Conveyor Belt Speed Adjustment . Speed control is a promising method of reducing the power consumption of belt conveyors. The material filling rate of the belt is. Importance of the conveyor belt tracking procedure. The skew angle, γ, should be 3° to 12° depending upon belt load, the friction between roller and belt, and on the belt speed. On variable speed conveyors, set the control at its lowest speed. Run the conveyor and observe the belt tracking at both ends. Steps for conveyor belt tracking procedure. An active speed control strategy based on fuzzy algorithm is proposed for belt conveyor. Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. By applying the principles of conveyor belt tracking theory to the adjustment and troubleshooting processes, operators can.

from hapman.com

Speed control is a promising method of reducing the power consumption of belt conveyors. Steps for conveyor belt tracking procedure. An active speed control strategy based on fuzzy algorithm is proposed for belt conveyor. On variable speed conveyors, set the control at its lowest speed. The material filling rate of the belt is. Run the conveyor and observe the belt tracking at both ends. Importance of the conveyor belt tracking procedure. Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. The skew angle, γ, should be 3° to 12° depending upon belt load, the friction between roller and belt, and on the belt speed. By applying the principles of conveyor belt tracking theory to the adjustment and troubleshooting processes, operators can.

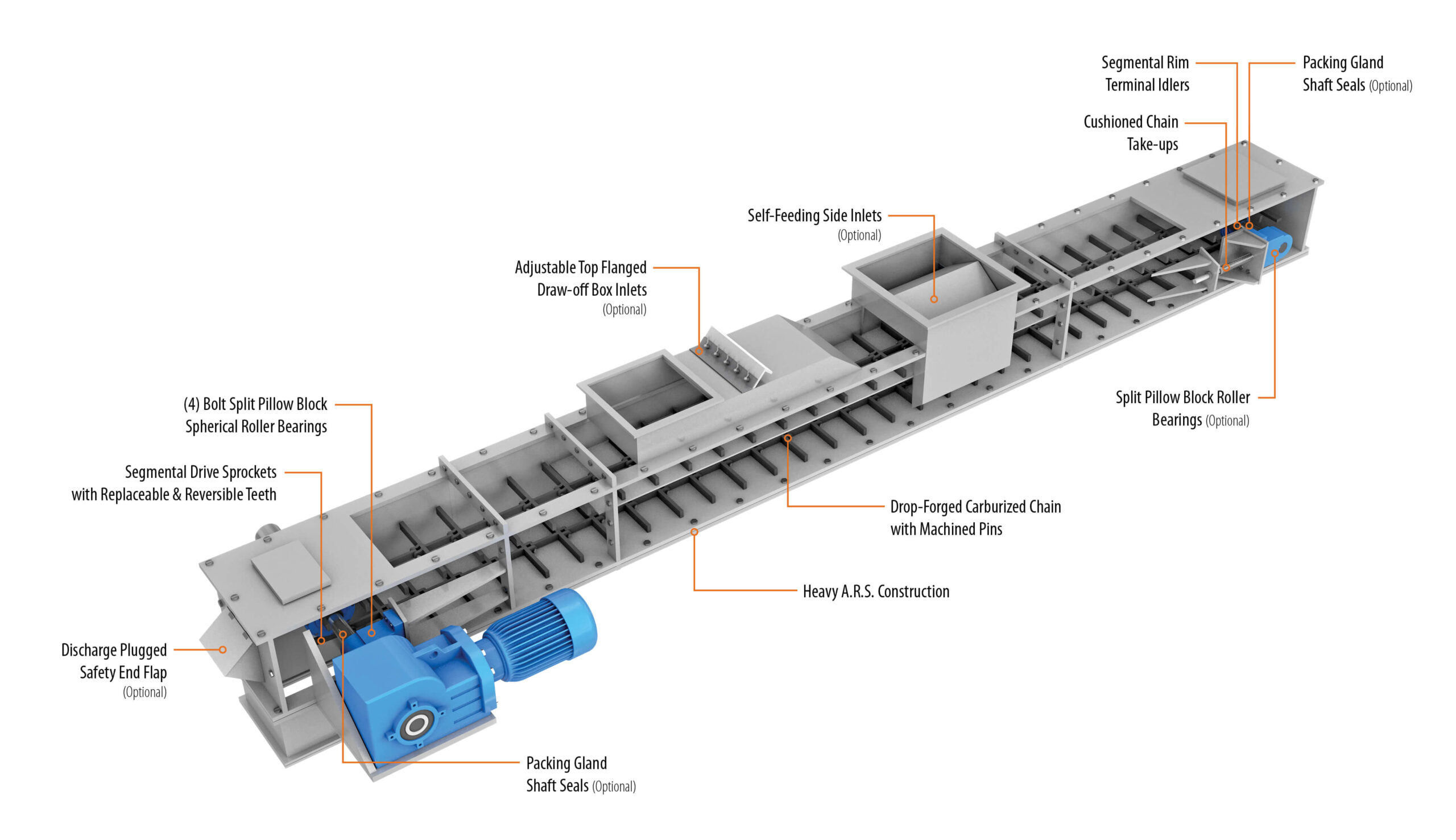

Drag Chain Conveyor Operation Understanding the Functional Differences

Conveyor Belt Speed Adjustment On variable speed conveyors, set the control at its lowest speed. The material filling rate of the belt is. Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. Run the conveyor and observe the belt tracking at both ends. Speed control is a promising method of reducing the power consumption of belt conveyors. Importance of the conveyor belt tracking procedure. By applying the principles of conveyor belt tracking theory to the adjustment and troubleshooting processes, operators can. On variable speed conveyors, set the control at its lowest speed. Steps for conveyor belt tracking procedure. An active speed control strategy based on fuzzy algorithm is proposed for belt conveyor. The skew angle, γ, should be 3° to 12° depending upon belt load, the friction between roller and belt, and on the belt speed.

From www.youtube.com

How to Measure the Speed of a Conveyor YouTube Conveyor Belt Speed Adjustment Run the conveyor and observe the belt tracking at both ends. The skew angle, γ, should be 3° to 12° depending upon belt load, the friction between roller and belt, and on the belt speed. The material filling rate of the belt is. Importance of the conveyor belt tracking procedure. By applying the principles of conveyor belt tracking theory to. Conveyor Belt Speed Adjustment.

From www.martin-eng.com

Conveyor Belt Alignment Reduce Damaging Belts Conveyor Belt Speed Adjustment Run the conveyor and observe the belt tracking at both ends. Speed control is a promising method of reducing the power consumption of belt conveyors. The skew angle, γ, should be 3° to 12° depending upon belt load, the friction between roller and belt, and on the belt speed. Steps for conveyor belt tracking procedure. By applying the principles of. Conveyor Belt Speed Adjustment.

From www.iqsdirectory.com

Conveyor Belts What Is It? How Does It Work? Types, Parts Conveyor Belt Speed Adjustment Run the conveyor and observe the belt tracking at both ends. Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. The material filling rate of the belt is. Steps for conveyor belt tracking procedure. The skew angle, γ, should be 3° to 12°. Conveyor Belt Speed Adjustment.

From www.dornerconveyors.com

Straight Modular Cleated Belt Dorner Conveyors Conveying Systems Conveyor Belt Speed Adjustment Run the conveyor and observe the belt tracking at both ends. The material filling rate of the belt is. The skew angle, γ, should be 3° to 12° depending upon belt load, the friction between roller and belt, and on the belt speed. Importance of the conveyor belt tracking procedure. Belt conveyors are available up to 72” wide and can. Conveyor Belt Speed Adjustment.

From wrightfield.co.uk

Conveyor Systems Types, Specifications and Selection Wrightfield Ltd Conveyor Belt Speed Adjustment On variable speed conveyors, set the control at its lowest speed. Steps for conveyor belt tracking procedure. Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. Importance of the conveyor belt tracking procedure. Run the conveyor and observe the belt tracking at both. Conveyor Belt Speed Adjustment.

From www.youtube.com

Inclined Conveyor Belt with Flights YouTube Conveyor Belt Speed Adjustment The material filling rate of the belt is. Run the conveyor and observe the belt tracking at both ends. Speed control is a promising method of reducing the power consumption of belt conveyors. An active speed control strategy based on fuzzy algorithm is proposed for belt conveyor. Importance of the conveyor belt tracking procedure. By applying the principles of conveyor. Conveyor Belt Speed Adjustment.

From www.ultimationinc.com

Belt Conveyor Adjustable Speed 16" OAW x 12" BW x 11' L Conveyor Belt Speed Adjustment Steps for conveyor belt tracking procedure. On variable speed conveyors, set the control at its lowest speed. The material filling rate of the belt is. Speed control is a promising method of reducing the power consumption of belt conveyors. An active speed control strategy based on fuzzy algorithm is proposed for belt conveyor. Run the conveyor and observe the belt. Conveyor Belt Speed Adjustment.

From www.researchgate.net

1. Basic components of a conveyor belt. Download Scientific Diagram Conveyor Belt Speed Adjustment Importance of the conveyor belt tracking procedure. Run the conveyor and observe the belt tracking at both ends. By applying the principles of conveyor belt tracking theory to the adjustment and troubleshooting processes, operators can. Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice. Conveyor Belt Speed Adjustment.

From birthdaywishes77.com

What Is It? How Does It Work? Types, Parts (2022) Conveyor Belt Speed Adjustment On variable speed conveyors, set the control at its lowest speed. Run the conveyor and observe the belt tracking at both ends. Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. By applying the principles of conveyor belt tracking theory to the adjustment. Conveyor Belt Speed Adjustment.

From www.conveyorbelting.news

How do you increase the speed of a conveyor belt? Conveyor Belt Speed Adjustment Speed control is a promising method of reducing the power consumption of belt conveyors. Run the conveyor and observe the belt tracking at both ends. The material filling rate of the belt is. The skew angle, γ, should be 3° to 12° depending upon belt load, the friction between roller and belt, and on the belt speed. By applying the. Conveyor Belt Speed Adjustment.

From dfe.com

Conveyor Belt Tension Measurement & Monitoring Dover Flexo Conveyor Belt Speed Adjustment Steps for conveyor belt tracking procedure. The material filling rate of the belt is. Speed control is a promising method of reducing the power consumption of belt conveyors. Importance of the conveyor belt tracking procedure. Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice. Conveyor Belt Speed Adjustment.

From www.alibaba.com

Customize Adjusted Speed Conveyor Belt Buy Customize Conveyor Belt Conveyor Belt Speed Adjustment Speed control is a promising method of reducing the power consumption of belt conveyors. Importance of the conveyor belt tracking procedure. The skew angle, γ, should be 3° to 12° depending upon belt load, the friction between roller and belt, and on the belt speed. Belt conveyors are available up to 72” wide and can operate at speeds up to. Conveyor Belt Speed Adjustment.

From www.indiamart.com

Aluminium Belt Conveyor Aluminum Frame Belt Conveyors, .5 Hp, Rs 108775 Conveyor Belt Speed Adjustment On variable speed conveyors, set the control at its lowest speed. The material filling rate of the belt is. Speed control is a promising method of reducing the power consumption of belt conveyors. The skew angle, γ, should be 3° to 12° depending upon belt load, the friction between roller and belt, and on the belt speed. Belt conveyors are. Conveyor Belt Speed Adjustment.

From www.youtube.com

CALCULATING FORCE, TIME, AND COST OF INCLINED BELT CONVEYORS YouTube Conveyor Belt Speed Adjustment Run the conveyor and observe the belt tracking at both ends. On variable speed conveyors, set the control at its lowest speed. By applying the principles of conveyor belt tracking theory to the adjustment and troubleshooting processes, operators can. Steps for conveyor belt tracking procedure. Importance of the conveyor belt tracking procedure. Belt conveyors are available up to 72” wide. Conveyor Belt Speed Adjustment.

From www.plastech.biz

Belt conveyor NI Belt speed adjustment! ON / OFF signal (Offer No Conveyor Belt Speed Adjustment Importance of the conveyor belt tracking procedure. By applying the principles of conveyor belt tracking theory to the adjustment and troubleshooting processes, operators can. Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. The material filling rate of the belt is. Speed control. Conveyor Belt Speed Adjustment.

From feeco.com

Stacking Conveyors Conveyor Belt Speed Adjustment Speed control is a promising method of reducing the power consumption of belt conveyors. The skew angle, γ, should be 3° to 12° depending upon belt load, the friction between roller and belt, and on the belt speed. Steps for conveyor belt tracking procedure. By applying the principles of conveyor belt tracking theory to the adjustment and troubleshooting processes, operators. Conveyor Belt Speed Adjustment.

From zhjgfillingmachine.en.made-in-china.com

Speed Adjustment Conveyor Belt for Plastic Bottles China Plastic Conveyor Belt Speed Adjustment Importance of the conveyor belt tracking procedure. Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. The material filling rate of the belt is. On variable speed conveyors, set the control at its lowest speed. By applying the principles of conveyor belt tracking. Conveyor Belt Speed Adjustment.

From hapman.com

Drag Chain Conveyor Operation Understanding the Functional Differences Conveyor Belt Speed Adjustment An active speed control strategy based on fuzzy algorithm is proposed for belt conveyor. The skew angle, γ, should be 3° to 12° depending upon belt load, the friction between roller and belt, and on the belt speed. Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them. Conveyor Belt Speed Adjustment.

From www.vn-ind.in

Conveyor My Site Conveyor Belt Speed Adjustment On variable speed conveyors, set the control at its lowest speed. An active speed control strategy based on fuzzy algorithm is proposed for belt conveyor. Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. Speed control is a promising method of reducing the. Conveyor Belt Speed Adjustment.

From www.finlay.com.au

Finlay TC80 Tracked Conveyor Crushing, Screening, Washing & Recycling Conveyor Belt Speed Adjustment Steps for conveyor belt tracking procedure. Importance of the conveyor belt tracking procedure. By applying the principles of conveyor belt tracking theory to the adjustment and troubleshooting processes, operators can. An active speed control strategy based on fuzzy algorithm is proposed for belt conveyor. Speed control is a promising method of reducing the power consumption of belt conveyors. Run the. Conveyor Belt Speed Adjustment.

From www.mknorthamerica.com

Aluminum Conveyors Belt Conveyors & Material Handling mk Conveyor Belt Speed Adjustment On variable speed conveyors, set the control at its lowest speed. Steps for conveyor belt tracking procedure. An active speed control strategy based on fuzzy algorithm is proposed for belt conveyor. Speed control is a promising method of reducing the power consumption of belt conveyors. The material filling rate of the belt is. Run the conveyor and observe the belt. Conveyor Belt Speed Adjustment.

From www.grainger.com

30 in Belt Wd, 2,275 lb Max Load Capacity, Belt Conveyor 42X878RB190 Conveyor Belt Speed Adjustment Importance of the conveyor belt tracking procedure. An active speed control strategy based on fuzzy algorithm is proposed for belt conveyor. The skew angle, γ, should be 3° to 12° depending upon belt load, the friction between roller and belt, and on the belt speed. Speed control is a promising method of reducing the power consumption of belt conveyors. The. Conveyor Belt Speed Adjustment.

From www.myxxgirl.com

What Is A Belt Conveyor How Are They Used Your Questions Answered My Conveyor Belt Speed Adjustment Importance of the conveyor belt tracking procedure. An active speed control strategy based on fuzzy algorithm is proposed for belt conveyor. Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. Steps for conveyor belt tracking procedure. Run the conveyor and observe the belt. Conveyor Belt Speed Adjustment.

From apesfillingsystems.com

A.P.E.S. Standard and Custom Variable Speed Conveyors Conveyor Belt Speed Adjustment Importance of the conveyor belt tracking procedure. Speed control is a promising method of reducing the power consumption of belt conveyors. Run the conveyor and observe the belt tracking at both ends. The material filling rate of the belt is. The skew angle, γ, should be 3° to 12° depending upon belt load, the friction between roller and belt, and. Conveyor Belt Speed Adjustment.

From www.royalconveyors.com

Tracking a Conveyor Belt Basic Belted Guide Royal Conveyor Solutions Conveyor Belt Speed Adjustment By applying the principles of conveyor belt tracking theory to the adjustment and troubleshooting processes, operators can. On variable speed conveyors, set the control at its lowest speed. The skew angle, γ, should be 3° to 12° depending upon belt load, the friction between roller and belt, and on the belt speed. Steps for conveyor belt tracking procedure. An active. Conveyor Belt Speed Adjustment.

From www.youtube.com

Low Cost Slow Running Aluminium Conveyor Belt YouTube Conveyor Belt Speed Adjustment The material filling rate of the belt is. Steps for conveyor belt tracking procedure. On variable speed conveyors, set the control at its lowest speed. Importance of the conveyor belt tracking procedure. By applying the principles of conveyor belt tracking theory to the adjustment and troubleshooting processes, operators can. Speed control is a promising method of reducing the power consumption. Conveyor Belt Speed Adjustment.

From www.researchgate.net

Conveyor Belt Speed Adjusting Mechanism The belt speed can be Conveyor Belt Speed Adjustment The material filling rate of the belt is. An active speed control strategy based on fuzzy algorithm is proposed for belt conveyor. The skew angle, γ, should be 3° to 12° depending upon belt load, the friction between roller and belt, and on the belt speed. Importance of the conveyor belt tracking procedure. By applying the principles of conveyor belt. Conveyor Belt Speed Adjustment.

From www.bid-on-equipment.com

PLASTIQUIP Variable Speed Flat Belt Conveyor Solid Belt Conveyors Conveyor Belt Speed Adjustment The skew angle, γ, should be 3° to 12° depending upon belt load, the friction between roller and belt, and on the belt speed. Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. Run the conveyor and observe the belt tracking at both. Conveyor Belt Speed Adjustment.

From www.91zds.com

What is the principle of belt conveyor systems Dahan Conveyor Conveyor Belt Speed Adjustment Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. Run the conveyor and observe the belt tracking at both ends. Importance of the conveyor belt tracking procedure. By applying the principles of conveyor belt tracking theory to the adjustment and troubleshooting processes, operators. Conveyor Belt Speed Adjustment.

From www.sparksbelting.com

Conveyor Belt Tracking Tips Sparks Belting Conveyor Belt Speed Adjustment The skew angle, γ, should be 3° to 12° depending upon belt load, the friction between roller and belt, and on the belt speed. Speed control is a promising method of reducing the power consumption of belt conveyors. Steps for conveyor belt tracking procedure. The material filling rate of the belt is. Run the conveyor and observe the belt tracking. Conveyor Belt Speed Adjustment.

From www.youtube.com

Simple Conveyor Rail Adjustment YouTube Conveyor Belt Speed Adjustment The material filling rate of the belt is. By applying the principles of conveyor belt tracking theory to the adjustment and troubleshooting processes, operators can. The skew angle, γ, should be 3° to 12° depending upon belt load, the friction between roller and belt, and on the belt speed. An active speed control strategy based on fuzzy algorithm is proposed. Conveyor Belt Speed Adjustment.

From mujiacn.en.made-in-china.com

China Bucket Adjustable Height Conveyor Belt Adjustment Cleats Conveyor Conveyor Belt Speed Adjustment Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. Speed control is a promising method of reducing the power consumption of belt conveyors. An active speed control strategy based on fuzzy algorithm is proposed for belt conveyor. Steps for conveyor belt tracking procedure.. Conveyor Belt Speed Adjustment.

From www.auger-conveyor.com

What is the principle of belt conveyor systems Dahan Conveyor Conveyor Belt Speed Adjustment Speed control is a promising method of reducing the power consumption of belt conveyors. An active speed control strategy based on fuzzy algorithm is proposed for belt conveyor. Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. On variable speed conveyors, set the. Conveyor Belt Speed Adjustment.

From www.alibaba.com

Efficiency Speed Adjustment Turning Curve Belt Conveyor With Pvc Belt Conveyor Belt Speed Adjustment An active speed control strategy based on fuzzy algorithm is proposed for belt conveyor. The skew angle, γ, should be 3° to 12° depending upon belt load, the friction between roller and belt, and on the belt speed. Speed control is a promising method of reducing the power consumption of belt conveyors. By applying the principles of conveyor belt tracking. Conveyor Belt Speed Adjustment.

From fmhconveyors.com

Flexible Gravity Conveyors FMH Conveyors Conveyor Belt Speed Adjustment Steps for conveyor belt tracking procedure. Importance of the conveyor belt tracking procedure. The skew angle, γ, should be 3° to 12° depending upon belt load, the friction between roller and belt, and on the belt speed. On variable speed conveyors, set the control at its lowest speed. By applying the principles of conveyor belt tracking theory to the adjustment. Conveyor Belt Speed Adjustment.