Laser Surface Finish . Nowadays, laser technology offers better ways to treat metals and meet engineering requirements with increased precision and consistency. Mill scale (oxide left from the steel manufacturer), must be ground off to weld, or paint. The process has common benefits,. Laser polishing is widely considered very suitable to improving the surface finish of metal components. The term encompasses a wide variety of processes, including deburring, coating, polishing, and texturing. Laser cutting delivers great edge quality in hot rolled steels. Using laser technology for surface finishing and cleaning means you can adapt from one material to the next. Surface finishing is the process of modifying a surface to improve specific properties, such as corrosion resistance, durability, adhesion, or appearance. Laser polishing is a technology of smoothening the surface of various materials with highly intense laser beams. The adherence depends on the characteristics of the mortar, the substrate (such as its porosity and roughness, which are.

from www.engineering.org.cn

Laser polishing is widely considered very suitable to improving the surface finish of metal components. Laser polishing is a technology of smoothening the surface of various materials with highly intense laser beams. The term encompasses a wide variety of processes, including deburring, coating, polishing, and texturing. The process has common benefits,. Surface finishing is the process of modifying a surface to improve specific properties, such as corrosion resistance, durability, adhesion, or appearance. The adherence depends on the characteristics of the mortar, the substrate (such as its porosity and roughness, which are. Using laser technology for surface finishing and cleaning means you can adapt from one material to the next. Mill scale (oxide left from the steel manufacturer), must be ground off to weld, or paint. Laser cutting delivers great edge quality in hot rolled steels. Nowadays, laser technology offers better ways to treat metals and meet engineering requirements with increased precision and consistency.

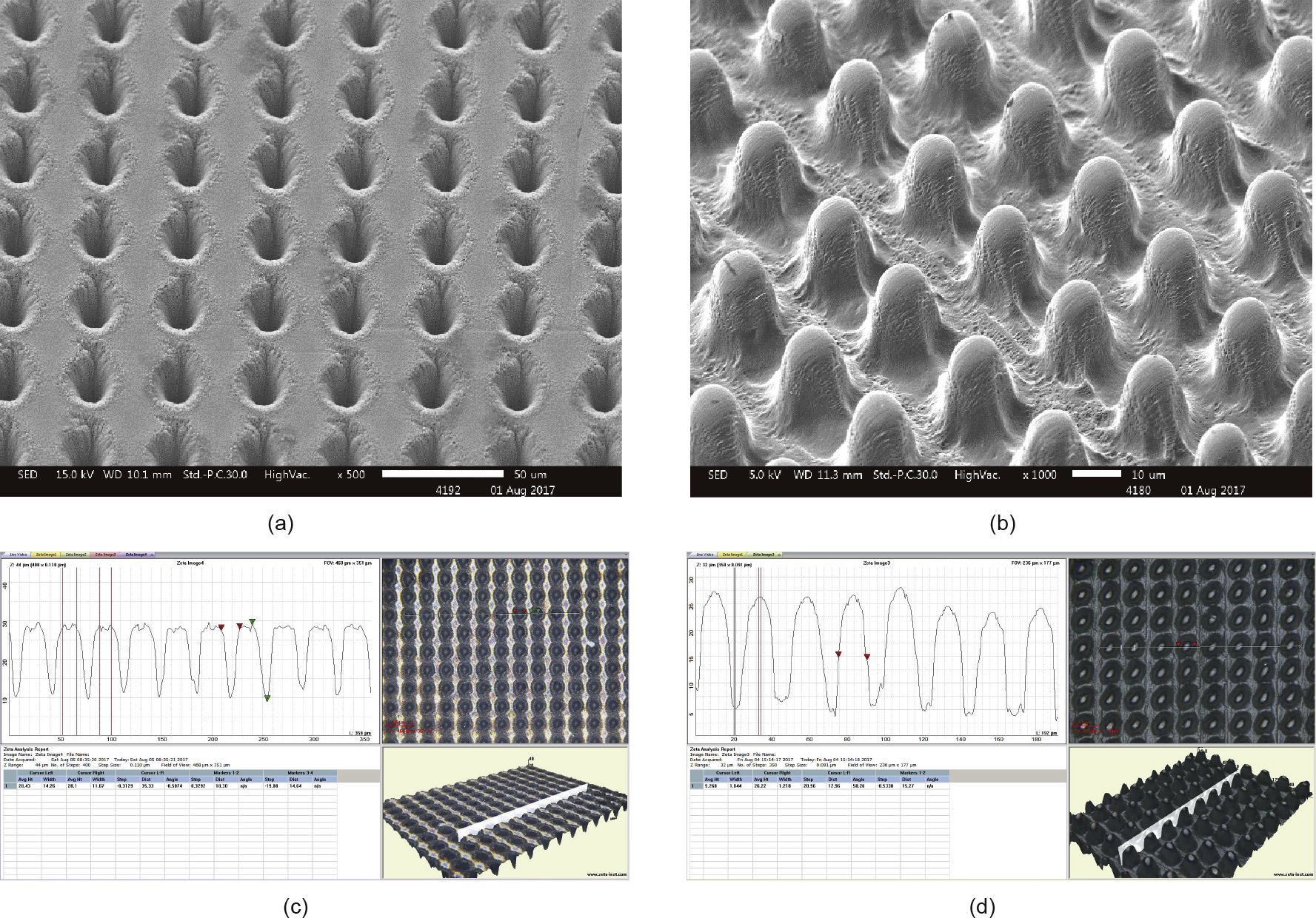

Picosecond Laser Surface Texturing of a Stavax Steel Substrate for

Laser Surface Finish Using laser technology for surface finishing and cleaning means you can adapt from one material to the next. The process has common benefits,. Laser polishing is a technology of smoothening the surface of various materials with highly intense laser beams. The term encompasses a wide variety of processes, including deburring, coating, polishing, and texturing. Mill scale (oxide left from the steel manufacturer), must be ground off to weld, or paint. Laser polishing is widely considered very suitable to improving the surface finish of metal components. Surface finishing is the process of modifying a surface to improve specific properties, such as corrosion resistance, durability, adhesion, or appearance. Nowadays, laser technology offers better ways to treat metals and meet engineering requirements with increased precision and consistency. Laser cutting delivers great edge quality in hot rolled steels. Using laser technology for surface finishing and cleaning means you can adapt from one material to the next. The adherence depends on the characteristics of the mortar, the substrate (such as its porosity and roughness, which are.

From mellowpine.com

Laser Cutting vs Plasma Cutting Which do you Need? MellowPine Laser Surface Finish Mill scale (oxide left from the steel manufacturer), must be ground off to weld, or paint. Laser polishing is widely considered very suitable to improving the surface finish of metal components. Laser cutting delivers great edge quality in hot rolled steels. The process has common benefits,. Using laser technology for surface finishing and cleaning means you can adapt from one. Laser Surface Finish.

From www.thefabricator.com

Shaping the laser beam for the best cut The Fabricator Laser Surface Finish Mill scale (oxide left from the steel manufacturer), must be ground off to weld, or paint. The process has common benefits,. Using laser technology for surface finishing and cleaning means you can adapt from one material to the next. Laser cutting delivers great edge quality in hot rolled steels. Surface finishing is the process of modifying a surface to improve. Laser Surface Finish.

From www.daysteel.co.uk

Laser Cutting Edge Quality Factors Affecting Laser Edge Finish Laser Surface Finish Surface finishing is the process of modifying a surface to improve specific properties, such as corrosion resistance, durability, adhesion, or appearance. Mill scale (oxide left from the steel manufacturer), must be ground off to weld, or paint. Laser polishing is a technology of smoothening the surface of various materials with highly intense laser beams. The adherence depends on the characteristics. Laser Surface Finish.

From www.mdpi.com

Photonics Free FullText Prediction of Surface Roughness in Laser Surface Finish Laser polishing is a technology of smoothening the surface of various materials with highly intense laser beams. The term encompasses a wide variety of processes, including deburring, coating, polishing, and texturing. Surface finishing is the process of modifying a surface to improve specific properties, such as corrosion resistance, durability, adhesion, or appearance. Using laser technology for surface finishing and cleaning. Laser Surface Finish.

From www.mdpi.com

Materials Free FullText Laser Peening Process and Its Impact on Laser Surface Finish Nowadays, laser technology offers better ways to treat metals and meet engineering requirements with increased precision and consistency. Laser polishing is widely considered very suitable to improving the surface finish of metal components. Laser cutting delivers great edge quality in hot rolled steels. Using laser technology for surface finishing and cleaning means you can adapt from one material to the. Laser Surface Finish.

From www.researchgate.net

Roughness spectra of surfaces laser polished with different laser beam Laser Surface Finish The process has common benefits,. Nowadays, laser technology offers better ways to treat metals and meet engineering requirements with increased precision and consistency. The term encompasses a wide variety of processes, including deburring, coating, polishing, and texturing. Laser polishing is widely considered very suitable to improving the surface finish of metal components. Surface finishing is the process of modifying a. Laser Surface Finish.

From www.mdpi.com

JMMP Free FullText The Impact of Process Parameters on Surface Laser Surface Finish Laser polishing is a technology of smoothening the surface of various materials with highly intense laser beams. Nowadays, laser technology offers better ways to treat metals and meet engineering requirements with increased precision and consistency. Laser cutting delivers great edge quality in hot rolled steels. The adherence depends on the characteristics of the mortar, the substrate (such as its porosity. Laser Surface Finish.

From www.researchgate.net

Schematic of laser surface alloying process using a preplaced powder Laser Surface Finish Using laser technology for surface finishing and cleaning means you can adapt from one material to the next. Laser polishing is widely considered very suitable to improving the surface finish of metal components. Surface finishing is the process of modifying a surface to improve specific properties, such as corrosion resistance, durability, adhesion, or appearance. The term encompasses a wide variety. Laser Surface Finish.

From adapt-laser.com

Laser Surface Roughening Adapt Laser Laser Surface Finish Laser cutting delivers great edge quality in hot rolled steels. Surface finishing is the process of modifying a surface to improve specific properties, such as corrosion resistance, durability, adhesion, or appearance. Laser polishing is a technology of smoothening the surface of various materials with highly intense laser beams. The term encompasses a wide variety of processes, including deburring, coating, polishing,. Laser Surface Finish.

From www.researchgate.net

Experimental setup for laser surface texturing Download Scientific Laser Surface Finish Laser polishing is widely considered very suitable to improving the surface finish of metal components. Laser polishing is a technology of smoothening the surface of various materials with highly intense laser beams. The adherence depends on the characteristics of the mortar, the substrate (such as its porosity and roughness, which are. Using laser technology for surface finishing and cleaning means. Laser Surface Finish.

From www.scirp.org

Laser Polishing of Laser Powder Bed Fusion AlSi10Mg Parts—Influence of Laser Surface Finish Laser polishing is widely considered very suitable to improving the surface finish of metal components. Using laser technology for surface finishing and cleaning means you can adapt from one material to the next. Laser polishing is a technology of smoothening the surface of various materials with highly intense laser beams. The adherence depends on the characteristics of the mortar, the. Laser Surface Finish.

From www.laserax.com

Laser Texturing to Prepare Metal for Bonding Laserax Laser Surface Finish Laser polishing is a technology of smoothening the surface of various materials with highly intense laser beams. Laser polishing is widely considered very suitable to improving the surface finish of metal components. Mill scale (oxide left from the steel manufacturer), must be ground off to weld, or paint. The adherence depends on the characteristics of the mortar, the substrate (such. Laser Surface Finish.

From ietresearch.onlinelibrary.wiley.com

Evaluation of surface roughness of a machined metal surface based on Laser Surface Finish Nowadays, laser technology offers better ways to treat metals and meet engineering requirements with increased precision and consistency. The term encompasses a wide variety of processes, including deburring, coating, polishing, and texturing. Using laser technology for surface finishing and cleaning means you can adapt from one material to the next. The adherence depends on the characteristics of the mortar, the. Laser Surface Finish.

From www.mdpi.com

Micromachines Free FullText Scanning Strategies in Laser Surface Laser Surface Finish Nowadays, laser technology offers better ways to treat metals and meet engineering requirements with increased precision and consistency. Mill scale (oxide left from the steel manufacturer), must be ground off to weld, or paint. Laser polishing is widely considered very suitable to improving the surface finish of metal components. The process has common benefits,. Surface finishing is the process of. Laser Surface Finish.

From www.engineering.org.cn

Picosecond Laser Surface Texturing of a Stavax Steel Substrate for Laser Surface Finish Nowadays, laser technology offers better ways to treat metals and meet engineering requirements with increased precision and consistency. Surface finishing is the process of modifying a surface to improve specific properties, such as corrosion resistance, durability, adhesion, or appearance. Laser polishing is widely considered very suitable to improving the surface finish of metal components. The adherence depends on the characteristics. Laser Surface Finish.

From www.mdpi.com

Coatings Free FullText Laser Surface Texturing for Biomedical Laser Surface Finish Laser cutting delivers great edge quality in hot rolled steels. Laser polishing is widely considered very suitable to improving the surface finish of metal components. The process has common benefits,. Nowadays, laser technology offers better ways to treat metals and meet engineering requirements with increased precision and consistency. Laser polishing is a technology of smoothening the surface of various materials. Laser Surface Finish.

From willrich.com

Laser Surface Roughness Bench Unit Willrich Precision Instruments Laser Surface Finish The process has common benefits,. Surface finishing is the process of modifying a surface to improve specific properties, such as corrosion resistance, durability, adhesion, or appearance. The adherence depends on the characteristics of the mortar, the substrate (such as its porosity and roughness, which are. Nowadays, laser technology offers better ways to treat metals and meet engineering requirements with increased. Laser Surface Finish.

From www.lasersystemseurope.com

An introduction to laser surface treatment Laser Systems Europe Laser Surface Finish The process has common benefits,. The adherence depends on the characteristics of the mortar, the substrate (such as its porosity and roughness, which are. Nowadays, laser technology offers better ways to treat metals and meet engineering requirements with increased precision and consistency. Laser cutting delivers great edge quality in hot rolled steels. Using laser technology for surface finishing and cleaning. Laser Surface Finish.

From www.thefabricator.com

4 ways to a better lasercut edge Laser Surface Finish The process has common benefits,. Mill scale (oxide left from the steel manufacturer), must be ground off to weld, or paint. The adherence depends on the characteristics of the mortar, the substrate (such as its porosity and roughness, which are. The term encompasses a wide variety of processes, including deburring, coating, polishing, and texturing. Laser cutting delivers great edge quality. Laser Surface Finish.

From axisfab.com

Fiber versus CO2 Lasers The Basic Differences Axis Fabrication Laser Surface Finish The term encompasses a wide variety of processes, including deburring, coating, polishing, and texturing. The adherence depends on the characteristics of the mortar, the substrate (such as its porosity and roughness, which are. Mill scale (oxide left from the steel manufacturer), must be ground off to weld, or paint. Surface finishing is the process of modifying a surface to improve. Laser Surface Finish.

From www.researchgate.net

The schematic diagram of the laser surface texturing. Using various LSO Laser Surface Finish Using laser technology for surface finishing and cleaning means you can adapt from one material to the next. Laser polishing is a technology of smoothening the surface of various materials with highly intense laser beams. Laser cutting delivers great edge quality in hot rolled steels. The term encompasses a wide variety of processes, including deburring, coating, polishing, and texturing. The. Laser Surface Finish.

From www.researchgate.net

Laser surface texturing using a stationary beam and a mask Laser Surface Finish Using laser technology for surface finishing and cleaning means you can adapt from one material to the next. Laser cutting delivers great edge quality in hot rolled steels. Mill scale (oxide left from the steel manufacturer), must be ground off to weld, or paint. The process has common benefits,. Laser polishing is a technology of smoothening the surface of various. Laser Surface Finish.

From www.researchgate.net

Schematic view of laser surface alloying. Download Scientific Diagram Laser Surface Finish Nowadays, laser technology offers better ways to treat metals and meet engineering requirements with increased precision and consistency. The process has common benefits,. Laser polishing is a technology of smoothening the surface of various materials with highly intense laser beams. Using laser technology for surface finishing and cleaning means you can adapt from one material to the next. Mill scale. Laser Surface Finish.

From www.lightmotif.nl

Lightmotif — Laser surface texturing Laser Surface Finish The term encompasses a wide variety of processes, including deburring, coating, polishing, and texturing. The process has common benefits,. Using laser technology for surface finishing and cleaning means you can adapt from one material to the next. Mill scale (oxide left from the steel manufacturer), must be ground off to weld, or paint. Laser cutting delivers great edge quality in. Laser Surface Finish.

From www.researchgate.net

Roughness spectra of surfaces laser polished with different laser beam Laser Surface Finish Surface finishing is the process of modifying a surface to improve specific properties, such as corrosion resistance, durability, adhesion, or appearance. Using laser technology for surface finishing and cleaning means you can adapt from one material to the next. Laser cutting delivers great edge quality in hot rolled steels. Laser polishing is widely considered very suitable to improving the surface. Laser Surface Finish.

From blog.thepipingmart.com

Overview of Stainless Steel Surface Finishes ThePipingMart Blog Laser Surface Finish The process has common benefits,. The term encompasses a wide variety of processes, including deburring, coating, polishing, and texturing. Laser cutting delivers great edge quality in hot rolled steels. The adherence depends on the characteristics of the mortar, the substrate (such as its porosity and roughness, which are. Surface finishing is the process of modifying a surface to improve specific. Laser Surface Finish.

From willrich.com

customized laser surface roughness 2 Willrich Precision Instruments Laser Surface Finish Laser polishing is a technology of smoothening the surface of various materials with highly intense laser beams. Using laser technology for surface finishing and cleaning means you can adapt from one material to the next. Surface finishing is the process of modifying a surface to improve specific properties, such as corrosion resistance, durability, adhesion, or appearance. The adherence depends on. Laser Surface Finish.

From ferroecoblast.com

Laser Surface Texturing as an alternative to Air blasting Advanced Laser Surface Finish Surface finishing is the process of modifying a surface to improve specific properties, such as corrosion resistance, durability, adhesion, or appearance. The term encompasses a wide variety of processes, including deburring, coating, polishing, and texturing. Laser polishing is a technology of smoothening the surface of various materials with highly intense laser beams. The adherence depends on the characteristics of the. Laser Surface Finish.

From mellowpine.com

Fiber Laser vs CO2 Laser Expert Guide [2023] MellowPine Laser Surface Finish Laser polishing is widely considered very suitable to improving the surface finish of metal components. Laser cutting delivers great edge quality in hot rolled steels. Nowadays, laser technology offers better ways to treat metals and meet engineering requirements with increased precision and consistency. Mill scale (oxide left from the steel manufacturer), must be ground off to weld, or paint. The. Laser Surface Finish.

From www.newfield.co.uk

Laser Cutting Services CNC Laser Cutting, Mild Steel, Stainless Laser Surface Finish The process has common benefits,. Mill scale (oxide left from the steel manufacturer), must be ground off to weld, or paint. Laser cutting delivers great edge quality in hot rolled steels. Surface finishing is the process of modifying a surface to improve specific properties, such as corrosion resistance, durability, adhesion, or appearance. Laser polishing is a technology of smoothening the. Laser Surface Finish.

From www.researchgate.net

Ti6Al4V LMD laser polished surface (Initial LMD surface roughness S a Laser Surface Finish The process has common benefits,. Using laser technology for surface finishing and cleaning means you can adapt from one material to the next. Laser polishing is widely considered very suitable to improving the surface finish of metal components. Laser cutting delivers great edge quality in hot rolled steels. Laser polishing is a technology of smoothening the surface of various materials. Laser Surface Finish.

From www.kemalmfg.com

A Comprehensive Guide to Surface Roughness, its Measurement, Standards Laser Surface Finish Surface finishing is the process of modifying a surface to improve specific properties, such as corrosion resistance, durability, adhesion, or appearance. The adherence depends on the characteristics of the mortar, the substrate (such as its porosity and roughness, which are. Laser cutting delivers great edge quality in hot rolled steels. The term encompasses a wide variety of processes, including deburring,. Laser Surface Finish.

From www.rapiddirect.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Laser Surface Finish Surface finishing is the process of modifying a surface to improve specific properties, such as corrosion resistance, durability, adhesion, or appearance. The adherence depends on the characteristics of the mortar, the substrate (such as its porosity and roughness, which are. The term encompasses a wide variety of processes, including deburring, coating, polishing, and texturing. Laser polishing is a technology of. Laser Surface Finish.

From ermelindamccutcheon.blogspot.com

machining surface finish grades Ermelinda Mccutcheon Laser Surface Finish Laser cutting delivers great edge quality in hot rolled steels. The term encompasses a wide variety of processes, including deburring, coating, polishing, and texturing. The process has common benefits,. The adherence depends on the characteristics of the mortar, the substrate (such as its porosity and roughness, which are. Using laser technology for surface finishing and cleaning means you can adapt. Laser Surface Finish.