Lathe Chuck Clamping Pressure . The other knob is for a tailstock or. Heavy chuck jaws require the same. One knob is for the primary chuck. Here’s a cnc lathe work holding thumb rule that tells you when you can hold in a chuck, when to use a tailstock, and when to use a steady, based on the l/d (length to diameter) ratio of. The ideal lathe chuck pressure for optimal performance is essential for achieving precision and accuracy in turning operations. The lathe can have two adjustment knobs. Learn about the factors to consider and the. Whenmounting the power chuck and the clamping cylinder on the lathe, the following safety requirements must be met: Properly setting the gripping force of the chuck is very important for safe and high quality lathe machining. Higher speeds require higher clamping pressure. 12 rows to adjust the pressure, turn the adjustment knob. If the gripping force is too high,. Centrifugal force will loosen the grip. Hydraulic control of the clamping pressure between high clamping force (for roughing operation) and low clamping force (for finishing operation of sensitive workpieces)

from www.alamy.com

The other knob is for a tailstock or. Properly setting the gripping force of the chuck is very important for safe and high quality lathe machining. Whenmounting the power chuck and the clamping cylinder on the lathe, the following safety requirements must be met: Hydraulic control of the clamping pressure between high clamping force (for roughing operation) and low clamping force (for finishing operation of sensitive workpieces) Here’s a cnc lathe work holding thumb rule that tells you when you can hold in a chuck, when to use a tailstock, and when to use a steady, based on the l/d (length to diameter) ratio of. Heavy chuck jaws require the same. The ideal lathe chuck pressure for optimal performance is essential for achieving precision and accuracy in turning operations. Centrifugal force will loosen the grip. Learn about the factors to consider and the. If the gripping force is too high,.

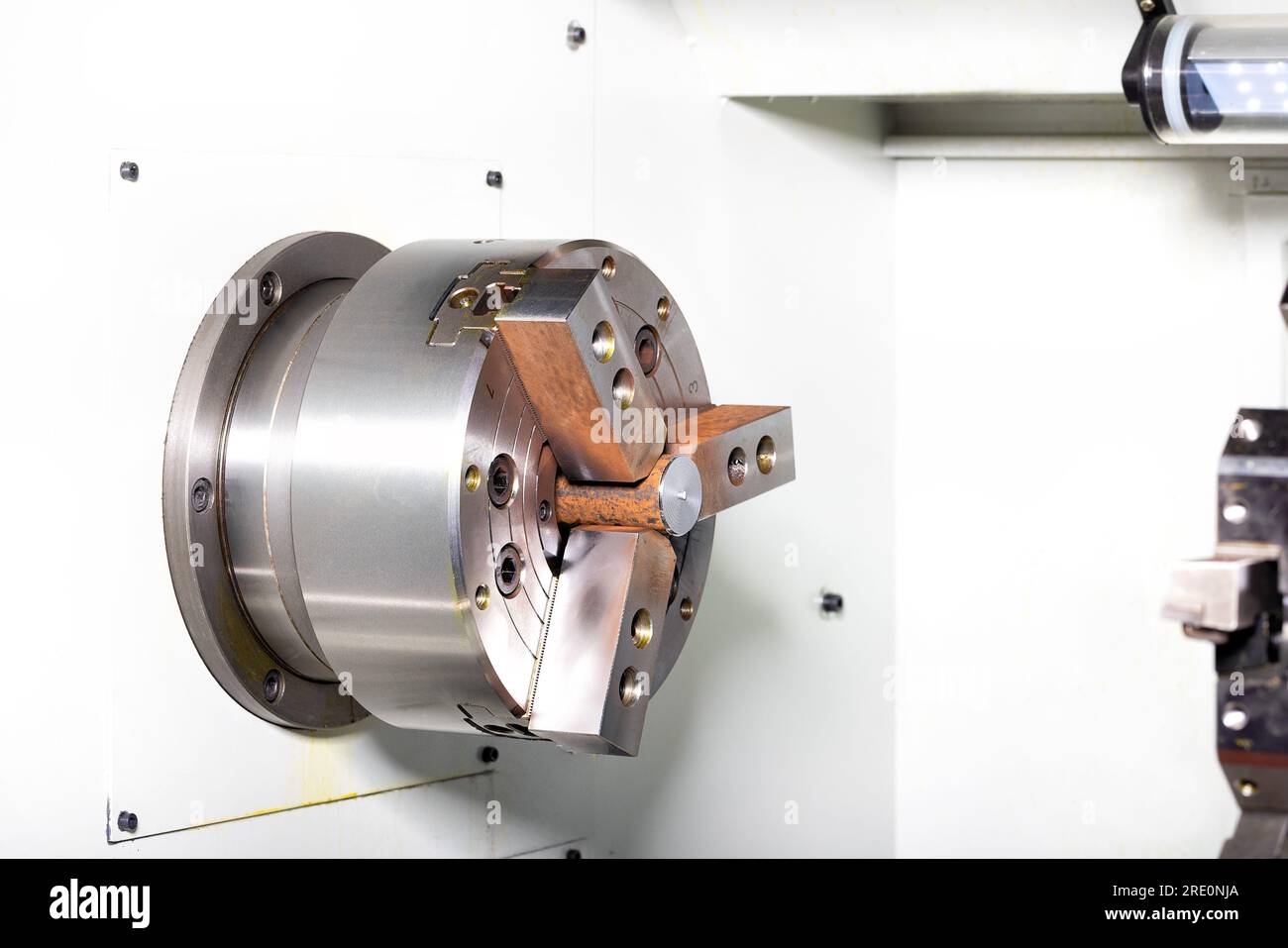

Fast pneumatic 3jaw chuck for gripping or clamping holder and

Lathe Chuck Clamping Pressure Whenmounting the power chuck and the clamping cylinder on the lathe, the following safety requirements must be met: Centrifugal force will loosen the grip. Heavy chuck jaws require the same. 12 rows to adjust the pressure, turn the adjustment knob. Hydraulic control of the clamping pressure between high clamping force (for roughing operation) and low clamping force (for finishing operation of sensitive workpieces) The other knob is for a tailstock or. Whenmounting the power chuck and the clamping cylinder on the lathe, the following safety requirements must be met: Learn about the factors to consider and the. The ideal lathe chuck pressure for optimal performance is essential for achieving precision and accuracy in turning operations. Properly setting the gripping force of the chuck is very important for safe and high quality lathe machining. One knob is for the primary chuck. If the gripping force is too high,. The lathe can have two adjustment knobs. Higher speeds require higher clamping pressure. Here’s a cnc lathe work holding thumb rule that tells you when you can hold in a chuck, when to use a tailstock, and when to use a steady, based on the l/d (length to diameter) ratio of.

From www.hainbuch.com

Special chucks the latest clamping device technology Hainbuch GmbH Lathe Chuck Clamping Pressure Higher speeds require higher clamping pressure. Here’s a cnc lathe work holding thumb rule that tells you when you can hold in a chuck, when to use a tailstock, and when to use a steady, based on the l/d (length to diameter) ratio of. Centrifugal force will loosen the grip. The ideal lathe chuck pressure for optimal performance is essential. Lathe Chuck Clamping Pressure.

From drake888.en.made-in-china.com

Lathe Hollow Clamping Fixture Pneumatic Rotary Collet Chuck China Air Lathe Chuck Clamping Pressure Hydraulic control of the clamping pressure between high clamping force (for roughing operation) and low clamping force (for finishing operation of sensitive workpieces) One knob is for the primary chuck. Centrifugal force will loosen the grip. If the gripping force is too high,. 12 rows to adjust the pressure, turn the adjustment knob. Whenmounting the power chuck and the clamping. Lathe Chuck Clamping Pressure.

From www.ultra-grip.com

Face Clamping Chuck UltraGrip International Lathe Chuck Clamping Pressure Centrifugal force will loosen the grip. Higher speeds require higher clamping pressure. The other knob is for a tailstock or. If the gripping force is too high,. 12 rows to adjust the pressure, turn the adjustment knob. Heavy chuck jaws require the same. The ideal lathe chuck pressure for optimal performance is essential for achieving precision and accuracy in turning. Lathe Chuck Clamping Pressure.

From www.alibaba.com

6 Inch Pneumatic Chuck Threejaw Lathe Fixture Cnc Lathe Machine Tool Lathe Chuck Clamping Pressure Whenmounting the power chuck and the clamping cylinder on the lathe, the following safety requirements must be met: 12 rows to adjust the pressure, turn the adjustment knob. Centrifugal force will loosen the grip. The lathe can have two adjustment knobs. One knob is for the primary chuck. Heavy chuck jaws require the same. Here’s a cnc lathe work holding. Lathe Chuck Clamping Pressure.

From www.vevor.com.au

VEVOR 3Jaw Lathe Chuck, 100 mm, SelfCentering Lathe Chuck, 2 100 mm Lathe Chuck Clamping Pressure Centrifugal force will loosen the grip. The ideal lathe chuck pressure for optimal performance is essential for achieving precision and accuracy in turning operations. Hydraulic control of the clamping pressure between high clamping force (for roughing operation) and low clamping force (for finishing operation of sensitive workpieces) 12 rows to adjust the pressure, turn the adjustment knob. Higher speeds require. Lathe Chuck Clamping Pressure.

From www.desertcart.co.za

Buy Turning Machine Chucks Set, Firm 96mm Outer Diameter 0.03mm Lathe Chuck Clamping Pressure Properly setting the gripping force of the chuck is very important for safe and high quality lathe machining. Centrifugal force will loosen the grip. Whenmounting the power chuck and the clamping cylinder on the lathe, the following safety requirements must be met: One knob is for the primary chuck. The other knob is for a tailstock or. 12 rows to. Lathe Chuck Clamping Pressure.

From www.dreamstime.com

CNC lathe Chuck stock photo. Image of collet, bumper 198659650 Lathe Chuck Clamping Pressure Centrifugal force will loosen the grip. The ideal lathe chuck pressure for optimal performance is essential for achieving precision and accuracy in turning operations. Here’s a cnc lathe work holding thumb rule that tells you when you can hold in a chuck, when to use a tailstock, and when to use a steady, based on the l/d (length to diameter). Lathe Chuck Clamping Pressure.

From www.vevor.com.au

VEVOR 3Jaw Lathe Chuck, 200 mm, SelfCentering Lathe Chuck, 4200 mm Lathe Chuck Clamping Pressure The lathe can have two adjustment knobs. Learn about the factors to consider and the. Hydraulic control of the clamping pressure between high clamping force (for roughing operation) and low clamping force (for finishing operation of sensitive workpieces) The ideal lathe chuck pressure for optimal performance is essential for achieving precision and accuracy in turning operations. If the gripping force. Lathe Chuck Clamping Pressure.

From anthropology.iresearchnet.com

4Jaw Lathe Chuck Wood Working Clamp Clamping Holder Hex Key Lathe Chuck Clamping Pressure Here’s a cnc lathe work holding thumb rule that tells you when you can hold in a chuck, when to use a tailstock, and when to use a steady, based on the l/d (length to diameter) ratio of. Hydraulic control of the clamping pressure between high clamping force (for roughing operation) and low clamping force (for finishing operation of sensitive. Lathe Chuck Clamping Pressure.

From gmt.co.in

CNC Lathe Chuck GMT Hydraulic Power Chucks Lathe Chuck Clamping Pressure Whenmounting the power chuck and the clamping cylinder on the lathe, the following safety requirements must be met: Heavy chuck jaws require the same. Hydraulic control of the clamping pressure between high clamping force (for roughing operation) and low clamping force (for finishing operation of sensitive workpieces) One knob is for the primary chuck. Properly setting the gripping force of. Lathe Chuck Clamping Pressure.

From www.alamy.com

Fast pneumatic 3jaw chuck for gripping or clamping holder and Lathe Chuck Clamping Pressure Hydraulic control of the clamping pressure between high clamping force (for roughing operation) and low clamping force (for finishing operation of sensitive workpieces) 12 rows to adjust the pressure, turn the adjustment knob. Learn about the factors to consider and the. Higher speeds require higher clamping pressure. Heavy chuck jaws require the same. The ideal lathe chuck pressure for optimal. Lathe Chuck Clamping Pressure.

From www.alamy.com

man load workpiece into lathe machine clamping Stock Photo 164921147 Lathe Chuck Clamping Pressure If the gripping force is too high,. Properly setting the gripping force of the chuck is very important for safe and high quality lathe machining. Whenmounting the power chuck and the clamping cylinder on the lathe, the following safety requirements must be met: Here’s a cnc lathe work holding thumb rule that tells you when you can hold in a. Lathe Chuck Clamping Pressure.

From www.laser-chuck.com

Pneumatic CNC Lathe Chuck Four Jaw For Laser Pipe Cutting Machine Lathe Chuck Clamping Pressure Here’s a cnc lathe work holding thumb rule that tells you when you can hold in a chuck, when to use a tailstock, and when to use a steady, based on the l/d (length to diameter) ratio of. Whenmounting the power chuck and the clamping cylinder on the lathe, the following safety requirements must be met: One knob is for. Lathe Chuck Clamping Pressure.

From thorgrinder.en.made-in-china.com

8 Inch Solid 3Jaw Hydraulic Chuck Oil Pressure for CNC Lathe Automatic Lathe Chuck Clamping Pressure Whenmounting the power chuck and the clamping cylinder on the lathe, the following safety requirements must be met: The ideal lathe chuck pressure for optimal performance is essential for achieving precision and accuracy in turning operations. Hydraulic control of the clamping pressure between high clamping force (for roughing operation) and low clamping force (for finishing operation of sensitive workpieces) Higher. Lathe Chuck Clamping Pressure.

From www.practicalmachinist.com

Lathe chuck pressure (Mazak QT15) Lathe Chuck Clamping Pressure Learn about the factors to consider and the. Centrifugal force will loosen the grip. Heavy chuck jaws require the same. 12 rows to adjust the pressure, turn the adjustment knob. Whenmounting the power chuck and the clamping cylinder on the lathe, the following safety requirements must be met: The ideal lathe chuck pressure for optimal performance is essential for achieving. Lathe Chuck Clamping Pressure.

From www.vishalmachinetools.com

Face Clamp Chuck Product at Vishal Machine Tools Lathe Chuck Clamping Pressure Higher speeds require higher clamping pressure. One knob is for the primary chuck. Learn about the factors to consider and the. Heavy chuck jaws require the same. The other knob is for a tailstock or. Hydraulic control of the clamping pressure between high clamping force (for roughing operation) and low clamping force (for finishing operation of sensitive workpieces) The lathe. Lathe Chuck Clamping Pressure.

From fyohelqyu.blob.core.windows.net

Hydraulic Chuck Clamping Pressure at Deedee Kirkpatrick blog Lathe Chuck Clamping Pressure One knob is for the primary chuck. 12 rows to adjust the pressure, turn the adjustment knob. The other knob is for a tailstock or. If the gripping force is too high,. Properly setting the gripping force of the chuck is very important for safe and high quality lathe machining. Here’s a cnc lathe work holding thumb rule that tells. Lathe Chuck Clamping Pressure.

From www.practicalmachinist.com

Lathe chuck pressure (Mazak QT15) Lathe Chuck Clamping Pressure 12 rows to adjust the pressure, turn the adjustment knob. Higher speeds require higher clamping pressure. Hydraulic control of the clamping pressure between high clamping force (for roughing operation) and low clamping force (for finishing operation of sensitive workpieces) One knob is for the primary chuck. If the gripping force is too high,. Properly setting the gripping force of the. Lathe Chuck Clamping Pressure.

From www.vevor.com.au

VEVOR 3Jaw Lathe Chuck, 200 mm, SelfCentering Lathe Chuck, 4200 mm Lathe Chuck Clamping Pressure Hydraulic control of the clamping pressure between high clamping force (for roughing operation) and low clamping force (for finishing operation of sensitive workpieces) Higher speeds require higher clamping pressure. If the gripping force is too high,. 12 rows to adjust the pressure, turn the adjustment knob. Whenmounting the power chuck and the clamping cylinder on the lathe, the following safety. Lathe Chuck Clamping Pressure.

From fyohelqyu.blob.core.windows.net

Hydraulic Chuck Clamping Pressure at Deedee Kirkpatrick blog Lathe Chuck Clamping Pressure One knob is for the primary chuck. The lathe can have two adjustment knobs. Heavy chuck jaws require the same. The other knob is for a tailstock or. If the gripping force is too high,. The ideal lathe chuck pressure for optimal performance is essential for achieving precision and accuracy in turning operations. Properly setting the gripping force of the. Lathe Chuck Clamping Pressure.

From www.vevor.com.au

VEVOR 3Jaw Lathe Chuck, 125 mm, SelfCentering Lathe Chuck, 2.5 125 Lathe Chuck Clamping Pressure The ideal lathe chuck pressure for optimal performance is essential for achieving precision and accuracy in turning operations. Learn about the factors to consider and the. One knob is for the primary chuck. The lathe can have two adjustment knobs. Centrifugal force will loosen the grip. If the gripping force is too high,. Whenmounting the power chuck and the clamping. Lathe Chuck Clamping Pressure.

From www.desertcart.ph

Buy BuoQua 10 Inch 250mm Lathe Chuck Independent Reversible Jaw for Lathe Chuck Clamping Pressure Whenmounting the power chuck and the clamping cylinder on the lathe, the following safety requirements must be met: If the gripping force is too high,. Heavy chuck jaws require the same. Higher speeds require higher clamping pressure. Here’s a cnc lathe work holding thumb rule that tells you when you can hold in a chuck, when to use a tailstock,. Lathe Chuck Clamping Pressure.

From www.penntoolco.com

Royal QuickGrip™ AccuLength™ CNC Collet Chuck, QG65 Collet, A28 Lathe Chuck Clamping Pressure One knob is for the primary chuck. The lathe can have two adjustment knobs. Hydraulic control of the clamping pressure between high clamping force (for roughing operation) and low clamping force (for finishing operation of sensitive workpieces) Higher speeds require higher clamping pressure. Whenmounting the power chuck and the clamping cylinder on the lathe, the following safety requirements must be. Lathe Chuck Clamping Pressure.

From anthropology.iresearchnet.com

Tools Machine Tools & Accessories pneumatic tapping machine chuck for Lathe Chuck Clamping Pressure Properly setting the gripping force of the chuck is very important for safe and high quality lathe machining. The lathe can have two adjustment knobs. 12 rows to adjust the pressure, turn the adjustment knob. Whenmounting the power chuck and the clamping cylinder on the lathe, the following safety requirements must be met: Here’s a cnc lathe work holding thumb. Lathe Chuck Clamping Pressure.

From www.directindustry.com

Power chuck Long Stroke Air Chucks Microcentric 3jaw / lathe / clamp Lathe Chuck Clamping Pressure The other knob is for a tailstock or. Whenmounting the power chuck and the clamping cylinder on the lathe, the following safety requirements must be met: Higher speeds require higher clamping pressure. Properly setting the gripping force of the chuck is very important for safe and high quality lathe machining. Heavy chuck jaws require the same. One knob is for. Lathe Chuck Clamping Pressure.

From www.vevor.com.au

VEVOR 3Jaw Lathe Chuck, 200 mm, SelfCentering Lathe Chuck, 4200 mm Lathe Chuck Clamping Pressure Heavy chuck jaws require the same. Properly setting the gripping force of the chuck is very important for safe and high quality lathe machining. Learn about the factors to consider and the. Here’s a cnc lathe work holding thumb rule that tells you when you can hold in a chuck, when to use a tailstock, and when to use a. Lathe Chuck Clamping Pressure.

From www.vevor.com.au

VEVOR 3Jaw Lathe Chuck, 200 mm, SelfCentering Lathe Chuck, 4200 mm Lathe Chuck Clamping Pressure One knob is for the primary chuck. Heavy chuck jaws require the same. If the gripping force is too high,. Hydraulic control of the clamping pressure between high clamping force (for roughing operation) and low clamping force (for finishing operation of sensitive workpieces) Learn about the factors to consider and the. The ideal lathe chuck pressure for optimal performance is. Lathe Chuck Clamping Pressure.

From www.vevor.com

VEVOR K11160 Lathe Chuck 6 Inch,SelfCentering Woodturning Chuck 3Jaw Lathe Chuck Clamping Pressure Learn about the factors to consider and the. The lathe can have two adjustment knobs. Whenmounting the power chuck and the clamping cylinder on the lathe, the following safety requirements must be met: If the gripping force is too high,. 12 rows to adjust the pressure, turn the adjustment knob. One knob is for the primary chuck. The ideal lathe. Lathe Chuck Clamping Pressure.

From picclick.co.uk

LATHE CHUCK 3JAW SelfCentering Mini Metal Lathe Clamping Chuck Lathe Chuck Clamping Pressure Properly setting the gripping force of the chuck is very important for safe and high quality lathe machining. Centrifugal force will loosen the grip. One knob is for the primary chuck. Hydraulic control of the clamping pressure between high clamping force (for roughing operation) and low clamping force (for finishing operation of sensitive workpieces) The lathe can have two adjustment. Lathe Chuck Clamping Pressure.

From www.vevor.com.au

VEVOR 3Jaw Lathe Chuck, 200 mm, SelfCentering Lathe Chuck, 4200 mm Lathe Chuck Clamping Pressure Whenmounting the power chuck and the clamping cylinder on the lathe, the following safety requirements must be met: Centrifugal force will loosen the grip. Hydraulic control of the clamping pressure between high clamping force (for roughing operation) and low clamping force (for finishing operation of sensitive workpieces) Here’s a cnc lathe work holding thumb rule that tells you when you. Lathe Chuck Clamping Pressure.

From www.machineryoffers.com

K11125 3 Jaws SelfCentering Chuck Sanou Brand 3 jaw chuck 5'' lathe Lathe Chuck Clamping Pressure One knob is for the primary chuck. Centrifugal force will loosen the grip. Here’s a cnc lathe work holding thumb rule that tells you when you can hold in a chuck, when to use a tailstock, and when to use a steady, based on the l/d (length to diameter) ratio of. The other knob is for a tailstock or. Learn. Lathe Chuck Clamping Pressure.

From fyohelqyu.blob.core.windows.net

Hydraulic Chuck Clamping Pressure at Deedee Kirkpatrick blog Lathe Chuck Clamping Pressure The lathe can have two adjustment knobs. Centrifugal force will loosen the grip. Heavy chuck jaws require the same. If the gripping force is too high,. Learn about the factors to consider and the. Whenmounting the power chuck and the clamping cylinder on the lathe, the following safety requirements must be met: Here’s a cnc lathe work holding thumb rule. Lathe Chuck Clamping Pressure.

From www.desertcart.ph

Buy Lathe Chuck, SANOU K11130 3Jaw SelfCentering Lathe Chuck 80mm Lathe Chuck Clamping Pressure Hydraulic control of the clamping pressure between high clamping force (for roughing operation) and low clamping force (for finishing operation of sensitive workpieces) Heavy chuck jaws require the same. 12 rows to adjust the pressure, turn the adjustment knob. One knob is for the primary chuck. Centrifugal force will loosen the grip. The other knob is for a tailstock or.. Lathe Chuck Clamping Pressure.

From www.vevor.com.au

VEVOR 3Jaw Lathe Chuck, 200 mm, SelfCentering Lathe Chuck, 4200 mm Lathe Chuck Clamping Pressure Learn about the factors to consider and the. Higher speeds require higher clamping pressure. Properly setting the gripping force of the chuck is very important for safe and high quality lathe machining. The other knob is for a tailstock or. One knob is for the primary chuck. Heavy chuck jaws require the same. Whenmounting the power chuck and the clamping. Lathe Chuck Clamping Pressure.

From fyohelqyu.blob.core.windows.net

Hydraulic Chuck Clamping Pressure at Deedee Kirkpatrick blog Lathe Chuck Clamping Pressure Whenmounting the power chuck and the clamping cylinder on the lathe, the following safety requirements must be met: The other knob is for a tailstock or. 12 rows to adjust the pressure, turn the adjustment knob. One knob is for the primary chuck. Here’s a cnc lathe work holding thumb rule that tells you when you can hold in a. Lathe Chuck Clamping Pressure.