How Hot Does A Tig Welder Get . The preheating temperature is carefully controlled and can range from 300°c to 800°c (572°f to 1472°f), depending on the material being welded and the desired outcomes. Because the heat input is often controlled by pressing on a foot pedal, tig allows you to heat up or cool down the weld puddle, providing precise weld bead control. Welding through tig is more than just sticking metal pieces together. One of the most vital controls for welding aluminum is balance, which maintains the cleaning versus. The gas tungsten arc welding process utilizes the heat of an arc between a nonconsumable tungsten electrode and the base metal. With the tig process, the heat comes from an electric. A tig machine has numerous controls. It’s a sophisticated process that demands skill and attention to detail.

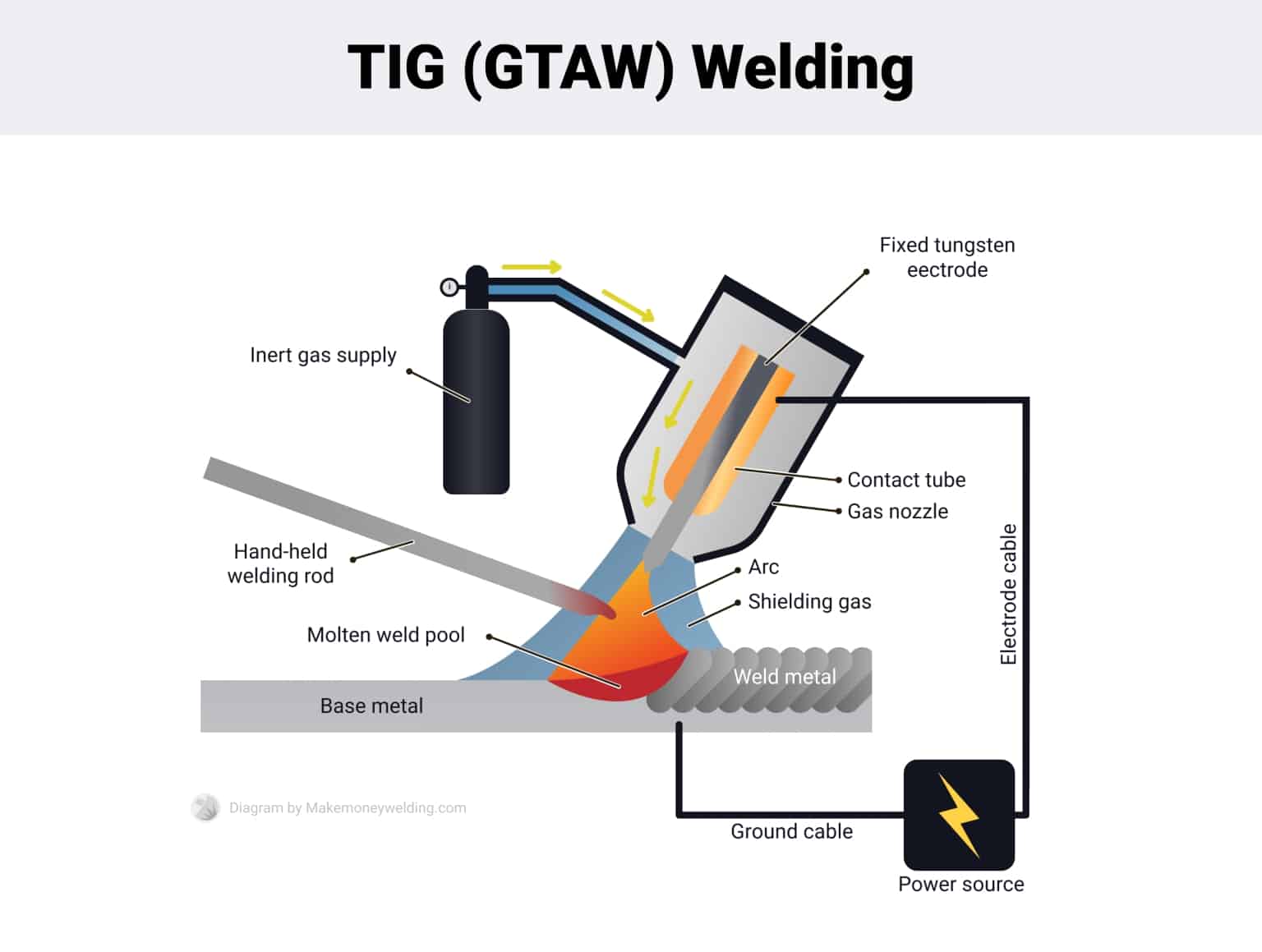

from makemoneywelding.com

The gas tungsten arc welding process utilizes the heat of an arc between a nonconsumable tungsten electrode and the base metal. With the tig process, the heat comes from an electric. One of the most vital controls for welding aluminum is balance, which maintains the cleaning versus. The preheating temperature is carefully controlled and can range from 300°c to 800°c (572°f to 1472°f), depending on the material being welded and the desired outcomes. Because the heat input is often controlled by pressing on a foot pedal, tig allows you to heat up or cool down the weld puddle, providing precise weld bead control. It’s a sophisticated process that demands skill and attention to detail. A tig machine has numerous controls. Welding through tig is more than just sticking metal pieces together.

MIG vs. TIG Welding Differences Which Is Better?

How Hot Does A Tig Welder Get The gas tungsten arc welding process utilizes the heat of an arc between a nonconsumable tungsten electrode and the base metal. Welding through tig is more than just sticking metal pieces together. A tig machine has numerous controls. Because the heat input is often controlled by pressing on a foot pedal, tig allows you to heat up or cool down the weld puddle, providing precise weld bead control. The preheating temperature is carefully controlled and can range from 300°c to 800°c (572°f to 1472°f), depending on the material being welded and the desired outcomes. It’s a sophisticated process that demands skill and attention to detail. With the tig process, the heat comes from an electric. One of the most vital controls for welding aluminum is balance, which maintains the cleaning versus. The gas tungsten arc welding process utilizes the heat of an arc between a nonconsumable tungsten electrode and the base metal.

From www.pinterest.com

Tig Welding Tips and Tricks for the Beginner and Pro Tig welding How Hot Does A Tig Welder Get A tig machine has numerous controls. Because the heat input is often controlled by pressing on a foot pedal, tig allows you to heat up or cool down the weld puddle, providing precise weld bead control. It’s a sophisticated process that demands skill and attention to detail. With the tig process, the heat comes from an electric. The preheating temperature. How Hot Does A Tig Welder Get.

From www.youtube.com

TIG welding MIG brazing How to do TIG WELDING हिंदी में TIG How Hot Does A Tig Welder Get With the tig process, the heat comes from an electric. The preheating temperature is carefully controlled and can range from 300°c to 800°c (572°f to 1472°f), depending on the material being welded and the desired outcomes. The gas tungsten arc welding process utilizes the heat of an arc between a nonconsumable tungsten electrode and the base metal. A tig machine. How Hot Does A Tig Welder Get.

From www.kingsofwelding.com

What is TIG Welding and How to TIG weld Kings of Welding How Hot Does A Tig Welder Get The gas tungsten arc welding process utilizes the heat of an arc between a nonconsumable tungsten electrode and the base metal. Because the heat input is often controlled by pressing on a foot pedal, tig allows you to heat up or cool down the weld puddle, providing precise weld bead control. The preheating temperature is carefully controlled and can range. How Hot Does A Tig Welder Get.

From makemoneywelding.com

MIG vs. TIG Welding Differences Which Is Better? How Hot Does A Tig Welder Get The gas tungsten arc welding process utilizes the heat of an arc between a nonconsumable tungsten electrode and the base metal. Welding through tig is more than just sticking metal pieces together. A tig machine has numerous controls. With the tig process, the heat comes from an electric. The preheating temperature is carefully controlled and can range from 300°c to. How Hot Does A Tig Welder Get.

From joisskxyv.blob.core.windows.net

Tig Welding Machine How To Use at Clinton Langford blog How Hot Does A Tig Welder Get The gas tungsten arc welding process utilizes the heat of an arc between a nonconsumable tungsten electrode and the base metal. One of the most vital controls for welding aluminum is balance, which maintains the cleaning versus. The preheating temperature is carefully controlled and can range from 300°c to 800°c (572°f to 1472°f), depending on the material being welded and. How Hot Does A Tig Welder Get.

From www.hotrod.com

Eastwood Launches Professional TIG 200 Welder at DIY Prices Hot Rod How Hot Does A Tig Welder Get Because the heat input is often controlled by pressing on a foot pedal, tig allows you to heat up or cool down the weld puddle, providing precise weld bead control. A tig machine has numerous controls. One of the most vital controls for welding aluminum is balance, which maintains the cleaning versus. The gas tungsten arc welding process utilizes the. How Hot Does A Tig Welder Get.

From dxobtwlor.blob.core.windows.net

How Hot Is A Tig Weld at Mary Woods blog How Hot Does A Tig Welder Get A tig machine has numerous controls. It’s a sophisticated process that demands skill and attention to detail. Welding through tig is more than just sticking metal pieces together. With the tig process, the heat comes from an electric. The gas tungsten arc welding process utilizes the heat of an arc between a nonconsumable tungsten electrode and the base metal. One. How Hot Does A Tig Welder Get.

From protigwelders.com

How Hot Is Tig Welding? 2024 ProTigWelders How Hot Does A Tig Welder Get The preheating temperature is carefully controlled and can range from 300°c to 800°c (572°f to 1472°f), depending on the material being welded and the desired outcomes. Because the heat input is often controlled by pressing on a foot pedal, tig allows you to heat up or cool down the weld puddle, providing precise weld bead control. With the tig process,. How Hot Does A Tig Welder Get.

From waterwelders.com

TIG Welding for Beginners 14 Tips & Tricks to Get You Started How Hot Does A Tig Welder Get One of the most vital controls for welding aluminum is balance, which maintains the cleaning versus. With the tig process, the heat comes from an electric. Welding through tig is more than just sticking metal pieces together. A tig machine has numerous controls. It’s a sophisticated process that demands skill and attention to detail. The gas tungsten arc welding process. How Hot Does A Tig Welder Get.

From americanindustrialsupl.com

TIG Welding What is TIG Welding and How Does it Work? American How Hot Does A Tig Welder Get A tig machine has numerous controls. The preheating temperature is carefully controlled and can range from 300°c to 800°c (572°f to 1472°f), depending on the material being welded and the desired outcomes. One of the most vital controls for welding aluminum is balance, which maintains the cleaning versus. Because the heat input is often controlled by pressing on a foot. How Hot Does A Tig Welder Get.

From cemdzwni.blob.core.windows.net

Gas For Tig Welder at James Chenard blog How Hot Does A Tig Welder Get A tig machine has numerous controls. The preheating temperature is carefully controlled and can range from 300°c to 800°c (572°f to 1472°f), depending on the material being welded and the desired outcomes. The gas tungsten arc welding process utilizes the heat of an arc between a nonconsumable tungsten electrode and the base metal. Welding through tig is more than just. How Hot Does A Tig Welder Get.

From exonmgdit.blob.core.windows.net

Tig Welder How It Works at David Clemons blog How Hot Does A Tig Welder Get A tig machine has numerous controls. One of the most vital controls for welding aluminum is balance, which maintains the cleaning versus. The gas tungsten arc welding process utilizes the heat of an arc between a nonconsumable tungsten electrode and the base metal. With the tig process, the heat comes from an electric. It’s a sophisticated process that demands skill. How Hot Does A Tig Welder Get.

From weldersmanual.com

TIG Welding Polarity A Beginners Guide Welders Manual How Hot Does A Tig Welder Get It’s a sophisticated process that demands skill and attention to detail. The gas tungsten arc welding process utilizes the heat of an arc between a nonconsumable tungsten electrode and the base metal. With the tig process, the heat comes from an electric. Because the heat input is often controlled by pressing on a foot pedal, tig allows you to heat. How Hot Does A Tig Welder Get.

From tiptigusa.com

How It Works Tip Tig Welding How Hot Does A Tig Welder Get Welding through tig is more than just sticking metal pieces together. The gas tungsten arc welding process utilizes the heat of an arc between a nonconsumable tungsten electrode and the base metal. It’s a sophisticated process that demands skill and attention to detail. With the tig process, the heat comes from an electric. One of the most vital controls for. How Hot Does A Tig Welder Get.

From weldingtroop.com

How Does a TIG Welder Work? >> What is TIG welding used for? How Hot Does A Tig Welder Get The preheating temperature is carefully controlled and can range from 300°c to 800°c (572°f to 1472°f), depending on the material being welded and the desired outcomes. One of the most vital controls for welding aluminum is balance, which maintains the cleaning versus. It’s a sophisticated process that demands skill and attention to detail. The gas tungsten arc welding process utilizes. How Hot Does A Tig Welder Get.

From exonmgdit.blob.core.windows.net

Tig Welder How It Works at David Clemons blog How Hot Does A Tig Welder Get The preheating temperature is carefully controlled and can range from 300°c to 800°c (572°f to 1472°f), depending on the material being welded and the desired outcomes. It’s a sophisticated process that demands skill and attention to detail. Welding through tig is more than just sticking metal pieces together. A tig machine has numerous controls. With the tig process, the heat. How Hot Does A Tig Welder Get.

From www.youtube.com

16"imaging tig welding hot pass/today my job tig welding/pipeline tig How Hot Does A Tig Welder Get A tig machine has numerous controls. One of the most vital controls for welding aluminum is balance, which maintains the cleaning versus. Because the heat input is often controlled by pressing on a foot pedal, tig allows you to heat up or cool down the weld puddle, providing precise weld bead control. Welding through tig is more than just sticking. How Hot Does A Tig Welder Get.

From dxobtwlor.blob.core.windows.net

How Hot Is A Tig Weld at Mary Woods blog How Hot Does A Tig Welder Get It’s a sophisticated process that demands skill and attention to detail. With the tig process, the heat comes from an electric. A tig machine has numerous controls. Because the heat input is often controlled by pressing on a foot pedal, tig allows you to heat up or cool down the weld puddle, providing precise weld bead control. One of the. How Hot Does A Tig Welder Get.

From www.youtube.com

How To Set Up A TIG Welder! YouTube How Hot Does A Tig Welder Get Because the heat input is often controlled by pressing on a foot pedal, tig allows you to heat up or cool down the weld puddle, providing precise weld bead control. One of the most vital controls for welding aluminum is balance, which maintains the cleaning versus. A tig machine has numerous controls. The preheating temperature is carefully controlled and can. How Hot Does A Tig Welder Get.

From www.adamsgas.co.uk

How Tig Welding Works & What It Is Used For Adams Gas Blog How Hot Does A Tig Welder Get With the tig process, the heat comes from an electric. The preheating temperature is carefully controlled and can range from 300°c to 800°c (572°f to 1472°f), depending on the material being welded and the desired outcomes. A tig machine has numerous controls. It’s a sophisticated process that demands skill and attention to detail. Because the heat input is often controlled. How Hot Does A Tig Welder Get.

From exonmgdit.blob.core.windows.net

Tig Welder How It Works at David Clemons blog How Hot Does A Tig Welder Get Because the heat input is often controlled by pressing on a foot pedal, tig allows you to heat up or cool down the weld puddle, providing precise weld bead control. The preheating temperature is carefully controlled and can range from 300°c to 800°c (572°f to 1472°f), depending on the material being welded and the desired outcomes. It’s a sophisticated process. How Hot Does A Tig Welder Get.

From www.youtube.com

Welding 101 How to TIG Weld and Teaching a Beginner YouTube How Hot Does A Tig Welder Get Welding through tig is more than just sticking metal pieces together. The preheating temperature is carefully controlled and can range from 300°c to 800°c (572°f to 1472°f), depending on the material being welded and the desired outcomes. The gas tungsten arc welding process utilizes the heat of an arc between a nonconsumable tungsten electrode and the base metal. One of. How Hot Does A Tig Welder Get.

From www.hotrod.com

Tig Welding Basics Hot Rod Network How Hot Does A Tig Welder Get It’s a sophisticated process that demands skill and attention to detail. Because the heat input is often controlled by pressing on a foot pedal, tig allows you to heat up or cool down the weld puddle, providing precise weld bead control. One of the most vital controls for welding aluminum is balance, which maintains the cleaning versus. A tig machine. How Hot Does A Tig Welder Get.

From www.youtube.com

Tig Hot pass welding work How to do TiG welding training 🙏🏻👍 YouTube How Hot Does A Tig Welder Get With the tig process, the heat comes from an electric. One of the most vital controls for welding aluminum is balance, which maintains the cleaning versus. A tig machine has numerous controls. The gas tungsten arc welding process utilizes the heat of an arc between a nonconsumable tungsten electrode and the base metal. The preheating temperature is carefully controlled and. How Hot Does A Tig Welder Get.

From www.youtube.com

Top 5 hot TIG welding tips with Keith Rucker YouTube How Hot Does A Tig Welder Get The gas tungsten arc welding process utilizes the heat of an arc between a nonconsumable tungsten electrode and the base metal. It’s a sophisticated process that demands skill and attention to detail. One of the most vital controls for welding aluminum is balance, which maintains the cleaning versus. With the tig process, the heat comes from an electric. A tig. How Hot Does A Tig Welder Get.

From www.youtube.com

TIG Welding Tips and Techniques YouTube How Hot Does A Tig Welder Get Welding through tig is more than just sticking metal pieces together. A tig machine has numerous controls. With the tig process, the heat comes from an electric. It’s a sophisticated process that demands skill and attention to detail. One of the most vital controls for welding aluminum is balance, which maintains the cleaning versus. The gas tungsten arc welding process. How Hot Does A Tig Welder Get.

From www.millerwelds.com

How a TIG Welder Works and When to TIG Weld MillerWelds How Hot Does A Tig Welder Get The gas tungsten arc welding process utilizes the heat of an arc between a nonconsumable tungsten electrode and the base metal. The preheating temperature is carefully controlled and can range from 300°c to 800°c (572°f to 1472°f), depending on the material being welded and the desired outcomes. With the tig process, the heat comes from an electric. Because the heat. How Hot Does A Tig Welder Get.

From www.youtube.com

TIG WELDING 101 Tips and Tricks when Welding with your LONGEVITY How Hot Does A Tig Welder Get One of the most vital controls for welding aluminum is balance, which maintains the cleaning versus. The preheating temperature is carefully controlled and can range from 300°c to 800°c (572°f to 1472°f), depending on the material being welded and the desired outcomes. It’s a sophisticated process that demands skill and attention to detail. With the tig process, the heat comes. How Hot Does A Tig Welder Get.

From www.perfectwelders.com

TIG PERFECT POWER Welders, Welding Wire, Welding Equipment How Hot Does A Tig Welder Get Welding through tig is more than just sticking metal pieces together. The gas tungsten arc welding process utilizes the heat of an arc between a nonconsumable tungsten electrode and the base metal. One of the most vital controls for welding aluminum is balance, which maintains the cleaning versus. With the tig process, the heat comes from an electric. It’s a. How Hot Does A Tig Welder Get.

From coeleveld.com

Welding How Hot Does A Tig Welder Get The preheating temperature is carefully controlled and can range from 300°c to 800°c (572°f to 1472°f), depending on the material being welded and the desired outcomes. With the tig process, the heat comes from an electric. Welding through tig is more than just sticking metal pieces together. Because the heat input is often controlled by pressing on a foot pedal,. How Hot Does A Tig Welder Get.

From worksheetzoneirene.z21.web.core.windows.net

Setting Up Tig Welder For Welding Aluminum How Hot Does A Tig Welder Get A tig machine has numerous controls. Because the heat input is often controlled by pressing on a foot pedal, tig allows you to heat up or cool down the weld puddle, providing precise weld bead control. One of the most vital controls for welding aluminum is balance, which maintains the cleaning versus. Welding through tig is more than just sticking. How Hot Does A Tig Welder Get.

From blog.thepipingmart.com

How to Spot Weld with a TIG Welder A Complete Guide How Hot Does A Tig Welder Get The gas tungsten arc welding process utilizes the heat of an arc between a nonconsumable tungsten electrode and the base metal. Because the heat input is often controlled by pressing on a foot pedal, tig allows you to heat up or cool down the weld puddle, providing precise weld bead control. It’s a sophisticated process that demands skill and attention. How Hot Does A Tig Welder Get.

From weldingwatch.com

How Hot is MIG Welding? WeldingWatch How Hot Does A Tig Welder Get The preheating temperature is carefully controlled and can range from 300°c to 800°c (572°f to 1472°f), depending on the material being welded and the desired outcomes. The gas tungsten arc welding process utilizes the heat of an arc between a nonconsumable tungsten electrode and the base metal. One of the most vital controls for welding aluminum is balance, which maintains. How Hot Does A Tig Welder Get.

From www.youtube.com

TIG WELDING STAINLESS STEEL HOW TO TIG WELD STAINLESS STEEL FOR How Hot Does A Tig Welder Get Welding through tig is more than just sticking metal pieces together. Because the heat input is often controlled by pressing on a foot pedal, tig allows you to heat up or cool down the weld puddle, providing precise weld bead control. It’s a sophisticated process that demands skill and attention to detail. A tig machine has numerous controls. One of. How Hot Does A Tig Welder Get.

From sensibledigs.com

How To TIG Weld (StepbyStep Process) Sensible Digs How Hot Does A Tig Welder Get Welding through tig is more than just sticking metal pieces together. With the tig process, the heat comes from an electric. It’s a sophisticated process that demands skill and attention to detail. One of the most vital controls for welding aluminum is balance, which maintains the cleaning versus. Because the heat input is often controlled by pressing on a foot. How Hot Does A Tig Welder Get.