Casting Mold Wash . Use in spraying, brushing, dipping or flow coating applications. Sufficient and workable lubricating properties at higher temperatures. Implementation of a cooling effect by adjusting various parts’ temps for relative stability. There are 7 types of casting defects caused by unsuitable mold material. Idea for casting of heavy section irons and steels. Defects in casting represent unwanted abnormality in the metal casting manufacturing process. These are areas of excess metals that occur when the molten metal washes away part of the molding sand. The different types of defects include surface defects, inclusion defects, molding and pouring defects, and cooling defects. Spherecoat prevents erosion of cores and molds during filling and prevents the molten metal from reacting with the molds materials. Some casting defects like a very rough surface are visible to the unassisted eye. Improvement of the overall casting quality and production efficiency. When this happens, the sand does not have enough strength to resist erosion.

from prototool.com

The different types of defects include surface defects, inclusion defects, molding and pouring defects, and cooling defects. These are areas of excess metals that occur when the molten metal washes away part of the molding sand. Use in spraying, brushing, dipping or flow coating applications. Defects in casting represent unwanted abnormality in the metal casting manufacturing process. Spherecoat prevents erosion of cores and molds during filling and prevents the molten metal from reacting with the molds materials. Improvement of the overall casting quality and production efficiency. Idea for casting of heavy section irons and steels. Implementation of a cooling effect by adjusting various parts’ temps for relative stability. When this happens, the sand does not have enough strength to resist erosion. Some casting defects like a very rough surface are visible to the unassisted eye.

Die Casting Mold Designing Tips 7 Steps Guide From Expert

Casting Mold Wash Defects in casting represent unwanted abnormality in the metal casting manufacturing process. Some casting defects like a very rough surface are visible to the unassisted eye. When this happens, the sand does not have enough strength to resist erosion. These are areas of excess metals that occur when the molten metal washes away part of the molding sand. There are 7 types of casting defects caused by unsuitable mold material. Defects in casting represent unwanted abnormality in the metal casting manufacturing process. The different types of defects include surface defects, inclusion defects, molding and pouring defects, and cooling defects. Spherecoat prevents erosion of cores and molds during filling and prevents the molten metal from reacting with the molds materials. Improvement of the overall casting quality and production efficiency. Sufficient and workable lubricating properties at higher temperatures. Implementation of a cooling effect by adjusting various parts’ temps for relative stability. Use in spraying, brushing, dipping or flow coating applications. Idea for casting of heavy section irons and steels.

From device.report

ROCKLER Silicone Handle Bank Casting Mold Instructions Casting Mold Wash Defects in casting represent unwanted abnormality in the metal casting manufacturing process. Improvement of the overall casting quality and production efficiency. Implementation of a cooling effect by adjusting various parts’ temps for relative stability. When this happens, the sand does not have enough strength to resist erosion. Spherecoat prevents erosion of cores and molds during filling and prevents the molten. Casting Mold Wash.

From www.millercastings.com

Mold Production » Miller Castings Casting Mold Wash Defects in casting represent unwanted abnormality in the metal casting manufacturing process. Spherecoat prevents erosion of cores and molds during filling and prevents the molten metal from reacting with the molds materials. Idea for casting of heavy section irons and steels. Implementation of a cooling effect by adjusting various parts’ temps for relative stability. When this happens, the sand does. Casting Mold Wash.

From www.youtube.com

LIVE How To Make Molds For Concrete Casting YouTube Casting Mold Wash The different types of defects include surface defects, inclusion defects, molding and pouring defects, and cooling defects. Spherecoat prevents erosion of cores and molds during filling and prevents the molten metal from reacting with the molds materials. Idea for casting of heavy section irons and steels. When this happens, the sand does not have enough strength to resist erosion. Sufficient. Casting Mold Wash.

From www.xometry.com

Ceramic Mold Casting Definition, Importance, How It Works Casting Mold Wash Spherecoat prevents erosion of cores and molds during filling and prevents the molten metal from reacting with the molds materials. Implementation of a cooling effect by adjusting various parts’ temps for relative stability. Use in spraying, brushing, dipping or flow coating applications. When this happens, the sand does not have enough strength to resist erosion. Some casting defects like a. Casting Mold Wash.

From www.pinterest.com

Casting in new molds Resin jewelry making, Mold making materials Casting Mold Wash Spherecoat prevents erosion of cores and molds during filling and prevents the molten metal from reacting with the molds materials. These are areas of excess metals that occur when the molten metal washes away part of the molding sand. Defects in casting represent unwanted abnormality in the metal casting manufacturing process. Some casting defects like a very rough surface are. Casting Mold Wash.

From www.ceramickingdomberlin.com

Moldmaking and Slipcasting — Ceramic Kingdom Casting Mold Wash These are areas of excess metals that occur when the molten metal washes away part of the molding sand. Use in spraying, brushing, dipping or flow coating applications. The different types of defects include surface defects, inclusion defects, molding and pouring defects, and cooling defects. There are 7 types of casting defects caused by unsuitable mold material. Some casting defects. Casting Mold Wash.

From prototool.com

Die Casting Mold Designing Tips 7 Steps Guide From Expert Casting Mold Wash These are areas of excess metals that occur when the molten metal washes away part of the molding sand. Idea for casting of heavy section irons and steels. The different types of defects include surface defects, inclusion defects, molding and pouring defects, and cooling defects. Spherecoat prevents erosion of cores and molds during filling and prevents the molten metal from. Casting Mold Wash.

From www.iqsdirectory.com

Permanent Mold Castings What Is It? How Does It Work? Advantages Casting Mold Wash Implementation of a cooling effect by adjusting various parts’ temps for relative stability. Improvement of the overall casting quality and production efficiency. Sufficient and workable lubricating properties at higher temperatures. Defects in casting represent unwanted abnormality in the metal casting manufacturing process. Spherecoat prevents erosion of cores and molds during filling and prevents the molten metal from reacting with the. Casting Mold Wash.

From prototool.com

Die Casting Mold Designing Tips 7 Steps Guide From Expert Casting Mold Wash Spherecoat prevents erosion of cores and molds during filling and prevents the molten metal from reacting with the molds materials. Some casting defects like a very rough surface are visible to the unassisted eye. These are areas of excess metals that occur when the molten metal washes away part of the molding sand. The different types of defects include surface. Casting Mold Wash.

From precisecast.com

Plaster Mold Casting Metal Casting Processes Learn More Casting Mold Wash Sufficient and workable lubricating properties at higher temperatures. Idea for casting of heavy section irons and steels. There are 7 types of casting defects caused by unsuitable mold material. When this happens, the sand does not have enough strength to resist erosion. Improvement of the overall casting quality and production efficiency. Use in spraying, brushing, dipping or flow coating applications.. Casting Mold Wash.

From www.humboldtmfg.com

Three Wheel Polishing Device Casting Mold Casting Mold Wash Improvement of the overall casting quality and production efficiency. There are 7 types of casting defects caused by unsuitable mold material. Spherecoat prevents erosion of cores and molds during filling and prevents the molten metal from reacting with the molds materials. When this happens, the sand does not have enough strength to resist erosion. Idea for casting of heavy section. Casting Mold Wash.

From www.iqsdirectory.com

Iron Castings Types, Applications, Process, and Benefits Casting Mold Wash The different types of defects include surface defects, inclusion defects, molding and pouring defects, and cooling defects. Defects in casting represent unwanted abnormality in the metal casting manufacturing process. These are areas of excess metals that occur when the molten metal washes away part of the molding sand. Use in spraying, brushing, dipping or flow coating applications. When this happens,. Casting Mold Wash.

From www.youtube.com

Shell Mold Casting Process 3D Animation YouTube Casting Mold Wash Sufficient and workable lubricating properties at higher temperatures. When this happens, the sand does not have enough strength to resist erosion. These are areas of excess metals that occur when the molten metal washes away part of the molding sand. Defects in casting represent unwanted abnormality in the metal casting manufacturing process. Idea for casting of heavy section irons and. Casting Mold Wash.

From vietnamcastiron.com

Instructions for Making Sand Casting Molds in detail Step by Step Casting Mold Wash These are areas of excess metals that occur when the molten metal washes away part of the molding sand. Defects in casting represent unwanted abnormality in the metal casting manufacturing process. Sufficient and workable lubricating properties at higher temperatures. The different types of defects include surface defects, inclusion defects, molding and pouring defects, and cooling defects. There are 7 types. Casting Mold Wash.

From www.clinchrivercasting.com

Molding Clinch River Casting NoBake Casting Foundry Casting Mold Wash Sufficient and workable lubricating properties at higher temperatures. Some casting defects like a very rough surface are visible to the unassisted eye. Use in spraying, brushing, dipping or flow coating applications. Defects in casting represent unwanted abnormality in the metal casting manufacturing process. The different types of defects include surface defects, inclusion defects, molding and pouring defects, and cooling defects.. Casting Mold Wash.

From www.leclairemfg.com

Ultimate Guide to the Permanent Mold Casting Process Casting Mold Wash Spherecoat prevents erosion of cores and molds during filling and prevents the molten metal from reacting with the molds materials. Implementation of a cooling effect by adjusting various parts’ temps for relative stability. Defects in casting represent unwanted abnormality in the metal casting manufacturing process. There are 7 types of casting defects caused by unsuitable mold material. Some casting defects. Casting Mold Wash.

From www.youtube.com

Sand Casting Molding Processes Binders Patterns Core Making Casting Mold Wash Use in spraying, brushing, dipping or flow coating applications. These are areas of excess metals that occur when the molten metal washes away part of the molding sand. The different types of defects include surface defects, inclusion defects, molding and pouring defects, and cooling defects. Some casting defects like a very rough surface are visible to the unassisted eye. Idea. Casting Mold Wash.

From ceramicsmokeware.com

How slip casting and plaster molds work Ceramic Smokeware Casting Mold Wash When this happens, the sand does not have enough strength to resist erosion. These are areas of excess metals that occur when the molten metal washes away part of the molding sand. Sufficient and workable lubricating properties at higher temperatures. Improvement of the overall casting quality and production efficiency. The different types of defects include surface defects, inclusion defects, molding. Casting Mold Wash.

From castingod.com

MOLD CASTING DESIGN FOR CUSTOM PARTS 11 features Casting Mold Wash Defects in casting represent unwanted abnormality in the metal casting manufacturing process. Idea for casting of heavy section irons and steels. There are 7 types of casting defects caused by unsuitable mold material. Use in spraying, brushing, dipping or flow coating applications. The different types of defects include surface defects, inclusion defects, molding and pouring defects, and cooling defects. Sufficient. Casting Mold Wash.

From www.diecasting-mould.com

Permanent Mold Casting vs Die Casting vs Sand Casting What is Casting Mold Wash Improvement of the overall casting quality and production efficiency. These are areas of excess metals that occur when the molten metal washes away part of the molding sand. Defects in casting represent unwanted abnormality in the metal casting manufacturing process. There are 7 types of casting defects caused by unsuitable mold material. Some casting defects like a very rough surface. Casting Mold Wash.

From www.diecasting-mould.com

Die Casting Mold Manufacturer & Supplier Mold Making Service Junying Casting Mold Wash The different types of defects include surface defects, inclusion defects, molding and pouring defects, and cooling defects. There are 7 types of casting defects caused by unsuitable mold material. Sufficient and workable lubricating properties at higher temperatures. Some casting defects like a very rough surface are visible to the unassisted eye. Defects in casting represent unwanted abnormality in the metal. Casting Mold Wash.

From www.ace-mold.com

Die Casting Mould Material for Industrial Applications Casting Mold Wash Improvement of the overall casting quality and production efficiency. These are areas of excess metals that occur when the molten metal washes away part of the molding sand. There are 7 types of casting defects caused by unsuitable mold material. Some casting defects like a very rough surface are visible to the unassisted eye. The different types of defects include. Casting Mold Wash.

From www.youtube.com

The Basic Permanent Mold Casting Process YouTube Casting Mold Wash Some casting defects like a very rough surface are visible to the unassisted eye. When this happens, the sand does not have enough strength to resist erosion. Use in spraying, brushing, dipping or flow coating applications. Implementation of a cooling effect by adjusting various parts’ temps for relative stability. Sufficient and workable lubricating properties at higher temperatures. The different types. Casting Mold Wash.

From batesvilleproducts.com

Aluminum permanent mold castings Batesville products, inc. Casting Mold Wash There are 7 types of casting defects caused by unsuitable mold material. Some casting defects like a very rough surface are visible to the unassisted eye. Defects in casting represent unwanted abnormality in the metal casting manufacturing process. Improvement of the overall casting quality and production efficiency. Spherecoat prevents erosion of cores and molds during filling and prevents the molten. Casting Mold Wash.

From blog.eaglegroupmanufacturers.com

Getting Started with Permanent Mold Casting Casting Mold Wash Use in spraying, brushing, dipping or flow coating applications. The different types of defects include surface defects, inclusion defects, molding and pouring defects, and cooling defects. Sufficient and workable lubricating properties at higher temperatures. Some casting defects like a very rough surface are visible to the unassisted eye. Spherecoat prevents erosion of cores and molds during filling and prevents the. Casting Mold Wash.

From thelibraryofmanufacturing.com

Basic Permanent Mold Casting Casting Mold Wash Implementation of a cooling effect by adjusting various parts’ temps for relative stability. These are areas of excess metals that occur when the molten metal washes away part of the molding sand. Spherecoat prevents erosion of cores and molds during filling and prevents the molten metal from reacting with the molds materials. There are 7 types of casting defects caused. Casting Mold Wash.

From www.youtube.com

Die Casting Permanent Mold Casting Processes. YouTube Casting Mold Wash The different types of defects include surface defects, inclusion defects, molding and pouring defects, and cooling defects. Use in spraying, brushing, dipping or flow coating applications. Improvement of the overall casting quality and production efficiency. Implementation of a cooling effect by adjusting various parts’ temps for relative stability. Idea for casting of heavy section irons and steels. Sufficient and workable. Casting Mold Wash.

From www.reliance-foundry.com

Shakeout, Cleaning, and Machining Metal Casting Blog Casting Mold Wash The different types of defects include surface defects, inclusion defects, molding and pouring defects, and cooling defects. When this happens, the sand does not have enough strength to resist erosion. Use in spraying, brushing, dipping or flow coating applications. Sufficient and workable lubricating properties at higher temperatures. Some casting defects like a very rough surface are visible to the unassisted. Casting Mold Wash.

From making-a-mold.blogspot.com

Mold making and Casting products through EnvironMolds, LLC Backdating Casting Mold Wash Use in spraying, brushing, dipping or flow coating applications. Improvement of the overall casting quality and production efficiency. Implementation of a cooling effect by adjusting various parts’ temps for relative stability. Spherecoat prevents erosion of cores and molds during filling and prevents the molten metal from reacting with the molds materials. Some casting defects like a very rough surface are. Casting Mold Wash.

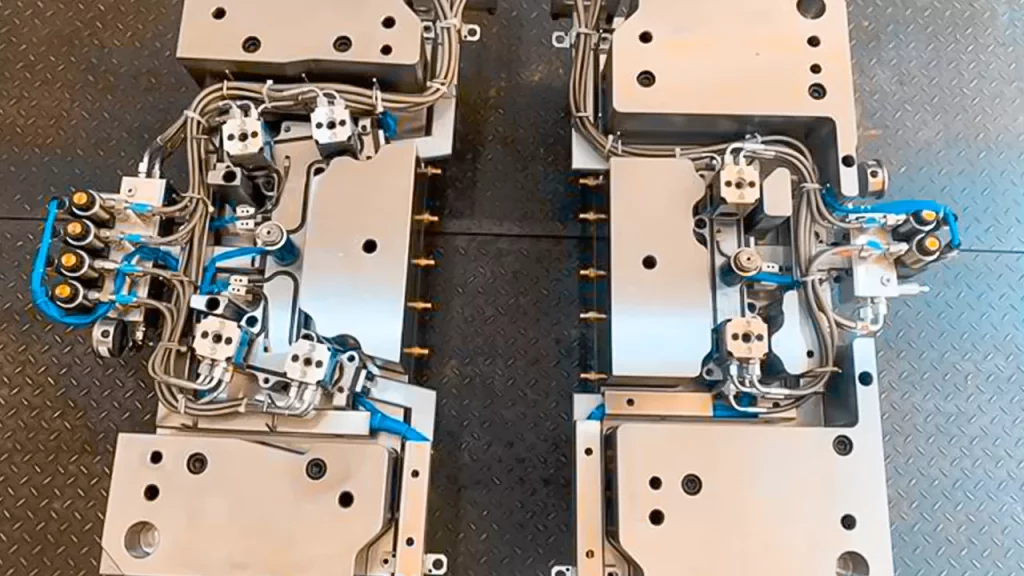

From www.kalmbach.de

Mold engineering for die casting Casting Mold Wash Idea for casting of heavy section irons and steels. Use in spraying, brushing, dipping or flow coating applications. There are 7 types of casting defects caused by unsuitable mold material. The different types of defects include surface defects, inclusion defects, molding and pouring defects, and cooling defects. Improvement of the overall casting quality and production efficiency. Defects in casting represent. Casting Mold Wash.

From customcastings.com

customcastingsmolds2 Custom Castings Casting Mold Wash Idea for casting of heavy section irons and steels. These are areas of excess metals that occur when the molten metal washes away part of the molding sand. Defects in casting represent unwanted abnormality in the metal casting manufacturing process. The different types of defects include surface defects, inclusion defects, molding and pouring defects, and cooling defects. Improvement of the. Casting Mold Wash.

From www.youtube.com

Mold Making and Casting Tutorials From SmoothOn YouTube Casting Mold Wash Use in spraying, brushing, dipping or flow coating applications. These are areas of excess metals that occur when the molten metal washes away part of the molding sand. Improvement of the overall casting quality and production efficiency. Implementation of a cooling effect by adjusting various parts’ temps for relative stability. Some casting defects like a very rough surface are visible. Casting Mold Wash.

From blog.eaglegroupmanufacturers.com

Tooling for Shell Mold Casting Casting Mold Wash Improvement of the overall casting quality and production efficiency. There are 7 types of casting defects caused by unsuitable mold material. Idea for casting of heavy section irons and steels. Some casting defects like a very rough surface are visible to the unassisted eye. When this happens, the sand does not have enough strength to resist erosion. These are areas. Casting Mold Wash.

From www.youtube.com

Shell Mould Casting Shell Moulding Process PPT ENGINEERING STUDY Casting Mold Wash Sufficient and workable lubricating properties at higher temperatures. The different types of defects include surface defects, inclusion defects, molding and pouring defects, and cooling defects. Use in spraying, brushing, dipping or flow coating applications. Implementation of a cooling effect by adjusting various parts’ temps for relative stability. Improvement of the overall casting quality and production efficiency. These are areas of. Casting Mold Wash.

From www.sunrise-metal.com

Die Casting Mold Expert Sunrise Metal Your Reliable Partner Casting Mold Wash Use in spraying, brushing, dipping or flow coating applications. Improvement of the overall casting quality and production efficiency. Spherecoat prevents erosion of cores and molds during filling and prevents the molten metal from reacting with the molds materials. Sufficient and workable lubricating properties at higher temperatures. Defects in casting represent unwanted abnormality in the metal casting manufacturing process. Idea for. Casting Mold Wash.