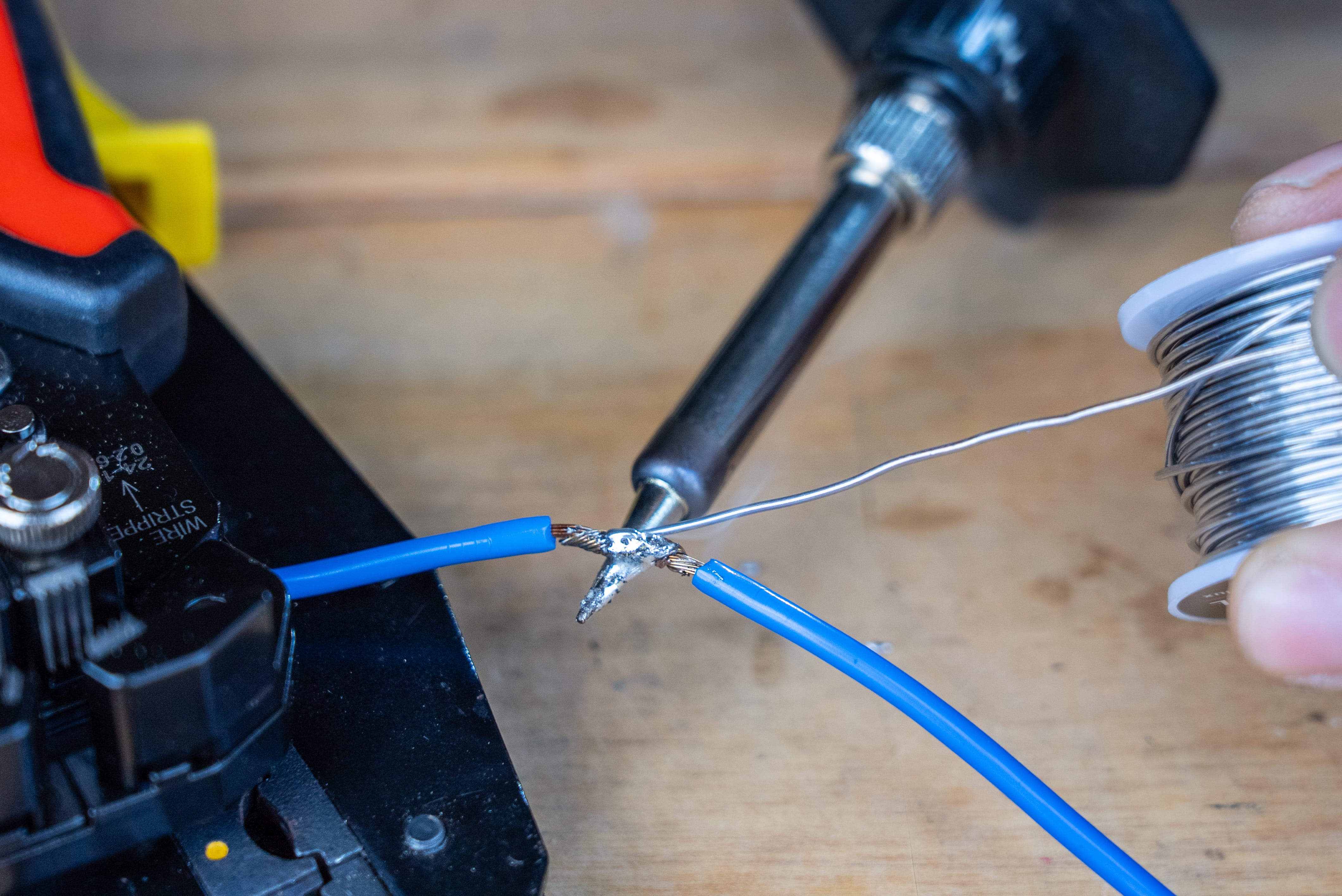

How To Solder Enameled Copper Wire . begin by melting a small amount of solder on the iron, then push the tip of the magnet wire a small distance into the molten solder and hold it there for a few. The coating lifts and floats away. Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on just. Next, tin the wire by applying a small. Scraping the enamel carefully off with a sharp knife or blade, while trying not to nick the. put the enamelled copper wire in 98% sulphuric acid for 10 minutes. first, clean the wire thoroughly by gently scraping off the enamel coating using fine sandpaper or a wire stripper. tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2. common ways of removing the insulation on enameled wire include: 66k views 11 years ago. how to solder enameled copper wire.

from www.supercheapauto.com.au

Next, tin the wire by applying a small. 66k views 11 years ago. begin by melting a small amount of solder on the iron, then push the tip of the magnet wire a small distance into the molten solder and hold it there for a few. Scraping the enamel carefully off with a sharp knife or blade, while trying not to nick the. Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on just. tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2. first, clean the wire thoroughly by gently scraping off the enamel coating using fine sandpaper or a wire stripper. The coating lifts and floats away. put the enamelled copper wire in 98% sulphuric acid for 10 minutes. common ways of removing the insulation on enameled wire include:

How to Solder Wires Wire Joining Supercheap Auto

How To Solder Enameled Copper Wire begin by melting a small amount of solder on the iron, then push the tip of the magnet wire a small distance into the molten solder and hold it there for a few. first, clean the wire thoroughly by gently scraping off the enamel coating using fine sandpaper or a wire stripper. Next, tin the wire by applying a small. tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2. The coating lifts and floats away. begin by melting a small amount of solder on the iron, then push the tip of the magnet wire a small distance into the molten solder and hold it there for a few. 66k views 11 years ago. common ways of removing the insulation on enameled wire include: put the enamelled copper wire in 98% sulphuric acid for 10 minutes. how to solder enameled copper wire. Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on just. Scraping the enamel carefully off with a sharp knife or blade, while trying not to nick the.

From weldingmastermind.com

Can You Solder Copper Wire? Here's How! Welding Mastermind How To Solder Enameled Copper Wire put the enamelled copper wire in 98% sulphuric acid for 10 minutes. tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2. The coating lifts and floats away. Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter. How To Solder Enameled Copper Wire.

From certqsaz.blob.core.windows.net

How To Solder Copper Wire To Terminal at Bruce Gambrell blog How To Solder Enameled Copper Wire Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on just. how to solder enameled copper wire. Next, tin the wire by applying a small. The coating lifts and floats away. common ways of removing the insulation on enameled wire include: put the enamelled copper wire in 98% sulphuric. How To Solder Enameled Copper Wire.

From www.amazon.ca

5pcs Enameled Copper Wire Winding Wire 0.1mm Thickness 12m How To Solder Enameled Copper Wire Scraping the enamel carefully off with a sharp knife or blade, while trying not to nick the. begin by melting a small amount of solder on the iron, then push the tip of the magnet wire a small distance into the molten solder and hold it there for a few. Next, tin the wire by applying a small. . How To Solder Enameled Copper Wire.

From www.ultrafinecopperwire.com

Winding Using Enameled Copper Wire Polyester Insulation With Good How To Solder Enameled Copper Wire Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on just. tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2. begin by melting a small amount of solder on the iron, then push the tip. How To Solder Enameled Copper Wire.

From blog.thepipingmart.com

How to Remove Solder from Copper Wire How To Solder Enameled Copper Wire Scraping the enamel carefully off with a sharp knife or blade, while trying not to nick the. tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2. put the enamelled copper wire in 98% sulphuric acid for 10 minutes. common ways of removing. How To Solder Enameled Copper Wire.

From blog.thepipingmart.com

How to Solder Copper Wire to Copper Wire How To Solder Enameled Copper Wire first, clean the wire thoroughly by gently scraping off the enamel coating using fine sandpaper or a wire stripper. put the enamelled copper wire in 98% sulphuric acid for 10 minutes. common ways of removing the insulation on enameled wire include: The coating lifts and floats away. 66k views 11 years ago. Tinning the wire at 400ºc,. How To Solder Enameled Copper Wire.

From www.instructables.com

How to Get Tons of Free Enameled Copper Wire 4 Steps Instructables How To Solder Enameled Copper Wire common ways of removing the insulation on enameled wire include: how to solder enameled copper wire. 66k views 11 years ago. Scraping the enamel carefully off with a sharp knife or blade, while trying not to nick the. put the enamelled copper wire in 98% sulphuric acid for 10 minutes. Tinning the wire at 400ºc, instead of. How To Solder Enameled Copper Wire.

From www.youtube.com

How to Solder Copper Pipe DIY HowTo Basics YouTube How To Solder Enameled Copper Wire first, clean the wire thoroughly by gently scraping off the enamel coating using fine sandpaper or a wire stripper. 66k views 11 years ago. Next, tin the wire by applying a small. how to solder enameled copper wire. The coating lifts and floats away. tldr ⚡ 1) set iron to 400 c 2) get a nice blob. How To Solder Enameled Copper Wire.

From www.ultrafinecopperwire.com

0.4 0.8mm Solderable Polyurethane Enameled Copper Wire How To Solder Enameled Copper Wire how to solder enameled copper wire. Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on just. Scraping the enamel carefully off with a sharp knife or blade, while trying not to nick the. put the enamelled copper wire in 98% sulphuric acid for 10 minutes. tldr ⚡ 1). How To Solder Enameled Copper Wire.

From blog.thepipingmart.com

How to Solder Copper Wire to Copper Pipe A Complete Guide How To Solder Enameled Copper Wire common ways of removing the insulation on enameled wire include: 66k views 11 years ago. begin by melting a small amount of solder on the iron, then push the tip of the magnet wire a small distance into the molten solder and hold it there for a few. first, clean the wire thoroughly by gently scraping off. How To Solder Enameled Copper Wire.

From solderingrepair.com

How to Solder Enameled Wire How To Solder Enameled Copper Wire first, clean the wire thoroughly by gently scraping off the enamel coating using fine sandpaper or a wire stripper. Next, tin the wire by applying a small. Scraping the enamel carefully off with a sharp knife or blade, while trying not to nick the. put the enamelled copper wire in 98% sulphuric acid for 10 minutes. Tinning the. How To Solder Enameled Copper Wire.

From www.youtube.com

How to solder enameled copper wire YouTube How To Solder Enameled Copper Wire how to solder enameled copper wire. begin by melting a small amount of solder on the iron, then push the tip of the magnet wire a small distance into the molten solder and hold it there for a few. The coating lifts and floats away. common ways of removing the insulation on enameled wire include: first,. How To Solder Enameled Copper Wire.

From schematicbraginamh.z4.web.core.windows.net

How To Properly Solder Wires For Electronics How To Solder Enameled Copper Wire 66k views 11 years ago. Next, tin the wire by applying a small. begin by melting a small amount of solder on the iron, then push the tip of the magnet wire a small distance into the molten solder and hold it there for a few. put the enamelled copper wire in 98% sulphuric acid for 10 minutes.. How To Solder Enameled Copper Wire.

From www.hardwaremise.com.my

Enameled Copper Wire Solderable Winding Wire Wire Coil Dawai How To Solder Enameled Copper Wire The coating lifts and floats away. begin by melting a small amount of solder on the iron, then push the tip of the magnet wire a small distance into the molten solder and hold it there for a few. how to solder enameled copper wire. Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked. How To Solder Enameled Copper Wire.

From www.flyrobo.in

0.1mm Copper Soldering Solder PPA Enameled Wire How To Solder Enameled Copper Wire begin by melting a small amount of solder on the iron, then push the tip of the magnet wire a small distance into the molten solder and hold it there for a few. Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on just. 66k views 11 years ago. The coating. How To Solder Enameled Copper Wire.

From blog.thepipingmart.com

How to Remove Solder from Copper Pipe Without Heat How To Solder Enameled Copper Wire tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2. Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on just. begin by melting a small amount of solder on the iron, then push the tip. How To Solder Enameled Copper Wire.

From www.flyrobo.in

0.1mm Copper Soldering Solder PPA Enameled Wire How To Solder Enameled Copper Wire begin by melting a small amount of solder on the iron, then push the tip of the magnet wire a small distance into the molten solder and hold it there for a few. Next, tin the wire by applying a small. tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat. How To Solder Enameled Copper Wire.

From www.youtube.com

How to tin Enameled Copper wire YouTube How To Solder Enameled Copper Wire first, clean the wire thoroughly by gently scraping off the enamel coating using fine sandpaper or a wire stripper. how to solder enameled copper wire. put the enamelled copper wire in 98% sulphuric acid for 10 minutes. The coating lifts and floats away. 66k views 11 years ago. Next, tin the wire by applying a small. . How To Solder Enameled Copper Wire.

From www.ultrafinecopperwire.com

Winding Using Enameled Copper Wire Polyester Insulation With Good How To Solder Enameled Copper Wire first, clean the wire thoroughly by gently scraping off the enamel coating using fine sandpaper or a wire stripper. Scraping the enamel carefully off with a sharp knife or blade, while trying not to nick the. common ways of removing the insulation on enameled wire include: 66k views 11 years ago. begin by melting a small amount. How To Solder Enameled Copper Wire.

From www.pinterest.com

1b5e73f1beb9bc98b6e541f707224c75.jpg 720×528 pixels Soldering jewelry How To Solder Enameled Copper Wire Scraping the enamel carefully off with a sharp knife or blade, while trying not to nick the. how to solder enameled copper wire. Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on just. 66k views 11 years ago. common ways of removing the insulation on enameled wire include: The. How To Solder Enameled Copper Wire.

From hackaday.com

Iron Tips Soldering Headphones And Enamel Wire Hackaday How To Solder Enameled Copper Wire Next, tin the wire by applying a small. 66k views 11 years ago. The coating lifts and floats away. begin by melting a small amount of solder on the iron, then push the tip of the magnet wire a small distance into the molten solder and hold it there for a few. tldr ⚡ 1) set iron to. How To Solder Enameled Copper Wire.

From www.youtube.com

SolderJS 135 The BEST Way to Tin Enameled Wire YouTube How To Solder Enameled Copper Wire The coating lifts and floats away. Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on just. Scraping the enamel carefully off with a sharp knife or blade, while trying not to nick the. put the enamelled copper wire in 98% sulphuric acid for 10 minutes. 66k views 11 years ago.. How To Solder Enameled Copper Wire.

From hackaday.com

Iron Tips Soldering Headphones And Enamel Wire Hackaday How To Solder Enameled Copper Wire begin by melting a small amount of solder on the iron, then push the tip of the magnet wire a small distance into the molten solder and hold it there for a few. put the enamelled copper wire in 98% sulphuric acid for 10 minutes. first, clean the wire thoroughly by gently scraping off the enamel coating. How To Solder Enameled Copper Wire.

From www.openimpulse.com

5pcs 0.1 mm Enameled Copper Soldering Wire Open ImpulseOpen Impulse How To Solder Enameled Copper Wire first, clean the wire thoroughly by gently scraping off the enamel coating using fine sandpaper or a wire stripper. begin by melting a small amount of solder on the iron, then push the tip of the magnet wire a small distance into the molten solder and hold it there for a few. Scraping the enamel carefully off with. How To Solder Enameled Copper Wire.

From alexnld.com

2Pcs 0.1MM Weld Copper Soldering Solder PPA Enamelled Reel Wire How To Solder Enameled Copper Wire how to solder enameled copper wire. common ways of removing the insulation on enameled wire include: The coating lifts and floats away. 66k views 11 years ago. Scraping the enamel carefully off with a sharp knife or blade, while trying not to nick the. begin by melting a small amount of solder on the iron, then push. How To Solder Enameled Copper Wire.

From cinnamonjewellery.blogspot.com

Experimenting With Copper Wire Solder How To Solder Enameled Copper Wire 66k views 11 years ago. Next, tin the wire by applying a small. put the enamelled copper wire in 98% sulphuric acid for 10 minutes. The coating lifts and floats away. first, clean the wire thoroughly by gently scraping off the enamel coating using fine sandpaper or a wire stripper. Scraping the enamel carefully off with a sharp. How To Solder Enameled Copper Wire.

From ciagent-stormwater.com

0.1mm Welding Enameled Copper Wire Coil 4g Jumper Wire Solder How To Solder Enameled Copper Wire put the enamelled copper wire in 98% sulphuric acid for 10 minutes. Scraping the enamel carefully off with a sharp knife or blade, while trying not to nick the. begin by melting a small amount of solder on the iron, then push the tip of the magnet wire a small distance into the molten solder and hold it. How To Solder Enameled Copper Wire.

From www.ultrafinecopperwire.com

Solderable Ultra Fine Enameled Copper Wire Self Bonding Enameled How To Solder Enameled Copper Wire The coating lifts and floats away. 66k views 11 years ago. Scraping the enamel carefully off with a sharp knife or blade, while trying not to nick the. put the enamelled copper wire in 98% sulphuric acid for 10 minutes. begin by melting a small amount of solder on the iron, then push the tip of the magnet. How To Solder Enameled Copper Wire.

From www.pinterest.com

[Visit to Buy] 5x 15m 0.1MM Copper Soldering Solder Enamelled Reel Wire How To Solder Enameled Copper Wire Scraping the enamel carefully off with a sharp knife or blade, while trying not to nick the. tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2. Next, tin the wire by applying a small. put the enamelled copper wire in 98% sulphuric acid. How To Solder Enameled Copper Wire.

From www.hardwaremise.com.my

Enameled Copper Wire Solderable Winding Wire Wire Coil Dawai How To Solder Enameled Copper Wire tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2. The coating lifts and floats away. how to solder enameled copper wire. Next, tin the wire by applying a small. first, clean the wire thoroughly by gently scraping off the enamel coating using. How To Solder Enameled Copper Wire.

From www.youtube.com

SolderJS 134 [LIVE] How to Strip and Solder Enameled Wire (See How To Solder Enameled Copper Wire first, clean the wire thoroughly by gently scraping off the enamel coating using fine sandpaper or a wire stripper. how to solder enameled copper wire. The coating lifts and floats away. Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on just. put the enamelled copper wire in 98%. How To Solder Enameled Copper Wire.

From exozqokfw.blob.core.windows.net

How To Solder Copper Wires at Lucille Walker blog How To Solder Enameled Copper Wire first, clean the wire thoroughly by gently scraping off the enamel coating using fine sandpaper or a wire stripper. 66k views 11 years ago. The coating lifts and floats away. tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2. begin by melting. How To Solder Enameled Copper Wire.

From www.walmart.com

0.1mm Diameter Copper Soldering Solder PPA Enamelled Repair Reel Wire How To Solder Enameled Copper Wire first, clean the wire thoroughly by gently scraping off the enamel coating using fine sandpaper or a wire stripper. The coating lifts and floats away. Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on just. tldr ⚡ 1) set iron to 400 c 2) get a nice blob of. How To Solder Enameled Copper Wire.

From exozqokfw.blob.core.windows.net

How To Solder Copper Wires at Lucille Walker blog How To Solder Enameled Copper Wire Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on just. how to solder enameled copper wire. 66k views 11 years ago. put the enamelled copper wire in 98% sulphuric acid for 10 minutes. first, clean the wire thoroughly by gently scraping off the enamel coating using fine sandpaper. How To Solder Enameled Copper Wire.

From www.supercheapauto.com.au

How to Solder Wires Wire Joining Supercheap Auto How To Solder Enameled Copper Wire common ways of removing the insulation on enameled wire include: how to solder enameled copper wire. The coating lifts and floats away. put the enamelled copper wire in 98% sulphuric acid for 10 minutes. tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn. How To Solder Enameled Copper Wire.