How To Crimp A Crimp Sleeve . With the stripped wire fully inserted into the terminal barrel, use the crimping tool to compress the terminal firmly around the wire. How are crimp sleeves applied? The process involves placing the. Otherwise, use pliers, or get a hammer and chisel and dent the sleeve at two or three points with the chisel. The process typically requires a crimping tool, which. Crimp sleeves are applied using a specialized crimping tool. If you can use a big vise to crush them down, that's probably the most 'controlled' way. How to make good crimps. How to connect ground wires: Crimping aluminum cable sleeves involves compressing an aluminum sleeve onto the end of a cable to create a secure connection. Expert tips for proper crimping of heavy monofilament and fluorocarbon leaders. But, unlike crimp sleeves meant for miniature cable, these. Crimping is the process of using a machine or tool to apply force to a sleeve to compress it onto a cable. To ensure that you get a maximum hold while crimping, allow the cable to.

from dxouttqfg.blob.core.windows.net

Crimping is the process of using a machine or tool to apply force to a sleeve to compress it onto a cable. The process typically requires a crimping tool, which. Crimp sleeves are applied using a specialized crimping tool. How to connect ground wires: With the stripped wire fully inserted into the terminal barrel, use the crimping tool to compress the terminal firmly around the wire. But, unlike crimp sleeves meant for miniature cable, these. The process involves placing the. Otherwise, use pliers, or get a hammer and chisel and dent the sleeve at two or three points with the chisel. To ensure that you get a maximum hold while crimping, allow the cable to. Expert tips for proper crimping of heavy monofilament and fluorocarbon leaders.

How To Crimp Brake Cable Ends at Dennis Corona blog

How To Crimp A Crimp Sleeve Crimp sleeves are applied using a specialized crimping tool. Crimping aluminum cable sleeves involves compressing an aluminum sleeve onto the end of a cable to create a secure connection. The process involves placing the. But, unlike crimp sleeves meant for miniature cable, these. The process typically requires a crimping tool, which. Crimping is the process of using a machine or tool to apply force to a sleeve to compress it onto a cable. With the stripped wire fully inserted into the terminal barrel, use the crimping tool to compress the terminal firmly around the wire. How to connect ground wires: If you can use a big vise to crush them down, that's probably the most 'controlled' way. To ensure that you get a maximum hold while crimping, allow the cable to. Expert tips for proper crimping of heavy monofilament and fluorocarbon leaders. How are crimp sleeves applied? How to make good crimps. Otherwise, use pliers, or get a hammer and chisel and dent the sleeve at two or three points with the chisel. Crimp sleeves are applied using a specialized crimping tool.

From loejknehw.blob.core.windows.net

How To Crimp Coax Connectors at Kyle Wenzel blog How To Crimp A Crimp Sleeve Expert tips for proper crimping of heavy monofilament and fluorocarbon leaders. If you can use a big vise to crush them down, that's probably the most 'controlled' way. Otherwise, use pliers, or get a hammer and chisel and dent the sleeve at two or three points with the chisel. How to make good crimps. With the stripped wire fully inserted. How To Crimp A Crimp Sleeve.

From www.rogeecar.co

wire rope sleeve crimp tool crimping tool for wire rope Singapp How To Crimp A Crimp Sleeve Crimping is the process of using a machine or tool to apply force to a sleeve to compress it onto a cable. How to make good crimps. The process involves placing the. Crimping aluminum cable sleeves involves compressing an aluminum sleeve onto the end of a cable to create a secure connection. To ensure that you get a maximum hold. How To Crimp A Crimp Sleeve.

From www.youtube.com

Steel Wire Rope Mini Crimping Tool 1mm 1.5mm 2mm 2.5mm YouTube How To Crimp A Crimp Sleeve With the stripped wire fully inserted into the terminal barrel, use the crimping tool to compress the terminal firmly around the wire. How to connect ground wires: Crimping aluminum cable sleeves involves compressing an aluminum sleeve onto the end of a cable to create a secure connection. Crimping is the process of using a machine or tool to apply force. How To Crimp A Crimp Sleeve.

From www.avoutlet.com

ViaBlue Speaker Wire Copper Crimp Sleeves How To Crimp A Crimp Sleeve Otherwise, use pliers, or get a hammer and chisel and dent the sleeve at two or three points with the chisel. How to make good crimps. Expert tips for proper crimping of heavy monofilament and fluorocarbon leaders. How are crimp sleeves applied? To ensure that you get a maximum hold while crimping, allow the cable to. Crimping is the process. How To Crimp A Crimp Sleeve.

From loeipeklj.blob.core.windows.net

How To Crimp Circular Connectors at Monique Johnson blog How To Crimp A Crimp Sleeve Crimp sleeves are applied using a specialized crimping tool. Crimping is the process of using a machine or tool to apply force to a sleeve to compress it onto a cable. Expert tips for proper crimping of heavy monofilament and fluorocarbon leaders. Crimping aluminum cable sleeves involves compressing an aluminum sleeve onto the end of a cable to create a. How To Crimp A Crimp Sleeve.

From www.amazon.ca

Single Barrel Crimp Sleeves 100pcs Copper Crimping Loop Sleeve Fishing How To Crimp A Crimp Sleeve Crimp sleeves are applied using a specialized crimping tool. With the stripped wire fully inserted into the terminal barrel, use the crimping tool to compress the terminal firmly around the wire. Otherwise, use pliers, or get a hammer and chisel and dent the sleeve at two or three points with the chisel. If you can use a big vise to. How To Crimp A Crimp Sleeve.

From schematicpartkaraoke.z14.web.core.windows.net

24 Gauge Wire Crimp Connectors How To Crimp A Crimp Sleeve If you can use a big vise to crush them down, that's probably the most 'controlled' way. How to connect ground wires: Otherwise, use pliers, or get a hammer and chisel and dent the sleeve at two or three points with the chisel. Crimp sleeves are applied using a specialized crimping tool. Crimping aluminum cable sleeves involves compressing an aluminum. How To Crimp A Crimp Sleeve.

From exodtbipw.blob.core.windows.net

How To Crimp Wires Together at Michael Mcninch blog How To Crimp A Crimp Sleeve To ensure that you get a maximum hold while crimping, allow the cable to. The process typically requires a crimping tool, which. Expert tips for proper crimping of heavy monofilament and fluorocarbon leaders. If you can use a big vise to crush them down, that's probably the most 'controlled' way. The process involves placing the. But, unlike crimp sleeves meant. How To Crimp A Crimp Sleeve.

From www.youtube.com

How to Use Crimping Pliers to Crimp Crimp Beads Tutorial Video Fusion How To Crimp A Crimp Sleeve Crimping is the process of using a machine or tool to apply force to a sleeve to compress it onto a cable. How are crimp sleeves applied? The process typically requires a crimping tool, which. Crimping aluminum cable sleeves involves compressing an aluminum sleeve onto the end of a cable to create a secure connection. How to connect ground wires:. How To Crimp A Crimp Sleeve.

From dxoyyvyli.blob.core.windows.net

How To Crimp A F Connector at William Rigg blog How To Crimp A Crimp Sleeve Expert tips for proper crimping of heavy monofilament and fluorocarbon leaders. But, unlike crimp sleeves meant for miniature cable, these. The process typically requires a crimping tool, which. Otherwise, use pliers, or get a hammer and chisel and dent the sleeve at two or three points with the chisel. Crimping aluminum cable sleeves involves compressing an aluminum sleeve onto the. How To Crimp A Crimp Sleeve.

From atelier-yuwa.ciao.jp

Crimping Wire atelieryuwa.ciao.jp How To Crimp A Crimp Sleeve The process involves placing the. But, unlike crimp sleeves meant for miniature cable, these. How are crimp sleeves applied? If you can use a big vise to crush them down, that's probably the most 'controlled' way. With the stripped wire fully inserted into the terminal barrel, use the crimping tool to compress the terminal firmly around the wire. Crimping aluminum. How To Crimp A Crimp Sleeve.

From www.aliexpress.com

Buy 100x Butt Splice Connectors 10mm Copper 22 10AWG How To Crimp A Crimp Sleeve Otherwise, use pliers, or get a hammer and chisel and dent the sleeve at two or three points with the chisel. Crimp sleeves are applied using a specialized crimping tool. Expert tips for proper crimping of heavy monofilament and fluorocarbon leaders. But, unlike crimp sleeves meant for miniature cable, these. If you can use a big vise to crush them. How To Crimp A Crimp Sleeve.

From joipcvhzx.blob.core.windows.net

How To Use Inline Crimp Connectors at Martin Jumper blog How To Crimp A Crimp Sleeve But, unlike crimp sleeves meant for miniature cable, these. To ensure that you get a maximum hold while crimping, allow the cable to. With the stripped wire fully inserted into the terminal barrel, use the crimping tool to compress the terminal firmly around the wire. How to make good crimps. The process involves placing the. Expert tips for proper crimping. How To Crimp A Crimp Sleeve.

From dxouttqfg.blob.core.windows.net

How To Crimp Brake Cable Ends at Dennis Corona blog How To Crimp A Crimp Sleeve The process typically requires a crimping tool, which. How to connect ground wires: But, unlike crimp sleeves meant for miniature cable, these. Otherwise, use pliers, or get a hammer and chisel and dent the sleeve at two or three points with the chisel. To ensure that you get a maximum hold while crimping, allow the cable to. If you can. How To Crimp A Crimp Sleeve.

From www.youtube.com

How To Crimp A JSTXH Pin PR3254/SN28B Crimping Tutorial for Dupont How To Crimp A Crimp Sleeve The process typically requires a crimping tool, which. How to connect ground wires: To ensure that you get a maximum hold while crimping, allow the cable to. With the stripped wire fully inserted into the terminal barrel, use the crimping tool to compress the terminal firmly around the wire. Crimp sleeves are applied using a specialized crimping tool. Expert tips. How To Crimp A Crimp Sleeve.

From natashaturner.z13.web.core.windows.net

Crimp Sleeve Size Chart How To Crimp A Crimp Sleeve How to make good crimps. Crimping aluminum cable sleeves involves compressing an aluminum sleeve onto the end of a cable to create a secure connection. How are crimp sleeves applied? The process involves placing the. Crimp sleeves are applied using a specialized crimping tool. Otherwise, use pliers, or get a hammer and chisel and dent the sleeve at two or. How To Crimp A Crimp Sleeve.

From electricbike.com

How To Crimp an Anderson Powerpole Connector How To Crimp A Crimp Sleeve If you can use a big vise to crush them down, that's probably the most 'controlled' way. But, unlike crimp sleeves meant for miniature cable, these. With the stripped wire fully inserted into the terminal barrel, use the crimping tool to compress the terminal firmly around the wire. Crimping is the process of using a machine or tool to apply. How To Crimp A Crimp Sleeve.

From loeipeklj.blob.core.windows.net

How To Crimp Circular Connectors at Monique Johnson blog How To Crimp A Crimp Sleeve If you can use a big vise to crush them down, that's probably the most 'controlled' way. To ensure that you get a maximum hold while crimping, allow the cable to. But, unlike crimp sleeves meant for miniature cable, these. The process typically requires a crimping tool, which. Crimping is the process of using a machine or tool to apply. How To Crimp A Crimp Sleeve.

From www.premier1supplies.com

Crimp Sleeves Premier1Supplies How To Crimp A Crimp Sleeve Crimp sleeves are applied using a specialized crimping tool. If you can use a big vise to crush them down, that's probably the most 'controlled' way. The process involves placing the. The process typically requires a crimping tool, which. Expert tips for proper crimping of heavy monofilament and fluorocarbon leaders. To ensure that you get a maximum hold while crimping,. How To Crimp A Crimp Sleeve.

From electronics.stackexchange.com

How to crimp a ferrules(end sleeve)without a crimper? Electrical How To Crimp A Crimp Sleeve The process typically requires a crimping tool, which. With the stripped wire fully inserted into the terminal barrel, use the crimping tool to compress the terminal firmly around the wire. How to connect ground wires: The process involves placing the. Crimp sleeves are applied using a specialized crimping tool. How are crimp sleeves applied? If you can use a big. How To Crimp A Crimp Sleeve.

From www.desertcart.in

Buy Sanuke Wire Rope Crimping Swaging Tool Cable Crimps up to 2.2mm(2 How To Crimp A Crimp Sleeve Otherwise, use pliers, or get a hammer and chisel and dent the sleeve at two or three points with the chisel. With the stripped wire fully inserted into the terminal barrel, use the crimping tool to compress the terminal firmly around the wire. To ensure that you get a maximum hold while crimping, allow the cable to. The process typically. How To Crimp A Crimp Sleeve.

From info.waytekwire.com

Wire Crimping Techniques & Tools by Molex® How To Crimp A Crimp Sleeve To ensure that you get a maximum hold while crimping, allow the cable to. The process typically requires a crimping tool, which. Crimp sleeves are applied using a specialized crimping tool. Expert tips for proper crimping of heavy monofilament and fluorocarbon leaders. But, unlike crimp sleeves meant for miniature cable, these. Otherwise, use pliers, or get a hammer and chisel. How To Crimp A Crimp Sleeve.

From klawtcqxl.blob.core.windows.net

How To Crimp Motorcycle Connectors at Bryan Redmond blog How To Crimp A Crimp Sleeve Otherwise, use pliers, or get a hammer and chisel and dent the sleeve at two or three points with the chisel. How to make good crimps. Crimping aluminum cable sleeves involves compressing an aluminum sleeve onto the end of a cable to create a secure connection. Crimp sleeves are applied using a specialized crimping tool. Crimping is the process of. How To Crimp A Crimp Sleeve.

From www.nichifu.co.jp

Basic Guide to Terminal Crimping 2. How to Crimp a Terminal Nichifu How To Crimp A Crimp Sleeve How are crimp sleeves applied? Crimp sleeves are applied using a specialized crimping tool. Otherwise, use pliers, or get a hammer and chisel and dent the sleeve at two or three points with the chisel. Crimping is the process of using a machine or tool to apply force to a sleeve to compress it onto a cable. To ensure that. How To Crimp A Crimp Sleeve.

From electronics.stackexchange.com

How to crimp a ferrules(end sleeve)without a crimper? Electrical How To Crimp A Crimp Sleeve The process typically requires a crimping tool, which. With the stripped wire fully inserted into the terminal barrel, use the crimping tool to compress the terminal firmly around the wire. Crimping aluminum cable sleeves involves compressing an aluminum sleeve onto the end of a cable to create a secure connection. To ensure that you get a maximum hold while crimping,. How To Crimp A Crimp Sleeve.

From www.etco.com

CRIMP ON SOLID WIRE ELIMINATES SOLDERING AND WELDING ETCO How To Crimp A Crimp Sleeve Crimping is the process of using a machine or tool to apply force to a sleeve to compress it onto a cable. Crimping aluminum cable sleeves involves compressing an aluminum sleeve onto the end of a cable to create a secure connection. Crimp sleeves are applied using a specialized crimping tool. The process involves placing the. But, unlike crimp sleeves. How To Crimp A Crimp Sleeve.

From johnmurray.com

Wire Rope Crimp Tips John Murray Productions How To Crimp A Crimp Sleeve Crimping is the process of using a machine or tool to apply force to a sleeve to compress it onto a cable. Crimp sleeves are applied using a specialized crimping tool. How to connect ground wires: If you can use a big vise to crush them down, that's probably the most 'controlled' way. The process typically requires a crimping tool,. How To Crimp A Crimp Sleeve.

From www.nsiindustries.com

Copper Crimp Sleeve for Grounding or Uninsulated Wires, 50 Pack NSI How To Crimp A Crimp Sleeve With the stripped wire fully inserted into the terminal barrel, use the crimping tool to compress the terminal firmly around the wire. How to make good crimps. But, unlike crimp sleeves meant for miniature cable, these. Crimping aluminum cable sleeves involves compressing an aluminum sleeve onto the end of a cable to create a secure connection. How to connect ground. How To Crimp A Crimp Sleeve.

From www.uta.com.tw

Bare Terminal Crimping Tool Ratchet Crimper UTA How To Crimp A Crimp Sleeve If you can use a big vise to crush them down, that's probably the most 'controlled' way. How are crimp sleeves applied? How to make good crimps. Crimping aluminum cable sleeves involves compressing an aluminum sleeve onto the end of a cable to create a secure connection. With the stripped wire fully inserted into the terminal barrel, use the crimping. How To Crimp A Crimp Sleeve.

From joimwscfy.blob.core.windows.net

How To Crimp And Solder Battery Cables at Delisa Voss blog How To Crimp A Crimp Sleeve But, unlike crimp sleeves meant for miniature cable, these. The process typically requires a crimping tool, which. Crimping is the process of using a machine or tool to apply force to a sleeve to compress it onto a cable. How to connect ground wires: How to make good crimps. To ensure that you get a maximum hold while crimping, allow. How To Crimp A Crimp Sleeve.

From wiringmanualreiterance.z21.web.core.windows.net

How To Use An Electrical Crimping Tool How To Crimp A Crimp Sleeve But, unlike crimp sleeves meant for miniature cable, these. Crimping is the process of using a machine or tool to apply force to a sleeve to compress it onto a cable. To ensure that you get a maximum hold while crimping, allow the cable to. How are crimp sleeves applied? Otherwise, use pliers, or get a hammer and chisel and. How To Crimp A Crimp Sleeve.

From exodtbipw.blob.core.windows.net

How To Crimp Wires Together at Michael Mcninch blog How To Crimp A Crimp Sleeve How are crimp sleeves applied? Crimping is the process of using a machine or tool to apply force to a sleeve to compress it onto a cable. The process typically requires a crimping tool, which. Expert tips for proper crimping of heavy monofilament and fluorocarbon leaders. Crimp sleeves are applied using a specialized crimping tool. Crimping aluminum cable sleeves involves. How To Crimp A Crimp Sleeve.

From www.youtube.com

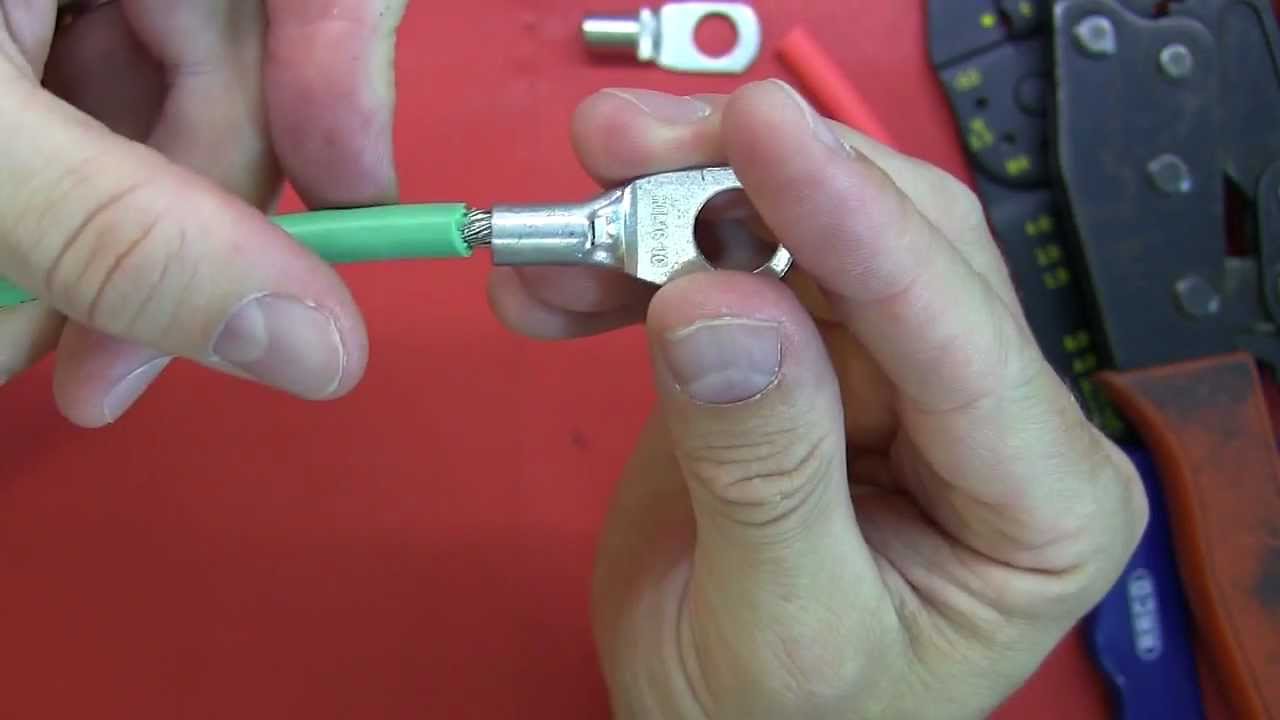

how to crimp a ground wire crimp sleeve using the south wire crimper How To Crimp A Crimp Sleeve How to connect ground wires: But, unlike crimp sleeves meant for miniature cable, these. With the stripped wire fully inserted into the terminal barrel, use the crimping tool to compress the terminal firmly around the wire. Crimping is the process of using a machine or tool to apply force to a sleeve to compress it onto a cable. Crimping aluminum. How To Crimp A Crimp Sleeve.

From jan-takayama.com

Crimp connector Jewelry & Beauty Findings How To Crimp A Crimp Sleeve But, unlike crimp sleeves meant for miniature cable, these. Crimping is the process of using a machine or tool to apply force to a sleeve to compress it onto a cable. Otherwise, use pliers, or get a hammer and chisel and dent the sleeve at two or three points with the chisel. To ensure that you get a maximum hold. How To Crimp A Crimp Sleeve.

From www.premier1supplies.com

Crimp Sleeves Premier1Supplies How To Crimp A Crimp Sleeve The process involves placing the. With the stripped wire fully inserted into the terminal barrel, use the crimping tool to compress the terminal firmly around the wire. But, unlike crimp sleeves meant for miniature cable, these. To ensure that you get a maximum hold while crimping, allow the cable to. Expert tips for proper crimping of heavy monofilament and fluorocarbon. How To Crimp A Crimp Sleeve.