Chatter On Boring Bar . Brass and bearing material cut better with a little neg. Reducing chatter is important to prevent wasting your materials and damaging the machine’s service life. Maximise the grip and support on the work piece. Workholding refers to the clamping method used to hold a workpiece in the machine ready for the machining process to take place. Anyone have any tips on reducing chatter in boring ops? I'm boring mild steel with a 2 dorian boring bar, cnmg432 style insert,. Try turning the bar in the boring head so it is negative rake and see if that helps. It has a sound that we can compare to microphone feedback. How to eliminate chatter when machining. Chatter is caused by unwanted vibration during your machining process. In general, to reduce chatter, you have to increase the rigidity of the setup and/or reduce the load on the tool. Eliminating chatter comes down to 3 factors when setting up: To preserve stiffness and prevent chatter, the boring head must be set up correctly, making sure the toolholder grips the boring bar firmly.

from www.mdpi.com

Chatter is caused by unwanted vibration during your machining process. Anyone have any tips on reducing chatter in boring ops? I'm boring mild steel with a 2 dorian boring bar, cnmg432 style insert,. Reducing chatter is important to prevent wasting your materials and damaging the machine’s service life. It has a sound that we can compare to microphone feedback. Workholding refers to the clamping method used to hold a workpiece in the machine ready for the machining process to take place. Brass and bearing material cut better with a little neg. How to eliminate chatter when machining. To preserve stiffness and prevent chatter, the boring head must be set up correctly, making sure the toolholder grips the boring bar firmly. Maximise the grip and support on the work piece.

JMMP Free FullText Design of ChatterResistant Damped Boring Bars

Chatter On Boring Bar How to eliminate chatter when machining. In general, to reduce chatter, you have to increase the rigidity of the setup and/or reduce the load on the tool. Brass and bearing material cut better with a little neg. Anyone have any tips on reducing chatter in boring ops? I'm boring mild steel with a 2 dorian boring bar, cnmg432 style insert,. Eliminating chatter comes down to 3 factors when setting up: Workholding refers to the clamping method used to hold a workpiece in the machine ready for the machining process to take place. Reducing chatter is important to prevent wasting your materials and damaging the machine’s service life. To preserve stiffness and prevent chatter, the boring head must be set up correctly, making sure the toolholder grips the boring bar firmly. It has a sound that we can compare to microphone feedback. How to eliminate chatter when machining. Try turning the bar in the boring head so it is negative rake and see if that helps. Maximise the grip and support on the work piece. Chatter is caused by unwanted vibration during your machining process.

From www.mdpi.com

Applied Sciences Free FullText Chatter and Stability Analysis of Chatter On Boring Bar To preserve stiffness and prevent chatter, the boring head must be set up correctly, making sure the toolholder grips the boring bar firmly. Reducing chatter is important to prevent wasting your materials and damaging the machine’s service life. Anyone have any tips on reducing chatter in boring ops? Try turning the bar in the boring head so it is negative. Chatter On Boring Bar.

From www.ebay.com

Boring Bar 12mm with free 2 Tungaloy Insert chatter free finish CCMT06 Chatter On Boring Bar How to eliminate chatter when machining. I'm boring mild steel with a 2 dorian boring bar, cnmg432 style insert,. In general, to reduce chatter, you have to increase the rigidity of the setup and/or reduce the load on the tool. Chatter is caused by unwanted vibration during your machining process. Workholding refers to the clamping method used to hold a. Chatter On Boring Bar.

From www.mdpi.com

Applied Sciences Free FullText Chatter and Stability Analysis of Chatter On Boring Bar I'm boring mild steel with a 2 dorian boring bar, cnmg432 style insert,. In general, to reduce chatter, you have to increase the rigidity of the setup and/or reduce the load on the tool. Reducing chatter is important to prevent wasting your materials and damaging the machine’s service life. Maximise the grip and support on the work piece. It has. Chatter On Boring Bar.

From www.semanticscholar.org

Figure 2 from A Biaxial Actively Damped Boring Bar for Chatter Chatter On Boring Bar It has a sound that we can compare to microphone feedback. Brass and bearing material cut better with a little neg. To preserve stiffness and prevent chatter, the boring head must be set up correctly, making sure the toolholder grips the boring bar firmly. Reducing chatter is important to prevent wasting your materials and damaging the machine’s service life. Anyone. Chatter On Boring Bar.

From www.carbideanddiamondtooling.com

MH24, 28, 32 LSER 4CFT Modular ChatterFree Boring Bar Head Chatter On Boring Bar Anyone have any tips on reducing chatter in boring ops? How to eliminate chatter when machining. Chatter is caused by unwanted vibration during your machining process. Brass and bearing material cut better with a little neg. In general, to reduce chatter, you have to increase the rigidity of the setup and/or reduce the load on the tool. Maximise the grip. Chatter On Boring Bar.

From www.mdpi.com

JMMP Free FullText Design of ChatterResistant Damped Boring Bars Chatter On Boring Bar In general, to reduce chatter, you have to increase the rigidity of the setup and/or reduce the load on the tool. Brass and bearing material cut better with a little neg. How to eliminate chatter when machining. I'm boring mild steel with a 2 dorian boring bar, cnmg432 style insert,. Eliminating chatter comes down to 3 factors when setting up:. Chatter On Boring Bar.

From www.canadianmetalworking.com

Crossing the Finish Line Chatter On Boring Bar To preserve stiffness and prevent chatter, the boring head must be set up correctly, making sure the toolholder grips the boring bar firmly. Maximise the grip and support on the work piece. In general, to reduce chatter, you have to increase the rigidity of the setup and/or reduce the load on the tool. Eliminating chatter comes down to 3 factors. Chatter On Boring Bar.

From www.youtube.com

Fully Tunable ChatterFree Boring Bar Increases Machining Performance Chatter On Boring Bar Try turning the bar in the boring head so it is negative rake and see if that helps. Reducing chatter is important to prevent wasting your materials and damaging the machine’s service life. Brass and bearing material cut better with a little neg. Maximise the grip and support on the work piece. It has a sound that we can compare. Chatter On Boring Bar.

From www.semanticscholar.org

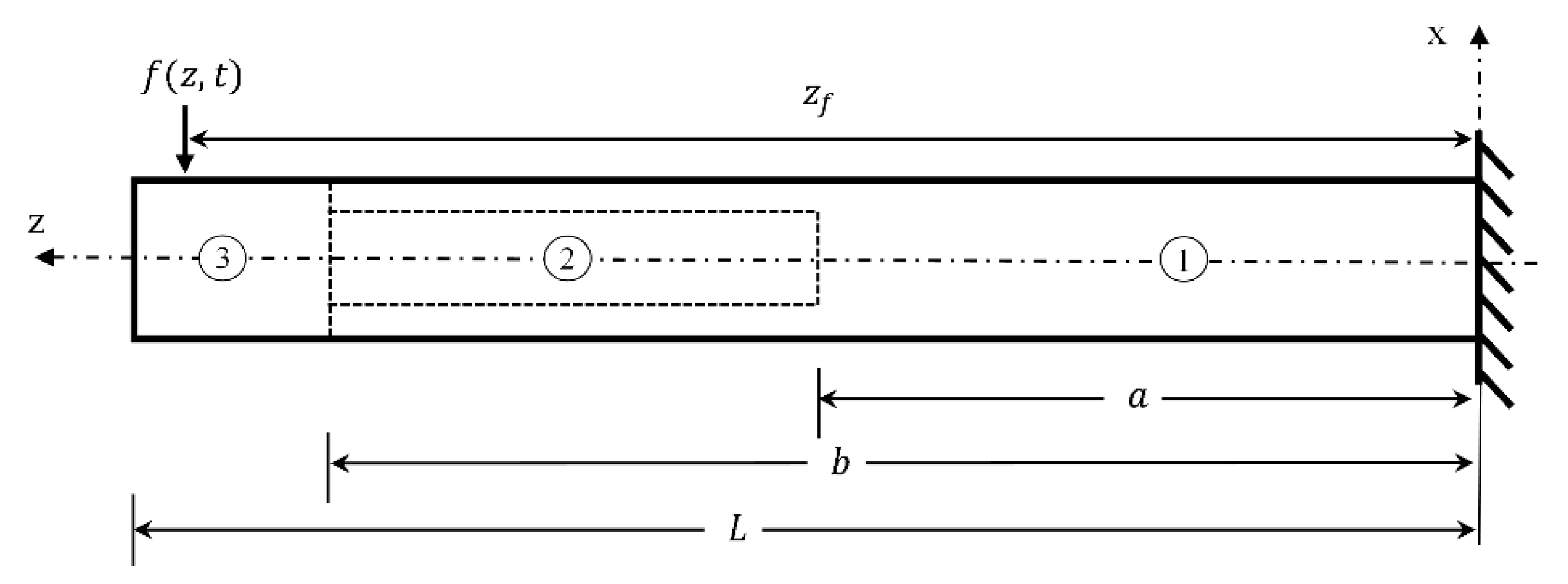

Figure 4 from Chatter control and stability analysis of a cantilever Chatter On Boring Bar Brass and bearing material cut better with a little neg. How to eliminate chatter when machining. It has a sound that we can compare to microphone feedback. In general, to reduce chatter, you have to increase the rigidity of the setup and/or reduce the load on the tool. Try turning the bar in the boring head so it is negative. Chatter On Boring Bar.

From budgetlightforum.com

kiribaru 8mm boring bar holder review. Offtopic Chatter Chatter On Boring Bar Eliminating chatter comes down to 3 factors when setting up: How to eliminate chatter when machining. Brass and bearing material cut better with a little neg. Maximise the grip and support on the work piece. I'm boring mild steel with a 2 dorian boring bar, cnmg432 style insert,. It has a sound that we can compare to microphone feedback. Reducing. Chatter On Boring Bar.

From www.ebay.com.au

Boring Bar 20mm with free 2 Tungaloy Insert chatter free finish CCMT09 Chatter On Boring Bar Try turning the bar in the boring head so it is negative rake and see if that helps. Reducing chatter is important to prevent wasting your materials and damaging the machine’s service life. Workholding refers to the clamping method used to hold a workpiece in the machine ready for the machining process to take place. How to eliminate chatter when. Chatter On Boring Bar.

From www.amazon.com

UltraDex SCFT B100010 ChatterFree Serrated Modular Boring Bar, 1.260 Chatter On Boring Bar To preserve stiffness and prevent chatter, the boring head must be set up correctly, making sure the toolholder grips the boring bar firmly. Brass and bearing material cut better with a little neg. It has a sound that we can compare to microphone feedback. Workholding refers to the clamping method used to hold a workpiece in the machine ready for. Chatter On Boring Bar.

From www.semanticscholar.org

Figure 1 from Design of ChatterResistant Damped Boring Bars Using a Chatter On Boring Bar Maximise the grip and support on the work piece. Brass and bearing material cut better with a little neg. How to eliminate chatter when machining. Reducing chatter is important to prevent wasting your materials and damaging the machine’s service life. I'm boring mild steel with a 2 dorian boring bar, cnmg432 style insert,. To preserve stiffness and prevent chatter, the. Chatter On Boring Bar.

From www.reddit.com

Running this Ingersoll TCAP Drill/Boring bar and can not find the feed Chatter On Boring Bar Reducing chatter is important to prevent wasting your materials and damaging the machine’s service life. Try turning the bar in the boring head so it is negative rake and see if that helps. To preserve stiffness and prevent chatter, the boring head must be set up correctly, making sure the toolholder grips the boring bar firmly. Anyone have any tips. Chatter On Boring Bar.

From www.mdpi.com

JMMP Free FullText Design of ChatterResistant Damped Boring Bars Chatter On Boring Bar In general, to reduce chatter, you have to increase the rigidity of the setup and/or reduce the load on the tool. To preserve stiffness and prevent chatter, the boring head must be set up correctly, making sure the toolholder grips the boring bar firmly. Chatter is caused by unwanted vibration during your machining process. Reducing chatter is important to prevent. Chatter On Boring Bar.

From www.amazon.com

UltraDex SCFT B50MM750 ChatterFree Serrated Modular Boring Bar, 1. Chatter On Boring Bar To preserve stiffness and prevent chatter, the boring head must be set up correctly, making sure the toolholder grips the boring bar firmly. Maximise the grip and support on the work piece. It has a sound that we can compare to microphone feedback. Workholding refers to the clamping method used to hold a workpiece in the machine ready for the. Chatter On Boring Bar.

From www.ebay.com

UltraDex MH20 SCLCR3CFT chatter free boring bar modular head 11/4 Chatter On Boring Bar Reducing chatter is important to prevent wasting your materials and damaging the machine’s service life. Try turning the bar in the boring head so it is negative rake and see if that helps. Workholding refers to the clamping method used to hold a workpiece in the machine ready for the machining process to take place. In general, to reduce chatter,. Chatter On Boring Bar.

From www.buyustools.com

6PCS 3/4" SHANK INDEXABLE BORING BARS SET buyustools Chatter On Boring Bar I'm boring mild steel with a 2 dorian boring bar, cnmg432 style insert,. Brass and bearing material cut better with a little neg. Anyone have any tips on reducing chatter in boring ops? It has a sound that we can compare to microphone feedback. Maximise the grip and support on the work piece. Chatter is caused by unwanted vibration during. Chatter On Boring Bar.

From budgetlightforum.com

kiribaru 8mm boring bar holder review. Offtopic Chatter Chatter On Boring Bar It has a sound that we can compare to microphone feedback. Try turning the bar in the boring head so it is negative rake and see if that helps. To preserve stiffness and prevent chatter, the boring head must be set up correctly, making sure the toolholder grips the boring bar firmly. Reducing chatter is important to prevent wasting your. Chatter On Boring Bar.

From budgetlightforum.com

kiribaru 8mm boring bar holder review. Offtopic Chatter Chatter On Boring Bar Reducing chatter is important to prevent wasting your materials and damaging the machine’s service life. Anyone have any tips on reducing chatter in boring ops? I'm boring mild steel with a 2 dorian boring bar, cnmg432 style insert,. Eliminating chatter comes down to 3 factors when setting up: In general, to reduce chatter, you have to increase the rigidity of. Chatter On Boring Bar.

From www.mdpi.com

JMMP Free FullText Design of ChatterResistant Damped Boring Bars Chatter On Boring Bar Eliminating chatter comes down to 3 factors when setting up: Try turning the bar in the boring head so it is negative rake and see if that helps. Workholding refers to the clamping method used to hold a workpiece in the machine ready for the machining process to take place. How to eliminate chatter when machining. Brass and bearing material. Chatter On Boring Bar.

From www.practicalmachinist.com

ULTRADEX Chatterfree Boring Bar Chatter On Boring Bar To preserve stiffness and prevent chatter, the boring head must be set up correctly, making sure the toolholder grips the boring bar firmly. Brass and bearing material cut better with a little neg. Maximise the grip and support on the work piece. Chatter is caused by unwanted vibration during your machining process. Workholding refers to the clamping method used to. Chatter On Boring Bar.

From www.youtube.com

Eliminate boring bar chatter with this super easy trick!!! YouTube Chatter On Boring Bar Workholding refers to the clamping method used to hold a workpiece in the machine ready for the machining process to take place. Maximise the grip and support on the work piece. In general, to reduce chatter, you have to increase the rigidity of the setup and/or reduce the load on the tool. How to eliminate chatter when machining. Anyone have. Chatter On Boring Bar.

From www.bidspotter.com

BORING BAR, UTRADEX CHATTER FREE MDL. CFTB200026, 2.000" dia. x 20"L Chatter On Boring Bar In general, to reduce chatter, you have to increase the rigidity of the setup and/or reduce the load on the tool. Workholding refers to the clamping method used to hold a workpiece in the machine ready for the machining process to take place. It has a sound that we can compare to microphone feedback. Maximise the grip and support on. Chatter On Boring Bar.

From www.bidspotter.com

ANTICHATTER BORING BAR, SANDVIK COROMAT SL MDL. A5703CD322740 Chatter On Boring Bar Chatter is caused by unwanted vibration during your machining process. Maximise the grip and support on the work piece. Workholding refers to the clamping method used to hold a workpiece in the machine ready for the machining process to take place. How to eliminate chatter when machining. It has a sound that we can compare to microphone feedback. In general,. Chatter On Boring Bar.

From budgetlightforum.com

kiribaru 8mm boring bar holder review. Offtopic Chatter Chatter On Boring Bar Anyone have any tips on reducing chatter in boring ops? Workholding refers to the clamping method used to hold a workpiece in the machine ready for the machining process to take place. Maximise the grip and support on the work piece. Brass and bearing material cut better with a little neg. Eliminating chatter comes down to 3 factors when setting. Chatter On Boring Bar.

From www.reddit.com

Chatter Free Boring Bar Is Now "Chatter Free" r/machining Chatter On Boring Bar How to eliminate chatter when machining. Try turning the bar in the boring head so it is negative rake and see if that helps. I'm boring mild steel with a 2 dorian boring bar, cnmg432 style insert,. Maximise the grip and support on the work piece. Eliminating chatter comes down to 3 factors when setting up: Anyone have any tips. Chatter On Boring Bar.

From www.mmc-carbide.com

Chatter resistant dimple bar series Addition of steel shank boring bar Chatter On Boring Bar Brass and bearing material cut better with a little neg. In general, to reduce chatter, you have to increase the rigidity of the setup and/or reduce the load on the tool. Maximise the grip and support on the work piece. Anyone have any tips on reducing chatter in boring ops? Chatter is caused by unwanted vibration during your machining process.. Chatter On Boring Bar.

From www.reddit.com

Who needs a silent boring bar, if you’ve got the trusty ol’ rubber Chatter On Boring Bar Anyone have any tips on reducing chatter in boring ops? Eliminating chatter comes down to 3 factors when setting up: Brass and bearing material cut better with a little neg. How to eliminate chatter when machining. Maximise the grip and support on the work piece. Workholding refers to the clamping method used to hold a workpiece in the machine ready. Chatter On Boring Bar.

From www.mdpi.com

JMMP Free FullText Design of ChatterResistant Damped Boring Bars Chatter On Boring Bar Maximise the grip and support on the work piece. I'm boring mild steel with a 2 dorian boring bar, cnmg432 style insert,. Try turning the bar in the boring head so it is negative rake and see if that helps. In general, to reduce chatter, you have to increase the rigidity of the setup and/or reduce the load on the. Chatter On Boring Bar.

From www.mdpi.com

JMMP Free FullText Design of ChatterResistant Damped Boring Bars Chatter On Boring Bar In general, to reduce chatter, you have to increase the rigidity of the setup and/or reduce the load on the tool. Brass and bearing material cut better with a little neg. I'm boring mild steel with a 2 dorian boring bar, cnmg432 style insert,. How to eliminate chatter when machining. Try turning the bar in the boring head so it. Chatter On Boring Bar.

From www.bidspotter.com

LOT OF ULTRA DEX CHATTER FREE BORING BARS (2), 1" dia. X 14"L. Chatter On Boring Bar Chatter is caused by unwanted vibration during your machining process. To preserve stiffness and prevent chatter, the boring head must be set up correctly, making sure the toolholder grips the boring bar firmly. Reducing chatter is important to prevent wasting your materials and damaging the machine’s service life. Maximise the grip and support on the work piece. Anyone have any. Chatter On Boring Bar.

From www.mdpi.com

Applied Sciences Free FullText Chatter and Stability Analysis of Chatter On Boring Bar In general, to reduce chatter, you have to increase the rigidity of the setup and/or reduce the load on the tool. I'm boring mild steel with a 2 dorian boring bar, cnmg432 style insert,. Anyone have any tips on reducing chatter in boring ops? Try turning the bar in the boring head so it is negative rake and see if. Chatter On Boring Bar.

From www.harveyperformance.com

Avoid These 5 Boring Bar Mistakes Causing Chatter In The Loupe Chatter On Boring Bar It has a sound that we can compare to microphone feedback. Eliminating chatter comes down to 3 factors when setting up: Try turning the bar in the boring head so it is negative rake and see if that helps. Chatter is caused by unwanted vibration during your machining process. Workholding refers to the clamping method used to hold a workpiece. Chatter On Boring Bar.

From cnsanhan.en.made-in-china.com

China Chatter Resistant Boring Bar China tool, cutting tool Chatter On Boring Bar Maximise the grip and support on the work piece. Workholding refers to the clamping method used to hold a workpiece in the machine ready for the machining process to take place. Brass and bearing material cut better with a little neg. To preserve stiffness and prevent chatter, the boring head must be set up correctly, making sure the toolholder grips. Chatter On Boring Bar.