Dimensional Tolerancing . These are the main benefits of using geometric dimensioning and tolerancing (gd&t): Gd&t, short for geometric dimensioning and tolerancing, is a system for defining and communicating design intent and. The use of tolerances helps to ensure that the final product is readily usable, especially if it is a part of a larger assembly. Geometric dimensioning and tolerancing (gd&t) is a tolerancing technique that is used in the mechanical design process to control the fit and function of parts and assemblies. It complements traditional “plus and minus” dimensional tolerancing by letting you control 14 different geometric characteristics. Dimensional tolerancing refers to the permissible limits or boundaries for the physical dimensions of manufactured parts, ensuring consistency. Geometric tolerances, indicated by special symbols related to part surfaces. “the y14.5 standard is considered the authoritative guideline for the design language of geometric dimensioning and tolerancing. Direct limits, or as tolerance values applied directly to a dimension. In mechanical engineering, tolerances set the allowable deviation from assigned dimensions.

from www.scribd.com

Dimensional tolerancing refers to the permissible limits or boundaries for the physical dimensions of manufactured parts, ensuring consistency. It complements traditional “plus and minus” dimensional tolerancing by letting you control 14 different geometric characteristics. Geometric tolerances, indicated by special symbols related to part surfaces. Direct limits, or as tolerance values applied directly to a dimension. Gd&t, short for geometric dimensioning and tolerancing, is a system for defining and communicating design intent and. These are the main benefits of using geometric dimensioning and tolerancing (gd&t): In mechanical engineering, tolerances set the allowable deviation from assigned dimensions. “the y14.5 standard is considered the authoritative guideline for the design language of geometric dimensioning and tolerancing. The use of tolerances helps to ensure that the final product is readily usable, especially if it is a part of a larger assembly. Geometric dimensioning and tolerancing (gd&t) is a tolerancing technique that is used in the mechanical design process to control the fit and function of parts and assemblies.

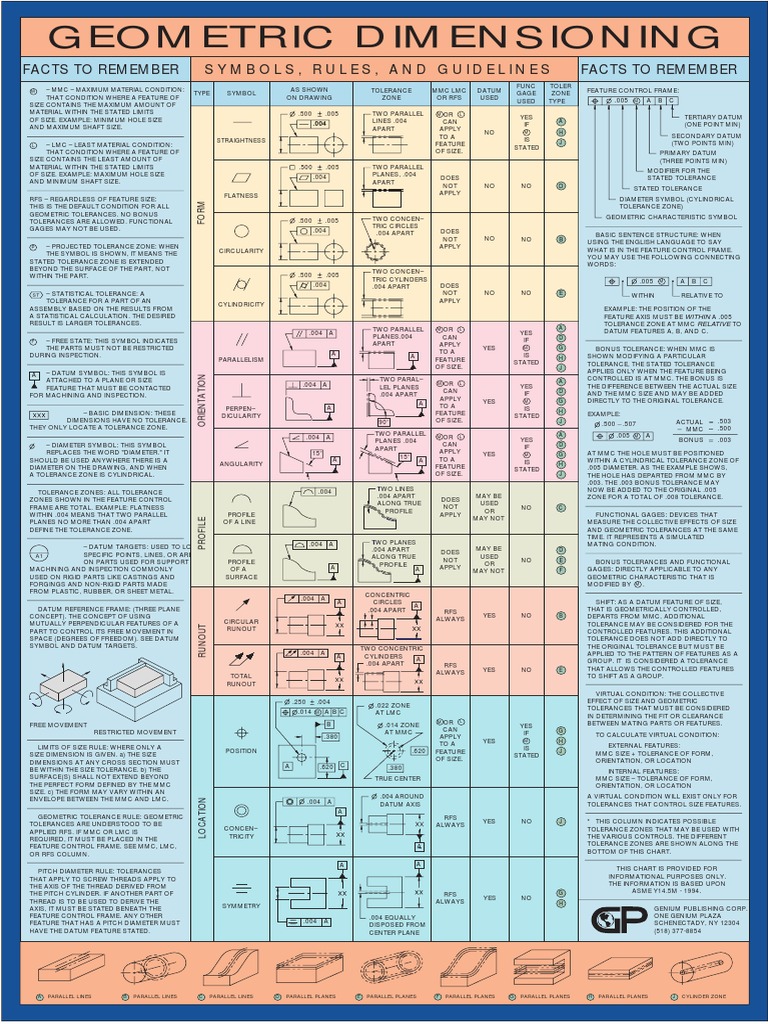

Geometric Tolerance Chart Engineering Tolerance Geometry

Dimensional Tolerancing Gd&t, short for geometric dimensioning and tolerancing, is a system for defining and communicating design intent and. In mechanical engineering, tolerances set the allowable deviation from assigned dimensions. Geometric tolerances, indicated by special symbols related to part surfaces. These are the main benefits of using geometric dimensioning and tolerancing (gd&t): Gd&t, short for geometric dimensioning and tolerancing, is a system for defining and communicating design intent and. It complements traditional “plus and minus” dimensional tolerancing by letting you control 14 different geometric characteristics. Geometric dimensioning and tolerancing (gd&t) is a tolerancing technique that is used in the mechanical design process to control the fit and function of parts and assemblies. Dimensional tolerancing refers to the permissible limits or boundaries for the physical dimensions of manufactured parts, ensuring consistency. The use of tolerances helps to ensure that the final product is readily usable, especially if it is a part of a larger assembly. “the y14.5 standard is considered the authoritative guideline for the design language of geometric dimensioning and tolerancing. Direct limits, or as tolerance values applied directly to a dimension.

From mavink.com

Geometric Tolerance Chart Dimensional Tolerancing Gd&t, short for geometric dimensioning and tolerancing, is a system for defining and communicating design intent and. It complements traditional “plus and minus” dimensional tolerancing by letting you control 14 different geometric characteristics. These are the main benefits of using geometric dimensioning and tolerancing (gd&t): In mechanical engineering, tolerances set the allowable deviation from assigned dimensions. Direct limits, or as. Dimensional Tolerancing.

From www.scribd.com

Geometric Tolerance Chart Engineering Tolerance Geometry Dimensional Tolerancing Direct limits, or as tolerance values applied directly to a dimension. In mechanical engineering, tolerances set the allowable deviation from assigned dimensions. Gd&t, short for geometric dimensioning and tolerancing, is a system for defining and communicating design intent and. These are the main benefits of using geometric dimensioning and tolerancing (gd&t): “the y14.5 standard is considered the authoritative guideline for. Dimensional Tolerancing.

From www.chegg.com

Geometric Dimensioning and Tolerancing Consider the Dimensional Tolerancing Dimensional tolerancing refers to the permissible limits or boundaries for the physical dimensions of manufactured parts, ensuring consistency. The use of tolerances helps to ensure that the final product is readily usable, especially if it is a part of a larger assembly. These are the main benefits of using geometric dimensioning and tolerancing (gd&t): In mechanical engineering, tolerances set the. Dimensional Tolerancing.

From www.pinterest.com

GD&T 101 An Introduction to Geometric Dimensioning and Tolerancing Dimensional Tolerancing In mechanical engineering, tolerances set the allowable deviation from assigned dimensions. Geometric dimensioning and tolerancing (gd&t) is a tolerancing technique that is used in the mechanical design process to control the fit and function of parts and assemblies. Dimensional tolerancing refers to the permissible limits or boundaries for the physical dimensions of manufactured parts, ensuring consistency. Gd&t, short for geometric. Dimensional Tolerancing.

From cqeacademy.com

Engineering Drawings & GD&T For the Quality Engineer Dimensional Tolerancing The use of tolerances helps to ensure that the final product is readily usable, especially if it is a part of a larger assembly. Dimensional tolerancing refers to the permissible limits or boundaries for the physical dimensions of manufactured parts, ensuring consistency. “the y14.5 standard is considered the authoritative guideline for the design language of geometric dimensioning and tolerancing. Direct. Dimensional Tolerancing.

From americanbobcat.blog

MECHANICAL DESIGN ENGINEERING Geometrical Dimensioning and Dimensional Tolerancing “the y14.5 standard is considered the authoritative guideline for the design language of geometric dimensioning and tolerancing. It complements traditional “plus and minus” dimensional tolerancing by letting you control 14 different geometric characteristics. Dimensional tolerancing refers to the permissible limits or boundaries for the physical dimensions of manufactured parts, ensuring consistency. The use of tolerances helps to ensure that the. Dimensional Tolerancing.

From moldedgroup.com

Dimensional Tolerancing Molded Dimensions Group Dimensional Tolerancing Geometric dimensioning and tolerancing (gd&t) is a tolerancing technique that is used in the mechanical design process to control the fit and function of parts and assemblies. “the y14.5 standard is considered the authoritative guideline for the design language of geometric dimensioning and tolerancing. It complements traditional “plus and minus” dimensional tolerancing by letting you control 14 different geometric characteristics.. Dimensional Tolerancing.

From www.youtube.com

Indicators for Dimensional Tolerancing Creo Elements/Direct Modeling Dimensional Tolerancing Geometric dimensioning and tolerancing (gd&t) is a tolerancing technique that is used in the mechanical design process to control the fit and function of parts and assemblies. In mechanical engineering, tolerances set the allowable deviation from assigned dimensions. It complements traditional “plus and minus” dimensional tolerancing by letting you control 14 different geometric characteristics. Gd&t, short for geometric dimensioning and. Dimensional Tolerancing.

From get-it-made.co.uk

Geometric Dimensioning and Tolerancing Get It Made Dimensional Tolerancing Geometric tolerances, indicated by special symbols related to part surfaces. In mechanical engineering, tolerances set the allowable deviation from assigned dimensions. Direct limits, or as tolerance values applied directly to a dimension. Dimensional tolerancing refers to the permissible limits or boundaries for the physical dimensions of manufactured parts, ensuring consistency. These are the main benefits of using geometric dimensioning and. Dimensional Tolerancing.

From www.mcgill.ca

Principles of Tolerancing Engineering Design McGill University Dimensional Tolerancing The use of tolerances helps to ensure that the final product is readily usable, especially if it is a part of a larger assembly. Gd&t, short for geometric dimensioning and tolerancing, is a system for defining and communicating design intent and. In mechanical engineering, tolerances set the allowable deviation from assigned dimensions. Geometric tolerances, indicated by special symbols related to. Dimensional Tolerancing.

From www.youtube.com

Dimensional tolerancing of a shaft YouTube Dimensional Tolerancing These are the main benefits of using geometric dimensioning and tolerancing (gd&t): It complements traditional “plus and minus” dimensional tolerancing by letting you control 14 different geometric characteristics. Dimensional tolerancing refers to the permissible limits or boundaries for the physical dimensions of manufactured parts, ensuring consistency. The use of tolerances helps to ensure that the final product is readily usable,. Dimensional Tolerancing.

From mavink.com

Geometric Tolerancing Symbols Chart Dimensional Tolerancing “the y14.5 standard is considered the authoritative guideline for the design language of geometric dimensioning and tolerancing. Dimensional tolerancing refers to the permissible limits or boundaries for the physical dimensions of manufactured parts, ensuring consistency. In mechanical engineering, tolerances set the allowable deviation from assigned dimensions. Gd&t, short for geometric dimensioning and tolerancing, is a system for defining and communicating. Dimensional Tolerancing.

From www.slideserve.com

PPT Geometric Dimensioning and Tolerance PowerPoint Presentation Dimensional Tolerancing “the y14.5 standard is considered the authoritative guideline for the design language of geometric dimensioning and tolerancing. These are the main benefits of using geometric dimensioning and tolerancing (gd&t): It complements traditional “plus and minus” dimensional tolerancing by letting you control 14 different geometric characteristics. The use of tolerances helps to ensure that the final product is readily usable, especially. Dimensional Tolerancing.

From en.wikipedia.org

Geometric dimensioning and tolerancing Wikipedia Dimensional Tolerancing Geometric dimensioning and tolerancing (gd&t) is a tolerancing technique that is used in the mechanical design process to control the fit and function of parts and assemblies. It complements traditional “plus and minus” dimensional tolerancing by letting you control 14 different geometric characteristics. Geometric tolerances, indicated by special symbols related to part surfaces. Gd&t, short for geometric dimensioning and tolerancing,. Dimensional Tolerancing.

From www.fictiv.com

GD&T 101 An Introduction to Geometric Dimensioning and Tolerancing Dimensional Tolerancing Geometric dimensioning and tolerancing (gd&t) is a tolerancing technique that is used in the mechanical design process to control the fit and function of parts and assemblies. Gd&t, short for geometric dimensioning and tolerancing, is a system for defining and communicating design intent and. In mechanical engineering, tolerances set the allowable deviation from assigned dimensions. These are the main benefits. Dimensional Tolerancing.

From www.manufacturinget.org

Geometric Dimensioning and Tolerancing Dimensional Tolerancing These are the main benefits of using geometric dimensioning and tolerancing (gd&t): Geometric tolerances, indicated by special symbols related to part surfaces. Direct limits, or as tolerance values applied directly to a dimension. Dimensional tolerancing refers to the permissible limits or boundaries for the physical dimensions of manufactured parts, ensuring consistency. “the y14.5 standard is considered the authoritative guideline for. Dimensional Tolerancing.

From www.slideserve.com

PPT GEOMETRIC DIMENSIONING AND TOLERANCING (GD&T) PowerPoint Dimensional Tolerancing “the y14.5 standard is considered the authoritative guideline for the design language of geometric dimensioning and tolerancing. In mechanical engineering, tolerances set the allowable deviation from assigned dimensions. It complements traditional “plus and minus” dimensional tolerancing by letting you control 14 different geometric characteristics. Geometric tolerances, indicated by special symbols related to part surfaces. Geometric dimensioning and tolerancing (gd&t) is. Dimensional Tolerancing.

From www.youtube.com

PowerPoint kit for presenting Geometric Tolerancing Fundamentals Dimensional Tolerancing In mechanical engineering, tolerances set the allowable deviation from assigned dimensions. The use of tolerances helps to ensure that the final product is readily usable, especially if it is a part of a larger assembly. Direct limits, or as tolerance values applied directly to a dimension. Gd&t, short for geometric dimensioning and tolerancing, is a system for defining and communicating. Dimensional Tolerancing.

From www.youtube.com

Rule 1 for Geometric Dimensioning and Tolerancing (GD&T) YouTube Dimensional Tolerancing “the y14.5 standard is considered the authoritative guideline for the design language of geometric dimensioning and tolerancing. It complements traditional “plus and minus” dimensional tolerancing by letting you control 14 different geometric characteristics. Geometric dimensioning and tolerancing (gd&t) is a tolerancing technique that is used in the mechanical design process to control the fit and function of parts and assemblies.. Dimensional Tolerancing.

From www.pinterest.ca

Drawing with tolerances Geometric tolerancing, Technical drawing Dimensional Tolerancing Geometric tolerances, indicated by special symbols related to part surfaces. The use of tolerances helps to ensure that the final product is readily usable, especially if it is a part of a larger assembly. In mechanical engineering, tolerances set the allowable deviation from assigned dimensions. Gd&t, short for geometric dimensioning and tolerancing, is a system for defining and communicating design. Dimensional Tolerancing.

From www.surajmech.com

Geometric Dimensioning and Tolerancing (GD & T) Dimensional Tolerancing “the y14.5 standard is considered the authoritative guideline for the design language of geometric dimensioning and tolerancing. The use of tolerances helps to ensure that the final product is readily usable, especially if it is a part of a larger assembly. Geometric dimensioning and tolerancing (gd&t) is a tolerancing technique that is used in the mechanical design process to control. Dimensional Tolerancing.

From moldedgroup.com

Dimensional Tolerancing Molded Dimensions Group Dimensional Tolerancing The use of tolerances helps to ensure that the final product is readily usable, especially if it is a part of a larger assembly. It complements traditional “plus and minus” dimensional tolerancing by letting you control 14 different geometric characteristics. Geometric dimensioning and tolerancing (gd&t) is a tolerancing technique that is used in the mechanical design process to control the. Dimensional Tolerancing.

From www.rmgtech.in

GD&T Basics of Geometric Dimensioning and Tolerance Dimensional Tolerancing Direct limits, or as tolerance values applied directly to a dimension. Geometric dimensioning and tolerancing (gd&t) is a tolerancing technique that is used in the mechanical design process to control the fit and function of parts and assemblies. In mechanical engineering, tolerances set the allowable deviation from assigned dimensions. “the y14.5 standard is considered the authoritative guideline for the design. Dimensional Tolerancing.

From mavink.com

Geometric Tolerancing Symbols Chart Dimensional Tolerancing Direct limits, or as tolerance values applied directly to a dimension. Gd&t, short for geometric dimensioning and tolerancing, is a system for defining and communicating design intent and. It complements traditional “plus and minus” dimensional tolerancing by letting you control 14 different geometric characteristics. In mechanical engineering, tolerances set the allowable deviation from assigned dimensions. “the y14.5 standard is considered. Dimensional Tolerancing.

From americanbobcat.blog

MECHANICAL DESIGN ENGINEERING Geometrical Dimensioning and Dimensional Tolerancing “the y14.5 standard is considered the authoritative guideline for the design language of geometric dimensioning and tolerancing. Direct limits, or as tolerance values applied directly to a dimension. The use of tolerances helps to ensure that the final product is readily usable, especially if it is a part of a larger assembly. Geometric dimensioning and tolerancing (gd&t) is a tolerancing. Dimensional Tolerancing.

From www.mcgill.ca

Principles of Tolerancing Engineering Design McGill University Dimensional Tolerancing These are the main benefits of using geometric dimensioning and tolerancing (gd&t): Gd&t, short for geometric dimensioning and tolerancing, is a system for defining and communicating design intent and. Dimensional tolerancing refers to the permissible limits or boundaries for the physical dimensions of manufactured parts, ensuring consistency. The use of tolerances helps to ensure that the final product is readily. Dimensional Tolerancing.

From www.engineeringpassion.com

Geometric Dimensioning and Tolerancing in Engineering Designs Dimensional Tolerancing Geometric tolerances, indicated by special symbols related to part surfaces. Direct limits, or as tolerance values applied directly to a dimension. Gd&t, short for geometric dimensioning and tolerancing, is a system for defining and communicating design intent and. The use of tolerances helps to ensure that the final product is readily usable, especially if it is a part of a. Dimensional Tolerancing.

From formlabs.com

The Basics of Geometric Dimensioning and Tolerancing (GD&T) Dimensional Tolerancing Dimensional tolerancing refers to the permissible limits or boundaries for the physical dimensions of manufactured parts, ensuring consistency. “the y14.5 standard is considered the authoritative guideline for the design language of geometric dimensioning and tolerancing. It complements traditional “plus and minus” dimensional tolerancing by letting you control 14 different geometric characteristics. Geometric tolerances, indicated by special symbols related to part. Dimensional Tolerancing.

From www.researchgate.net

Dimensional tolerancing after face turning with uncoated mixed alumina Dimensional Tolerancing Direct limits, or as tolerance values applied directly to a dimension. In mechanical engineering, tolerances set the allowable deviation from assigned dimensions. The use of tolerances helps to ensure that the final product is readily usable, especially if it is a part of a larger assembly. It complements traditional “plus and minus” dimensional tolerancing by letting you control 14 different. Dimensional Tolerancing.

From www.wasyresearch.com

3D tolerance stackup analysis with examples Dimensional Tolerancing Geometric dimensioning and tolerancing (gd&t) is a tolerancing technique that is used in the mechanical design process to control the fit and function of parts and assemblies. Geometric tolerances, indicated by special symbols related to part surfaces. Dimensional tolerancing refers to the permissible limits or boundaries for the physical dimensions of manufactured parts, ensuring consistency. It complements traditional “plus and. Dimensional Tolerancing.

From www.fictiv.com

GD&T 101 An Introduction to Geometric Dimensioning and Tolerancing Dimensional Tolerancing Direct limits, or as tolerance values applied directly to a dimension. The use of tolerances helps to ensure that the final product is readily usable, especially if it is a part of a larger assembly. Geometric tolerances, indicated by special symbols related to part surfaces. In mechanical engineering, tolerances set the allowable deviation from assigned dimensions. Dimensional tolerancing refers to. Dimensional Tolerancing.

From www.slideserve.com

PPT Geometric Dimensioning and Tolerancing PowerPoint Presentation Dimensional Tolerancing These are the main benefits of using geometric dimensioning and tolerancing (gd&t): Direct limits, or as tolerance values applied directly to a dimension. “the y14.5 standard is considered the authoritative guideline for the design language of geometric dimensioning and tolerancing. Dimensional tolerancing refers to the permissible limits or boundaries for the physical dimensions of manufactured parts, ensuring consistency. It complements. Dimensional Tolerancing.

From www.scribd.com

Dimensional Tolerancing and Geometric Dimensioning & Tolerancing (GD&T Dimensional Tolerancing Geometric tolerances, indicated by special symbols related to part surfaces. Dimensional tolerancing refers to the permissible limits or boundaries for the physical dimensions of manufactured parts, ensuring consistency. Gd&t, short for geometric dimensioning and tolerancing, is a system for defining and communicating design intent and. In mechanical engineering, tolerances set the allowable deviation from assigned dimensions. “the y14.5 standard is. Dimensional Tolerancing.

From www.smlease.com

GD&T Basics Introduction to Geometric Dimension and Tolerance Dimensional Tolerancing Geometric tolerances, indicated by special symbols related to part surfaces. Geometric dimensioning and tolerancing (gd&t) is a tolerancing technique that is used in the mechanical design process to control the fit and function of parts and assemblies. It complements traditional “plus and minus” dimensional tolerancing by letting you control 14 different geometric characteristics. These are the main benefits of using. Dimensional Tolerancing.

From formlabs.com

GD&T The Basics of Geometric Dimensioning and Tolerancing Formlabs Dimensional Tolerancing Dimensional tolerancing refers to the permissible limits or boundaries for the physical dimensions of manufactured parts, ensuring consistency. In mechanical engineering, tolerances set the allowable deviation from assigned dimensions. Gd&t, short for geometric dimensioning and tolerancing, is a system for defining and communicating design intent and. It complements traditional “plus and minus” dimensional tolerancing by letting you control 14 different. Dimensional Tolerancing.