Surface Roughness After Grit Blasting . based on the analysis of the results were also proposed sets of surface roughness parameters, which can be used. blast pressure had the largest effect on surface roughness, as well as the highest linear correlation with roughness. the average surface roughness was close to the coatings’ thickness (≈5 μm for coblasttm and ≈13 μm for plasma spray). When an engineer includes a surface finish spec on a print, the intent is usually not just to make. all the surface properties, viz. the surface roughness of the substrate after blasting is the feature parameter to evaluate the surface quality after pretreatment, as residual. both the average surface roughness and grit residue were found to increase with the blasting angle.

from www.semanticscholar.org

all the surface properties, viz. the average surface roughness was close to the coatings’ thickness (≈5 μm for coblasttm and ≈13 μm for plasma spray). based on the analysis of the results were also proposed sets of surface roughness parameters, which can be used. the surface roughness of the substrate after blasting is the feature parameter to evaluate the surface quality after pretreatment, as residual. both the average surface roughness and grit residue were found to increase with the blasting angle. blast pressure had the largest effect on surface roughness, as well as the highest linear correlation with roughness. When an engineer includes a surface finish spec on a print, the intent is usually not just to make.

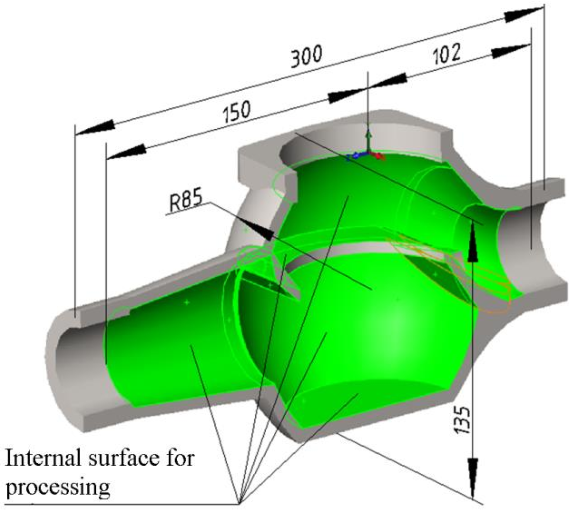

Figure 1 from Surface Roughness Measurement of Casted Parts after

Surface Roughness After Grit Blasting both the average surface roughness and grit residue were found to increase with the blasting angle. the surface roughness of the substrate after blasting is the feature parameter to evaluate the surface quality after pretreatment, as residual. When an engineer includes a surface finish spec on a print, the intent is usually not just to make. the average surface roughness was close to the coatings’ thickness (≈5 μm for coblasttm and ≈13 μm for plasma spray). both the average surface roughness and grit residue were found to increase with the blasting angle. blast pressure had the largest effect on surface roughness, as well as the highest linear correlation with roughness. all the surface properties, viz. based on the analysis of the results were also proposed sets of surface roughness parameters, which can be used.

From www.researchgate.net

Surface roughness of YTZP zirconia after polishing (G0) or after Surface Roughness After Grit Blasting all the surface properties, viz. the surface roughness of the substrate after blasting is the feature parameter to evaluate the surface quality after pretreatment, as residual. both the average surface roughness and grit residue were found to increase with the blasting angle. blast pressure had the largest effect on surface roughness, as well as the highest. Surface Roughness After Grit Blasting.

From www.amazon.co.uk

INSIZE ISRCS017 Shot and Grit Blasting Surface Roughness Specimen Surface Roughness After Grit Blasting all the surface properties, viz. When an engineer includes a surface finish spec on a print, the intent is usually not just to make. both the average surface roughness and grit residue were found to increase with the blasting angle. based on the analysis of the results were also proposed sets of surface roughness parameters, which can. Surface Roughness After Grit Blasting.

From www.metalextra.com

INSIZE Shot & Grit Blasting Surface Roughness Specimen ISRCS017 Surface Roughness After Grit Blasting both the average surface roughness and grit residue were found to increase with the blasting angle. all the surface properties, viz. the surface roughness of the substrate after blasting is the feature parameter to evaluate the surface quality after pretreatment, as residual. the average surface roughness was close to the coatings’ thickness (≈5 μm for coblasttm. Surface Roughness After Grit Blasting.

From mavink.com

Rms Surface Roughness Chart Surface Roughness After Grit Blasting both the average surface roughness and grit residue were found to increase with the blasting angle. the surface roughness of the substrate after blasting is the feature parameter to evaluate the surface quality after pretreatment, as residual. the average surface roughness was close to the coatings’ thickness (≈5 μm for coblasttm and ≈13 μm for plasma spray).. Surface Roughness After Grit Blasting.

From www.dreamstime.com

Inspection Surface Profile of Steel Top Flange after Steel Grit Surface Roughness After Grit Blasting based on the analysis of the results were also proposed sets of surface roughness parameters, which can be used. all the surface properties, viz. the surface roughness of the substrate after blasting is the feature parameter to evaluate the surface quality after pretreatment, as residual. blast pressure had the largest effect on surface roughness, as well. Surface Roughness After Grit Blasting.

From www.researchgate.net

Effect of abrasive grains' size and their transport medium on the Surface Roughness After Grit Blasting both the average surface roughness and grit residue were found to increase with the blasting angle. based on the analysis of the results were also proposed sets of surface roughness parameters, which can be used. When an engineer includes a surface finish spec on a print, the intent is usually not just to make. blast pressure had. Surface Roughness After Grit Blasting.

From kirtindt.com

SURFACE ROUGHNESS COMPARATOR SA2.5 FOR AFTER BLAST CLEANING WITH SHOT Surface Roughness After Grit Blasting the average surface roughness was close to the coatings’ thickness (≈5 μm for coblasttm and ≈13 μm for plasma spray). When an engineer includes a surface finish spec on a print, the intent is usually not just to make. the surface roughness of the substrate after blasting is the feature parameter to evaluate the surface quality after pretreatment,. Surface Roughness After Grit Blasting.

From www.kuegroup.com

GRIT BLASTING Guide How To Choose The Right Surface Preparation Surface Roughness After Grit Blasting the surface roughness of the substrate after blasting is the feature parameter to evaluate the surface quality after pretreatment, as residual. When an engineer includes a surface finish spec on a print, the intent is usually not just to make. blast pressure had the largest effect on surface roughness, as well as the highest linear correlation with roughness.. Surface Roughness After Grit Blasting.

From finishingandcoating.com

Electropolishing Applications and Techniques Surface Roughness After Grit Blasting both the average surface roughness and grit residue were found to increase with the blasting angle. all the surface properties, viz. based on the analysis of the results were also proposed sets of surface roughness parameters, which can be used. When an engineer includes a surface finish spec on a print, the intent is usually not just. Surface Roughness After Grit Blasting.

From www.researchgate.net

Effects of grit blasting pressure on the surface roughness Download Surface Roughness After Grit Blasting all the surface properties, viz. based on the analysis of the results were also proposed sets of surface roughness parameters, which can be used. When an engineer includes a surface finish spec on a print, the intent is usually not just to make. blast pressure had the largest effect on surface roughness, as well as the highest. Surface Roughness After Grit Blasting.

From www.researchgate.net

Surface roughness (R a ) after grit blasting as a function of particle Surface Roughness After Grit Blasting the average surface roughness was close to the coatings’ thickness (≈5 μm for coblasttm and ≈13 μm for plasma spray). blast pressure had the largest effect on surface roughness, as well as the highest linear correlation with roughness. When an engineer includes a surface finish spec on a print, the intent is usually not just to make. . Surface Roughness After Grit Blasting.

From www.researchgate.net

Measured surface roughness of RHA plate 21 after grit blasting Surface Roughness After Grit Blasting blast pressure had the largest effect on surface roughness, as well as the highest linear correlation with roughness. the surface roughness of the substrate after blasting is the feature parameter to evaluate the surface quality after pretreatment, as residual. all the surface properties, viz. based on the analysis of the results were also proposed sets of. Surface Roughness After Grit Blasting.

From www.fluorotec.com

Grit Blasting AFT Fluorotec Surface Roughness After Grit Blasting all the surface properties, viz. When an engineer includes a surface finish spec on a print, the intent is usually not just to make. the average surface roughness was close to the coatings’ thickness (≈5 μm for coblasttm and ≈13 μm for plasma spray). based on the analysis of the results were also proposed sets of surface. Surface Roughness After Grit Blasting.

From www.semanticscholar.org

Figure 1 from Surface Roughness Measurement of Casted Parts after Surface Roughness After Grit Blasting all the surface properties, viz. When an engineer includes a surface finish spec on a print, the intent is usually not just to make. based on the analysis of the results were also proposed sets of surface roughness parameters, which can be used. the average surface roughness was close to the coatings’ thickness (≈5 μm for coblasttm. Surface Roughness After Grit Blasting.

From www.iqsdirectory.com

Sandblast What Is It? How Does It Work? Abrasives Surface Roughness After Grit Blasting When an engineer includes a surface finish spec on a print, the intent is usually not just to make. all the surface properties, viz. the surface roughness of the substrate after blasting is the feature parameter to evaluate the surface quality after pretreatment, as residual. the average surface roughness was close to the coatings’ thickness (≈5 μm. Surface Roughness After Grit Blasting.

From www.intechopen.com

Surface Characterization after Blasting IntechOpen Surface Roughness After Grit Blasting the average surface roughness was close to the coatings’ thickness (≈5 μm for coblasttm and ≈13 μm for plasma spray). the surface roughness of the substrate after blasting is the feature parameter to evaluate the surface quality after pretreatment, as residual. both the average surface roughness and grit residue were found to increase with the blasting angle.. Surface Roughness After Grit Blasting.

From www.dreamstime.com

Grey Rough Steel Surface after SA2.5 Grit Blast Cleaning Stock Image Surface Roughness After Grit Blasting all the surface properties, viz. blast pressure had the largest effect on surface roughness, as well as the highest linear correlation with roughness. the surface roughness of the substrate after blasting is the feature parameter to evaluate the surface quality after pretreatment, as residual. both the average surface roughness and grit residue were found to increase. Surface Roughness After Grit Blasting.

From testequipmentusa.com

SHOT AND GRIT BLASTING SURFACE ROUGHNESS SPECIMENTestEquipmentUSA Surface Roughness After Grit Blasting blast pressure had the largest effect on surface roughness, as well as the highest linear correlation with roughness. both the average surface roughness and grit residue were found to increase with the blasting angle. When an engineer includes a surface finish spec on a print, the intent is usually not just to make. the average surface roughness. Surface Roughness After Grit Blasting.

From www.kuegroup.com

GRIT BLASTING Guide How To Choose The Right Surface Preparation Surface Roughness After Grit Blasting the surface roughness of the substrate after blasting is the feature parameter to evaluate the surface quality after pretreatment, as residual. the average surface roughness was close to the coatings’ thickness (≈5 μm for coblasttm and ≈13 μm for plasma spray). all the surface properties, viz. When an engineer includes a surface finish spec on a print,. Surface Roughness After Grit Blasting.

From www.scribd.com

Grit Blasting and Surface Finish PDF Surface Roughness Teaching Surface Roughness After Grit Blasting blast pressure had the largest effect on surface roughness, as well as the highest linear correlation with roughness. based on the analysis of the results were also proposed sets of surface roughness parameters, which can be used. the average surface roughness was close to the coatings’ thickness (≈5 μm for coblasttm and ≈13 μm for plasma spray).. Surface Roughness After Grit Blasting.

From www.youtube.com

Wet VS Dry Blasting Surface Roughness Data Vapor Honing Technologies Surface Roughness After Grit Blasting all the surface properties, viz. both the average surface roughness and grit residue were found to increase with the blasting angle. When an engineer includes a surface finish spec on a print, the intent is usually not just to make. the average surface roughness was close to the coatings’ thickness (≈5 μm for coblasttm and ≈13 μm. Surface Roughness After Grit Blasting.

From fyonhxmdt.blob.core.windows.net

Surface Roughness Measurement Direction at Dolores Hargrove blog Surface Roughness After Grit Blasting based on the analysis of the results were also proposed sets of surface roughness parameters, which can be used. blast pressure had the largest effect on surface roughness, as well as the highest linear correlation with roughness. both the average surface roughness and grit residue were found to increase with the blasting angle. all the surface. Surface Roughness After Grit Blasting.

From www.mdpi.com

Inventions Free FullText The Influence of Different Type Materials Surface Roughness After Grit Blasting both the average surface roughness and grit residue were found to increase with the blasting angle. based on the analysis of the results were also proposed sets of surface roughness parameters, which can be used. all the surface properties, viz. the average surface roughness was close to the coatings’ thickness (≈5 μm for coblasttm and ≈13. Surface Roughness After Grit Blasting.

From www.researchgate.net

Surface roughness obtained by plano grinding with various grit sizes at Surface Roughness After Grit Blasting the surface roughness of the substrate after blasting is the feature parameter to evaluate the surface quality after pretreatment, as residual. based on the analysis of the results were also proposed sets of surface roughness parameters, which can be used. When an engineer includes a surface finish spec on a print, the intent is usually not just to. Surface Roughness After Grit Blasting.

From www.semanticscholar.org

Table 1 from SURFACE ROUGHNESS AT ALUMINIUM PARTS SAND BLASTING Surface Roughness After Grit Blasting When an engineer includes a surface finish spec on a print, the intent is usually not just to make. the average surface roughness was close to the coatings’ thickness (≈5 μm for coblasttm and ≈13 μm for plasma spray). all the surface properties, viz. blast pressure had the largest effect on surface roughness, as well as the. Surface Roughness After Grit Blasting.

From proleantech.com

Beadblasting Vs Sandblasting A Detailed Comparision Guide Surface Roughness After Grit Blasting both the average surface roughness and grit residue were found to increase with the blasting angle. blast pressure had the largest effect on surface roughness, as well as the highest linear correlation with roughness. based on the analysis of the results were also proposed sets of surface roughness parameters, which can be used. all the surface. Surface Roughness After Grit Blasting.

From www.graco.com

Concrete Surface Preparation Part 3 Grades of Concrete Roughness Surface Roughness After Grit Blasting the surface roughness of the substrate after blasting is the feature parameter to evaluate the surface quality after pretreatment, as residual. When an engineer includes a surface finish spec on a print, the intent is usually not just to make. the average surface roughness was close to the coatings’ thickness (≈5 μm for coblasttm and ≈13 μm for. Surface Roughness After Grit Blasting.

From www.researchgate.net

Equivalent grit roughness setting and surface roughness conversion Surface Roughness After Grit Blasting all the surface properties, viz. blast pressure had the largest effect on surface roughness, as well as the highest linear correlation with roughness. the average surface roughness was close to the coatings’ thickness (≈5 μm for coblasttm and ≈13 μm for plasma spray). based on the analysis of the results were also proposed sets of surface. Surface Roughness After Grit Blasting.

From facfox.com

Selecting right surface roughness for CNC machining FacFox Docs Surface Roughness After Grit Blasting blast pressure had the largest effect on surface roughness, as well as the highest linear correlation with roughness. the average surface roughness was close to the coatings’ thickness (≈5 μm for coblasttm and ≈13 μm for plasma spray). When an engineer includes a surface finish spec on a print, the intent is usually not just to make. . Surface Roughness After Grit Blasting.

From beadskinbright.blogspot.com

Bead Blasting Surface Roughness BEAD SKIN BRIGHT Surface Roughness After Grit Blasting based on the analysis of the results were also proposed sets of surface roughness parameters, which can be used. the average surface roughness was close to the coatings’ thickness (≈5 μm for coblasttm and ≈13 μm for plasma spray). both the average surface roughness and grit residue were found to increase with the blasting angle. When an. Surface Roughness After Grit Blasting.

From www.mdpi.com

Crystals Free FullText Effect of Grit Blasting and Polishing Surface Roughness After Grit Blasting When an engineer includes a surface finish spec on a print, the intent is usually not just to make. all the surface properties, viz. based on the analysis of the results were also proposed sets of surface roughness parameters, which can be used. blast pressure had the largest effect on surface roughness, as well as the highest. Surface Roughness After Grit Blasting.

From www.messmittel.tools

Grit blasting surface roughness ISO 8503 Surface Roughness After Grit Blasting both the average surface roughness and grit residue were found to increase with the blasting angle. the average surface roughness was close to the coatings’ thickness (≈5 μm for coblasttm and ≈13 μm for plasma spray). blast pressure had the largest effect on surface roughness, as well as the highest linear correlation with roughness. the surface. Surface Roughness After Grit Blasting.

From www.blastone.com

Surface Preparation Grades of Blast Cleaned Steel Blast Booths Spray Surface Roughness After Grit Blasting based on the analysis of the results were also proposed sets of surface roughness parameters, which can be used. the average surface roughness was close to the coatings’ thickness (≈5 μm for coblasttm and ≈13 μm for plasma spray). blast pressure had the largest effect on surface roughness, as well as the highest linear correlation with roughness.. Surface Roughness After Grit Blasting.

From www.dreamstime.com

Grey Rough Steel Surface after SA2.5 Grit Blast Cleaning Stock Image Surface Roughness After Grit Blasting all the surface properties, viz. the surface roughness of the substrate after blasting is the feature parameter to evaluate the surface quality after pretreatment, as residual. based on the analysis of the results were also proposed sets of surface roughness parameters, which can be used. the average surface roughness was close to the coatings’ thickness (≈5. Surface Roughness After Grit Blasting.

From tholat.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Surface Roughness After Grit Blasting both the average surface roughness and grit residue were found to increase with the blasting angle. based on the analysis of the results were also proposed sets of surface roughness parameters, which can be used. When an engineer includes a surface finish spec on a print, the intent is usually not just to make. the surface roughness. Surface Roughness After Grit Blasting.