Solder Joint Reliability Simulation . to tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints. the results show that adding an imc layer to the simulation model can improve the accuracy of prediction. the presented simplified linear simulation approach allows us to predict the solder joint reliability for the critical. this book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. based on the finite element (fe) analyses, it is found that the small interval between voids brought in a stress. a general reliability model was constructed using the stress life and arrhenius equations to predict the solder. a more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver.

from www.semanticscholar.org

a more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. the presented simplified linear simulation approach allows us to predict the solder joint reliability for the critical. this book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. based on the finite element (fe) analyses, it is found that the small interval between voids brought in a stress. to tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints. a general reliability model was constructed using the stress life and arrhenius equations to predict the solder. the results show that adding an imc layer to the simulation model can improve the accuracy of prediction.

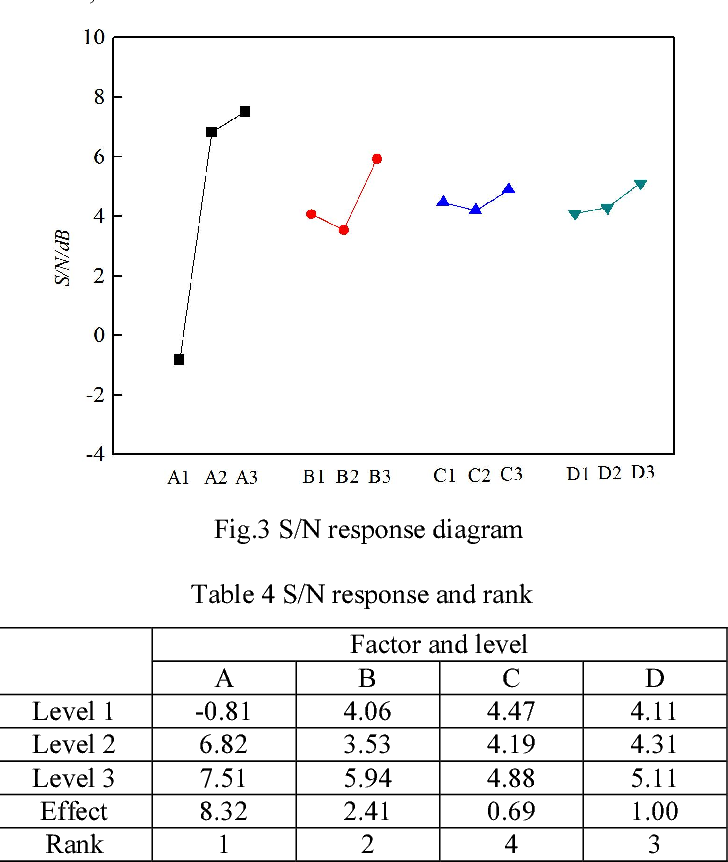

Table 4 from Reliability of Pbfree solder joints in FCBGA using finite

Solder Joint Reliability Simulation this book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. the results show that adding an imc layer to the simulation model can improve the accuracy of prediction. based on the finite element (fe) analyses, it is found that the small interval between voids brought in a stress. a more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. a general reliability model was constructed using the stress life and arrhenius equations to predict the solder. the presented simplified linear simulation approach allows us to predict the solder joint reliability for the critical. this book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. to tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints.

From www.mdpi.com

Materials Free FullText Solder Joint Reliability Risk Estimation Solder Joint Reliability Simulation a more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. based on the finite element (fe) analyses, it is found that the small interval between voids brought in a stress. this book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. . Solder Joint Reliability Simulation.

From www.researchgate.net

(PDF) Implementation of and extensions to Darveaux's approach to finite Solder Joint Reliability Simulation based on the finite element (fe) analyses, it is found that the small interval between voids brought in a stress. a more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. to tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints. the. Solder Joint Reliability Simulation.

From www.researchgate.net

(PDF) Study on Board Level Solder Joint Reliability for Extreme Large Solder Joint Reliability Simulation based on the finite element (fe) analyses, it is found that the small interval between voids brought in a stress. this book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. a general reliability model was constructed using the stress life and arrhenius equations to predict the solder. the. Solder Joint Reliability Simulation.

From www.bol.com

Solder Joint Reliability Prediction for Multiple Environments Solder Joint Reliability Simulation to tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints. this book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. a general reliability model was constructed using the stress life and arrhenius equations to predict the solder. a more powerful, yet. Solder Joint Reliability Simulation.

From mindworks.shoutwiki.com

Solder Joint Reliability Mindworks Solder Joint Reliability Simulation based on the finite element (fe) analyses, it is found that the small interval between voids brought in a stress. to tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints. a general reliability model was constructed using the stress life and arrhenius equations to predict the solder. the results. Solder Joint Reliability Simulation.

From www.mdpi.com

Materials Free FullText Solder Joint Reliability Risk Estimation Solder Joint Reliability Simulation the results show that adding an imc layer to the simulation model can improve the accuracy of prediction. a general reliability model was constructed using the stress life and arrhenius equations to predict the solder. a more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. the presented simplified. Solder Joint Reliability Simulation.

From www.mdpi.com

Materials Free FullText Solder Joint Reliability Risk Estimation Solder Joint Reliability Simulation the results show that adding an imc layer to the simulation model can improve the accuracy of prediction. a general reliability model was constructed using the stress life and arrhenius equations to predict the solder. to tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints. a more powerful, yet. Solder Joint Reliability Simulation.

From www.singularityeng.com

Darveaux Solder Joint Reliability Example — Singularity Engineering LLC Solder Joint Reliability Simulation this book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. the results show that adding an imc layer to the simulation model can improve the accuracy of prediction. based on the finite element (fe) analyses, it is found that the small interval between voids brought in a stress. . Solder Joint Reliability Simulation.

From www.researchgate.net

Strain simulation of single solder joint. Download Scientific Diagram Solder Joint Reliability Simulation to tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints. the presented simplified linear simulation approach allows us to predict the solder joint reliability for the critical. based on the finite element (fe) analyses, it is found that the small interval between voids brought in a stress. this book. Solder Joint Reliability Simulation.

From avishtech.com

Solder Joint Reliability for PCBs in Gauss Stack Avishtech Solder Joint Reliability Simulation this book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. a more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. based on the finite element (fe) analyses, it is found that the small interval between voids brought in a stress. . Solder Joint Reliability Simulation.

From ein.iconnect007.com

Solder Ball Joint Reliability with Electroless Ni/Pd/Au Plating Solder Joint Reliability Simulation a general reliability model was constructed using the stress life and arrhenius equations to predict the solder. to tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints. based on the finite element (fe) analyses, it is found that the small interval between voids brought in a stress. the results. Solder Joint Reliability Simulation.

From www.researchgate.net

(PDF) Implementation of and extensions to Darveaux's approach to finite Solder Joint Reliability Simulation this book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. a general reliability model was constructed using the stress life and arrhenius equations to predict the solder. to tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints. the results show that. Solder Joint Reliability Simulation.

From www.mdpi.com

Materials Free FullText Solder Joint Reliability Risk Estimation Solder Joint Reliability Simulation this book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. to tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints. a general reliability model was constructed using the stress life and arrhenius equations to predict the solder. the presented simplified linear. Solder Joint Reliability Simulation.

From www.semanticscholar.org

Solder Joint Reliability Simulation of Fanout Wafer Level Package Solder Joint Reliability Simulation to tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints. based on the finite element (fe) analyses, it is found that the small interval between voids brought in a stress. a more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. a. Solder Joint Reliability Simulation.

From www.mdpi.com

Materials Free FullText Solder Joint Reliability Risk Estimation Solder Joint Reliability Simulation a general reliability model was constructed using the stress life and arrhenius equations to predict the solder. a more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. the presented simplified linear simulation approach allows us to predict the solder joint reliability for the critical. this book presents a. Solder Joint Reliability Simulation.

From www.researchgate.net

Nonunderfill FCOB solder joint. (a) Plastic strain energy density from Solder Joint Reliability Simulation a general reliability model was constructed using the stress life and arrhenius equations to predict the solder. based on the finite element (fe) analyses, it is found that the small interval between voids brought in a stress. the presented simplified linear simulation approach allows us to predict the solder joint reliability for the critical. the results. Solder Joint Reliability Simulation.

From www.ebay.com.au

Solder Joint Reliability Assessment Finite Element Simulation Solder Joint Reliability Simulation based on the finite element (fe) analyses, it is found that the small interval between voids brought in a stress. to tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints. the results show that adding an imc layer to the simulation model can improve the accuracy of prediction. the. Solder Joint Reliability Simulation.

From www.mdpi.com

Materials Free FullText Solder Joint Reliability Risk Estimation Solder Joint Reliability Simulation this book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. a more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. the results show that adding an imc layer to the simulation model can improve the accuracy of prediction. based on. Solder Joint Reliability Simulation.

From www.scientific.net

Solder Joint Reliability Analysis of WLCSP Based on Inelastic Analysis Solder Joint Reliability Simulation based on the finite element (fe) analyses, it is found that the small interval between voids brought in a stress. this book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. a more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. . Solder Joint Reliability Simulation.

From www.youtube.com

Solder Joint Reliability simulation using DFR Sherlock YouTube Solder Joint Reliability Simulation the presented simplified linear simulation approach allows us to predict the solder joint reliability for the critical. to tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints. a more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. the results show that. Solder Joint Reliability Simulation.

From www.amazon.in

Solder Joint Reliability Assessment Finite Element Simulation Solder Joint Reliability Simulation the presented simplified linear simulation approach allows us to predict the solder joint reliability for the critical. the results show that adding an imc layer to the simulation model can improve the accuracy of prediction. a general reliability model was constructed using the stress life and arrhenius equations to predict the solder. based on the finite. Solder Joint Reliability Simulation.

From www.semanticscholar.org

Figure 3 from Reliability of Leadfree Solder Joints in WLCSP Device Solder Joint Reliability Simulation to tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints. the presented simplified linear simulation approach allows us to predict the solder joint reliability for the critical. based on the finite element (fe) analyses, it is found that the small interval between voids brought in a stress. this book. Solder Joint Reliability Simulation.

From www.academia.edu

(PDF) Reliability of solder joints assembled with leadfree solder Solder Joint Reliability Simulation the results show that adding an imc layer to the simulation model can improve the accuracy of prediction. to tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints. this book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. a more powerful,. Solder Joint Reliability Simulation.

From www.semanticscholar.org

Table 1 from Solder Joint Reliability Simulation of Fanout Wafer Level Solder Joint Reliability Simulation a general reliability model was constructed using the stress life and arrhenius equations to predict the solder. a more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. this book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. the presented simplified. Solder Joint Reliability Simulation.

From www.semanticscholar.org

Table 1 from Solder Joint Reliability Simulation of Fanout Wafer Level Solder Joint Reliability Simulation a general reliability model was constructed using the stress life and arrhenius equations to predict the solder. based on the finite element (fe) analyses, it is found that the small interval between voids brought in a stress. the presented simplified linear simulation approach allows us to predict the solder joint reliability for the critical. this book. Solder Joint Reliability Simulation.

From docslib.org

Improving the Solder Joint Reliability of a Power Leadframe Package Solder Joint Reliability Simulation a more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. the presented simplified linear simulation approach allows us to predict the solder joint reliability for the critical. the results show that adding an imc layer to the simulation model can improve the accuracy of prediction. to tackle this. Solder Joint Reliability Simulation.

From www.mdpi.com

Materials Free FullText Solder Joint Reliability Risk Estimation Solder Joint Reliability Simulation the results show that adding an imc layer to the simulation model can improve the accuracy of prediction. to tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints. this book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. a general reliability. Solder Joint Reliability Simulation.

From www.academia.edu

(PDF) Package and solder joint reliability analysed by FEM simulation Solder Joint Reliability Simulation a general reliability model was constructed using the stress life and arrhenius equations to predict the solder. this book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. the results show that adding an imc layer to the simulation model can improve the accuracy of prediction. to tackle this. Solder Joint Reliability Simulation.

From www.slideshare.net

A solder joint reliability model for the philips lumileds luxeon rebe… Solder Joint Reliability Simulation to tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints. the results show that adding an imc layer to the simulation model can improve the accuracy of prediction. a more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. this book presents. Solder Joint Reliability Simulation.

From forum.ansys.com

Solder Joint Reliability The solver engine was unable to converge on Solder Joint Reliability Simulation the presented simplified linear simulation approach allows us to predict the solder joint reliability for the critical. a general reliability model was constructed using the stress life and arrhenius equations to predict the solder. the results show that adding an imc layer to the simulation model can improve the accuracy of prediction. based on the finite. Solder Joint Reliability Simulation.

From www.researchgate.net

(PDF) Solder Joint Reliability Risk Estimation by AIAssisted Solder Joint Reliability Simulation to tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints. a more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. this book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. the presented simplified. Solder Joint Reliability Simulation.

From www.semanticscholar.org

Figure 1 from Implementation of and extensions to Darveaux's approach Solder Joint Reliability Simulation based on the finite element (fe) analyses, it is found that the small interval between voids brought in a stress. to tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints. the presented simplified linear simulation approach allows us to predict the solder joint reliability for the critical. a more. Solder Joint Reliability Simulation.

From www.semanticscholar.org

Figure 10 from MECHANICAL SHOCK AND DROP RELIABILITY EVALUATION OF THE Solder Joint Reliability Simulation a more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. the presented simplified linear simulation approach allows us to predict the solder joint reliability for the critical. this book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. a general reliability. Solder Joint Reliability Simulation.

From www.researchgate.net

(PDF) Stateoftheart of Leadfree SolderJoint Reliability Solder Joint Reliability Simulation the presented simplified linear simulation approach allows us to predict the solder joint reliability for the critical. to tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints. a more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. based on the finite. Solder Joint Reliability Simulation.

From www.semanticscholar.org

Table 4 from Reliability of Pbfree solder joints in FCBGA using finite Solder Joint Reliability Simulation the results show that adding an imc layer to the simulation model can improve the accuracy of prediction. to tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints. this book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. a general reliability. Solder Joint Reliability Simulation.