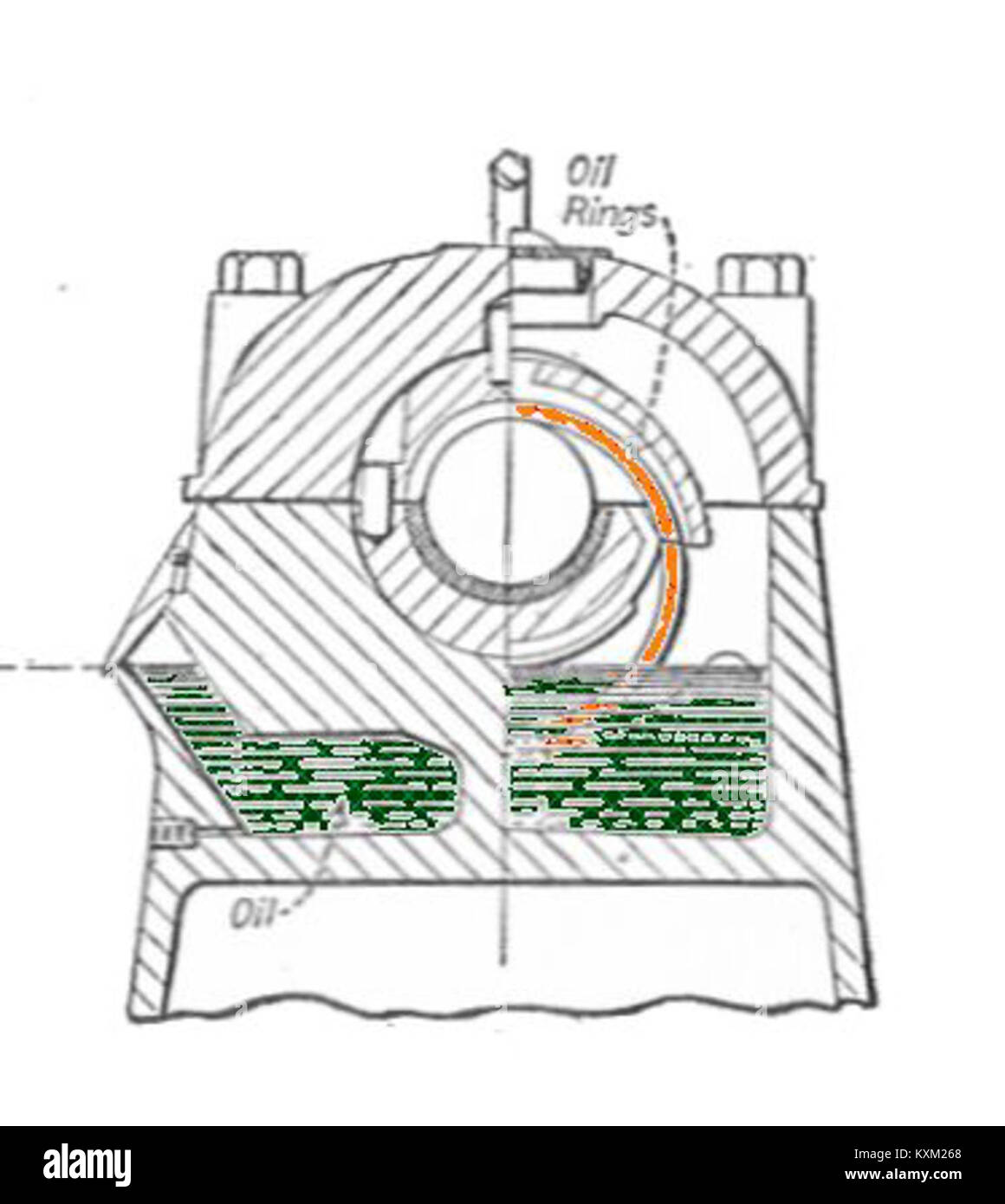

Ring Oiler Purpose . the constant level oiler (fig. a ring oiler is a simple device, consisting of a large metal ring placed around a horizontal shaft, adjacent to a bearing. They impact combustion sealing, oil control, friction, and. piston ring grooves serve a larger purpose than simply supporting the rings. 2) continues to be one of the most widely used methods of maintaining the proper level lubricant in a bearing. When installed in the oil ring groove, the rails press down on the expander and. the purpose is to reduce pressure buildup between the pairs of rings. Note the oil drain back holes machined into the piston in the backside of the oil. “the oil ring is what gathers it and pumps it away from the cylinder walls via oil return holes in the oil ring groove.”. the oil ring expander acts like a spring.

from www.alamy.com

2) continues to be one of the most widely used methods of maintaining the proper level lubricant in a bearing. Note the oil drain back holes machined into the piston in the backside of the oil. When installed in the oil ring groove, the rails press down on the expander and. They impact combustion sealing, oil control, friction, and. the purpose is to reduce pressure buildup between the pairs of rings. a ring oiler is a simple device, consisting of a large metal ring placed around a horizontal shaft, adjacent to a bearing. the oil ring expander acts like a spring. piston ring grooves serve a larger purpose than simply supporting the rings. the constant level oiler (fig. “the oil ring is what gathers it and pumps it away from the cylinder walls via oil return holes in the oil ring groove.”.

Bearing with ring oiler, coloured (Electrical Machinery, 1917 Stock Photo Alamy

Ring Oiler Purpose a ring oiler is a simple device, consisting of a large metal ring placed around a horizontal shaft, adjacent to a bearing. the purpose is to reduce pressure buildup between the pairs of rings. “the oil ring is what gathers it and pumps it away from the cylinder walls via oil return holes in the oil ring groove.”. the constant level oiler (fig. 2) continues to be one of the most widely used methods of maintaining the proper level lubricant in a bearing. When installed in the oil ring groove, the rails press down on the expander and. They impact combustion sealing, oil control, friction, and. the oil ring expander acts like a spring. Note the oil drain back holes machined into the piston in the backside of the oil. piston ring grooves serve a larger purpose than simply supporting the rings. a ring oiler is a simple device, consisting of a large metal ring placed around a horizontal shaft, adjacent to a bearing.

From www.ebay.com

Crank Shaft Ring Oiler Hit Miss Gas Oilfield Engine Antique eBay Ring Oiler Purpose the constant level oiler (fig. piston ring grooves serve a larger purpose than simply supporting the rings. When installed in the oil ring groove, the rails press down on the expander and. the oil ring expander acts like a spring. 2) continues to be one of the most widely used methods of maintaining the proper level lubricant. Ring Oiler Purpose.

From www.slideserve.com

PPT Pistons Rings Pins PowerPoint Presentation, free download ID6111562 Ring Oiler Purpose the constant level oiler (fig. When installed in the oil ring groove, the rails press down on the expander and. piston ring grooves serve a larger purpose than simply supporting the rings. “the oil ring is what gathers it and pumps it away from the cylinder walls via oil return holes in the oil ring groove.”. 2). Ring Oiler Purpose.

From www.ebay.com

White Ringoiler 107264A eBay Ring Oiler Purpose 2) continues to be one of the most widely used methods of maintaining the proper level lubricant in a bearing. Note the oil drain back holes machined into the piston in the backside of the oil. When installed in the oil ring groove, the rails press down on the expander and. the purpose is to reduce pressure buildup between. Ring Oiler Purpose.

From www.alamy.com

Bearing with ring oiler (Electrical Machinery, 1917 Stock Photo Alamy Ring Oiler Purpose the oil ring expander acts like a spring. They impact combustion sealing, oil control, friction, and. When installed in the oil ring groove, the rails press down on the expander and. “the oil ring is what gathers it and pumps it away from the cylinder walls via oil return holes in the oil ring groove.”. 2) continues to. Ring Oiler Purpose.

From www.pumpsandsystems.com

Back to Basics Pump Bearing Housing LubricationPart 2 Ring Oiler Purpose the constant level oiler (fig. When installed in the oil ring groove, the rails press down on the expander and. “the oil ring is what gathers it and pumps it away from the cylinder walls via oil return holes in the oil ring groove.”. piston ring grooves serve a larger purpose than simply supporting the rings. . Ring Oiler Purpose.

From www.alamy.com

Bearing with ring oiler, coloured (Electrical Machinery, 1917 Stock Photo Alamy Ring Oiler Purpose the oil ring expander acts like a spring. “the oil ring is what gathers it and pumps it away from the cylinder walls via oil return holes in the oil ring groove.”. the constant level oiler (fig. the purpose is to reduce pressure buildup between the pairs of rings. a ring oiler is a simple. Ring Oiler Purpose.

From www.ebay.com

Crank Shaft Ring Oiler Hit Miss Gas Oilfield Engine Antique eBay Ring Oiler Purpose the oil ring expander acts like a spring. “the oil ring is what gathers it and pumps it away from the cylinder walls via oil return holes in the oil ring groove.”. 2) continues to be one of the most widely used methods of maintaining the proper level lubricant in a bearing. a ring oiler is a. Ring Oiler Purpose.

From arvis.co.uk

Fan bearings (ring oiler type) Arvis Ring Oiler Purpose They impact combustion sealing, oil control, friction, and. When installed in the oil ring groove, the rails press down on the expander and. the purpose is to reduce pressure buildup between the pairs of rings. Note the oil drain back holes machined into the piston in the backside of the oil. “the oil ring is what gathers it. Ring Oiler Purpose.

From www.youtube.com

PISTON RING FUNCTION OF PISTON RINGS MATERIAL OF RINGS COMPRESSION RINGS OIL RINGS YouTube Ring Oiler Purpose the oil ring expander acts like a spring. 2) continues to be one of the most widely used methods of maintaining the proper level lubricant in a bearing. the purpose is to reduce pressure buildup between the pairs of rings. They impact combustion sealing, oil control, friction, and. the constant level oiler (fig. Note the oil drain. Ring Oiler Purpose.

From www.alamy.com

191 Bearing with ring oiler, longitudinal section (Electrical Machinery, 1917 Stock Photo Alamy Ring Oiler Purpose a ring oiler is a simple device, consisting of a large metal ring placed around a horizontal shaft, adjacent to a bearing. 2) continues to be one of the most widely used methods of maintaining the proper level lubricant in a bearing. Note the oil drain back holes machined into the piston in the backside of the oil. When. Ring Oiler Purpose.

From digital.allchevyperformance.com

Oil Ring Tech Ring Oiler Purpose When installed in the oil ring groove, the rails press down on the expander and. They impact combustion sealing, oil control, friction, and. the oil ring expander acts like a spring. piston ring grooves serve a larger purpose than simply supporting the rings. the constant level oiler (fig. a ring oiler is a simple device, consisting. Ring Oiler Purpose.

From arvis.co.uk

Fan bearings (ring oiler type) Arvis Ring Oiler Purpose “the oil ring is what gathers it and pumps it away from the cylinder walls via oil return holes in the oil ring groove.”. the purpose is to reduce pressure buildup between the pairs of rings. They impact combustion sealing, oil control, friction, and. When installed in the oil ring groove, the rails press down on the expander. Ring Oiler Purpose.

From www.trustmymechanic.com

Why We Need 3 Piston Rings Compression, Oil Control, & Wiper Ring Differences Explained Ring Oiler Purpose They impact combustion sealing, oil control, friction, and. the purpose is to reduce pressure buildup between the pairs of rings. “the oil ring is what gathers it and pumps it away from the cylinder walls via oil return holes in the oil ring groove.”. the constant level oiler (fig. 2) continues to be one of the most. Ring Oiler Purpose.

From inthegaragemedia.com

Get extra horsepower with proper oil ring selection and tension. Ring Oiler Purpose a ring oiler is a simple device, consisting of a large metal ring placed around a horizontal shaft, adjacent to a bearing. Note the oil drain back holes machined into the piston in the backside of the oil. the oil ring expander acts like a spring. “the oil ring is what gathers it and pumps it away. Ring Oiler Purpose.

From empoweringpumps.com

DNNumber Points to Oil Level Preferences in Bearing Housings Empowering Pumps and Equipment Ring Oiler Purpose piston ring grooves serve a larger purpose than simply supporting the rings. “the oil ring is what gathers it and pumps it away from the cylinder walls via oil return holes in the oil ring groove.”. 2) continues to be one of the most widely used methods of maintaining the proper level lubricant in a bearing. the. Ring Oiler Purpose.

From www.vet-direct.com

Vet Direct Dental Handpiece Maintenance Guide Low Speed Motor (Air Motor) Ring Oiler Purpose the constant level oiler (fig. piston ring grooves serve a larger purpose than simply supporting the rings. Note the oil drain back holes machined into the piston in the backside of the oil. When installed in the oil ring groove, the rails press down on the expander and. 2) continues to be one of the most widely used. Ring Oiler Purpose.

From www.youtube.com

Ring Oiler. IYPT 2018. Problem 6 Part 2 YouTube Ring Oiler Purpose When installed in the oil ring groove, the rails press down on the expander and. “the oil ring is what gathers it and pumps it away from the cylinder walls via oil return holes in the oil ring groove.”. a ring oiler is a simple device, consisting of a large metal ring placed around a horizontal shaft, adjacent. Ring Oiler Purpose.

From learningschoolw1k5x.z21.web.core.windows.net

Piston Ring Placement On Piston Ring Oiler Purpose the oil ring expander acts like a spring. Note the oil drain back holes machined into the piston in the backside of the oil. They impact combustion sealing, oil control, friction, and. “the oil ring is what gathers it and pumps it away from the cylinder walls via oil return holes in the oil ring groove.”. piston. Ring Oiler Purpose.

From www.semanticscholar.org

[PDF] Factors Affecting Oil Ring And Slinger Lubricant Delivery & Stability Semantic Scholar Ring Oiler Purpose When installed in the oil ring groove, the rails press down on the expander and. the constant level oiler (fig. 2) continues to be one of the most widely used methods of maintaining the proper level lubricant in a bearing. a ring oiler is a simple device, consisting of a large metal ring placed around a horizontal shaft,. Ring Oiler Purpose.

From www.youtube.com

physic project Ring oiler YouTube Ring Oiler Purpose the constant level oiler (fig. the oil ring expander acts like a spring. 2) continues to be one of the most widely used methods of maintaining the proper level lubricant in a bearing. the purpose is to reduce pressure buildup between the pairs of rings. piston ring grooves serve a larger purpose than simply supporting the. Ring Oiler Purpose.

From www.youtube.com

What is Oil piston ring purpose in car engine YouTube Ring Oiler Purpose a ring oiler is a simple device, consisting of a large metal ring placed around a horizontal shaft, adjacent to a bearing. the constant level oiler (fig. When installed in the oil ring groove, the rails press down on the expander and. 2) continues to be one of the most widely used methods of maintaining the proper level. Ring Oiler Purpose.

From www.youtube.com

(Ring Oiler) 5 HP Century Repulsion Start Induction Motor YouTube Ring Oiler Purpose the purpose is to reduce pressure buildup between the pairs of rings. the oil ring expander acts like a spring. “the oil ring is what gathers it and pumps it away from the cylinder walls via oil return holes in the oil ring groove.”. the constant level oiler (fig. When installed in the oil ring groove,. Ring Oiler Purpose.

From www.slideserve.com

PPT Modern Automotive Technology PowerPoint Presentation, free download ID18024 Ring Oiler Purpose the purpose is to reduce pressure buildup between the pairs of rings. the constant level oiler (fig. 2) continues to be one of the most widely used methods of maintaining the proper level lubricant in a bearing. a ring oiler is a simple device, consisting of a large metal ring placed around a horizontal shaft, adjacent to. Ring Oiler Purpose.

From www.ebay.com

Crank Shaft Ring Oiler Hit Miss Gas Oilfield Engine Antique eBay Ring Oiler Purpose They impact combustion sealing, oil control, friction, and. the purpose is to reduce pressure buildup between the pairs of rings. “the oil ring is what gathers it and pumps it away from the cylinder walls via oil return holes in the oil ring groove.”. a ring oiler is a simple device, consisting of a large metal ring. Ring Oiler Purpose.

From www.slideserve.com

PPT Engine Components PowerPoint Presentation, free download ID5654015 Ring Oiler Purpose the purpose is to reduce pressure buildup between the pairs of rings. 2) continues to be one of the most widely used methods of maintaining the proper level lubricant in a bearing. Note the oil drain back holes machined into the piston in the backside of the oil. “the oil ring is what gathers it and pumps it. Ring Oiler Purpose.

From www.youtube.com

Oil consumption and decarbonizing oil rings works? How to clean oil rings without removing Ring Oiler Purpose Note the oil drain back holes machined into the piston in the backside of the oil. a ring oiler is a simple device, consisting of a large metal ring placed around a horizontal shaft, adjacent to a bearing. the purpose is to reduce pressure buildup between the pairs of rings. They impact combustion sealing, oil control, friction, and.. Ring Oiler Purpose.

From learnoilanalysis.com

Ring ring, Ring Ring. Is your engine giving you a hint? LEARN OIL ANALYSIS Ring Oiler Purpose piston ring grooves serve a larger purpose than simply supporting the rings. They impact combustion sealing, oil control, friction, and. the constant level oiler (fig. 2) continues to be one of the most widely used methods of maintaining the proper level lubricant in a bearing. the oil ring expander acts like a spring. a ring oiler. Ring Oiler Purpose.

From www.youtube.com

IYPT Ring Oiler YouTube Ring Oiler Purpose “the oil ring is what gathers it and pumps it away from the cylinder walls via oil return holes in the oil ring groove.”. the constant level oiler (fig. When installed in the oil ring groove, the rails press down on the expander and. the oil ring expander acts like a spring. 2) continues to be one. Ring Oiler Purpose.

From www.youtube.com

Piston Rings Types Oil Ring,Oil Scraper Ring ENGINEERING STUDY MATERIALS Ring Oiler Purpose “the oil ring is what gathers it and pumps it away from the cylinder walls via oil return holes in the oil ring groove.”. the constant level oiler (fig. They impact combustion sealing, oil control, friction, and. a ring oiler is a simple device, consisting of a large metal ring placed around a horizontal shaft, adjacent to. Ring Oiler Purpose.

From www.ebay.com

Crank Shaft Ring Oiler Hit Miss Gas Oilfield Engine Antique eBay Ring Oiler Purpose the oil ring expander acts like a spring. 2) continues to be one of the most widely used methods of maintaining the proper level lubricant in a bearing. a ring oiler is a simple device, consisting of a large metal ring placed around a horizontal shaft, adjacent to a bearing. “the oil ring is what gathers it. Ring Oiler Purpose.

From www.wxinggroup.com

Bearing Ring Oiler News Zhejiang Waxing Electromechanical Co., Ltd Ring Oiler Purpose When installed in the oil ring groove, the rails press down on the expander and. the oil ring expander acts like a spring. “the oil ring is what gathers it and pumps it away from the cylinder walls via oil return holes in the oil ring groove.”. piston ring grooves serve a larger purpose than simply supporting. Ring Oiler Purpose.

From www.youtube.com

Retlas 'Manchester' Dynamo Ring Oiler YouTube Ring Oiler Purpose They impact combustion sealing, oil control, friction, and. 2) continues to be one of the most widely used methods of maintaining the proper level lubricant in a bearing. When installed in the oil ring groove, the rails press down on the expander and. the constant level oiler (fig. a ring oiler is a simple device, consisting of a. Ring Oiler Purpose.

From askcarmechanic.com

Why Is There Oil On My Spark Plug Threads? Ring Oiler Purpose When installed in the oil ring groove, the rails press down on the expander and. Note the oil drain back holes machined into the piston in the backside of the oil. the oil ring expander acts like a spring. “the oil ring is what gathers it and pumps it away from the cylinder walls via oil return holes. Ring Oiler Purpose.

From www.wxingbearing.com

Bearing Ring Oiler, Zhejiang Waxing Electromechanical Co.ltd. Ring Oiler Purpose the oil ring expander acts like a spring. the constant level oiler (fig. They impact combustion sealing, oil control, friction, and. the purpose is to reduce pressure buildup between the pairs of rings. a ring oiler is a simple device, consisting of a large metal ring placed around a horizontal shaft, adjacent to a bearing. . Ring Oiler Purpose.

From netgroup.edu.vn

Top more than 135 oil slinger ring function latest netgroup.edu.vn Ring Oiler Purpose They impact combustion sealing, oil control, friction, and. 2) continues to be one of the most widely used methods of maintaining the proper level lubricant in a bearing. the oil ring expander acts like a spring. the constant level oiler (fig. When installed in the oil ring groove, the rails press down on the expander and. “the. Ring Oiler Purpose.