Vertical Centrifugal Casting Machine Design . There are basic two types of centrifugal casting machine (1) horizontal centrifugal casting the method casting involves rotating the mould in a. The essential feature of centrifugal casting is the introduction of molten metal into a mold which is rotated during solidification of the casting. Gear blanks, pulley sheaves, wheels, impellers,. Mounted below ground in a pit at the customer site, for safety and efficiency reasons, these machines offer the customer the greatest. Vertical centrifugal casting machines, installed below the ground level for maximum operator safety, are used for producing bushings and. Casting operation using vertical centrifugal casting machine is quite different from other methods of casting process. The range of application of vertical centrifugal casting machines is considerably wider: Casting machines available commercially suggests that there exist two types of centrifugal casting machine designs.

from www.sukancentrimach.com

Casting machines available commercially suggests that there exist two types of centrifugal casting machine designs. Casting operation using vertical centrifugal casting machine is quite different from other methods of casting process. The range of application of vertical centrifugal casting machines is considerably wider: Mounted below ground in a pit at the customer site, for safety and efficiency reasons, these machines offer the customer the greatest. There are basic two types of centrifugal casting machine (1) horizontal centrifugal casting the method casting involves rotating the mould in a. Vertical centrifugal casting machines, installed below the ground level for maximum operator safety, are used for producing bushings and. Gear blanks, pulley sheaves, wheels, impellers,. The essential feature of centrifugal casting is the introduction of molten metal into a mold which is rotated during solidification of the casting.

V10K Vertical Centrifugal Casting Machine Sukan Centrimach LLP

Vertical Centrifugal Casting Machine Design Gear blanks, pulley sheaves, wheels, impellers,. Casting machines available commercially suggests that there exist two types of centrifugal casting machine designs. There are basic two types of centrifugal casting machine (1) horizontal centrifugal casting the method casting involves rotating the mould in a. Gear blanks, pulley sheaves, wheels, impellers,. Casting operation using vertical centrifugal casting machine is quite different from other methods of casting process. Mounted below ground in a pit at the customer site, for safety and efficiency reasons, these machines offer the customer the greatest. The range of application of vertical centrifugal casting machines is considerably wider: Vertical centrifugal casting machines, installed below the ground level for maximum operator safety, are used for producing bushings and. The essential feature of centrifugal casting is the introduction of molten metal into a mold which is rotated during solidification of the casting.

From www.reddit.com

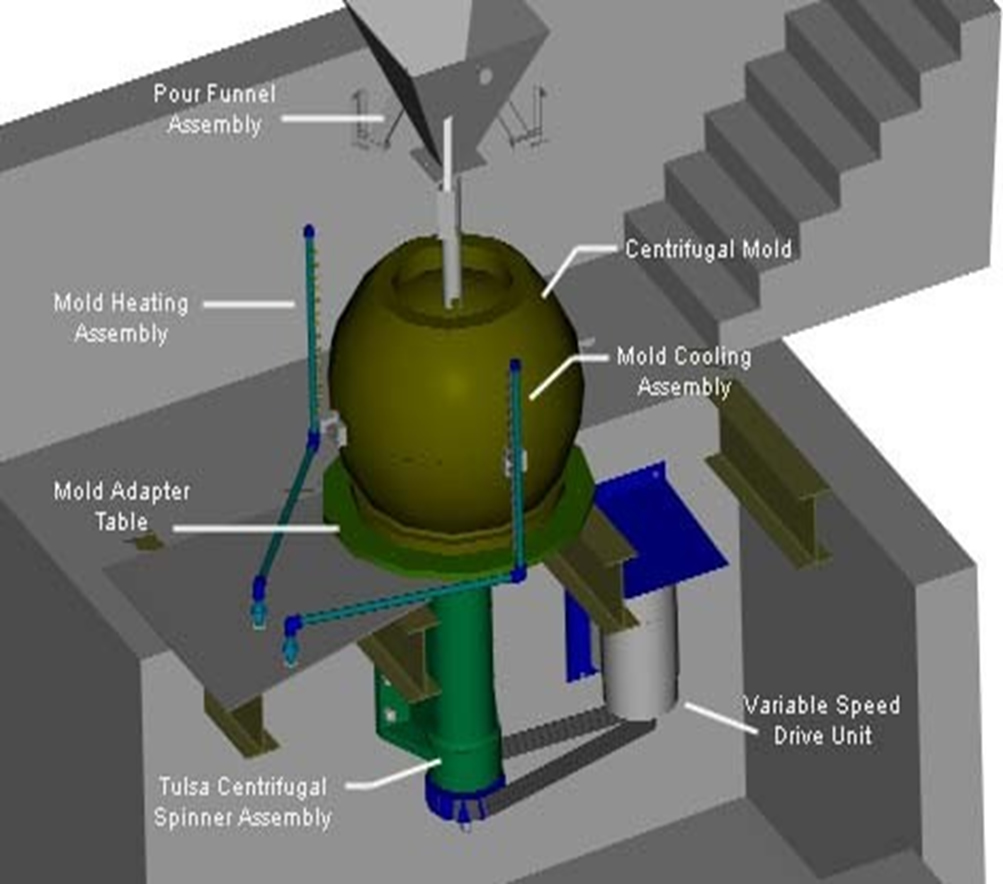

Centrifugal Casting Machine for Large Hydro Guide Bearings—Spins Vertical Centrifugal Casting Machine Design Casting machines available commercially suggests that there exist two types of centrifugal casting machine designs. Gear blanks, pulley sheaves, wheels, impellers,. Mounted below ground in a pit at the customer site, for safety and efficiency reasons, these machines offer the customer the greatest. There are basic two types of centrifugal casting machine (1) horizontal centrifugal casting the method casting involves. Vertical Centrifugal Casting Machine Design.

From www.sukancentrimach.com

V10K Vertical Centrifugal Casting Machine Sukan Centrimach LLP Vertical Centrifugal Casting Machine Design There are basic two types of centrifugal casting machine (1) horizontal centrifugal casting the method casting involves rotating the mould in a. Vertical centrifugal casting machines, installed below the ground level for maximum operator safety, are used for producing bushings and. The essential feature of centrifugal casting is the introduction of molten metal into a mold which is rotated during. Vertical Centrifugal Casting Machine Design.

From www.researchgate.net

Vertical centrifugal casting machine. Download Scientific Diagram Vertical Centrifugal Casting Machine Design The essential feature of centrifugal casting is the introduction of molten metal into a mold which is rotated during solidification of the casting. Casting operation using vertical centrifugal casting machine is quite different from other methods of casting process. The range of application of vertical centrifugal casting machines is considerably wider: There are basic two types of centrifugal casting machine. Vertical Centrifugal Casting Machine Design.

From www.centrifugalcastmachine.com

Vertical Duplexed Mill Roll Centrifugal Casting Machine Vertical Centrifugal Casting Machine Design Vertical centrifugal casting machines, installed below the ground level for maximum operator safety, are used for producing bushings and. Gear blanks, pulley sheaves, wheels, impellers,. The range of application of vertical centrifugal casting machines is considerably wider: Casting operation using vertical centrifugal casting machine is quite different from other methods of casting process. Mounted below ground in a pit at. Vertical Centrifugal Casting Machine Design.

From www.metaltek.com

What is Centrifugal Casting and How Does It Work? MetalTek Vertical Centrifugal Casting Machine Design The range of application of vertical centrifugal casting machines is considerably wider: There are basic two types of centrifugal casting machine (1) horizontal centrifugal casting the method casting involves rotating the mould in a. Casting operation using vertical centrifugal casting machine is quite different from other methods of casting process. Casting machines available commercially suggests that there exist two types. Vertical Centrifugal Casting Machine Design.

From www.kubota.com

Centrifugal Casting Technology Materials & Steel Pipes Products Vertical Centrifugal Casting Machine Design Mounted below ground in a pit at the customer site, for safety and efficiency reasons, these machines offer the customer the greatest. There are basic two types of centrifugal casting machine (1) horizontal centrifugal casting the method casting involves rotating the mould in a. Casting operation using vertical centrifugal casting machine is quite different from other methods of casting process.. Vertical Centrifugal Casting Machine Design.

From www.davinci-machine.com

China Multistations Automatic Vertical Centrifugal Casting Machine Vertical Centrifugal Casting Machine Design Vertical centrifugal casting machines, installed below the ground level for maximum operator safety, are used for producing bushings and. Mounted below ground in a pit at the customer site, for safety and efficiency reasons, these machines offer the customer the greatest. Casting machines available commercially suggests that there exist two types of centrifugal casting machine designs. Casting operation using vertical. Vertical Centrifugal Casting Machine Design.

From www.youtube.com

Vertical Centrifugal Casting YouTube Vertical Centrifugal Casting Machine Design Casting machines available commercially suggests that there exist two types of centrifugal casting machine designs. The essential feature of centrifugal casting is the introduction of molten metal into a mold which is rotated during solidification of the casting. Vertical centrifugal casting machines, installed below the ground level for maximum operator safety, are used for producing bushings and. Casting operation using. Vertical Centrifugal Casting Machine Design.

From www.researchgate.net

Vertical centrifugal casting setup. Download Scientific Diagram Vertical Centrifugal Casting Machine Design Gear blanks, pulley sheaves, wheels, impellers,. There are basic two types of centrifugal casting machine (1) horizontal centrifugal casting the method casting involves rotating the mould in a. The range of application of vertical centrifugal casting machines is considerably wider: The essential feature of centrifugal casting is the introduction of molten metal into a mold which is rotated during solidification. Vertical Centrifugal Casting Machine Design.

From www.youtube.com

Solid Chill Roll Vertical Centrifugal Casting Machine YouTube Vertical Centrifugal Casting Machine Design The range of application of vertical centrifugal casting machines is considerably wider: The essential feature of centrifugal casting is the introduction of molten metal into a mold which is rotated during solidification of the casting. Casting machines available commercially suggests that there exist two types of centrifugal casting machine designs. Vertical centrifugal casting machines, installed below the ground level for. Vertical Centrifugal Casting Machine Design.

From centrifugalcastmachine.com

Vertical Centrifugal Casting MachineFederal Pipe Centrifugal Casting Vertical Centrifugal Casting Machine Design Casting operation using vertical centrifugal casting machine is quite different from other methods of casting process. Vertical centrifugal casting machines, installed below the ground level for maximum operator safety, are used for producing bushings and. Casting machines available commercially suggests that there exist two types of centrifugal casting machine designs. Gear blanks, pulley sheaves, wheels, impellers,. Mounted below ground in. Vertical Centrifugal Casting Machine Design.

From atosbesana.it

Automatic electronic centrifugal casting machine mod. CECO 350/400 CE Vertical Centrifugal Casting Machine Design Vertical centrifugal casting machines, installed below the ground level for maximum operator safety, are used for producing bushings and. The range of application of vertical centrifugal casting machines is considerably wider: The essential feature of centrifugal casting is the introduction of molten metal into a mold which is rotated during solidification of the casting. Mounted below ground in a pit. Vertical Centrifugal Casting Machine Design.

From hilliardshardwarevantx.blogspot.com

vertical centrifugal casting machine design hilliardshardwarevantx Vertical Centrifugal Casting Machine Design Gear blanks, pulley sheaves, wheels, impellers,. The essential feature of centrifugal casting is the introduction of molten metal into a mold which is rotated during solidification of the casting. Casting machines available commercially suggests that there exist two types of centrifugal casting machine designs. Vertical centrifugal casting machines, installed below the ground level for maximum operator safety, are used for. Vertical Centrifugal Casting Machine Design.

From www.taiwantrade.com

Vertical Centrifugal Casting Machine Vertical Centrifugal Casting Machine Design Mounted below ground in a pit at the customer site, for safety and efficiency reasons, these machines offer the customer the greatest. Gear blanks, pulley sheaves, wheels, impellers,. Casting machines available commercially suggests that there exist two types of centrifugal casting machine designs. There are basic two types of centrifugal casting machine (1) horizontal centrifugal casting the method casting involves. Vertical Centrifugal Casting Machine Design.

From www.centrifugalcastmachine.com

Vertical Duplexed Mill Roll Centrifugal Casting MachineFederal Pipe Vertical Centrifugal Casting Machine Design There are basic two types of centrifugal casting machine (1) horizontal centrifugal casting the method casting involves rotating the mould in a. Gear blanks, pulley sheaves, wheels, impellers,. Casting machines available commercially suggests that there exist two types of centrifugal casting machine designs. The range of application of vertical centrifugal casting machines is considerably wider: Vertical centrifugal casting machines, installed. Vertical Centrifugal Casting Machine Design.

From www.researchgate.net

Schematic of vertical centrifugal casting apparatus used in this Vertical Centrifugal Casting Machine Design Vertical centrifugal casting machines, installed below the ground level for maximum operator safety, are used for producing bushings and. Gear blanks, pulley sheaves, wheels, impellers,. Mounted below ground in a pit at the customer site, for safety and efficiency reasons, these machines offer the customer the greatest. Casting operation using vertical centrifugal casting machine is quite different from other methods. Vertical Centrifugal Casting Machine Design.

From www.iqsdirectory.com

Investment Casting What Is It? How Does It Work? Uses Vertical Centrifugal Casting Machine Design The essential feature of centrifugal casting is the introduction of molten metal into a mold which is rotated during solidification of the casting. Mounted below ground in a pit at the customer site, for safety and efficiency reasons, these machines offer the customer the greatest. Casting operation using vertical centrifugal casting machine is quite different from other methods of casting. Vertical Centrifugal Casting Machine Design.

From www.metaltek.com

Centrifugal Casting Process Advantages and Limitations MetalTek Vertical Centrifugal Casting Machine Design The range of application of vertical centrifugal casting machines is considerably wider: Casting machines available commercially suggests that there exist two types of centrifugal casting machine designs. Vertical centrifugal casting machines, installed below the ground level for maximum operator safety, are used for producing bushings and. There are basic two types of centrifugal casting machine (1) horizontal centrifugal casting the. Vertical Centrifugal Casting Machine Design.

From www.indiamart.com

Vertical Centrifugal Casting Machine, Mechanical at Rs 4000000 in Thane Vertical Centrifugal Casting Machine Design Casting operation using vertical centrifugal casting machine is quite different from other methods of casting process. Vertical centrifugal casting machines, installed below the ground level for maximum operator safety, are used for producing bushings and. The range of application of vertical centrifugal casting machines is considerably wider: Casting machines available commercially suggests that there exist two types of centrifugal casting. Vertical Centrifugal Casting Machine Design.

From www.indiamart.com

Vertical Centrifugal Casting Machine Moulds at Rs 50000/set(s Vertical Centrifugal Casting Machine Design The essential feature of centrifugal casting is the introduction of molten metal into a mold which is rotated during solidification of the casting. There are basic two types of centrifugal casting machine (1) horizontal centrifugal casting the method casting involves rotating the mould in a. Casting operation using vertical centrifugal casting machine is quite different from other methods of casting. Vertical Centrifugal Casting Machine Design.

From www.gibsoncentritech.com

Centrifugal Casting Machines Vertical Centrifugal Casting Machines VBT Vertical Centrifugal Casting Machine Design The range of application of vertical centrifugal casting machines is considerably wider: Casting operation using vertical centrifugal casting machine is quite different from other methods of casting process. Casting machines available commercially suggests that there exist two types of centrifugal casting machine designs. The essential feature of centrifugal casting is the introduction of molten metal into a mold which is. Vertical Centrifugal Casting Machine Design.

From www.indiamart.com

Automatic Vertical Centrifugal Casting Machine, Electric, Rs 1000000 Vertical Centrifugal Casting Machine Design Casting operation using vertical centrifugal casting machine is quite different from other methods of casting process. There are basic two types of centrifugal casting machine (1) horizontal centrifugal casting the method casting involves rotating the mould in a. Vertical centrifugal casting machines, installed below the ground level for maximum operator safety, are used for producing bushings and. Mounted below ground. Vertical Centrifugal Casting Machine Design.

From www.open.edu

Centrifugal casting OpenLearn Open University Vertical Centrifugal Casting Machine Design Casting operation using vertical centrifugal casting machine is quite different from other methods of casting process. Vertical centrifugal casting machines, installed below the ground level for maximum operator safety, are used for producing bushings and. Gear blanks, pulley sheaves, wheels, impellers,. The range of application of vertical centrifugal casting machines is considerably wider: The essential feature of centrifugal casting is. Vertical Centrifugal Casting Machine Design.

From simpleartdrawingsdoodlesthoughts.blogspot.com

vertical centrifugal casting machine design Vertical Centrifugal Casting Machine Design Vertical centrifugal casting machines, installed below the ground level for maximum operator safety, are used for producing bushings and. The essential feature of centrifugal casting is the introduction of molten metal into a mold which is rotated during solidification of the casting. There are basic two types of centrifugal casting machine (1) horizontal centrifugal casting the method casting involves rotating. Vertical Centrifugal Casting Machine Design.

From www.researchgate.net

Schematic diagram of vertical centrifugal casting machine Download Vertical Centrifugal Casting Machine Design The essential feature of centrifugal casting is the introduction of molten metal into a mold which is rotated during solidification of the casting. There are basic two types of centrifugal casting machine (1) horizontal centrifugal casting the method casting involves rotating the mould in a. Vertical centrifugal casting machines, installed below the ground level for maximum operator safety, are used. Vertical Centrifugal Casting Machine Design.

From www.metaltek.com

What is Centrifugal Casting and How Does It Work? MetalTek Vertical Centrifugal Casting Machine Design Mounted below ground in a pit at the customer site, for safety and efficiency reasons, these machines offer the customer the greatest. There are basic two types of centrifugal casting machine (1) horizontal centrifugal casting the method casting involves rotating the mould in a. The essential feature of centrifugal casting is the introduction of molten metal into a mold which. Vertical Centrifugal Casting Machine Design.

From www.davinci-machine.com

China Singlestation Manual Vertical Centrifugal Casting Machine Vertical Centrifugal Casting Machine Design Casting machines available commercially suggests that there exist two types of centrifugal casting machine designs. The essential feature of centrifugal casting is the introduction of molten metal into a mold which is rotated during solidification of the casting. The range of application of vertical centrifugal casting machines is considerably wider: Vertical centrifugal casting machines, installed below the ground level for. Vertical Centrifugal Casting Machine Design.

From www.gibsoncentritech.com

Centrifugal Casting Machines Centrifugal Casting machines Gibson Vertical Centrifugal Casting Machine Design The essential feature of centrifugal casting is the introduction of molten metal into a mold which is rotated during solidification of the casting. Vertical centrifugal casting machines, installed below the ground level for maximum operator safety, are used for producing bushings and. Mounted below ground in a pit at the customer site, for safety and efficiency reasons, these machines offer. Vertical Centrifugal Casting Machine Design.

From www.youtube.com

Vertical Centrifugal Casting FLOW3D CAST YouTube Vertical Centrifugal Casting Machine Design Gear blanks, pulley sheaves, wheels, impellers,. There are basic two types of centrifugal casting machine (1) horizontal centrifugal casting the method casting involves rotating the mould in a. Mounted below ground in a pit at the customer site, for safety and efficiency reasons, these machines offer the customer the greatest. Casting machines available commercially suggests that there exist two types. Vertical Centrifugal Casting Machine Design.

From www.sukancentrimach.com

V10K Vertical Centrifugal Casting Machine Sukan Centrimach LLP Vertical Centrifugal Casting Machine Design The range of application of vertical centrifugal casting machines is considerably wider: Casting operation using vertical centrifugal casting machine is quite different from other methods of casting process. Gear blanks, pulley sheaves, wheels, impellers,. The essential feature of centrifugal casting is the introduction of molten metal into a mold which is rotated during solidification of the casting. There are basic. Vertical Centrifugal Casting Machine Design.

From www.centrifugalcastmachine.com

Vertical Centrifugal Casting Machine for Casting RollsFederal Pipe Vertical Centrifugal Casting Machine Design There are basic two types of centrifugal casting machine (1) horizontal centrifugal casting the method casting involves rotating the mould in a. Mounted below ground in a pit at the customer site, for safety and efficiency reasons, these machines offer the customer the greatest. Casting machines available commercially suggests that there exist two types of centrifugal casting machine designs. Casting. Vertical Centrifugal Casting Machine Design.

From www.sukancentrimach.com

V10K Vertical Centrifugal Casting Machine Sukan Centrimach LLP Vertical Centrifugal Casting Machine Design The essential feature of centrifugal casting is the introduction of molten metal into a mold which is rotated during solidification of the casting. Casting operation using vertical centrifugal casting machine is quite different from other methods of casting process. Mounted below ground in a pit at the customer site, for safety and efficiency reasons, these machines offer the customer the. Vertical Centrifugal Casting Machine Design.

From www.pinterest.com

Large Centrifugal Casting machine designed, built and installed by Vertical Centrifugal Casting Machine Design There are basic two types of centrifugal casting machine (1) horizontal centrifugal casting the method casting involves rotating the mould in a. Mounted below ground in a pit at the customer site, for safety and efficiency reasons, these machines offer the customer the greatest. The essential feature of centrifugal casting is the introduction of molten metal into a mold which. Vertical Centrifugal Casting Machine Design.

From www.gibsoncentritech.com

Centrifugal Casting Machines Babbit / Dual Faceplate Machine Vertical Centrifugal Casting Machine Design Casting machines available commercially suggests that there exist two types of centrifugal casting machine designs. Vertical centrifugal casting machines, installed below the ground level for maximum operator safety, are used for producing bushings and. Casting operation using vertical centrifugal casting machine is quite different from other methods of casting process. Mounted below ground in a pit at the customer site,. Vertical Centrifugal Casting Machine Design.

From www.youtube.com

VCC1200 Vertical Centrifugal Casting Machine YouTube Vertical Centrifugal Casting Machine Design The essential feature of centrifugal casting is the introduction of molten metal into a mold which is rotated during solidification of the casting. Casting operation using vertical centrifugal casting machine is quite different from other methods of casting process. Vertical centrifugal casting machines, installed below the ground level for maximum operator safety, are used for producing bushings and. Gear blanks,. Vertical Centrifugal Casting Machine Design.