What Is Joining In Engineering . Joining processes are the processes that are used for joining metal parts and metal fabrication work. Mechanical joining, using fasteners where the elastic and/or. In general terms, there are three basic methods of joining material together: The three most common methods which are practiced by automotive manufacturers are fusion welding, adhesive bonding, and mechanical fasteners. The primary difference between joining and forming processes is that joining processes involve fusing multiple components together, whereas forming processes involve. By definition, joining is one of the manufacturing processes by which two or more materials can be permanently or temporarily joined or assembled. Joining methods can affect the cost, quality,. It is the process of permanent or temporary joining of two metal pieces with the help of heat or pressure. Two metal parts are assembled by applying an. Putting one or more piece together to form a permanent shape is called joining.

from www.hpac.com

It is the process of permanent or temporary joining of two metal pieces with the help of heat or pressure. Mechanical joining, using fasteners where the elastic and/or. Joining processes are the processes that are used for joining metal parts and metal fabrication work. The primary difference between joining and forming processes is that joining processes involve fusing multiple components together, whereas forming processes involve. Putting one or more piece together to form a permanent shape is called joining. The three most common methods which are practiced by automotive manufacturers are fusion welding, adhesive bonding, and mechanical fasteners. In general terms, there are three basic methods of joining material together: Joining methods can affect the cost, quality,. Two metal parts are assembled by applying an. By definition, joining is one of the manufacturing processes by which two or more materials can be permanently or temporarily joined or assembled.

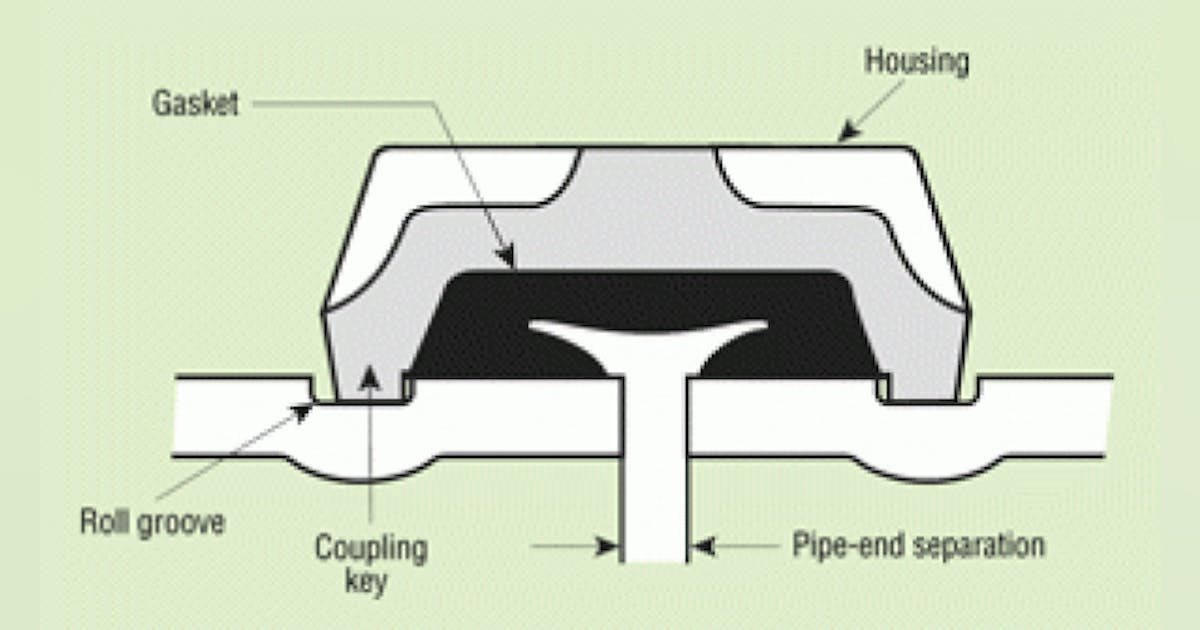

Grooved Mechanical PipeJoining Systems HPAC Engineering

What Is Joining In Engineering In general terms, there are three basic methods of joining material together: Putting one or more piece together to form a permanent shape is called joining. Two metal parts are assembled by applying an. Mechanical joining, using fasteners where the elastic and/or. In general terms, there are three basic methods of joining material together: By definition, joining is one of the manufacturing processes by which two or more materials can be permanently or temporarily joined or assembled. The three most common methods which are practiced by automotive manufacturers are fusion welding, adhesive bonding, and mechanical fasteners. It is the process of permanent or temporary joining of two metal pieces with the help of heat or pressure. Joining methods can affect the cost, quality,. The primary difference between joining and forming processes is that joining processes involve fusing multiple components together, whereas forming processes involve. Joining processes are the processes that are used for joining metal parts and metal fabrication work.

From www.youtube.com

Metal Joining Processes Welding, Riveting, Bolting, Brazing, Soldering What Is Joining In Engineering In general terms, there are three basic methods of joining material together: Joining methods can affect the cost, quality,. Putting one or more piece together to form a permanent shape is called joining. Two metal parts are assembled by applying an. It is the process of permanent or temporary joining of two metal pieces with the help of heat or. What Is Joining In Engineering.

From www.slideshare.net

Introduction on Materials Joining Engineering What Is Joining In Engineering The primary difference between joining and forming processes is that joining processes involve fusing multiple components together, whereas forming processes involve. By definition, joining is one of the manufacturing processes by which two or more materials can be permanently or temporarily joined or assembled. The three most common methods which are practiced by automotive manufacturers are fusion welding, adhesive bonding,. What Is Joining In Engineering.

From www.youtube.com

Joining Methods Introduction YouTube What Is Joining In Engineering Joining processes are the processes that are used for joining metal parts and metal fabrication work. Putting one or more piece together to form a permanent shape is called joining. By definition, joining is one of the manufacturing processes by which two or more materials can be permanently or temporarily joined or assembled. Two metal parts are assembled by applying. What Is Joining In Engineering.

From www.cpvmfg.com

Joining Metals Your Frequently Asked Questions About Brazing, Answered What Is Joining In Engineering In general terms, there are three basic methods of joining material together: Mechanical joining, using fasteners where the elastic and/or. Putting one or more piece together to form a permanent shape is called joining. It is the process of permanent or temporary joining of two metal pieces with the help of heat or pressure. Joining processes are the processes that. What Is Joining In Engineering.

From www.slideserve.com

PPT Crafting a Successful Engineering Career PowerPoint Presentation What Is Joining In Engineering Mechanical joining, using fasteners where the elastic and/or. The three most common methods which are practiced by automotive manufacturers are fusion welding, adhesive bonding, and mechanical fasteners. The primary difference between joining and forming processes is that joining processes involve fusing multiple components together, whereas forming processes involve. Putting one or more piece together to form a permanent shape is. What Is Joining In Engineering.

From ewi.org

Welding & Joining Processes EWI Welding & Joining Technology What Is Joining In Engineering Putting one or more piece together to form a permanent shape is called joining. By definition, joining is one of the manufacturing processes by which two or more materials can be permanently or temporarily joined or assembled. Mechanical joining, using fasteners where the elastic and/or. Joining methods can affect the cost, quality,. The primary difference between joining and forming processes. What Is Joining In Engineering.

From www.youtube.com

temporary joining methods YouTube What Is Joining In Engineering In general terms, there are three basic methods of joining material together: It is the process of permanent or temporary joining of two metal pieces with the help of heat or pressure. Joining processes are the processes that are used for joining metal parts and metal fabrication work. Joining methods can affect the cost, quality,. The three most common methods. What Is Joining In Engineering.

From www.difference.minaprem.com

Difference Between Temporary Joining and Permanent Joining What Is Joining In Engineering Mechanical joining, using fasteners where the elastic and/or. In general terms, there are three basic methods of joining material together: By definition, joining is one of the manufacturing processes by which two or more materials can be permanently or temporarily joined or assembled. The three most common methods which are practiced by automotive manufacturers are fusion welding, adhesive bonding, and. What Is Joining In Engineering.

From www.slideserve.com

PPT Materials Technology Joining Processes PowerPoint Presentation What Is Joining In Engineering The three most common methods which are practiced by automotive manufacturers are fusion welding, adhesive bonding, and mechanical fasteners. In general terms, there are three basic methods of joining material together: Putting one or more piece together to form a permanent shape is called joining. By definition, joining is one of the manufacturing processes by which two or more materials. What Is Joining In Engineering.

From www.theengineeringprojects.com

Skills & Attributes Needed In Engineering The Engineering Projects What Is Joining In Engineering Two metal parts are assembled by applying an. The three most common methods which are practiced by automotive manufacturers are fusion welding, adhesive bonding, and mechanical fasteners. Joining methods can affect the cost, quality,. In general terms, there are three basic methods of joining material together: Mechanical joining, using fasteners where the elastic and/or. By definition, joining is one of. What Is Joining In Engineering.

From www.differencebox.com

Difference Between Temporary Joining and Permanent Joining What Is Joining In Engineering Joining processes are the processes that are used for joining metal parts and metal fabrication work. By definition, joining is one of the manufacturing processes by which two or more materials can be permanently or temporarily joined or assembled. Two metal parts are assembled by applying an. Mechanical joining, using fasteners where the elastic and/or. The primary difference between joining. What Is Joining In Engineering.

From www.slideserve.com

PPT Materials Technology Joining Processes PowerPoint Presentation What Is Joining In Engineering In general terms, there are three basic methods of joining material together: The three most common methods which are practiced by automotive manufacturers are fusion welding, adhesive bonding, and mechanical fasteners. Two metal parts are assembled by applying an. Joining processes are the processes that are used for joining metal parts and metal fabrication work. By definition, joining is one. What Is Joining In Engineering.

From www.researchgate.net

Schematic diagram of joining process. Download Scientific Diagram What Is Joining In Engineering The three most common methods which are practiced by automotive manufacturers are fusion welding, adhesive bonding, and mechanical fasteners. Putting one or more piece together to form a permanent shape is called joining. Mechanical joining, using fasteners where the elastic and/or. Joining processes are the processes that are used for joining metal parts and metal fabrication work. It is the. What Is Joining In Engineering.

From www.youtube.com

MANUFACTURING PROCESS (HINDI) METAL JOINING PROCESS (HINDI) WORKING What Is Joining In Engineering Mechanical joining, using fasteners where the elastic and/or. Two metal parts are assembled by applying an. It is the process of permanent or temporary joining of two metal pieces with the help of heat or pressure. In general terms, there are three basic methods of joining material together: Joining methods can affect the cost, quality,. By definition, joining is one. What Is Joining In Engineering.

From education.nationalgeographic.org

The Engineering Design Process Taco Party What Is Joining In Engineering Two metal parts are assembled by applying an. The three most common methods which are practiced by automotive manufacturers are fusion welding, adhesive bonding, and mechanical fasteners. Joining processes are the processes that are used for joining metal parts and metal fabrication work. It is the process of permanent or temporary joining of two metal pieces with the help of. What Is Joining In Engineering.

From www.differencebox.com

Difference Between Joining and Welding What Is Joining In Engineering It is the process of permanent or temporary joining of two metal pieces with the help of heat or pressure. By definition, joining is one of the manufacturing processes by which two or more materials can be permanently or temporarily joined or assembled. The primary difference between joining and forming processes is that joining processes involve fusing multiple components together,. What Is Joining In Engineering.

From www.hpac.com

Grooved Mechanical PipeJoining Systems HPAC Engineering What Is Joining In Engineering It is the process of permanent or temporary joining of two metal pieces with the help of heat or pressure. Two metal parts are assembled by applying an. Joining processes are the processes that are used for joining metal parts and metal fabrication work. Putting one or more piece together to form a permanent shape is called joining. Joining methods. What Is Joining In Engineering.

From www.twi-global.com

What is the Engineering Design Process? A Complete Guide TWI What Is Joining In Engineering The primary difference between joining and forming processes is that joining processes involve fusing multiple components together, whereas forming processes involve. The three most common methods which are practiced by automotive manufacturers are fusion welding, adhesive bonding, and mechanical fasteners. Joining methods can affect the cost, quality,. It is the process of permanent or temporary joining of two metal pieces. What Is Joining In Engineering.

From www.youtube.com

What are Joining Processes (metalworking)? YouTube What Is Joining In Engineering Two metal parts are assembled by applying an. The three most common methods which are practiced by automotive manufacturers are fusion welding, adhesive bonding, and mechanical fasteners. Joining processes are the processes that are used for joining metal parts and metal fabrication work. By definition, joining is one of the manufacturing processes by which two or more materials can be. What Is Joining In Engineering.

From www.slideserve.com

PPT Materials Technology Joining Processes PowerPoint Presentation What Is Joining In Engineering The three most common methods which are practiced by automotive manufacturers are fusion welding, adhesive bonding, and mechanical fasteners. Joining processes are the processes that are used for joining metal parts and metal fabrication work. Joining methods can affect the cost, quality,. In general terms, there are three basic methods of joining material together: Two metal parts are assembled by. What Is Joining In Engineering.

From www.slideshare.net

Introduction on Materials Joining Engineering What Is Joining In Engineering Putting one or more piece together to form a permanent shape is called joining. It is the process of permanent or temporary joining of two metal pieces with the help of heat or pressure. Joining methods can affect the cost, quality,. By definition, joining is one of the manufacturing processes by which two or more materials can be permanently or. What Is Joining In Engineering.

From iimtu.edu.in

Why Join Civil Engineering as a Career? What Is Joining In Engineering Joining processes are the processes that are used for joining metal parts and metal fabrication work. The three most common methods which are practiced by automotive manufacturers are fusion welding, adhesive bonding, and mechanical fasteners. By definition, joining is one of the manufacturing processes by which two or more materials can be permanently or temporarily joined or assembled. It is. What Is Joining In Engineering.

From www.slideshare.net

Introduction on Materials Joining Engineering What Is Joining In Engineering It is the process of permanent or temporary joining of two metal pieces with the help of heat or pressure. Putting one or more piece together to form a permanent shape is called joining. Two metal parts are assembled by applying an. Joining methods can affect the cost, quality,. The three most common methods which are practiced by automotive manufacturers. What Is Joining In Engineering.

From www.slideshare.net

Introduction on Materials Joining Engineering What Is Joining In Engineering Joining methods can affect the cost, quality,. The primary difference between joining and forming processes is that joining processes involve fusing multiple components together, whereas forming processes involve. It is the process of permanent or temporary joining of two metal pieces with the help of heat or pressure. In general terms, there are three basic methods of joining material together:. What Is Joining In Engineering.

From www.slideserve.com

PPT Unit 6 Manufacturing Processes Machining and Joining PowerPoint What Is Joining In Engineering The primary difference between joining and forming processes is that joining processes involve fusing multiple components together, whereas forming processes involve. Joining processes are the processes that are used for joining metal parts and metal fabrication work. Two metal parts are assembled by applying an. The three most common methods which are practiced by automotive manufacturers are fusion welding, adhesive. What Is Joining In Engineering.

From technonguide.com

TOP REASONS TO JOIN ENGINEERING FOR A GREAT CAREER What Is Joining In Engineering Joining processes are the processes that are used for joining metal parts and metal fabrication work. Joining methods can affect the cost, quality,. The primary difference between joining and forming processes is that joining processes involve fusing multiple components together, whereas forming processes involve. It is the process of permanent or temporary joining of two metal pieces with the help. What Is Joining In Engineering.

From www.mastersportal.com

What Can I with a Master's Degree in Civil Engineering What Is Joining In Engineering Joining processes are the processes that are used for joining metal parts and metal fabrication work. In general terms, there are three basic methods of joining material together: Joining methods can affect the cost, quality,. The primary difference between joining and forming processes is that joining processes involve fusing multiple components together, whereas forming processes involve. Two metal parts are. What Is Joining In Engineering.

From www.youtube.com

Lecture 3 Joining Techniques YouTube What Is Joining In Engineering The three most common methods which are practiced by automotive manufacturers are fusion welding, adhesive bonding, and mechanical fasteners. Joining processes are the processes that are used for joining metal parts and metal fabrication work. Putting one or more piece together to form a permanent shape is called joining. By definition, joining is one of the manufacturing processes by which. What Is Joining In Engineering.

From www.youtube.com

Introduction to joining process Types of Joining Lecture 1 YouTube What Is Joining In Engineering By definition, joining is one of the manufacturing processes by which two or more materials can be permanently or temporarily joined or assembled. In general terms, there are three basic methods of joining material together: It is the process of permanent or temporary joining of two metal pieces with the help of heat or pressure. Mechanical joining, using fasteners where. What Is Joining In Engineering.

From www.slideshare.net

Introduction on Materials Joining Engineering What Is Joining In Engineering By definition, joining is one of the manufacturing processes by which two or more materials can be permanently or temporarily joined or assembled. Mechanical joining, using fasteners where the elastic and/or. Joining processes are the processes that are used for joining metal parts and metal fabrication work. Putting one or more piece together to form a permanent shape is called. What Is Joining In Engineering.

From www.dreamstime.com

Engineers and Architecture Joining Handshake Together after Meet Stock What Is Joining In Engineering By definition, joining is one of the manufacturing processes by which two or more materials can be permanently or temporarily joined or assembled. The primary difference between joining and forming processes is that joining processes involve fusing multiple components together, whereas forming processes involve. Two metal parts are assembled by applying an. Joining processes are the processes that are used. What Is Joining In Engineering.

From www.researchgate.net

Different joining techniques for composite materials and their What Is Joining In Engineering It is the process of permanent or temporary joining of two metal pieces with the help of heat or pressure. The three most common methods which are practiced by automotive manufacturers are fusion welding, adhesive bonding, and mechanical fasteners. Joining methods can affect the cost, quality,. The primary difference between joining and forming processes is that joining processes involve fusing. What Is Joining In Engineering.

From www.slideserve.com

PPT Materials Technology Joining Processes PowerPoint Presentation What Is Joining In Engineering Joining processes are the processes that are used for joining metal parts and metal fabrication work. The three most common methods which are practiced by automotive manufacturers are fusion welding, adhesive bonding, and mechanical fasteners. Joining methods can affect the cost, quality,. In general terms, there are three basic methods of joining material together: By definition, joining is one of. What Is Joining In Engineering.

From www.slideshare.net

Introduction on Materials Joining Engineering What Is Joining In Engineering Joining methods can affect the cost, quality,. Putting one or more piece together to form a permanent shape is called joining. The primary difference between joining and forming processes is that joining processes involve fusing multiple components together, whereas forming processes involve. It is the process of permanent or temporary joining of two metal pieces with the help of heat. What Is Joining In Engineering.

From loeyjoqsz.blob.core.windows.net

Examples Of Joining Tools at Frederick Dougherty blog What Is Joining In Engineering Putting one or more piece together to form a permanent shape is called joining. By definition, joining is one of the manufacturing processes by which two or more materials can be permanently or temporarily joined or assembled. Joining processes are the processes that are used for joining metal parts and metal fabrication work. The primary difference between joining and forming. What Is Joining In Engineering.