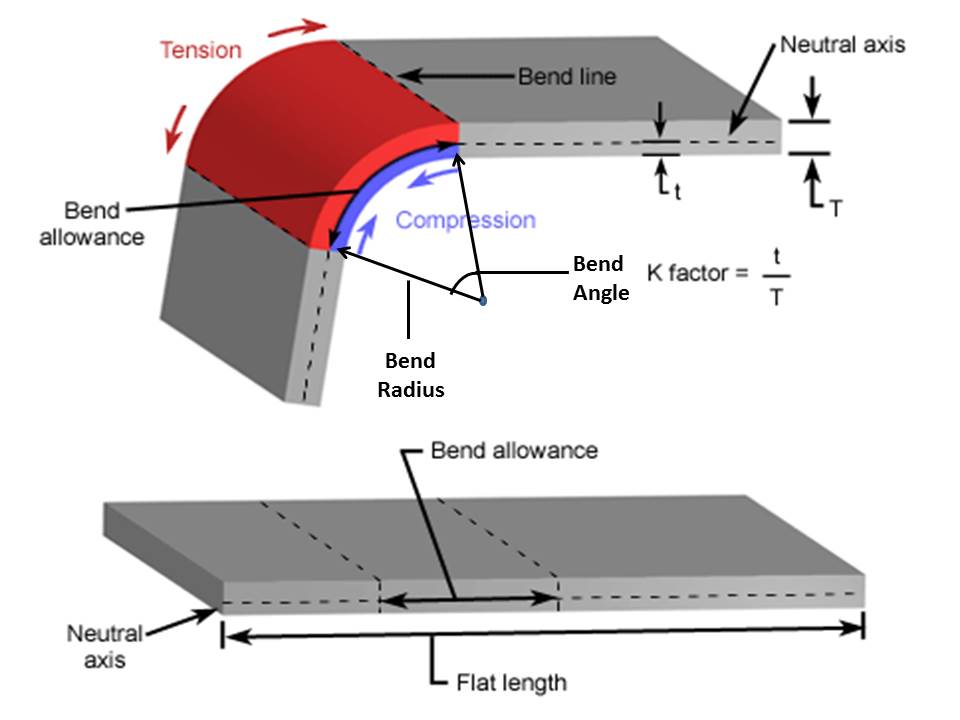

SolidWorks Tutorial Sheet Metal 2012 What does bend allowance mean Sheet Metal Bending Grain Direction Understanding these elements can help avoid common issues like cracking or inaccurate bends. In general the structure of the normalised plate is finer. Grain direction in metal bending. When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction (see figure 1). This is because grain direction makes sheet metal stronger. Sheet Metal Bending Grain Direction.

From www.vowin.cn

A Designer’s Guide For Ensuring The Manufacturability Of Sheet Metal Sheet Metal Bending Grain Direction This is because grain direction makes sheet metal stronger in some directions and weaker in others. Understanding these elements can help avoid common issues like cracking or inaccurate bends. In general the structure of the normalised plate is finer. During the process of turning ingots of metal into sheet at the mill, the metal is forced between a set of. Sheet Metal Bending Grain Direction.

From www.choonngaiengineering.com

Metal Guidelines Methods of Sheet Metal Bending Sheet Metal Bending Grain Direction Grain direction in metal bending. This is because grain direction makes sheet metal stronger in some directions and weaker in others. When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction (see figure 1). The direction of the grain is an important factor to consider before any sheet metal fabrication. Sheet Metal Bending Grain Direction.

From www.thefabricator.com

Grain size, Part II How metal grain size affects a bending operation Sheet Metal Bending Grain Direction During the process of turning ingots of metal into sheet at the mill, the metal is forced between a set of rollers. When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction (see figure 1). Understanding these elements can help avoid common issues like cracking or inaccurate bends. In general. Sheet Metal Bending Grain Direction.

From smlease.com

Sheetmetal Design Guidelines SMLease Design SMLease Design Sheet Metal Bending Grain Direction When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction (see figure 1). Several factors influence a sheet metal’s bendability, including its thickness, grain direction, hardness, and the radius of the bend. This paper reviews the various parameters affecting spring back such as punch angle, grain direction of sheet metal. Sheet Metal Bending Grain Direction.

From www.pa-international.com.au

sheet metal bend allowance and deduction Sheet Metal Bending Grain Direction Understanding these elements can help avoid common issues like cracking or inaccurate bends. Plate bending can be split into two main categories, plate rolling and press. In general the structure of the normalised plate is finer. Several factors influence a sheet metal’s bendability, including its thickness, grain direction, hardness, and the radius of the bend. This paper reviews the various. Sheet Metal Bending Grain Direction.

From msvs-dei.vlabs.ac.in

Virtual LabDayalbagh Educational Institute Sheet Metal Bending Grain Direction Grain direction in metal bending. During the process of turning ingots of metal into sheet at the mill, the metal is forced between a set of rollers. When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction (see figure 1). The direction of the grain is an important factor to. Sheet Metal Bending Grain Direction.

From klayuyzce.blob.core.windows.net

Aluminum Bending Strength at Tamara Schneider blog Sheet Metal Bending Grain Direction Understanding these elements can help avoid common issues like cracking or inaccurate bends. Grain direction in metal bending. The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. Several factors influence a sheet metal’s bendability, including its thickness, grain direction, hardness, and the radius. Sheet Metal Bending Grain Direction.

From www.machinemfg.com

Principles of Structural Design for Sheet Metal Bending Parts MachineMFG Sheet Metal Bending Grain Direction The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. Several factors influence a sheet metal’s bendability, including its thickness, grain direction, hardness, and the radius of the bend. This paper reviews the various parameters affecting spring back such as punch angle, grain direction. Sheet Metal Bending Grain Direction.

From www.aaaairsupport.com

Metal Grain Direction What You Need To Know AAA Air Support Sheet Metal Bending Grain Direction Plate bending can be split into two main categories, plate rolling and press. Understanding these elements can help avoid common issues like cracking or inaccurate bends. Several factors influence a sheet metal’s bendability, including its thickness, grain direction, hardness, and the radius of the bend. This is because grain direction makes sheet metal stronger in some directions and weaker in. Sheet Metal Bending Grain Direction.

From thelibraryofmanufacturing.com

Sheet Metal Bending Sheet Metal Bending Grain Direction Understanding these elements can help avoid common issues like cracking or inaccurate bends. The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction (see. Sheet Metal Bending Grain Direction.

From www.youtube.com

Exploring Sheet Metal Bending YouTube Sheet Metal Bending Grain Direction When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction (see figure 1). Understanding these elements can help avoid common issues like cracking or inaccurate bends. The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar. Sheet Metal Bending Grain Direction.

From www.thefabricator.com

Analyzing the kfactor in sheet metal bending Sheet Metal Bending Grain Direction During the process of turning ingots of metal into sheet at the mill, the metal is forced between a set of rollers. This paper reviews the various parameters affecting spring back such as punch angle, grain direction of sheet metal material, die opening, ratio of die radius to sheet thickness, sheet. The direction of the grain is an important factor. Sheet Metal Bending Grain Direction.

From mybluecollarphotos.blogspot.com

Sheet Metal Grain Direction / Rolling metal into sheet form at the mill Sheet Metal Bending Grain Direction This is because grain direction makes sheet metal stronger in some directions and weaker in others. Plate bending can be split into two main categories, plate rolling and press. In general the structure of the normalised plate is finer. Grain direction in metal bending. During the process of turning ingots of metal into sheet at the mill, the metal is. Sheet Metal Bending Grain Direction.

From localrevive.com

Sheet Metal KFactor, Bend Allowance and Flat Length Calculations (2022) Sheet Metal Bending Grain Direction Understanding these elements can help avoid common issues like cracking or inaccurate bends. Plate bending can be split into two main categories, plate rolling and press. In general the structure of the normalised plate is finer. This paper reviews the various parameters affecting spring back such as punch angle, grain direction of sheet metal material, die opening, ratio of die. Sheet Metal Bending Grain Direction.

From www.javelin-tech.com

Sheet Metal Bend Direction Sheet Metal Bending Grain Direction In general the structure of the normalised plate is finer. During the process of turning ingots of metal into sheet at the mill, the metal is forced between a set of rollers. This is because grain direction makes sheet metal stronger in some directions and weaker in others. Understanding these elements can help avoid common issues like cracking or inaccurate. Sheet Metal Bending Grain Direction.

From www.minifaber.com

The art of sheet metal bending Sheet Metal Bending Grain Direction Several factors influence a sheet metal’s bendability, including its thickness, grain direction, hardness, and the radius of the bend. Grain direction in metal bending. Understanding these elements can help avoid common issues like cracking or inaccurate bends. The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and. Sheet Metal Bending Grain Direction.

From metalscut4u.com

How To Bend Sheet Metal The Ultimate Guide Sheet Metal Bending Grain Direction This is because grain direction makes sheet metal stronger in some directions and weaker in others. Several factors influence a sheet metal’s bendability, including its thickness, grain direction, hardness, and the radius of the bend. During the process of turning ingots of metal into sheet at the mill, the metal is forced between a set of rollers. The direction of. Sheet Metal Bending Grain Direction.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Sheet Metal Bending Grain Direction Several factors influence a sheet metal’s bendability, including its thickness, grain direction, hardness, and the radius of the bend. During the process of turning ingots of metal into sheet at the mill, the metal is forced between a set of rollers. Understanding these elements can help avoid common issues like cracking or inaccurate bends. Grain direction in metal bending. In. Sheet Metal Bending Grain Direction.

From www.youtube.com

Introduction to sheet metal process Grain direction Bend allowance Sheet Metal Bending Grain Direction Grain direction in metal bending. This is because grain direction makes sheet metal stronger in some directions and weaker in others. Several factors influence a sheet metal’s bendability, including its thickness, grain direction, hardness, and the radius of the bend. Plate bending can be split into two main categories, plate rolling and press. The direction of the grain is an. Sheet Metal Bending Grain Direction.

From www.thefabricator.com

What sheet metal shops wish you knew Reasonable tolerances, grain Sheet Metal Bending Grain Direction Understanding these elements can help avoid common issues like cracking or inaccurate bends. The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. Grain direction in metal bending. This is because grain direction makes sheet metal stronger in some directions and weaker in others.. Sheet Metal Bending Grain Direction.

From www.thefabricator.com

Grain direction’s effect on sheet metal bending Sheet Metal Bending Grain Direction In general the structure of the normalised plate is finer. The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. Plate bending can be split into two main categories, plate rolling and press. When working with plate, pay close attention to whether you are. Sheet Metal Bending Grain Direction.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart Sheet Metal Bending Grain Direction This paper reviews the various parameters affecting spring back such as punch angle, grain direction of sheet metal material, die opening, ratio of die radius to sheet thickness, sheet. When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction (see figure 1). During the process of turning ingots of metal. Sheet Metal Bending Grain Direction.

From www.es3.co.nz

The Importance of Grain Direction in Folding ES3 Sheet Metal Bending Grain Direction Plate bending can be split into two main categories, plate rolling and press. This paper reviews the various parameters affecting spring back such as punch angle, grain direction of sheet metal material, die opening, ratio of die radius to sheet thickness, sheet. Understanding these elements can help avoid common issues like cracking or inaccurate bends. During the process of turning. Sheet Metal Bending Grain Direction.

From www.goengineer.com

Show Sheet Metal Bend Lines in a SOLIDWORKS Drawing GoEngineer Sheet Metal Bending Grain Direction Grain direction in metal bending. This paper reviews the various parameters affecting spring back such as punch angle, grain direction of sheet metal material, die opening, ratio of die radius to sheet thickness, sheet. Plate bending can be split into two main categories, plate rolling and press. The direction of the grain is an important factor to consider before any. Sheet Metal Bending Grain Direction.

From starwaymfg.en.made-in-china.com

Metal Plate Bending Grain Direction in Sheet Metal Bending Custom Sheet Sheet Metal Bending Grain Direction The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. Grain direction in metal bending. This paper reviews the various parameters affecting spring back such as punch angle, grain direction of sheet metal material, die opening, ratio of die radius to sheet thickness, sheet.. Sheet Metal Bending Grain Direction.

From www.youtube.com

The Effect Of Grain Direction In Sheet Metal Bending YouTube Sheet Metal Bending Grain Direction This is because grain direction makes sheet metal stronger in some directions and weaker in others. Several factors influence a sheet metal’s bendability, including its thickness, grain direction, hardness, and the radius of the bend. Understanding these elements can help avoid common issues like cracking or inaccurate bends. During the process of turning ingots of metal into sheet at the. Sheet Metal Bending Grain Direction.

From journals.sagepub.com

Development of a design and manufacturing framework for Sheet Metal Bending Grain Direction This paper reviews the various parameters affecting spring back such as punch angle, grain direction of sheet metal material, die opening, ratio of die radius to sheet thickness, sheet. Several factors influence a sheet metal’s bendability, including its thickness, grain direction, hardness, and the radius of the bend. During the process of turning ingots of metal into sheet at the. Sheet Metal Bending Grain Direction.

From xometry.eu

Sheet Metal Design Tips For Bending Xometry Europe Sheet Metal Bending Grain Direction Plate bending can be split into two main categories, plate rolling and press. This paper reviews the various parameters affecting spring back such as punch angle, grain direction of sheet metal material, die opening, ratio of die radius to sheet thickness, sheet. Grain direction in metal bending. This is because grain direction makes sheet metal stronger in some directions and. Sheet Metal Bending Grain Direction.

From artizono.com

Guide To Calculating Unfolded Dimensions For Sheet Metal Bending Artizono Sheet Metal Bending Grain Direction During the process of turning ingots of metal into sheet at the mill, the metal is forced between a set of rollers. The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. This is because grain direction makes sheet metal stronger in some directions. Sheet Metal Bending Grain Direction.

From www.komaspec.com

An Engineers’ Guide to Sheet Metal Bending & Laser Cutting Komaspec Sheet Metal Bending Grain Direction The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. This is because grain direction makes sheet metal stronger in some directions and weaker in others. Plate bending can be split into two main categories, plate rolling and press. When working with plate, pay. Sheet Metal Bending Grain Direction.