Vacuum Forming Tooling Cost . Vacuum forming is notably less expensive compared to other methods such as injection molding. This is especially the case when producing large parts, as the equipment and tooling costs are significantly lower. Uncover the key cost factors in vacuum forming with our comprehensive guide. One of the most significant advantages of vacuum forming is the relatively low cost of tooling compared to other manufacturing processes such as injection molding. Vacuum forming costs vary based on material, design, and quantity. As a leading vacuum forming company serving customers throughout north carolina, south carolina, maryland, georgia and pennsylvania, our thermoforming experts at advanced. The molds used in vacuum forming, especially those made from wood or epoxy, are less expensive to produce. Explore how design complexity, material selection, mold costs,.

from www.brayplastics.co.uk

As a leading vacuum forming company serving customers throughout north carolina, south carolina, maryland, georgia and pennsylvania, our thermoforming experts at advanced. One of the most significant advantages of vacuum forming is the relatively low cost of tooling compared to other manufacturing processes such as injection molding. Uncover the key cost factors in vacuum forming with our comprehensive guide. The molds used in vacuum forming, especially those made from wood or epoxy, are less expensive to produce. Vacuum forming is notably less expensive compared to other methods such as injection molding. Explore how design complexity, material selection, mold costs,. This is especially the case when producing large parts, as the equipment and tooling costs are significantly lower. Vacuum forming costs vary based on material, design, and quantity.

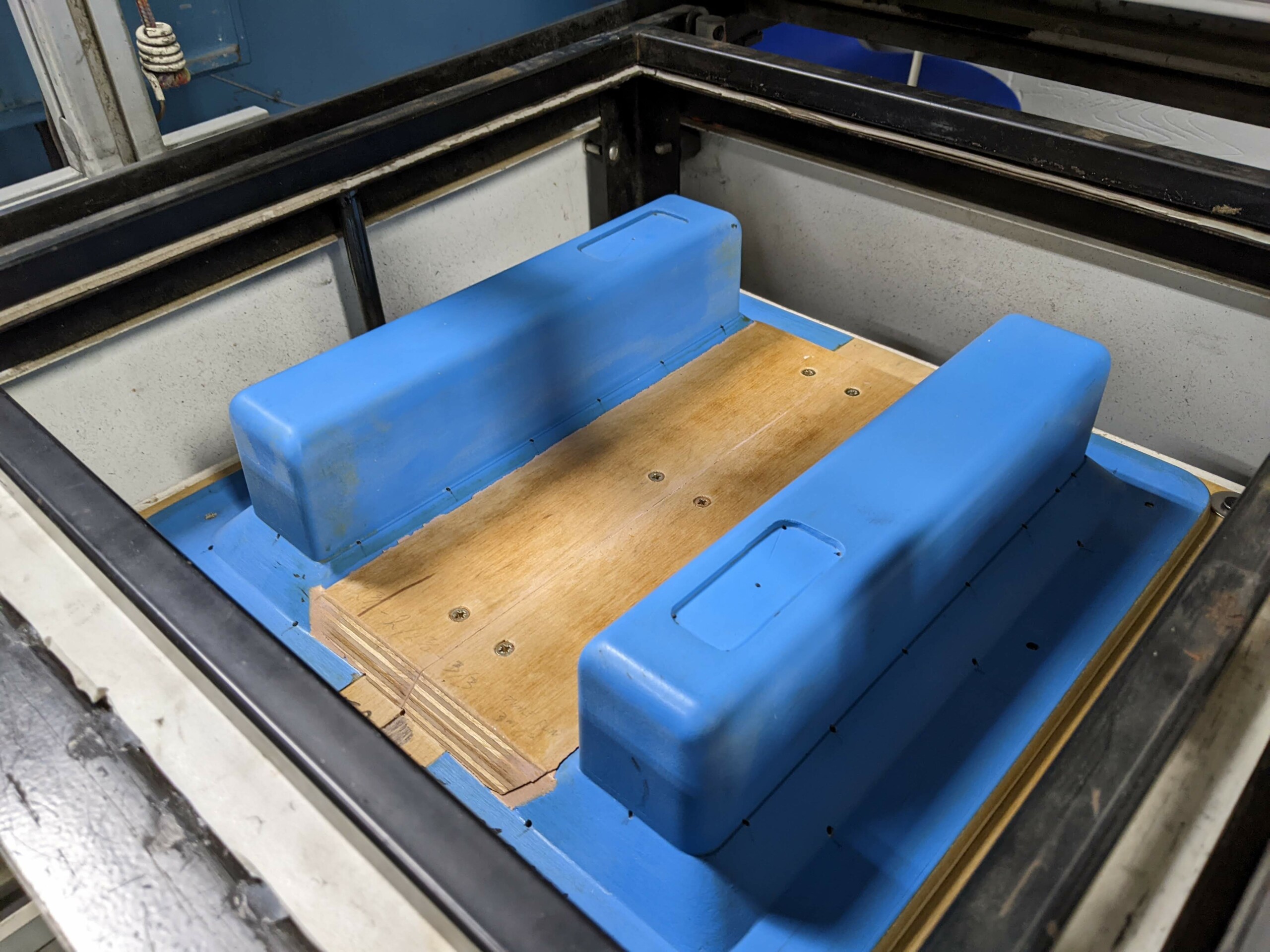

Vac Forming mould Bray Plastics

Vacuum Forming Tooling Cost Vacuum forming is notably less expensive compared to other methods such as injection molding. Uncover the key cost factors in vacuum forming with our comprehensive guide. The molds used in vacuum forming, especially those made from wood or epoxy, are less expensive to produce. Vacuum forming is notably less expensive compared to other methods such as injection molding. This is especially the case when producing large parts, as the equipment and tooling costs are significantly lower. As a leading vacuum forming company serving customers throughout north carolina, south carolina, maryland, georgia and pennsylvania, our thermoforming experts at advanced. One of the most significant advantages of vacuum forming is the relatively low cost of tooling compared to other manufacturing processes such as injection molding. Vacuum forming costs vary based on material, design, and quantity. Explore how design complexity, material selection, mold costs,.

From www.axiompd.co.uk

Tooling for vacuum forming CNC manufacturing + product dev Axiom Vacuum Forming Tooling Cost Vacuum forming costs vary based on material, design, and quantity. Uncover the key cost factors in vacuum forming with our comprehensive guide. One of the most significant advantages of vacuum forming is the relatively low cost of tooling compared to other manufacturing processes such as injection molding. The molds used in vacuum forming, especially those made from wood or epoxy,. Vacuum Forming Tooling Cost.

From phase-2.org

What are the benefits of vacuum forming? Move to a new phase Vacuum Forming Tooling Cost One of the most significant advantages of vacuum forming is the relatively low cost of tooling compared to other manufacturing processes such as injection molding. Explore how design complexity, material selection, mold costs,. Uncover the key cost factors in vacuum forming with our comprehensive guide. The molds used in vacuum forming, especially those made from wood or epoxy, are less. Vacuum Forming Tooling Cost.

From www.madearia.com

Vacuum Forming Process, Materials & Benefit Aria Manufacturing Limited Vacuum Forming Tooling Cost The molds used in vacuum forming, especially those made from wood or epoxy, are less expensive to produce. One of the most significant advantages of vacuum forming is the relatively low cost of tooling compared to other manufacturing processes such as injection molding. Vacuum forming is notably less expensive compared to other methods such as injection molding. Vacuum forming costs. Vacuum Forming Tooling Cost.

From www.plas-tech.co.uk

Vac Forming The Advantages of Vacuum Forming Vacuum Forming Tooling Cost Vacuum forming costs vary based on material, design, and quantity. The molds used in vacuum forming, especially those made from wood or epoxy, are less expensive to produce. Vacuum forming is notably less expensive compared to other methods such as injection molding. This is especially the case when producing large parts, as the equipment and tooling costs are significantly lower.. Vacuum Forming Tooling Cost.

From www.axiompd.co.uk

Vacuum Forming Tooling for Plastics How does this work Vacuum Forming Tooling Cost The molds used in vacuum forming, especially those made from wood or epoxy, are less expensive to produce. One of the most significant advantages of vacuum forming is the relatively low cost of tooling compared to other manufacturing processes such as injection molding. Explore how design complexity, material selection, mold costs,. As a leading vacuum forming company serving customers throughout. Vacuum Forming Tooling Cost.

From 3dprintscape.com

Is Vacuum Forming Cheaper than Injection Molding? Vacuum Forming Tooling Cost The molds used in vacuum forming, especially those made from wood or epoxy, are less expensive to produce. This is especially the case when producing large parts, as the equipment and tooling costs are significantly lower. Explore how design complexity, material selection, mold costs,. As a leading vacuum forming company serving customers throughout north carolina, south carolina, maryland, georgia and. Vacuum Forming Tooling Cost.

From team.ucdavis.edu

Vacuum Forming The TEAM Lab Vacuum Forming Tooling Cost Explore how design complexity, material selection, mold costs,. This is especially the case when producing large parts, as the equipment and tooling costs are significantly lower. Vacuum forming is notably less expensive compared to other methods such as injection molding. One of the most significant advantages of vacuum forming is the relatively low cost of tooling compared to other manufacturing. Vacuum Forming Tooling Cost.

From schoutengroup.com

Vacuum forming Schouten Group Vacuum Forming Tooling Cost Explore how design complexity, material selection, mold costs,. Vacuum forming is notably less expensive compared to other methods such as injection molding. Uncover the key cost factors in vacuum forming with our comprehensive guide. The molds used in vacuum forming, especially those made from wood or epoxy, are less expensive to produce. This is especially the case when producing large. Vacuum Forming Tooling Cost.

From www.indiamart.com

Vacuum Forming Tool Service at best price in Bengaluru by Thaare Vacuum Forming Tooling Cost Vacuum forming costs vary based on material, design, and quantity. Explore how design complexity, material selection, mold costs,. One of the most significant advantages of vacuum forming is the relatively low cost of tooling compared to other manufacturing processes such as injection molding. This is especially the case when producing large parts, as the equipment and tooling costs are significantly. Vacuum Forming Tooling Cost.

From www.plas-tech.co.uk

How Does Vac Forming Work? Vacuum Forming Yorkshire Vacuum Forming Tooling Cost Explore how design complexity, material selection, mold costs,. Vacuum forming costs vary based on material, design, and quantity. One of the most significant advantages of vacuum forming is the relatively low cost of tooling compared to other manufacturing processes such as injection molding. Uncover the key cost factors in vacuum forming with our comprehensive guide. As a leading vacuum forming. Vacuum Forming Tooling Cost.

From www.youtube.com

Vacuum forming 01 main process YouTube Vacuum Forming Tooling Cost The molds used in vacuum forming, especially those made from wood or epoxy, are less expensive to produce. Vacuum forming is notably less expensive compared to other methods such as injection molding. As a leading vacuum forming company serving customers throughout north carolina, south carolina, maryland, georgia and pennsylvania, our thermoforming experts at advanced. Uncover the key cost factors in. Vacuum Forming Tooling Cost.

From meadowtool.com

Plastic Mould Tooling Vacuum Forming Tooling Meadows Vacuum Forming Tooling Cost This is especially the case when producing large parts, as the equipment and tooling costs are significantly lower. Vacuum forming is notably less expensive compared to other methods such as injection molding. Vacuum forming costs vary based on material, design, and quantity. Explore how design complexity, material selection, mold costs,. The molds used in vacuum forming, especially those made from. Vacuum Forming Tooling Cost.

From www.pinterest.com.mx

Formech Vacuum Former FM660 Signage design, Vacuum, Acrylic display Vacuum Forming Tooling Cost Vacuum forming is notably less expensive compared to other methods such as injection molding. Vacuum forming costs vary based on material, design, and quantity. One of the most significant advantages of vacuum forming is the relatively low cost of tooling compared to other manufacturing processes such as injection molding. As a leading vacuum forming company serving customers throughout north carolina,. Vacuum Forming Tooling Cost.

From www.axiompd.co.uk

Tooling for vacuum forming CNC manufacturing + product dev Axiom Vacuum Forming Tooling Cost This is especially the case when producing large parts, as the equipment and tooling costs are significantly lower. The molds used in vacuum forming, especially those made from wood or epoxy, are less expensive to produce. Explore how design complexity, material selection, mold costs,. As a leading vacuum forming company serving customers throughout north carolina, south carolina, maryland, georgia and. Vacuum Forming Tooling Cost.

From www.ameripakpackaging.com

Vacuum Formed Trays in Michigan Ameripak Company Vacuum Forming Tooling Cost This is especially the case when producing large parts, as the equipment and tooling costs are significantly lower. One of the most significant advantages of vacuum forming is the relatively low cost of tooling compared to other manufacturing processes such as injection molding. The molds used in vacuum forming, especially those made from wood or epoxy, are less expensive to. Vacuum Forming Tooling Cost.

From www.brayplastics.co.uk

Vac Forming mould Bray Plastics Vacuum Forming Tooling Cost As a leading vacuum forming company serving customers throughout north carolina, south carolina, maryland, georgia and pennsylvania, our thermoforming experts at advanced. One of the most significant advantages of vacuum forming is the relatively low cost of tooling compared to other manufacturing processes such as injection molding. This is especially the case when producing large parts, as the equipment and. Vacuum Forming Tooling Cost.

From www.rocheindustry.com

Handbook The Ultimate Guide To Vacuum Forming 2024 Updated Vacuum Forming Tooling Cost Vacuum forming costs vary based on material, design, and quantity. The molds used in vacuum forming, especially those made from wood or epoxy, are less expensive to produce. As a leading vacuum forming company serving customers throughout north carolina, south carolina, maryland, georgia and pennsylvania, our thermoforming experts at advanced. This is especially the case when producing large parts, as. Vacuum Forming Tooling Cost.

From www.techsoft.co.uk

Vacuum Forming TechSoft Vacuum Forming Tooling Cost This is especially the case when producing large parts, as the equipment and tooling costs are significantly lower. Uncover the key cost factors in vacuum forming with our comprehensive guide. As a leading vacuum forming company serving customers throughout north carolina, south carolina, maryland, georgia and pennsylvania, our thermoforming experts at advanced. Vacuum forming is notably less expensive compared to. Vacuum Forming Tooling Cost.

From jrtindustries.com.au

Vacuum Forming Services JRT Industries Bundaberg Vacuum Forming Tooling Cost One of the most significant advantages of vacuum forming is the relatively low cost of tooling compared to other manufacturing processes such as injection molding. This is especially the case when producing large parts, as the equipment and tooling costs are significantly lower. Vacuum forming costs vary based on material, design, and quantity. Explore how design complexity, material selection, mold. Vacuum Forming Tooling Cost.

From www.youtube.com

Formech 508FS Manual Vacuum Forming Machine YouTube Vacuum Forming Tooling Cost One of the most significant advantages of vacuum forming is the relatively low cost of tooling compared to other manufacturing processes such as injection molding. This is especially the case when producing large parts, as the equipment and tooling costs are significantly lower. Explore how design complexity, material selection, mold costs,. Vacuum forming is notably less expensive compared to other. Vacuum Forming Tooling Cost.

From oczami-gonczego.blogspot.com

Diy Vacuum Forming Abs Plastic / Make A Good Cheap Upgradeable Sheet Vacuum Forming Tooling Cost This is especially the case when producing large parts, as the equipment and tooling costs are significantly lower. Explore how design complexity, material selection, mold costs,. As a leading vacuum forming company serving customers throughout north carolina, south carolina, maryland, georgia and pennsylvania, our thermoforming experts at advanced. One of the most significant advantages of vacuum forming is the relatively. Vacuum Forming Tooling Cost.

From www.axiompd.co.uk

Tooling for vacuum forming CNC manufacturing + product dev Axiom Vacuum Forming Tooling Cost As a leading vacuum forming company serving customers throughout north carolina, south carolina, maryland, georgia and pennsylvania, our thermoforming experts at advanced. One of the most significant advantages of vacuum forming is the relatively low cost of tooling compared to other manufacturing processes such as injection molding. Uncover the key cost factors in vacuum forming with our comprehensive guide. Vacuum. Vacuum Forming Tooling Cost.

From www.axiompd.co.uk

Tooling for vacuum forming CNC manufacturing + product dev Axiom Vacuum Forming Tooling Cost One of the most significant advantages of vacuum forming is the relatively low cost of tooling compared to other manufacturing processes such as injection molding. Uncover the key cost factors in vacuum forming with our comprehensive guide. Vacuum forming is notably less expensive compared to other methods such as injection molding. The molds used in vacuum forming, especially those made. Vacuum Forming Tooling Cost.

From www.pinterest.com

Pin on Vacuum Forming Vacuum Forming Tooling Cost Uncover the key cost factors in vacuum forming with our comprehensive guide. Vacuum forming costs vary based on material, design, and quantity. Vacuum forming is notably less expensive compared to other methods such as injection molding. This is especially the case when producing large parts, as the equipment and tooling costs are significantly lower. The molds used in vacuum forming,. Vacuum Forming Tooling Cost.

From www.axiompd.co.uk

Tooling for vacuum forming CNC manufacturing + product dev Axiom Vacuum Forming Tooling Cost Explore how design complexity, material selection, mold costs,. The molds used in vacuum forming, especially those made from wood or epoxy, are less expensive to produce. Uncover the key cost factors in vacuum forming with our comprehensive guide. As a leading vacuum forming company serving customers throughout north carolina, south carolina, maryland, georgia and pennsylvania, our thermoforming experts at advanced.. Vacuum Forming Tooling Cost.

From prestigetooling.com

Vacuum Forming Mold Types Thermoforming Molds Solid Surface Molds Vacuum Forming Tooling Cost Vacuum forming is notably less expensive compared to other methods such as injection molding. One of the most significant advantages of vacuum forming is the relatively low cost of tooling compared to other manufacturing processes such as injection molding. Explore how design complexity, material selection, mold costs,. As a leading vacuum forming company serving customers throughout north carolina, south carolina,. Vacuum Forming Tooling Cost.

From www.axiompd.co.uk

Could a specialist trim fixture assist your manufacturing process? Vacuum Forming Tooling Cost Uncover the key cost factors in vacuum forming with our comprehensive guide. Vacuum forming costs vary based on material, design, and quantity. Explore how design complexity, material selection, mold costs,. This is especially the case when producing large parts, as the equipment and tooling costs are significantly lower. The molds used in vacuum forming, especially those made from wood or. Vacuum Forming Tooling Cost.

From ufpmedtech.com

Vacuum Forming for Medical Devices & Sterile Packaging UFP MedTech Vacuum Forming Tooling Cost Vacuum forming is notably less expensive compared to other methods such as injection molding. One of the most significant advantages of vacuum forming is the relatively low cost of tooling compared to other manufacturing processes such as injection molding. Explore how design complexity, material selection, mold costs,. Vacuum forming costs vary based on material, design, and quantity. As a leading. Vacuum Forming Tooling Cost.

From www.axiompd.co.uk

Quick turnaround vacuum forming tools Vacuum Forming Tooling Cost Uncover the key cost factors in vacuum forming with our comprehensive guide. One of the most significant advantages of vacuum forming is the relatively low cost of tooling compared to other manufacturing processes such as injection molding. As a leading vacuum forming company serving customers throughout north carolina, south carolina, maryland, georgia and pennsylvania, our thermoforming experts at advanced. Explore. Vacuum Forming Tooling Cost.

From www.loftingservices.co.uk

Vacuum Forming Tools Lofting Services Vacuum Forming Tooling Cost Vacuum forming costs vary based on material, design, and quantity. The molds used in vacuum forming, especially those made from wood or epoxy, are less expensive to produce. Vacuum forming is notably less expensive compared to other methods such as injection molding. Explore how design complexity, material selection, mold costs,. One of the most significant advantages of vacuum forming is. Vacuum Forming Tooling Cost.

From www.pinterest.com

Formech 508FS Manual Vacuum Forming Machine YouTube Vacuum Forming Tooling Cost Explore how design complexity, material selection, mold costs,. One of the most significant advantages of vacuum forming is the relatively low cost of tooling compared to other manufacturing processes such as injection molding. As a leading vacuum forming company serving customers throughout north carolina, south carolina, maryland, georgia and pennsylvania, our thermoforming experts at advanced. Vacuum forming costs vary based. Vacuum Forming Tooling Cost.

From www.rutlandplastics.co.uk

Plastics Moulding Methods Vac Rutland Plastics Vacuum Forming Tooling Cost Vacuum forming is notably less expensive compared to other methods such as injection molding. This is especially the case when producing large parts, as the equipment and tooling costs are significantly lower. Vacuum forming costs vary based on material, design, and quantity. As a leading vacuum forming company serving customers throughout north carolina, south carolina, maryland, georgia and pennsylvania, our. Vacuum Forming Tooling Cost.

From www.motortrend.com

How to build a vacuum forming mold to make your own plastic parts Vacuum Forming Tooling Cost One of the most significant advantages of vacuum forming is the relatively low cost of tooling compared to other manufacturing processes such as injection molding. Uncover the key cost factors in vacuum forming with our comprehensive guide. Explore how design complexity, material selection, mold costs,. Vacuum forming is notably less expensive compared to other methods such as injection molding. The. Vacuum Forming Tooling Cost.

From www.techsoft.co.uk

Vacuum Forming TechSoft Vacuum Forming Tooling Cost Vacuum forming costs vary based on material, design, and quantity. One of the most significant advantages of vacuum forming is the relatively low cost of tooling compared to other manufacturing processes such as injection molding. As a leading vacuum forming company serving customers throughout north carolina, south carolina, maryland, georgia and pennsylvania, our thermoforming experts at advanced. Explore how design. Vacuum Forming Tooling Cost.

From www.youtube.com

Formech explores how vacuum forming is innovating design at Pratt Vacuum Forming Tooling Cost As a leading vacuum forming company serving customers throughout north carolina, south carolina, maryland, georgia and pennsylvania, our thermoforming experts at advanced. Vacuum forming costs vary based on material, design, and quantity. This is especially the case when producing large parts, as the equipment and tooling costs are significantly lower. Explore how design complexity, material selection, mold costs,. Uncover the. Vacuum Forming Tooling Cost.