Laser Cut Electronics Enclosure . April 26, 2017 at 5:04 pm. Here, i would like to share. Now, i’ve learned my lesson: Thorough walkthrough of the unboxing and assembly of the parts ordered (built around the makercase. Build your own custom laser cut box boxes! This can be a challenge with laser cutting. Everyone likes putting things in boxes, and there is something so satisfying about laser cutting your own enclosure to neatly round off a diy project. Here are some tricks and tips for. We offer laser cutting, punching, stamping, and machining. Before making the final determination if laser cutting is right for your electronics build, it’s important to understand. A kit enclosure should be more than just a box. Always prepare an enclosure for each development board that you want to take care of. We also offer inhouse finishing options between powder coat, painting among other.

from robotics.ong.id.au

Now, i’ve learned my lesson: This can be a challenge with laser cutting. Thorough walkthrough of the unboxing and assembly of the parts ordered (built around the makercase. Here are some tricks and tips for. We offer laser cutting, punching, stamping, and machining. We also offer inhouse finishing options between powder coat, painting among other. Build your own custom laser cut box boxes! April 26, 2017 at 5:04 pm. Before making the final determination if laser cutting is right for your electronics build, it’s important to understand. Here, i would like to share.

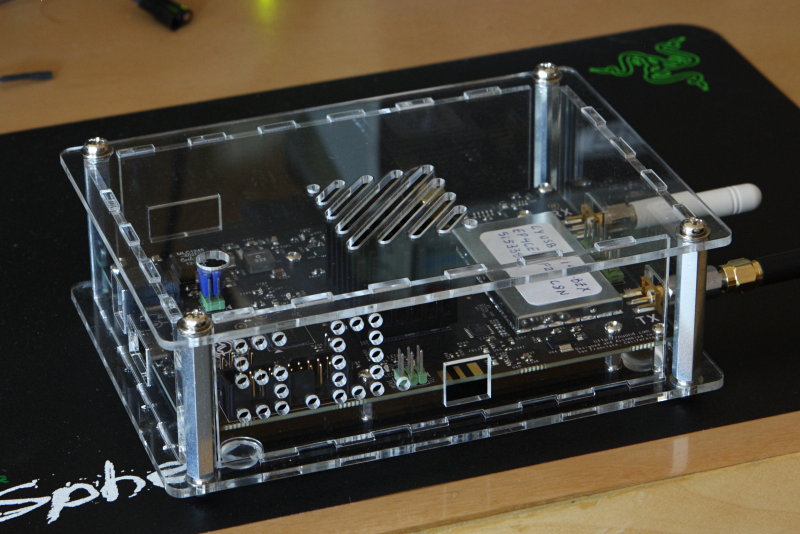

bladeRF enclosure made from laser cut acrylic All Things Electronics

Laser Cut Electronics Enclosure Here are some tricks and tips for. Here, i would like to share. April 26, 2017 at 5:04 pm. Before making the final determination if laser cutting is right for your electronics build, it’s important to understand. Now, i’ve learned my lesson: Build your own custom laser cut box boxes! Always prepare an enclosure for each development board that you want to take care of. This can be a challenge with laser cutting. A kit enclosure should be more than just a box. Here are some tricks and tips for. Thorough walkthrough of the unboxing and assembly of the parts ordered (built around the makercase. We also offer inhouse finishing options between powder coat, painting among other. We offer laser cutting, punching, stamping, and machining. Everyone likes putting things in boxes, and there is something so satisfying about laser cutting your own enclosure to neatly round off a diy project.

From www.ponoko.com

Mounting And Protecting Custom PCBs With Laser Cut Faceplates, Panels Laser Cut Electronics Enclosure Build your own custom laser cut box boxes! April 26, 2017 at 5:04 pm. A kit enclosure should be more than just a box. We offer laser cutting, punching, stamping, and machining. This can be a challenge with laser cutting. Everyone likes putting things in boxes, and there is something so satisfying about laser cutting your own enclosure to neatly. Laser Cut Electronics Enclosure.

From yishang.en.made-in-china.com

Outdoor Stainless Steel Box Laser Cutting Service Industrial Wall Mount Laser Cut Electronics Enclosure Now, i’ve learned my lesson: We offer laser cutting, punching, stamping, and machining. This can be a challenge with laser cutting. Everyone likes putting things in boxes, and there is something so satisfying about laser cutting your own enclosure to neatly round off a diy project. A kit enclosure should be more than just a box. We also offer inhouse. Laser Cut Electronics Enclosure.

From hightron99.en.made-in-china.com

Custom Laser Cutting Enclosure Electronic Equipment Medical Laser Cut Electronics Enclosure Now, i’ve learned my lesson: Here, i would like to share. This can be a challenge with laser cutting. We also offer inhouse finishing options between powder coat, painting among other. April 26, 2017 at 5:04 pm. Before making the final determination if laser cutting is right for your electronics build, it’s important to understand. Build your own custom laser. Laser Cut Electronics Enclosure.

From ysyelectric.en.made-in-china.com

Customized Sheet Metal Enclosure Aluminum Stamping Laser Cutting Laser Cut Electronics Enclosure Always prepare an enclosure for each development board that you want to take care of. This can be a challenge with laser cutting. Build your own custom laser cut box boxes! Now, i’ve learned my lesson: We offer laser cutting, punching, stamping, and machining. Everyone likes putting things in boxes, and there is something so satisfying about laser cutting your. Laser Cut Electronics Enclosure.

From zhongshanyingbo.en.made-in-china.com

Customized Laser Cutting/Bending Metal Sheet Stamping Steel Aluminum Laser Cut Electronics Enclosure Now, i’ve learned my lesson: This can be a challenge with laser cutting. April 26, 2017 at 5:04 pm. Build your own custom laser cut box boxes! Here, i would like to share. We also offer inhouse finishing options between powder coat, painting among other. We offer laser cutting, punching, stamping, and machining. Everyone likes putting things in boxes, and. Laser Cut Electronics Enclosure.

From www.mldmetal.com

Supply Laser Cutting Of electronic product enclosures Wholesale Factory Laser Cut Electronics Enclosure Here, i would like to share. Before making the final determination if laser cutting is right for your electronics build, it’s important to understand. A kit enclosure should be more than just a box. This can be a challenge with laser cutting. Now, i’ve learned my lesson: We also offer inhouse finishing options between powder coat, painting among other. April. Laser Cut Electronics Enclosure.

From hackaday.io

Laser cut speaker enclosure Hackaday.io Laser Cut Electronics Enclosure Here, i would like to share. Everyone likes putting things in boxes, and there is something so satisfying about laser cutting your own enclosure to neatly round off a diy project. We offer laser cutting, punching, stamping, and machining. Before making the final determination if laser cutting is right for your electronics build, it’s important to understand. Thorough walkthrough of. Laser Cut Electronics Enclosure.

From robotics.ong.id.au

bladeRF enclosure made from laser cut acrylic All Things Electronics Laser Cut Electronics Enclosure Here, i would like to share. We also offer inhouse finishing options between powder coat, painting among other. Now, i’ve learned my lesson: A kit enclosure should be more than just a box. We offer laser cutting, punching, stamping, and machining. Here are some tricks and tips for. Everyone likes putting things in boxes, and there is something so satisfying. Laser Cut Electronics Enclosure.

From www.instructables.com

ESP32 Cam Laser Cut Acrylic Enclosure 3 Steps (with Pictures Laser Cut Electronics Enclosure Build your own custom laser cut box boxes! This can be a challenge with laser cutting. Always prepare an enclosure for each development board that you want to take care of. Now, i’ve learned my lesson: A kit enclosure should be more than just a box. Everyone likes putting things in boxes, and there is something so satisfying about laser. Laser Cut Electronics Enclosure.

From core-electronics.com.au

Laser Cut Case / Box / Enclosure Combo for Raspberry Pi B Australia Laser Cut Electronics Enclosure Here, i would like to share. A kit enclosure should be more than just a box. Here are some tricks and tips for. Everyone likes putting things in boxes, and there is something so satisfying about laser cutting your own enclosure to neatly round off a diy project. Always prepare an enclosure for each development board that you want to. Laser Cut Electronics Enclosure.

From kumair.com

Kumair Engineering and Carbon Fiber Composites Manufacturing Laser Cut Electronics Enclosure Before making the final determination if laser cutting is right for your electronics build, it’s important to understand. Now, i’ve learned my lesson: Here, i would like to share. April 26, 2017 at 5:04 pm. A kit enclosure should be more than just a box. Build your own custom laser cut box boxes! This can be a challenge with laser. Laser Cut Electronics Enclosure.

From djsheetmetal.en.made-in-china.com

OEM Custom Drawing Laser Cut Welding Aluminum Electronic Enclosure Laser Cut Electronics Enclosure Everyone likes putting things in boxes, and there is something so satisfying about laser cutting your own enclosure to neatly round off a diy project. Build your own custom laser cut box boxes! Now, i’ve learned my lesson: This can be a challenge with laser cutting. We offer laser cutting, punching, stamping, and machining. Here, i would like to share.. Laser Cut Electronics Enclosure.

From www.sheet-metalfab.com

Ip68 Acrylic Electronics Rack Enclosure Plastic Laser Cutting Sheet Laser Cut Electronics Enclosure This can be a challenge with laser cutting. We offer laser cutting, punching, stamping, and machining. Always prepare an enclosure for each development board that you want to take care of. Now, i’ve learned my lesson: Before making the final determination if laser cutting is right for your electronics build, it’s important to understand. April 26, 2017 at 5:04 pm.. Laser Cut Electronics Enclosure.

From www.vandf.co.uk

Laser cutting sheet metal electronics enclosures with a Trumpf 3030 fibre Laser Cut Electronics Enclosure Now, i’ve learned my lesson: April 26, 2017 at 5:04 pm. Everyone likes putting things in boxes, and there is something so satisfying about laser cutting your own enclosure to neatly round off a diy project. We offer laser cutting, punching, stamping, and machining. Here are some tricks and tips for. Build your own custom laser cut box boxes! Before. Laser Cut Electronics Enclosure.

From marchton.en.made-in-china.com

CNC Machining Laser Cutting Bending Customized Electronic Box Part Laser Cut Electronics Enclosure We also offer inhouse finishing options between powder coat, painting among other. April 26, 2017 at 5:04 pm. We offer laser cutting, punching, stamping, and machining. Thorough walkthrough of the unboxing and assembly of the parts ordered (built around the makercase. This can be a challenge with laser cutting. Build your own custom laser cut box boxes! A kit enclosure. Laser Cut Electronics Enclosure.

From djsheetmetal.en.made-in-china.com

CNC Metal Fabrication Laser Cut Enclosure Case China Enclosure Box Laser Cut Electronics Enclosure This can be a challenge with laser cutting. We offer laser cutting, punching, stamping, and machining. Build your own custom laser cut box boxes! Always prepare an enclosure for each development board that you want to take care of. Thorough walkthrough of the unboxing and assembly of the parts ordered (built around the makercase. Now, i’ve learned my lesson: A. Laser Cut Electronics Enclosure.

From endurancelasers.com

How to make an enclosure for Ortur Laser Master 2 EnduranceLasers Laser Cut Electronics Enclosure We offer laser cutting, punching, stamping, and machining. Build your own custom laser cut box boxes! This can be a challenge with laser cutting. Everyone likes putting things in boxes, and there is something so satisfying about laser cutting your own enclosure to neatly round off a diy project. A kit enclosure should be more than just a box. Now,. Laser Cut Electronics Enclosure.

From zhongshanyingbo.en.made-in-china.com

OEM Custom Sheet Metal Laser Cut Steel Aluminum Electronic Enclosure Laser Cut Electronics Enclosure We offer laser cutting, punching, stamping, and machining. Thorough walkthrough of the unboxing and assembly of the parts ordered (built around the makercase. Everyone likes putting things in boxes, and there is something so satisfying about laser cutting your own enclosure to neatly round off a diy project. April 26, 2017 at 5:04 pm. Here, i would like to share.. Laser Cut Electronics Enclosure.

From kaiximetal.en.made-in-china.com

OEM Custom Battery Box Shell Sheet Metal Laser Cutting Service Laser Cut Electronics Enclosure Build your own custom laser cut box boxes! We also offer inhouse finishing options between powder coat, painting among other. April 26, 2017 at 5:04 pm. A kit enclosure should be more than just a box. Here, i would like to share. We offer laser cutting, punching, stamping, and machining. Here are some tricks and tips for. Everyone likes putting. Laser Cut Electronics Enclosure.

From www.kdmsteel.com

Electrical Enclosure Laser Cutting KDM Steel Laser Cut Electronics Enclosure Now, i’ve learned my lesson: We also offer inhouse finishing options between powder coat, painting among other. April 26, 2017 at 5:04 pm. Before making the final determination if laser cutting is right for your electronics build, it’s important to understand. Always prepare an enclosure for each development board that you want to take care of. This can be a. Laser Cut Electronics Enclosure.

From www.ponoko.com

150 Amazing Laser Cutter Projects And Ideas To Inspire You Laser Cut Electronics Enclosure We offer laser cutting, punching, stamping, and machining. Before making the final determination if laser cutting is right for your electronics build, it’s important to understand. Here are some tricks and tips for. Everyone likes putting things in boxes, and there is something so satisfying about laser cutting your own enclosure to neatly round off a diy project. Thorough walkthrough. Laser Cut Electronics Enclosure.

From djsheetmetal.en.made-in-china.com

Custom Metal Fabricaiton Manufacturer Laser Cut Weld Assembly Sheet Laser Cut Electronics Enclosure Always prepare an enclosure for each development board that you want to take care of. We offer laser cutting, punching, stamping, and machining. Everyone likes putting things in boxes, and there is something so satisfying about laser cutting your own enclosure to neatly round off a diy project. We also offer inhouse finishing options between powder coat, painting among other.. Laser Cut Electronics Enclosure.

From www.lasercutz.com

Electronics Prototyping Enclosure Laser Engraving • LaserCutZ NYC Laser Cut Electronics Enclosure Now, i’ve learned my lesson: Here are some tricks and tips for. A kit enclosure should be more than just a box. April 26, 2017 at 5:04 pm. We offer laser cutting, punching, stamping, and machining. Everyone likes putting things in boxes, and there is something so satisfying about laser cutting your own enclosure to neatly round off a diy. Laser Cut Electronics Enclosure.

From www.sheet-metalfab.com

Ip68 Acrylic Electronics Rack Enclosure Plastic Laser Cutting Sheet Laser Cut Electronics Enclosure Here are some tricks and tips for. Always prepare an enclosure for each development board that you want to take care of. We also offer inhouse finishing options between powder coat, painting among other. We offer laser cutting, punching, stamping, and machining. This can be a challenge with laser cutting. Here, i would like to share. Thorough walkthrough of the. Laser Cut Electronics Enclosure.

From www.everychina.com

Furniture Sheet Metal Enclosures Laser Cutting Electronic Box Enclosure Laser Cut Electronics Enclosure Now, i’ve learned my lesson: A kit enclosure should be more than just a box. We also offer inhouse finishing options between powder coat, painting among other. April 26, 2017 at 5:04 pm. Everyone likes putting things in boxes, and there is something so satisfying about laser cutting your own enclosure to neatly round off a diy project. Build your. Laser Cut Electronics Enclosure.

From www.ponoko.com

Customized Laser Cut Enclosures for Tech Geeks Laser Cut Electronics Enclosure A kit enclosure should be more than just a box. Everyone likes putting things in boxes, and there is something so satisfying about laser cutting your own enclosure to neatly round off a diy project. Now, i’ve learned my lesson: We offer laser cutting, punching, stamping, and machining. Build your own custom laser cut box boxes! We also offer inhouse. Laser Cut Electronics Enclosure.

From learn.adafruit.com

Overview LaserCut Enclosure Design Adafruit Learning System Laser Cut Electronics Enclosure Here are some tricks and tips for. Always prepare an enclosure for each development board that you want to take care of. We offer laser cutting, punching, stamping, and machining. We also offer inhouse finishing options between powder coat, painting among other. April 26, 2017 at 5:04 pm. Everyone likes putting things in boxes, and there is something so satisfying. Laser Cut Electronics Enclosure.

From www.mldmetal.com

Supply Laser Cutting Of electronic product enclosures Wholesale Factory Laser Cut Electronics Enclosure Before making the final determination if laser cutting is right for your electronics build, it’s important to understand. This can be a challenge with laser cutting. Always prepare an enclosure for each development board that you want to take care of. April 26, 2017 at 5:04 pm. Here, i would like to share. We also offer inhouse finishing options between. Laser Cut Electronics Enclosure.

From www.alibaba.com

Custom Stainless Steel 3d Printer Electronic Enclosure Metal Laser Cut Laser Cut Electronics Enclosure A kit enclosure should be more than just a box. Build your own custom laser cut box boxes! We offer laser cutting, punching, stamping, and machining. April 26, 2017 at 5:04 pm. Always prepare an enclosure for each development board that you want to take care of. Now, i’ve learned my lesson: Here, i would like to share. Thorough walkthrough. Laser Cut Electronics Enclosure.

From endurancelasers.com

Simple Laser Enclosure and Air Exhaust system DIY laser enclosure Laser Cut Electronics Enclosure Build your own custom laser cut box boxes! Everyone likes putting things in boxes, and there is something so satisfying about laser cutting your own enclosure to neatly round off a diy project. Before making the final determination if laser cutting is right for your electronics build, it’s important to understand. Here are some tricks and tips for. A kit. Laser Cut Electronics Enclosure.

From www.laser-cutz.com

LaserCutZ Laser Cutting Laser Cut Electronics Enclosure April 26, 2017 at 5:04 pm. Everyone likes putting things in boxes, and there is something so satisfying about laser cutting your own enclosure to neatly round off a diy project. Build your own custom laser cut box boxes! Always prepare an enclosure for each development board that you want to take care of. A kit enclosure should be more. Laser Cut Electronics Enclosure.

From www.reddit.com

Finished Laser Engraver Enclosure Laserengraving Laser Cut Electronics Enclosure Build your own custom laser cut box boxes! Everyone likes putting things in boxes, and there is something so satisfying about laser cutting your own enclosure to neatly round off a diy project. We offer laser cutting, punching, stamping, and machining. April 26, 2017 at 5:04 pm. Now, i’ve learned my lesson: Thorough walkthrough of the unboxing and assembly of. Laser Cut Electronics Enclosure.

From rapidwhale.gnarboards.com

Laser Cutting Examples Rapid Whale Laser Cut Electronics Enclosure Thorough walkthrough of the unboxing and assembly of the parts ordered (built around the makercase. We offer laser cutting, punching, stamping, and machining. Now, i’ve learned my lesson: We also offer inhouse finishing options between powder coat, painting among other. Here, i would like to share. Build your own custom laser cut box boxes! April 26, 2017 at 5:04 pm.. Laser Cut Electronics Enclosure.

From www.cncmetalwork.com

OEM Factory laser cutting aluminum electronic enclosure Buy Laser Cut Electronics Enclosure Here, i would like to share. This can be a challenge with laser cutting. Now, i’ve learned my lesson: Here are some tricks and tips for. Always prepare an enclosure for each development board that you want to take care of. Build your own custom laser cut box boxes! Before making the final determination if laser cutting is right for. Laser Cut Electronics Enclosure.

From makertradingpost.com

LaserCut Raspberry Pi Enclosure (Pi 4 Compatible) Maker Trading Post Laser Cut Electronics Enclosure Everyone likes putting things in boxes, and there is something so satisfying about laser cutting your own enclosure to neatly round off a diy project. Before making the final determination if laser cutting is right for your electronics build, it’s important to understand. Thorough walkthrough of the unboxing and assembly of the parts ordered (built around the makercase. Build your. Laser Cut Electronics Enclosure.