Ply Making Process . In this article, we’ll delve into the. Plywood production requires a good log, called a peeler, which is generally straighter and larger in diameter than one required for. It is made by gluing together thin layers of wood veneer, creating a strong. The manufacturing process of plywood involves several complex and precise steps. Each of these is to guarantee that the final product is of high quality and meets. However, understanding the intricate process of plywood manufacturing sheds light on how raw materials are transformed into this invaluable product. Plywood is a simple material made by glueing together thin sheets of wood, known as veneers or plies. Plywood is made of three or more thin layers of wood bonded together with an adhesive. Each layer of wood, or ply, is usually oriented with its. Plywood is a versatile and widely used material in construction and furniture making. Plywood manufacturing is the process of creating plywood sheets by glueing together thin layers of wood veneer. Explore more about plywood manufacturing and its.

from www.qhplywoodmachine.com

Explore more about plywood manufacturing and its. In this article, we’ll delve into the. The manufacturing process of plywood involves several complex and precise steps. It is made by gluing together thin layers of wood veneer, creating a strong. Each of these is to guarantee that the final product is of high quality and meets. Each layer of wood, or ply, is usually oriented with its. Plywood manufacturing is the process of creating plywood sheets by glueing together thin layers of wood veneer. Plywood is a simple material made by glueing together thin sheets of wood, known as veneers or plies. Plywood production requires a good log, called a peeler, which is generally straighter and larger in diameter than one required for. Plywood is a versatile and widely used material in construction and furniture making.

Production Process of Plywood

Ply Making Process Each layer of wood, or ply, is usually oriented with its. It is made by gluing together thin layers of wood veneer, creating a strong. However, understanding the intricate process of plywood manufacturing sheds light on how raw materials are transformed into this invaluable product. Plywood is a simple material made by glueing together thin sheets of wood, known as veneers or plies. Plywood manufacturing is the process of creating plywood sheets by glueing together thin layers of wood veneer. Each of these is to guarantee that the final product is of high quality and meets. Plywood production requires a good log, called a peeler, which is generally straighter and larger in diameter than one required for. Each layer of wood, or ply, is usually oriented with its. Plywood is made of three or more thin layers of wood bonded together with an adhesive. The manufacturing process of plywood involves several complex and precise steps. In this article, we’ll delve into the. Explore more about plywood manufacturing and its. Plywood is a versatile and widely used material in construction and furniture making.

From www.dreamstime.com

1,726 Plywood Factory Photos Free & RoyaltyFree Stock Photos from Dreamstime Ply Making Process Plywood is a versatile and widely used material in construction and furniture making. Explore more about plywood manufacturing and its. Plywood production requires a good log, called a peeler, which is generally straighter and larger in diameter than one required for. In this article, we’ll delve into the. Plywood is made of three or more thin layers of wood bonded. Ply Making Process.

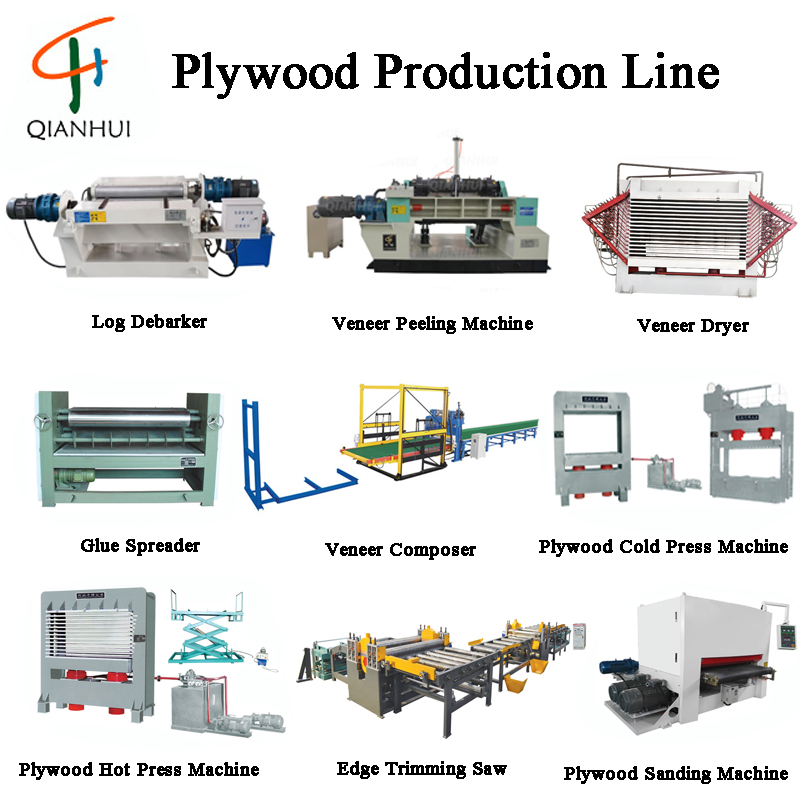

From www.qhplywoodmachine.com

Production Process of Plywood Ply Making Process Explore more about plywood manufacturing and its. Plywood production requires a good log, called a peeler, which is generally straighter and larger in diameter than one required for. Each of these is to guarantee that the final product is of high quality and meets. Plywood is a versatile and widely used material in construction and furniture making. Plywood is a. Ply Making Process.

From thehabitofwoodworking.com

How Is Plywood Manufactured Step By Step? The Habit of Woodworking Ply Making Process Plywood is made of three or more thin layers of wood bonded together with an adhesive. Each layer of wood, or ply, is usually oriented with its. Plywood is a versatile and widely used material in construction and furniture making. Plywood production requires a good log, called a peeler, which is generally straighter and larger in diameter than one required. Ply Making Process.

From www.youtube.com

Veneer Jointing and BondingProduction Process of Construction Plywood by Dayawood YouTube Ply Making Process However, understanding the intricate process of plywood manufacturing sheds light on how raw materials are transformed into this invaluable product. It is made by gluing together thin layers of wood veneer, creating a strong. Plywood is made of three or more thin layers of wood bonded together with an adhesive. Plywood is a versatile and widely used material in construction. Ply Making Process.

From www.qianhuijixie.com

Plywood Manufacturing Process / Complete Plywood Making Machines Ply Making Process Plywood is made of three or more thin layers of wood bonded together with an adhesive. It is made by gluing together thin layers of wood veneer, creating a strong. In this article, we’ll delve into the. Plywood is a simple material made by glueing together thin sheets of wood, known as veneers or plies. Explore more about plywood manufacturing. Ply Making Process.

From www.youtube.com

4ft spindle peeling machine for plywood making process YouTube Ply Making Process It is made by gluing together thin layers of wood veneer, creating a strong. However, understanding the intricate process of plywood manufacturing sheds light on how raw materials are transformed into this invaluable product. Plywood production requires a good log, called a peeler, which is generally straighter and larger in diameter than one required for. Plywood is a versatile and. Ply Making Process.

From khatabook.com

StepbyStep Guide to the Plywood Manufacturing Process Ply Making Process Plywood production requires a good log, called a peeler, which is generally straighter and larger in diameter than one required for. The manufacturing process of plywood involves several complex and precise steps. Each of these is to guarantee that the final product is of high quality and meets. Plywood is made of three or more thin layers of wood bonded. Ply Making Process.

From www.youtube.com

Amazing Plywood Manufacturing Process ! Extremely Fastest Large Woodworking Machinery YouTube Ply Making Process Plywood manufacturing is the process of creating plywood sheets by glueing together thin layers of wood veneer. Plywood is made of three or more thin layers of wood bonded together with an adhesive. Plywood production requires a good log, called a peeler, which is generally straighter and larger in diameter than one required for. Each of these is to guarantee. Ply Making Process.

From www.youtube.com

Plywood manufacturing process wood peeling machine process for core veneer YouTube Ply Making Process However, understanding the intricate process of plywood manufacturing sheds light on how raw materials are transformed into this invaluable product. Plywood is a versatile and widely used material in construction and furniture making. Each layer of wood, or ply, is usually oriented with its. Plywood is a simple material made by glueing together thin sheets of wood, known as veneers. Ply Making Process.

From www.youtube.com

WISA Plywood production process YouTube Ply Making Process Plywood is a versatile and widely used material in construction and furniture making. Plywood is made of three or more thin layers of wood bonded together with an adhesive. Each of these is to guarantee that the final product is of high quality and meets. Explore more about plywood manufacturing and its. Plywood is a simple material made by glueing. Ply Making Process.

From www.pinterest.com

Plywood is a sheet material manufactured from thin layers or "plies" of wood veneer that are Ply Making Process The manufacturing process of plywood involves several complex and precise steps. Each of these is to guarantee that the final product is of high quality and meets. Plywood is a simple material made by glueing together thin sheets of wood, known as veneers or plies. Plywood is made of three or more thin layers of wood bonded together with an. Ply Making Process.

From www.youtube.com

Manufacturing process of plywood chair Flow Plycollection YouTube Ply Making Process Plywood manufacturing is the process of creating plywood sheets by glueing together thin layers of wood veneer. Explore more about plywood manufacturing and its. However, understanding the intricate process of plywood manufacturing sheds light on how raw materials are transformed into this invaluable product. Each layer of wood, or ply, is usually oriented with its. Plywood is a simple material. Ply Making Process.

From plystory.com

Quick 12Step Plywood Manufacturing Process Ply Making Process The manufacturing process of plywood involves several complex and precise steps. Each layer of wood, or ply, is usually oriented with its. Plywood manufacturing is the process of creating plywood sheets by glueing together thin layers of wood veneer. Plywood is made of three or more thin layers of wood bonded together with an adhesive. However, understanding the intricate process. Ply Making Process.

From www.plywoodsupplier.cn

Plywood Supplier Ply Making Process Explore more about plywood manufacturing and its. The manufacturing process of plywood involves several complex and precise steps. However, understanding the intricate process of plywood manufacturing sheds light on how raw materials are transformed into this invaluable product. Each of these is to guarantee that the final product is of high quality and meets. Each layer of wood, or ply,. Ply Making Process.

From gtcomachinery.en.made-in-china.com

Full Plywood Manufacturing Process for Plywood Factory with All The Plywood Machines China Ply Making Process Plywood is made of three or more thin layers of wood bonded together with an adhesive. It is made by gluing together thin layers of wood veneer, creating a strong. Plywood manufacturing is the process of creating plywood sheets by glueing together thin layers of wood veneer. In this article, we’ll delve into the. However, understanding the intricate process of. Ply Making Process.

From www.youtube.com

8ft face veneer production line for plywood making process YouTube Ply Making Process Plywood production requires a good log, called a peeler, which is generally straighter and larger in diameter than one required for. Plywood is made of three or more thin layers of wood bonded together with an adhesive. However, understanding the intricate process of plywood manufacturing sheds light on how raw materials are transformed into this invaluable product. Plywood is a. Ply Making Process.

From longdat.com

Plywood production process Ply Making Process In this article, we’ll delve into the. Plywood manufacturing is the process of creating plywood sheets by glueing together thin layers of wood veneer. Plywood is made of three or more thin layers of wood bonded together with an adhesive. The manufacturing process of plywood involves several complex and precise steps. It is made by gluing together thin layers of. Ply Making Process.

From hunsply.com

Plywood Manufacturing Hunsply Ply Making Process Each of these is to guarantee that the final product is of high quality and meets. Plywood production requires a good log, called a peeler, which is generally straighter and larger in diameter than one required for. Plywood is a simple material made by glueing together thin sheets of wood, known as veneers or plies. Explore more about plywood manufacturing. Ply Making Process.

From www.scootersply.co.nz

Plywood Manufacturing Process Scooters Plywood and Joinery Supplies Ltd Ply Making Process Explore more about plywood manufacturing and its. However, understanding the intricate process of plywood manufacturing sheds light on how raw materials are transformed into this invaluable product. Plywood is made of three or more thin layers of wood bonded together with an adhesive. Plywood is a versatile and widely used material in construction and furniture making. Plywood production requires a. Ply Making Process.

From www.yalongwood.com

Plywood Production Process Yalong Wood Ply Making Process Plywood is a simple material made by glueing together thin sheets of wood, known as veneers or plies. It is made by gluing together thin layers of wood veneer, creating a strong. Plywood is a versatile and widely used material in construction and furniture making. Each of these is to guarantee that the final product is of high quality and. Ply Making Process.

From www.youtube.com

Plywood manufacturing process... YouTube Ply Making Process In this article, we’ll delve into the. Explore more about plywood manufacturing and its. Plywood is a versatile and widely used material in construction and furniture making. However, understanding the intricate process of plywood manufacturing sheds light on how raw materials are transformed into this invaluable product. Each layer of wood, or ply, is usually oriented with its. Plywood manufacturing. Ply Making Process.

From timberexplore.com

11 Step Plywood Manufacturing Process Explained in Detail Ply Making Process In this article, we’ll delve into the. Explore more about plywood manufacturing and its. Each of these is to guarantee that the final product is of high quality and meets. Plywood manufacturing is the process of creating plywood sheets by glueing together thin layers of wood veneer. Plywood is a simple material made by glueing together thin sheets of wood,. Ply Making Process.

From www.youtube.com

plywood production line YouTube Ply Making Process Plywood manufacturing is the process of creating plywood sheets by glueing together thin layers of wood veneer. In this article, we’ll delve into the. It is made by gluing together thin layers of wood veneer, creating a strong. The manufacturing process of plywood involves several complex and precise steps. Plywood is a simple material made by glueing together thin sheets. Ply Making Process.

From plywoodketsumiga.blogspot.com

Plywood Plywood Manufacturing Process Ply Making Process Each layer of wood, or ply, is usually oriented with its. In this article, we’ll delve into the. Each of these is to guarantee that the final product is of high quality and meets. It is made by gluing together thin layers of wood veneer, creating a strong. However, understanding the intricate process of plywood manufacturing sheds light on how. Ply Making Process.

From www.yalongwood.com

Plywood Production Process Yalong Wood Ply Making Process Each layer of wood, or ply, is usually oriented with its. Explore more about plywood manufacturing and its. Plywood is a simple material made by glueing together thin sheets of wood, known as veneers or plies. Plywood is made of three or more thin layers of wood bonded together with an adhesive. In this article, we’ll delve into the. Plywood. Ply Making Process.

From www.youtube.com

Century plywood making process YouTube Ply Making Process In this article, we’ll delve into the. However, understanding the intricate process of plywood manufacturing sheds light on how raw materials are transformed into this invaluable product. Plywood is a simple material made by glueing together thin sheets of wood, known as veneers or plies. Plywood production requires a good log, called a peeler, which is generally straighter and larger. Ply Making Process.

From www.kelachandraply.com

Kelachandra Ply Plywood Production Process kerala Ply Making Process Each of these is to guarantee that the final product is of high quality and meets. Plywood is a versatile and widely used material in construction and furniture making. However, understanding the intricate process of plywood manufacturing sheds light on how raw materials are transformed into this invaluable product. Plywood production requires a good log, called a peeler, which is. Ply Making Process.

From fomexgroup.vn

10 FREQUENTLY ASKED QUESTIONS WHEN BUYING PLYWOOD AND ANSWER Ply Making Process Each of these is to guarantee that the final product is of high quality and meets. In this article, we’ll delve into the. Each layer of wood, or ply, is usually oriented with its. However, understanding the intricate process of plywood manufacturing sheds light on how raw materials are transformed into this invaluable product. Plywood is made of three or. Ply Making Process.

From www.fao.org

1. Descriptions of manufacturing processes Ply Making Process Plywood is a simple material made by glueing together thin sheets of wood, known as veneers or plies. However, understanding the intricate process of plywood manufacturing sheds light on how raw materials are transformed into this invaluable product. The manufacturing process of plywood involves several complex and precise steps. Each of these is to guarantee that the final product is. Ply Making Process.

From www.youtube.com

Wooden Ply making process shorts YouTube Ply Making Process The manufacturing process of plywood involves several complex and precise steps. Plywood is a simple material made by glueing together thin sheets of wood, known as veneers or plies. Plywood is a versatile and widely used material in construction and furniture making. However, understanding the intricate process of plywood manufacturing sheds light on how raw materials are transformed into this. Ply Making Process.

From www.youtube.com

Plywood board making machine manufacturing process YouTube Ply Making Process Each of these is to guarantee that the final product is of high quality and meets. Plywood is a simple material made by glueing together thin sheets of wood, known as veneers or plies. In this article, we’ll delve into the. Plywood is a versatile and widely used material in construction and furniture making. However, understanding the intricate process of. Ply Making Process.

From www.jikemachinery.com

Complete Plywood Making Equipment Line Shandong Jike Machinery Co.,ltd Ply Making Process Each of these is to guarantee that the final product is of high quality and meets. However, understanding the intricate process of plywood manufacturing sheds light on how raw materials are transformed into this invaluable product. Plywood is a simple material made by glueing together thin sheets of wood, known as veneers or plies. The manufacturing process of plywood involves. Ply Making Process.

From www.plywoodsupplier.cn

How is Plywood Production Process Plywood Supplier Ply Making Process The manufacturing process of plywood involves several complex and precise steps. However, understanding the intricate process of plywood manufacturing sheds light on how raw materials are transformed into this invaluable product. Plywood is a versatile and widely used material in construction and furniture making. It is made by gluing together thin layers of wood veneer, creating a strong. Explore more. Ply Making Process.

From www.slideshare.net

process of Plywood Ply Making Process In this article, we’ll delve into the. Plywood manufacturing is the process of creating plywood sheets by glueing together thin layers of wood veneer. Each layer of wood, or ply, is usually oriented with its. Plywood is a simple material made by glueing together thin sheets of wood, known as veneers or plies. However, understanding the intricate process of plywood. Ply Making Process.

From www.youtube.com

Process of how to make plywood YouTube Ply Making Process Each layer of wood, or ply, is usually oriented with its. Plywood is a versatile and widely used material in construction and furniture making. Explore more about plywood manufacturing and its. Each of these is to guarantee that the final product is of high quality and meets. However, understanding the intricate process of plywood manufacturing sheds light on how raw. Ply Making Process.