Rib Definition Engineering . First, there is the integration width that defines the area for the integration of internal forces. Ribs are a great way to add strength and stiffness to a part while keeping material consumption to a minimum. Ribs are thin wall protrusions that extend perpendicularly from a wall or plane. All about ribs in product design. Ribbing is a hallmark of injection moulded parts because this detail does not “cost” anything on a per part basis. They are often used strategically to replace thick wall. An elongated projection on a shape, forging or casting to provide stiffening. This is especially true for. Ribs are thin support features frequently found in plastic injection moulded part designs. Engnet is an engineering directory, buyers guide and search. However, a word of caution:. For the rib in a 3d position, there are two essential parameters. One of the best ways to communicate one’s ideas is through some form of picture or drawing.

from www.animalia-life.club

They are often used strategically to replace thick wall. Ribbing is a hallmark of injection moulded parts because this detail does not “cost” anything on a per part basis. Engnet is an engineering directory, buyers guide and search. Ribs are thin wall protrusions that extend perpendicularly from a wall or plane. Ribs are thin support features frequently found in plastic injection moulded part designs. One of the best ways to communicate one’s ideas is through some form of picture or drawing. An elongated projection on a shape, forging or casting to provide stiffening. This is especially true for. All about ribs in product design. First, there is the integration width that defines the area for the integration of internal forces.

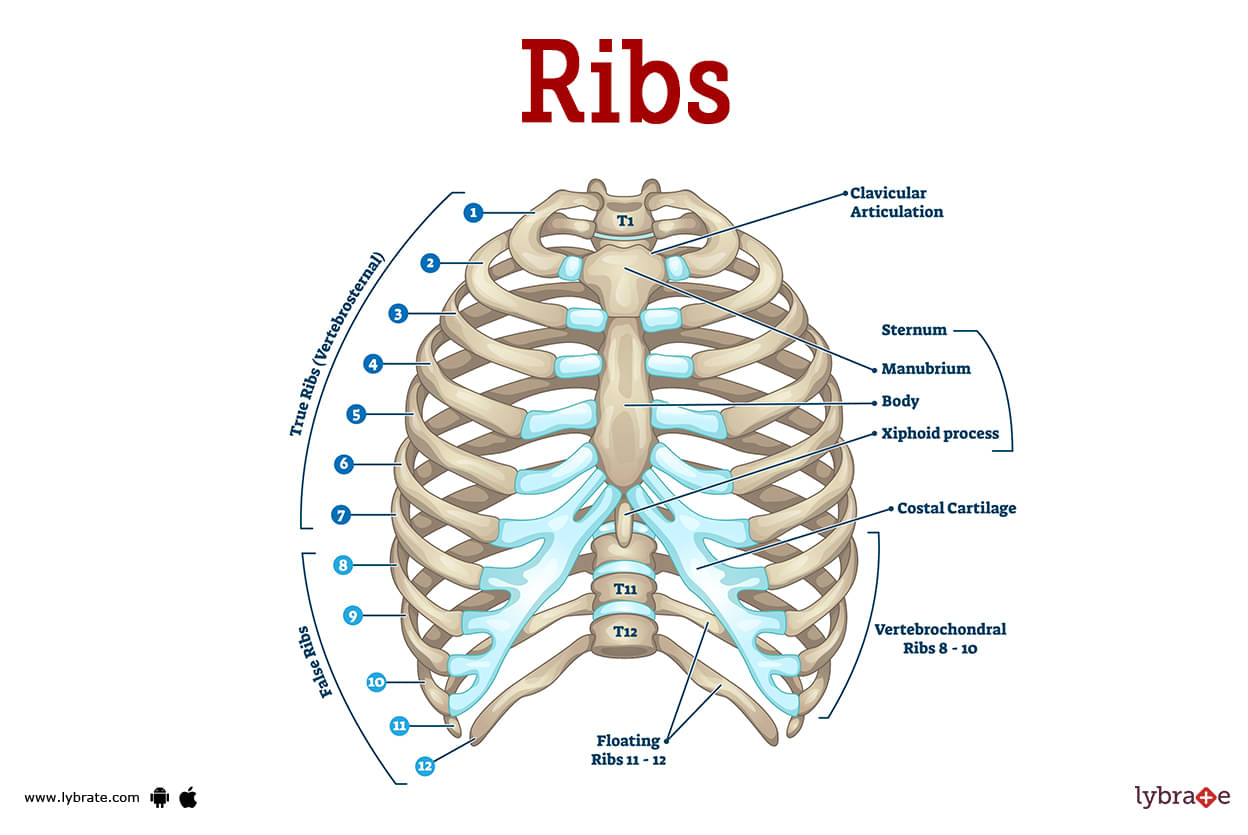

Floating Ribs

Rib Definition Engineering One of the best ways to communicate one’s ideas is through some form of picture or drawing. Ribbing is a hallmark of injection moulded parts because this detail does not “cost” anything on a per part basis. For the rib in a 3d position, there are two essential parameters. This is especially true for. One of the best ways to communicate one’s ideas is through some form of picture or drawing. Engnet is an engineering directory, buyers guide and search. Ribs are a great way to add strength and stiffness to a part while keeping material consumption to a minimum. Ribs are thin wall protrusions that extend perpendicularly from a wall or plane. Ribs are thin support features frequently found in plastic injection moulded part designs. An elongated projection on a shape, forging or casting to provide stiffening. However, a word of caution:. They are often used strategically to replace thick wall. First, there is the integration width that defines the area for the integration of internal forces. All about ribs in product design.

From giozezosp.blob.core.windows.net

Define Ribs And Function at Esmeralda Yang blog Rib Definition Engineering They are often used strategically to replace thick wall. This is especially true for. Ribs are a great way to add strength and stiffness to a part while keeping material consumption to a minimum. However, a word of caution:. An elongated projection on a shape, forging or casting to provide stiffening. All about ribs in product design. Ribbing is a. Rib Definition Engineering.

From www.researchgate.net

(a) Schematic diagram of rib profile of rebar; (b) front view of the Rib Definition Engineering Ribbing is a hallmark of injection moulded parts because this detail does not “cost” anything on a per part basis. First, there is the integration width that defines the area for the integration of internal forces. Ribs are thin wall protrusions that extend perpendicularly from a wall or plane. However, a word of caution:. Ribs are thin support features frequently. Rib Definition Engineering.

From giozezosp.blob.core.windows.net

Define Ribs And Function at Esmeralda Yang blog Rib Definition Engineering One of the best ways to communicate one’s ideas is through some form of picture or drawing. An elongated projection on a shape, forging or casting to provide stiffening. However, a word of caution:. Ribs are thin wall protrusions that extend perpendicularly from a wall or plane. All about ribs in product design. Ribbing is a hallmark of injection moulded. Rib Definition Engineering.

From www.youtube.com

True rib definition of TRUE RIB YouTube Rib Definition Engineering They are often used strategically to replace thick wall. One of the best ways to communicate one’s ideas is through some form of picture or drawing. Ribs are thin wall protrusions that extend perpendicularly from a wall or plane. Ribbing is a hallmark of injection moulded parts because this detail does not “cost” anything on a per part basis. For. Rib Definition Engineering.

From www.youtube.com

Structure Of The Rib Cage How Many Ribs In Human Body What Is The Rib Definition Engineering One of the best ways to communicate one’s ideas is through some form of picture or drawing. Ribbing is a hallmark of injection moulded parts because this detail does not “cost” anything on a per part basis. They are often used strategically to replace thick wall. Engnet is an engineering directory, buyers guide and search. Ribs are a great way. Rib Definition Engineering.

From www.nexpcb.com

How To Increase The Rigidity of Your Plastic The Rib Design Rib Definition Engineering All about ribs in product design. Engnet is an engineering directory, buyers guide and search. An elongated projection on a shape, forging or casting to provide stiffening. They are often used strategically to replace thick wall. This is especially true for. Ribs are a great way to add strength and stiffness to a part while keeping material consumption to a. Rib Definition Engineering.

From www.cannondigi.com

Rib Beam Slab The Best Picture Of Beam Rib Definition Engineering Engnet is an engineering directory, buyers guide and search. First, there is the integration width that defines the area for the integration of internal forces. Ribbing is a hallmark of injection moulded parts because this detail does not “cost” anything on a per part basis. However, a word of caution:. Ribs are a great way to add strength and stiffness. Rib Definition Engineering.

From engineeringdiscoveries.com

Different Types Of Arches Engineering Discoveries Rib Definition Engineering One of the best ways to communicate one’s ideas is through some form of picture or drawing. However, a word of caution:. An elongated projection on a shape, forging or casting to provide stiffening. Ribs are thin support features frequently found in plastic injection moulded part designs. Ribs are thin wall protrusions that extend perpendicularly from a wall or plane.. Rib Definition Engineering.

From www.slideshare.net

Engineering Drawing Chapter 10 convention in section Rib Definition Engineering Ribs are thin wall protrusions that extend perpendicularly from a wall or plane. Ribs are thin support features frequently found in plastic injection moulded part designs. This is especially true for. Ribs are a great way to add strength and stiffness to a part while keeping material consumption to a minimum. However, a word of caution:. First, there is the. Rib Definition Engineering.

From hxeyydirv.blob.core.windows.net

Rib Definition For Kindergarten at Tom Sullivan blog Rib Definition Engineering Ribs are a great way to add strength and stiffness to a part while keeping material consumption to a minimum. All about ribs in product design. They are often used strategically to replace thick wall. First, there is the integration width that defines the area for the integration of internal forces. This is especially true for. Ribs are thin wall. Rib Definition Engineering.

From microbenotes.com

Rib Cage Anatomy, Parts, Bones, Structures, Functions Rib Definition Engineering However, a word of caution:. One of the best ways to communicate one’s ideas is through some form of picture or drawing. Engnet is an engineering directory, buyers guide and search. For the rib in a 3d position, there are two essential parameters. Ribs are thin support features frequently found in plastic injection moulded part designs. Ribs are a great. Rib Definition Engineering.

From www.researchgate.net

Design and evaluation of the insuit rib prosthesis. (A) Resection plan Rib Definition Engineering Engnet is an engineering directory, buyers guide and search. An elongated projection on a shape, forging or casting to provide stiffening. First, there is the integration width that defines the area for the integration of internal forces. Ribs are thin wall protrusions that extend perpendicularly from a wall or plane. Ribs are a great way to add strength and stiffness. Rib Definition Engineering.

From dictionary.langeek.co

Definition & Meaning of "Rib" LanGeek Rib Definition Engineering Ribbing is a hallmark of injection moulded parts because this detail does not “cost” anything on a per part basis. One of the best ways to communicate one’s ideas is through some form of picture or drawing. Ribs are thin wall protrusions that extend perpendicularly from a wall or plane. Ribs are a great way to add strength and stiffness. Rib Definition Engineering.

From www.youtube.com

Rib Anatomy True Ribs, False Ribs, Floating Ribs Typical vs Rib Definition Engineering First, there is the integration width that defines the area for the integration of internal forces. Ribs are thin wall protrusions that extend perpendicularly from a wall or plane. Engnet is an engineering directory, buyers guide and search. Ribs are a great way to add strength and stiffness to a part while keeping material consumption to a minimum. For the. Rib Definition Engineering.

From byjus.com

What are true ribs, false ribs, and floating ribs? Why are floating Rib Definition Engineering Ribs are thin wall protrusions that extend perpendicularly from a wall or plane. This is especially true for. They are often used strategically to replace thick wall. Ribs are a great way to add strength and stiffness to a part while keeping material consumption to a minimum. An elongated projection on a shape, forging or casting to provide stiffening. One. Rib Definition Engineering.

From www.meddeviceonline.com

Ribs Design Guide Rib Definition Engineering Ribbing is a hallmark of injection moulded parts because this detail does not “cost” anything on a per part basis. Engnet is an engineering directory, buyers guide and search. First, there is the integration width that defines the area for the integration of internal forces. However, a word of caution:. They are often used strategically to replace thick wall. An. Rib Definition Engineering.

From www.pinterest.com

Pin on construction Rib Definition Engineering One of the best ways to communicate one’s ideas is through some form of picture or drawing. Ribbing is a hallmark of injection moulded parts because this detail does not “cost” anything on a per part basis. An elongated projection on a shape, forging or casting to provide stiffening. However, a word of caution:. They are often used strategically to. Rib Definition Engineering.

From www.animalia-life.club

Floating Ribs Rib Definition Engineering Ribs are thin wall protrusions that extend perpendicularly from a wall or plane. One of the best ways to communicate one’s ideas is through some form of picture or drawing. For the rib in a 3d position, there are two essential parameters. Ribs are a great way to add strength and stiffness to a part while keeping material consumption to. Rib Definition Engineering.

From www.animalia-life.club

Floating Ribs Rib Definition Engineering First, there is the integration width that defines the area for the integration of internal forces. For the rib in a 3d position, there are two essential parameters. This is especially true for. However, a word of caution:. An elongated projection on a shape, forging or casting to provide stiffening. Ribs are thin support features frequently found in plastic injection. Rib Definition Engineering.

From help.scia.net

Rib in the slab Rib Definition Engineering However, a word of caution:. This is especially true for. Ribbing is a hallmark of injection moulded parts because this detail does not “cost” anything on a per part basis. First, there is the integration width that defines the area for the integration of internal forces. For the rib in a 3d position, there are two essential parameters. Ribs are. Rib Definition Engineering.

From www.mdpi.com

Sustainability Free FullText Numerical Investigation of the Ribs Rib Definition Engineering For the rib in a 3d position, there are two essential parameters. An elongated projection on a shape, forging or casting to provide stiffening. This is especially true for. Engnet is an engineering directory, buyers guide and search. Ribbing is a hallmark of injection moulded parts because this detail does not “cost” anything on a per part basis. However, a. Rib Definition Engineering.

From quizlet.com

Ribs Labeling Diagram Quizlet Rib Definition Engineering This is especially true for. One of the best ways to communicate one’s ideas is through some form of picture or drawing. They are often used strategically to replace thick wall. Engnet is an engineering directory, buyers guide and search. Ribs are thin wall protrusions that extend perpendicularly from a wall or plane. An elongated projection on a shape, forging. Rib Definition Engineering.

From www.youtube.com

Typical Ribs YouTube Rib Definition Engineering Ribbing is a hallmark of injection moulded parts because this detail does not “cost” anything on a per part basis. An elongated projection on a shape, forging or casting to provide stiffening. Ribs are a great way to add strength and stiffness to a part while keeping material consumption to a minimum. For the rib in a 3d position, there. Rib Definition Engineering.

From www.mdpi.com

Buildings Free FullText Research on Optimal Arch Rib Inclination Rib Definition Engineering An elongated projection on a shape, forging or casting to provide stiffening. Ribs are thin support features frequently found in plastic injection moulded part designs. However, a word of caution:. They are often used strategically to replace thick wall. For the rib in a 3d position, there are two essential parameters. Ribs are thin wall protrusions that extend perpendicularly from. Rib Definition Engineering.

From madeincalifornia.blogspot.com

MADEinCALIFORNIA ///Co.De. Ribs structure Rib Definition Engineering One of the best ways to communicate one’s ideas is through some form of picture or drawing. Ribs are a great way to add strength and stiffness to a part while keeping material consumption to a minimum. All about ribs in product design. However, a word of caution:. Ribbing is a hallmark of injection moulded parts because this detail does. Rib Definition Engineering.

From medandbiology.blogspot.com

Rib Medically Rib Definition Engineering An elongated projection on a shape, forging or casting to provide stiffening. For the rib in a 3d position, there are two essential parameters. This is especially true for. Ribbing is a hallmark of injection moulded parts because this detail does not “cost” anything on a per part basis. Ribs are a great way to add strength and stiffness to. Rib Definition Engineering.

From www.vrogue.co

Free Images Night Arch Bridge Tied Arch Bridge Reflec vrogue.co Rib Definition Engineering Engnet is an engineering directory, buyers guide and search. This is especially true for. They are often used strategically to replace thick wall. Ribs are thin support features frequently found in plastic injection moulded part designs. Ribbing is a hallmark of injection moulded parts because this detail does not “cost” anything on a per part basis. Ribs are thin wall. Rib Definition Engineering.

From www.vedantu.com

Vertebrochondral ribs in man are(a) 8^{th}, 9^{th}, 10^{th} rib(b Rib Definition Engineering For the rib in a 3d position, there are two essential parameters. They are often used strategically to replace thick wall. However, a word of caution:. Engnet is an engineering directory, buyers guide and search. Ribbing is a hallmark of injection moulded parts because this detail does not “cost” anything on a per part basis. Ribs are a great way. Rib Definition Engineering.

From dictionary.langeek.co

Definition & Meaning of "Rib" LanGeek Rib Definition Engineering This is especially true for. Ribs are thin support features frequently found in plastic injection moulded part designs. One of the best ways to communicate one’s ideas is through some form of picture or drawing. Ribs are a great way to add strength and stiffness to a part while keeping material consumption to a minimum. For the rib in a. Rib Definition Engineering.

From structville.com

Structural Design of Ribbed Slabs Structville Rib Definition Engineering Ribs are a great way to add strength and stiffness to a part while keeping material consumption to a minimum. For the rib in a 3d position, there are two essential parameters. This is especially true for. However, a word of caution:. An elongated projection on a shape, forging or casting to provide stiffening. Ribbing is a hallmark of injection. Rib Definition Engineering.

From exondbfqj.blob.core.windows.net

Ribs Structure Definition at Samuel Thomas blog Rib Definition Engineering They are often used strategically to replace thick wall. One of the best ways to communicate one’s ideas is through some form of picture or drawing. Ribs are thin support features frequently found in plastic injection moulded part designs. However, a word of caution:. Ribs are a great way to add strength and stiffness to a part while keeping material. Rib Definition Engineering.

From hxeyydirv.blob.core.windows.net

Rib Definition For Kindergarten at Tom Sullivan blog Rib Definition Engineering This is especially true for. An elongated projection on a shape, forging or casting to provide stiffening. Ribs are a great way to add strength and stiffness to a part while keeping material consumption to a minimum. They are often used strategically to replace thick wall. First, there is the integration width that defines the area for the integration of. Rib Definition Engineering.

From quizlet.com

Rib Cage Anatomy Diagram Quizlet Rib Definition Engineering Ribbing is a hallmark of injection moulded parts because this detail does not “cost” anything on a per part basis. Ribs are thin wall protrusions that extend perpendicularly from a wall or plane. They are often used strategically to replace thick wall. First, there is the integration width that defines the area for the integration of internal forces. Ribs are. Rib Definition Engineering.

From www.youtube.com

Pronunciation of Rib Definition of Rib YouTube Rib Definition Engineering One of the best ways to communicate one’s ideas is through some form of picture or drawing. Ribs are thin support features frequently found in plastic injection moulded part designs. This is especially true for. They are often used strategically to replace thick wall. However, a word of caution:. An elongated projection on a shape, forging or casting to provide. Rib Definition Engineering.

From engineering.stackexchange.com

modeling How to draw hidden rib in Autodesk Inventor Engineering Rib Definition Engineering An elongated projection on a shape, forging or casting to provide stiffening. All about ribs in product design. This is especially true for. Ribbing is a hallmark of injection moulded parts because this detail does not “cost” anything on a per part basis. Engnet is an engineering directory, buyers guide and search. One of the best ways to communicate one’s. Rib Definition Engineering.