Rubber Moulding Machine Process . The process involves placing an unvulcanized rubber mixture into a mold, applying heat and pressure to make it flow and fill the mold cavity, and finally undergoing a vulcanization reaction to form a strong and durable finished product. Rubber injection molding turns heated material into the final molded rubber parts with complex shapes and high precision by rubber injection moulding process. The rubber compression molding process is one of the rubber molding manufacturing processes for shaping rubber into custom products. Check out this guide to learn about timco’s rubber molding processes, including injection molding, transfer molding, rubber compression molding, and more. In this post, we will explore the rubber compression molding process steps, commonly used materials, compression mold types, and pros and cons.

from www.rubbermolding.org

In this post, we will explore the rubber compression molding process steps, commonly used materials, compression mold types, and pros and cons. The process involves placing an unvulcanized rubber mixture into a mold, applying heat and pressure to make it flow and fill the mold cavity, and finally undergoing a vulcanization reaction to form a strong and durable finished product. The rubber compression molding process is one of the rubber molding manufacturing processes for shaping rubber into custom products. Check out this guide to learn about timco’s rubber molding processes, including injection molding, transfer molding, rubber compression molding, and more. Rubber injection molding turns heated material into the final molded rubber parts with complex shapes and high precision by rubber injection moulding process.

Rubber Injection Molding Rubber Molding

Rubber Moulding Machine Process In this post, we will explore the rubber compression molding process steps, commonly used materials, compression mold types, and pros and cons. In this post, we will explore the rubber compression molding process steps, commonly used materials, compression mold types, and pros and cons. The rubber compression molding process is one of the rubber molding manufacturing processes for shaping rubber into custom products. The process involves placing an unvulcanized rubber mixture into a mold, applying heat and pressure to make it flow and fill the mold cavity, and finally undergoing a vulcanization reaction to form a strong and durable finished product. Check out this guide to learn about timco’s rubber molding processes, including injection molding, transfer molding, rubber compression molding, and more. Rubber injection molding turns heated material into the final molded rubber parts with complex shapes and high precision by rubber injection moulding process.

From www.youtube.com

Rubber Molding Machine with top ejector YouTube Rubber Moulding Machine Process Rubber injection molding turns heated material into the final molded rubber parts with complex shapes and high precision by rubber injection moulding process. In this post, we will explore the rubber compression molding process steps, commonly used materials, compression mold types, and pros and cons. The rubber compression molding process is one of the rubber molding manufacturing processes for shaping. Rubber Moulding Machine Process.

From www.arptech.com.au

Injection Moulding Process Explained ArpTechBlog Rubber Moulding Machine Process In this post, we will explore the rubber compression molding process steps, commonly used materials, compression mold types, and pros and cons. The rubber compression molding process is one of the rubber molding manufacturing processes for shaping rubber into custom products. The process involves placing an unvulcanized rubber mixture into a mold, applying heat and pressure to make it flow. Rubber Moulding Machine Process.

From supergum.com

Rubber Injection Moulding Technology Supergum Rubber Moulding Machine Process In this post, we will explore the rubber compression molding process steps, commonly used materials, compression mold types, and pros and cons. The process involves placing an unvulcanized rubber mixture into a mold, applying heat and pressure to make it flow and fill the mold cavity, and finally undergoing a vulcanization reaction to form a strong and durable finished product.. Rubber Moulding Machine Process.

From www.poly-tek.com

Rubber Injection Molding PolyTek Rubber Moulding Machine Process The rubber compression molding process is one of the rubber molding manufacturing processes for shaping rubber into custom products. In this post, we will explore the rubber compression molding process steps, commonly used materials, compression mold types, and pros and cons. The process involves placing an unvulcanized rubber mixture into a mold, applying heat and pressure to make it flow. Rubber Moulding Machine Process.

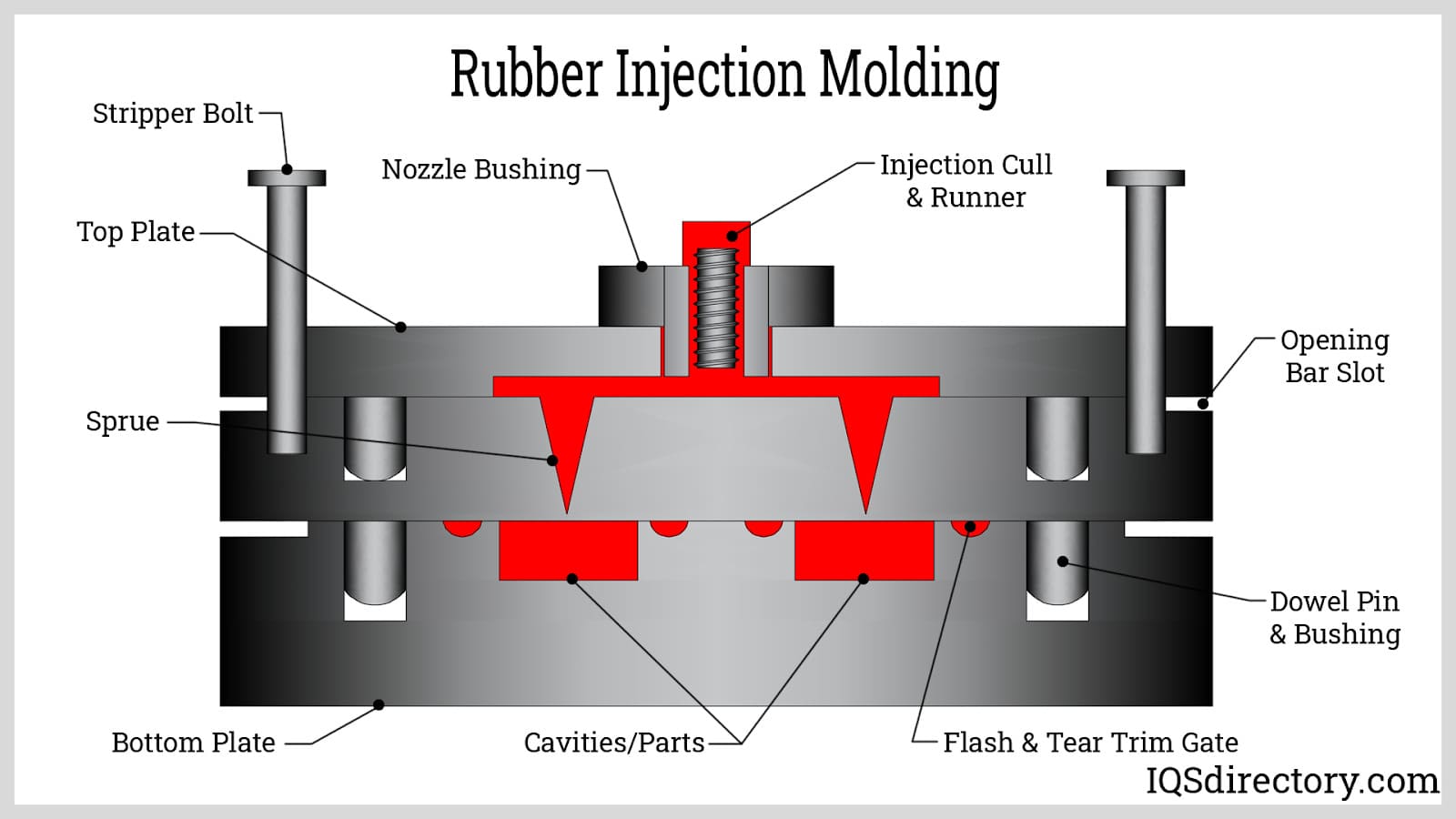

From www.iqsdirectory.com

Rubber Injection Molding Applications, Processes, Benefits Rubber Moulding Machine Process Check out this guide to learn about timco’s rubber molding processes, including injection molding, transfer molding, rubber compression molding, and more. Rubber injection molding turns heated material into the final molded rubber parts with complex shapes and high precision by rubber injection moulding process. The process involves placing an unvulcanized rubber mixture into a mold, applying heat and pressure to. Rubber Moulding Machine Process.

From srm-industries.com

Rubber transfer moulding SRM Industries Rubber Moulding Machine Process In this post, we will explore the rubber compression molding process steps, commonly used materials, compression mold types, and pros and cons. Rubber injection molding turns heated material into the final molded rubber parts with complex shapes and high precision by rubber injection moulding process. Check out this guide to learn about timco’s rubber molding processes, including injection molding, transfer. Rubber Moulding Machine Process.

From howtomakerubbermolding.blogspot.com

How to make rubber molding Liquid silicone rubber injection moulding Rubber Moulding Machine Process In this post, we will explore the rubber compression molding process steps, commonly used materials, compression mold types, and pros and cons. Check out this guide to learn about timco’s rubber molding processes, including injection molding, transfer molding, rubber compression molding, and more. Rubber injection molding turns heated material into the final molded rubber parts with complex shapes and high. Rubber Moulding Machine Process.

From kus-usa.com

Rubber Mixing, Molding and Processing KUS Americas, Inc. Rubber Moulding Machine Process The rubber compression molding process is one of the rubber molding manufacturing processes for shaping rubber into custom products. In this post, we will explore the rubber compression molding process steps, commonly used materials, compression mold types, and pros and cons. Check out this guide to learn about timco’s rubber molding processes, including injection molding, transfer molding, rubber compression molding,. Rubber Moulding Machine Process.

From www.youtube.com

rubber vacuum molding machine YouTube Rubber Moulding Machine Process Rubber injection molding turns heated material into the final molded rubber parts with complex shapes and high precision by rubber injection moulding process. The rubber compression molding process is one of the rubber molding manufacturing processes for shaping rubber into custom products. Check out this guide to learn about timco’s rubber molding processes, including injection molding, transfer molding, rubber compression. Rubber Moulding Machine Process.

From www.youtube.com

100 Tons Rubber Moulding Machine with Manual Slider Mechanism YouTube Rubber Moulding Machine Process The rubber compression molding process is one of the rubber molding manufacturing processes for shaping rubber into custom products. In this post, we will explore the rubber compression molding process steps, commonly used materials, compression mold types, and pros and cons. Rubber injection molding turns heated material into the final molded rubber parts with complex shapes and high precision by. Rubber Moulding Machine Process.

From www.gmtrubber.com

Rubber Injection Moulding and Compression Moulding Rubber Moulding Machine Process In this post, we will explore the rubber compression molding process steps, commonly used materials, compression mold types, and pros and cons. Rubber injection molding turns heated material into the final molded rubber parts with complex shapes and high precision by rubber injection moulding process. The rubber compression molding process is one of the rubber molding manufacturing processes for shaping. Rubber Moulding Machine Process.

From jocelyn8888.en.made-in-china.com

Vertical Injection Molding Machine China Rubber Machinery and Rubber Rubber Moulding Machine Process Rubber injection molding turns heated material into the final molded rubber parts with complex shapes and high precision by rubber injection moulding process. The process involves placing an unvulcanized rubber mixture into a mold, applying heat and pressure to make it flow and fill the mold cavity, and finally undergoing a vulcanization reaction to form a strong and durable finished. Rubber Moulding Machine Process.

From www.indiamart.com

800 Tons Hydraulic Rubber Transfer Moulding Machine at Rs 2399998 Rubber Moulding Machine Process The process involves placing an unvulcanized rubber mixture into a mold, applying heat and pressure to make it flow and fill the mold cavity, and finally undergoing a vulcanization reaction to form a strong and durable finished product. Rubber injection molding turns heated material into the final molded rubber parts with complex shapes and high precision by rubber injection moulding. Rubber Moulding Machine Process.

From www.indiamart.com

200 Tons Rubber Injection Moulding Machine at Rs 1500000 Rubber Rubber Moulding Machine Process Rubber injection molding turns heated material into the final molded rubber parts with complex shapes and high precision by rubber injection moulding process. The process involves placing an unvulcanized rubber mixture into a mold, applying heat and pressure to make it flow and fill the mold cavity, and finally undergoing a vulcanization reaction to form a strong and durable finished. Rubber Moulding Machine Process.

From www.youtube.com

RT560 Rubber Injection Moulding Machine Factory Trial YouTube Rubber Moulding Machine Process Check out this guide to learn about timco’s rubber molding processes, including injection molding, transfer molding, rubber compression molding, and more. Rubber injection molding turns heated material into the final molded rubber parts with complex shapes and high precision by rubber injection moulding process. The process involves placing an unvulcanized rubber mixture into a mold, applying heat and pressure to. Rubber Moulding Machine Process.

From www.ace-mold.com

Advanced Rubber Injection Molding Machinesacemold Rubber Moulding Machine Process Rubber injection molding turns heated material into the final molded rubber parts with complex shapes and high precision by rubber injection moulding process. The process involves placing an unvulcanized rubber mixture into a mold, applying heat and pressure to make it flow and fill the mold cavity, and finally undergoing a vulcanization reaction to form a strong and durable finished. Rubber Moulding Machine Process.

From www.panstone.com

Rubber Injection Molding Supplier PAN STONE HYDRAULIC INDUS. CO. LTD. Rubber Moulding Machine Process The process involves placing an unvulcanized rubber mixture into a mold, applying heat and pressure to make it flow and fill the mold cavity, and finally undergoing a vulcanization reaction to form a strong and durable finished product. Check out this guide to learn about timco’s rubber molding processes, including injection molding, transfer molding, rubber compression molding, and more. In. Rubber Moulding Machine Process.

From barwell.com

Barwell Rubber Compression Moulding Machines Rubber Moulding Machine Process The process involves placing an unvulcanized rubber mixture into a mold, applying heat and pressure to make it flow and fill the mold cavity, and finally undergoing a vulcanization reaction to form a strong and durable finished product. Check out this guide to learn about timco’s rubber molding processes, including injection molding, transfer molding, rubber compression molding, and more. In. Rubber Moulding Machine Process.

From en.dekuma.com

Rubber Injection Moulding Machine Vertical Injection Machine DEKUMA Rubber Moulding Machine Process In this post, we will explore the rubber compression molding process steps, commonly used materials, compression mold types, and pros and cons. Rubber injection molding turns heated material into the final molded rubber parts with complex shapes and high precision by rubber injection moulding process. The rubber compression molding process is one of the rubber molding manufacturing processes for shaping. Rubber Moulding Machine Process.

From siliconemakers.com

Liquid Silicone Rubber Molding Lanxin Rubber Moulding Machine Process Rubber injection molding turns heated material into the final molded rubber parts with complex shapes and high precision by rubber injection moulding process. The process involves placing an unvulcanized rubber mixture into a mold, applying heat and pressure to make it flow and fill the mold cavity, and finally undergoing a vulcanization reaction to form a strong and durable finished. Rubber Moulding Machine Process.

From www.researchgate.net

FIFO rubber injection moulding unit (source Maplan GmbH) and prototype Rubber Moulding Machine Process Rubber injection molding turns heated material into the final molded rubber parts with complex shapes and high precision by rubber injection moulding process. In this post, we will explore the rubber compression molding process steps, commonly used materials, compression mold types, and pros and cons. The process involves placing an unvulcanized rubber mixture into a mold, applying heat and pressure. Rubber Moulding Machine Process.

From www.timcorubber.com

Rubber Injection Molding & Molded Rubber Molding Process Rubber Moulding Machine Process Check out this guide to learn about timco’s rubber molding processes, including injection molding, transfer molding, rubber compression molding, and more. Rubber injection molding turns heated material into the final molded rubber parts with complex shapes and high precision by rubber injection moulding process. In this post, we will explore the rubber compression molding process steps, commonly used materials, compression. Rubber Moulding Machine Process.

From www.rnaautomation.com

Robotics in Injection Moulding RNA Automation Rubber Moulding Machine Process The process involves placing an unvulcanized rubber mixture into a mold, applying heat and pressure to make it flow and fill the mold cavity, and finally undergoing a vulcanization reaction to form a strong and durable finished product. The rubber compression molding process is one of the rubber molding manufacturing processes for shaping rubber into custom products. Check out this. Rubber Moulding Machine Process.

From www.rubbermolding.org

Rubber Injection Molding Rubber Molding Rubber Moulding Machine Process The process involves placing an unvulcanized rubber mixture into a mold, applying heat and pressure to make it flow and fill the mold cavity, and finally undergoing a vulcanization reaction to form a strong and durable finished product. Check out this guide to learn about timco’s rubber molding processes, including injection molding, transfer molding, rubber compression molding, and more. Rubber. Rubber Moulding Machine Process.

From engineeringlearn.com

16 Types of Moulding [Explained with Complete Details] Engineering Learn Rubber Moulding Machine Process Check out this guide to learn about timco’s rubber molding processes, including injection molding, transfer molding, rubber compression molding, and more. The rubber compression molding process is one of the rubber molding manufacturing processes for shaping rubber into custom products. The process involves placing an unvulcanized rubber mixture into a mold, applying heat and pressure to make it flow and. Rubber Moulding Machine Process.

From en.dekuma.com

Rubber Injection Moulding Machine Vertical Injection Machine DEKUMA Rubber Moulding Machine Process Rubber injection molding turns heated material into the final molded rubber parts with complex shapes and high precision by rubber injection moulding process. Check out this guide to learn about timco’s rubber molding processes, including injection molding, transfer molding, rubber compression molding, and more. The rubber compression molding process is one of the rubber molding manufacturing processes for shaping rubber. Rubber Moulding Machine Process.

From www.huayijx.com

Rubber Molding Machinery NewsRubber Molding Machine NewsRubber Tech News Rubber Moulding Machine Process The process involves placing an unvulcanized rubber mixture into a mold, applying heat and pressure to make it flow and fill the mold cavity, and finally undergoing a vulcanization reaction to form a strong and durable finished product. Check out this guide to learn about timco’s rubber molding processes, including injection molding, transfer molding, rubber compression molding, and more. Rubber. Rubber Moulding Machine Process.

From dpseals.com

Rubber Moulding Process Comparisons DP Seals Rubber Moulding Machine Process Check out this guide to learn about timco’s rubber molding processes, including injection molding, transfer molding, rubber compression molding, and more. In this post, we will explore the rubber compression molding process steps, commonly used materials, compression mold types, and pros and cons. The rubber compression molding process is one of the rubber molding manufacturing processes for shaping rubber into. Rubber Moulding Machine Process.

From www.youtube.com

Vacuum Type Compression / Transfer Rubber Moulding Machine YouTube Rubber Moulding Machine Process The process involves placing an unvulcanized rubber mixture into a mold, applying heat and pressure to make it flow and fill the mold cavity, and finally undergoing a vulcanization reaction to form a strong and durable finished product. The rubber compression molding process is one of the rubber molding manufacturing processes for shaping rubber into custom products. Check out this. Rubber Moulding Machine Process.

From www.siliconerubberinjectionmoldingmachine.com

6000 KN Clamp Force Vertical Rubber Injection Molding Machine 6000cc Volumn Rubber Moulding Machine Process The rubber compression molding process is one of the rubber molding manufacturing processes for shaping rubber into custom products. Check out this guide to learn about timco’s rubber molding processes, including injection molding, transfer molding, rubber compression molding, and more. Rubber injection molding turns heated material into the final molded rubber parts with complex shapes and high precision by rubber. Rubber Moulding Machine Process.

From qualiformrubbermolding.com

Rubber Transfer Molding Custom Rubber Transfer Molding Experts Rubber Moulding Machine Process The process involves placing an unvulcanized rubber mixture into a mold, applying heat and pressure to make it flow and fill the mold cavity, and finally undergoing a vulcanization reaction to form a strong and durable finished product. Rubber injection molding turns heated material into the final molded rubber parts with complex shapes and high precision by rubber injection moulding. Rubber Moulding Machine Process.

From www.exportersindia.com

Rubber Injection Moulding Machine by Techno Machines India, rubber Rubber Moulding Machine Process The rubber compression molding process is one of the rubber molding manufacturing processes for shaping rubber into custom products. The process involves placing an unvulcanized rubber mixture into a mold, applying heat and pressure to make it flow and fill the mold cavity, and finally undergoing a vulcanization reaction to form a strong and durable finished product. In this post,. Rubber Moulding Machine Process.

From www.siliconerubberinjectionmoldingmachine.com

Mechanical Vertical Rubber Injection Molding Machine With High Torque Rubber Moulding Machine Process The rubber compression molding process is one of the rubber molding manufacturing processes for shaping rubber into custom products. In this post, we will explore the rubber compression molding process steps, commonly used materials, compression mold types, and pros and cons. Check out this guide to learn about timco’s rubber molding processes, including injection molding, transfer molding, rubber compression molding,. Rubber Moulding Machine Process.

From www.simtec-silicone.com

Optical Liquid Silicone Rubber Injection Molding SIMTEC Rubber Moulding Machine Process The process involves placing an unvulcanized rubber mixture into a mold, applying heat and pressure to make it flow and fill the mold cavity, and finally undergoing a vulcanization reaction to form a strong and durable finished product. Rubber injection molding turns heated material into the final molded rubber parts with complex shapes and high precision by rubber injection moulding. Rubber Moulding Machine Process.

From www.iqsdirectory.com

Rubber Injection Molding Applications, Processes, Benefits Rubber Moulding Machine Process The rubber compression molding process is one of the rubber molding manufacturing processes for shaping rubber into custom products. In this post, we will explore the rubber compression molding process steps, commonly used materials, compression mold types, and pros and cons. Check out this guide to learn about timco’s rubber molding processes, including injection molding, transfer molding, rubber compression molding,. Rubber Moulding Machine Process.