Soap Bars Production . The process starts with a hot liquid base. I've scaled two different soap companies to production soapmaking methods personally, as well as working with hundreds of soapmakers to do the same. The factory can produce over 7,000 soap bars a day. Each part of the soapmaking. Liquid oils (sweet almond, sunflower, olive) produce a softer bar. We explain the basics of bar soap manufacturing. Then color and fragrance are mixed in. How is bar soap made? There are four basic raw materials involved in the manufacturing of soap and also there are three basic process methods that are used. Solid at room temperature oils (like coconut, palm, lard, or shea butter) will produce a harder finished bar of soap. Understanding the steps in bar soap manufacturing is crucial for any business in the cosmetics and skincare industry aiming to. Shapes like these stars and anchors are made with. And what are my aesthetic options? When choosing oils, a good rule of thumb to remember:

from www.stratviewresearch.com

Shapes like these stars and anchors are made with. Then color and fragrance are mixed in. We explain the basics of bar soap manufacturing. Liquid oils (sweet almond, sunflower, olive) produce a softer bar. And what are my aesthetic options? Solid at room temperature oils (like coconut, palm, lard, or shea butter) will produce a harder finished bar of soap. When choosing oils, a good rule of thumb to remember: I've scaled two different soap companies to production soapmaking methods personally, as well as working with hundreds of soapmakers to do the same. Each part of the soapmaking. Understanding the steps in bar soap manufacturing is crucial for any business in the cosmetics and skincare industry aiming to.

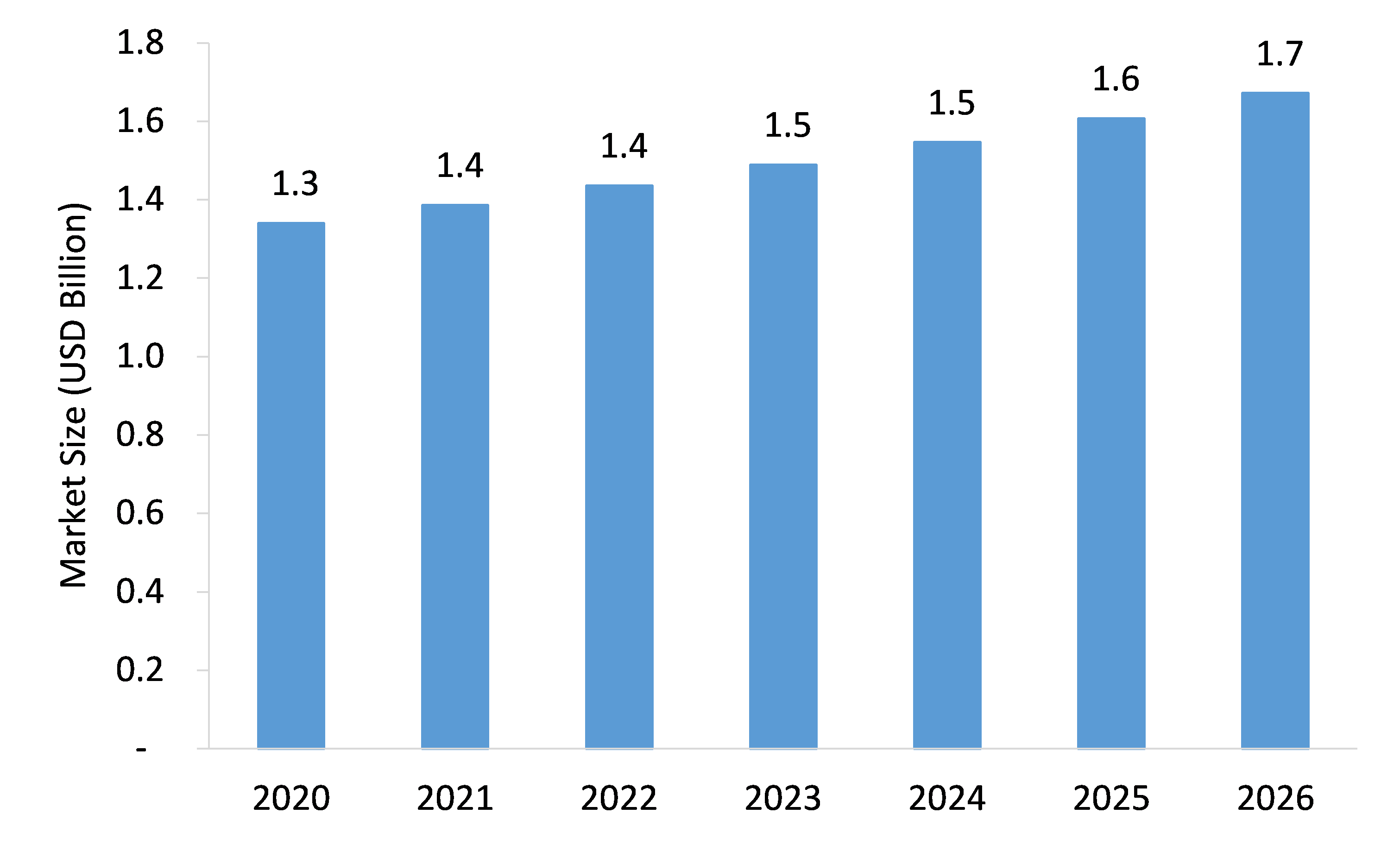

Bar Soap Market Market Size, Share & Forecast Analysis

Soap Bars Production The factory can produce over 7,000 soap bars a day. Each part of the soapmaking. Shapes like these stars and anchors are made with. Understanding the steps in bar soap manufacturing is crucial for any business in the cosmetics and skincare industry aiming to. We explain the basics of bar soap manufacturing. Solid at room temperature oils (like coconut, palm, lard, or shea butter) will produce a harder finished bar of soap. Liquid oils (sweet almond, sunflower, olive) produce a softer bar. And what are my aesthetic options? I've scaled two different soap companies to production soapmaking methods personally, as well as working with hundreds of soapmakers to do the same. How is bar soap made? The process starts with a hot liquid base. Then color and fragrance are mixed in. When choosing oils, a good rule of thumb to remember: The factory can produce over 7,000 soap bars a day. There are four basic raw materials involved in the manufacturing of soap and also there are three basic process methods that are used.

From zhaoqianyong.en.made-in-china.com

3050kg/H Small Scale Toilet Laundry Bar Soap Production Making Machine Soap Bars Production Each part of the soapmaking. We explain the basics of bar soap manufacturing. Solid at room temperature oils (like coconut, palm, lard, or shea butter) will produce a harder finished bar of soap. How is bar soap made? When choosing oils, a good rule of thumb to remember: The process starts with a hot liquid base. Liquid oils (sweet almond,. Soap Bars Production.

From www.dontwasteyourmoney.com

The Best Bar Soap Reviews, Ratings, Comparisons Soap Bars Production Liquid oils (sweet almond, sunflower, olive) produce a softer bar. How is bar soap made? And what are my aesthetic options? Then color and fragrance are mixed in. The factory can produce over 7,000 soap bars a day. Understanding the steps in bar soap manufacturing is crucial for any business in the cosmetics and skincare industry aiming to. We explain. Soap Bars Production.

From zerowastefamily.com

How to Make Scented Bar Soap The Zero Waste Family® Soap Bars Production Understanding the steps in bar soap manufacturing is crucial for any business in the cosmetics and skincare industry aiming to. And what are my aesthetic options? When choosing oils, a good rule of thumb to remember: There are four basic raw materials involved in the manufacturing of soap and also there are three basic process methods that are used. I've. Soap Bars Production.

From zhaoqianyong.en.made-in-china.com

100200kg/H Small Bar Soap Production Making Machine Soap Making Soap Bars Production Each part of the soapmaking. When choosing oils, a good rule of thumb to remember: Solid at room temperature oils (like coconut, palm, lard, or shea butter) will produce a harder finished bar of soap. Liquid oils (sweet almond, sunflower, olive) produce a softer bar. Then color and fragrance are mixed in. Understanding the steps in bar soap manufacturing is. Soap Bars Production.

From www.sharpestarena.com

Production of Soap Complete Project on Soap Making Soap Bars Production Liquid oils (sweet almond, sunflower, olive) produce a softer bar. The factory can produce over 7,000 soap bars a day. I've scaled two different soap companies to production soapmaking methods personally, as well as working with hundreds of soapmakers to do the same. There are four basic raw materials involved in the manufacturing of soap and also there are three. Soap Bars Production.

From wuhanhdc.en.made-in-china.com

China Best Price Soap Bar Production Making Line China Soap Making Soap Bars Production There are four basic raw materials involved in the manufacturing of soap and also there are three basic process methods that are used. Understanding the steps in bar soap manufacturing is crucial for any business in the cosmetics and skincare industry aiming to. The process starts with a hot liquid base. The factory can produce over 7,000 soap bars a. Soap Bars Production.

From www.treehugger.com

The Best Bar Soaps for Every Body Part Soap Bars Production Liquid oils (sweet almond, sunflower, olive) produce a softer bar. There are four basic raw materials involved in the manufacturing of soap and also there are three basic process methods that are used. Solid at room temperature oils (like coconut, palm, lard, or shea butter) will produce a harder finished bar of soap. Each part of the soapmaking. The factory. Soap Bars Production.

From www.azmanmetal.com

Soap Production Line Azman Metal Soap Bars Production Solid at room temperature oils (like coconut, palm, lard, or shea butter) will produce a harder finished bar of soap. Then color and fragrance are mixed in. I've scaled two different soap companies to production soapmaking methods personally, as well as working with hundreds of soapmakers to do the same. The process starts with a hot liquid base. And what. Soap Bars Production.

From www.acma.it

The rediscovery of soap bars ecofriendly, valuable and organic ACMA Soap Bars Production Understanding the steps in bar soap manufacturing is crucial for any business in the cosmetics and skincare industry aiming to. Each part of the soapmaking. Then color and fragrance are mixed in. The factory can produce over 7,000 soap bars a day. I've scaled two different soap companies to production soapmaking methods personally, as well as working with hundreds of. Soap Bars Production.

From mizihomachinery.com

Soap making machine soap production line Miziho Machinery Soap Bars Production We explain the basics of bar soap manufacturing. How is bar soap made? Each part of the soapmaking. When choosing oils, a good rule of thumb to remember: And what are my aesthetic options? Solid at room temperature oils (like coconut, palm, lard, or shea butter) will produce a harder finished bar of soap. Liquid oils (sweet almond, sunflower, olive). Soap Bars Production.

From www.azmanmetal.com

Soap Production Line Azman Metal Soap Bars Production And what are my aesthetic options? When choosing oils, a good rule of thumb to remember: How is bar soap made? Each part of the soapmaking. There are four basic raw materials involved in the manufacturing of soap and also there are three basic process methods that are used. I've scaled two different soap companies to production soapmaking methods personally,. Soap Bars Production.

From www.stratviewresearch.com

Bar Soap Market Market Size, Share & Forecast Analysis Soap Bars Production Solid at room temperature oils (like coconut, palm, lard, or shea butter) will produce a harder finished bar of soap. Each part of the soapmaking. How is bar soap made? I've scaled two different soap companies to production soapmaking methods personally, as well as working with hundreds of soapmakers to do the same. The factory can produce over 7,000 soap. Soap Bars Production.

From www.woodyglobal.com

SOAP BAR PRODUCTION LINES Soap Bars Production Shapes like these stars and anchors are made with. Then color and fragrance are mixed in. When choosing oils, a good rule of thumb to remember: How is bar soap made? Each part of the soapmaking. The process starts with a hot liquid base. Understanding the steps in bar soap manufacturing is crucial for any business in the cosmetics and. Soap Bars Production.

From www.researchgate.net

Flow diagram of soap production by bath process. Download Scientific Soap Bars Production When choosing oils, a good rule of thumb to remember: The factory can produce over 7,000 soap bars a day. Shapes like these stars and anchors are made with. Solid at room temperature oils (like coconut, palm, lard, or shea butter) will produce a harder finished bar of soap. Understanding the steps in bar soap manufacturing is crucial for any. Soap Bars Production.

From www.wesleybaker.com

The growth of soap making Wesley Baker Small Business Soap Making Soap Bars Production The factory can produce over 7,000 soap bars a day. When choosing oils, a good rule of thumb to remember: And what are my aesthetic options? Each part of the soapmaking. There are four basic raw materials involved in the manufacturing of soap and also there are three basic process methods that are used. Solid at room temperature oils (like. Soap Bars Production.

From www.alibaba.com

Soap Making Machine With Full Automatic/soap Bar Production Line/small Soap Bars Production We explain the basics of bar soap manufacturing. When choosing oils, a good rule of thumb to remember: There are four basic raw materials involved in the manufacturing of soap and also there are three basic process methods that are used. The process starts with a hot liquid base. Solid at room temperature oils (like coconut, palm, lard, or shea. Soap Bars Production.

From www.pinterest.com

How to make your own soap howtomakesoap Diy soap bars, Homemade soap Soap Bars Production There are four basic raw materials involved in the manufacturing of soap and also there are three basic process methods that are used. I've scaled two different soap companies to production soapmaking methods personally, as well as working with hundreds of soapmakers to do the same. Understanding the steps in bar soap manufacturing is crucial for any business in the. Soap Bars Production.

From www.mysoapy.com

WHOLESALE Handmade Soap Bars ReSeller 10 pack Soapy Bath and Soap Bars Production And what are my aesthetic options? Then color and fragrance are mixed in. How is bar soap made? Liquid oils (sweet almond, sunflower, olive) produce a softer bar. We explain the basics of bar soap manufacturing. The process starts with a hot liquid base. When choosing oils, a good rule of thumb to remember: There are four basic raw materials. Soap Bars Production.

From www.youtube.com

HOW TO MAKE A HOMEMADE BAR SOAP FROM SCRATCH. YouTube Soap Bars Production Then color and fragrance are mixed in. There are four basic raw materials involved in the manufacturing of soap and also there are three basic process methods that are used. The process starts with a hot liquid base. The factory can produce over 7,000 soap bars a day. When choosing oils, a good rule of thumb to remember: Solid at. Soap Bars Production.

From www.alibaba.com

Automatic Laundry Bar Soap Production Line Buy Toliet Soap Making Soap Bars Production Liquid oils (sweet almond, sunflower, olive) produce a softer bar. There are four basic raw materials involved in the manufacturing of soap and also there are three basic process methods that are used. I've scaled two different soap companies to production soapmaking methods personally, as well as working with hundreds of soapmakers to do the same. Shapes like these stars. Soap Bars Production.

From www.jagdishexports.com

Laundry Soap Machinery, Laundry Bar Soap Machinery, Laundry Soap Plant Soap Bars Production The process starts with a hot liquid base. Understanding the steps in bar soap manufacturing is crucial for any business in the cosmetics and skincare industry aiming to. There are four basic raw materials involved in the manufacturing of soap and also there are three basic process methods that are used. When choosing oils, a good rule of thumb to. Soap Bars Production.

From www.twincraft.com

Bar Soap Contract Manufacturing in the USA Soap Bars Production How is bar soap made? And what are my aesthetic options? The factory can produce over 7,000 soap bars a day. Then color and fragrance are mixed in. Solid at room temperature oils (like coconut, palm, lard, or shea butter) will produce a harder finished bar of soap. There are four basic raw materials involved in the manufacturing of soap. Soap Bars Production.

From zerowastefamily.com

How to Make Scented Bar Soap The Zero Waste Family® Soap Bars Production Each part of the soapmaking. The factory can produce over 7,000 soap bars a day. Liquid oils (sweet almond, sunflower, olive) produce a softer bar. We explain the basics of bar soap manufacturing. I've scaled two different soap companies to production soapmaking methods personally, as well as working with hundreds of soapmakers to do the same. How is bar soap. Soap Bars Production.

From jiji-blog.com

How To Make Bar Soap In Nigeria Jiji Blog Soap Bars Production We explain the basics of bar soap manufacturing. Understanding the steps in bar soap manufacturing is crucial for any business in the cosmetics and skincare industry aiming to. The process starts with a hot liquid base. Each part of the soapmaking. The factory can produce over 7,000 soap bars a day. Solid at room temperature oils (like coconut, palm, lard,. Soap Bars Production.

From www.alibaba.com

Soap Making Machine With Full Automatic/soap Bar Production Line/small Soap Bars Production The process starts with a hot liquid base. There are four basic raw materials involved in the manufacturing of soap and also there are three basic process methods that are used. Understanding the steps in bar soap manufacturing is crucial for any business in the cosmetics and skincare industry aiming to. The factory can produce over 7,000 soap bars a. Soap Bars Production.

From www.indiamart.com

Small Scale Washing Bar Soap Making Plant & Machines, Capacity Approx Soap Bars Production Each part of the soapmaking. How is bar soap made? Then color and fragrance are mixed in. We explain the basics of bar soap manufacturing. I've scaled two different soap companies to production soapmaking methods personally, as well as working with hundreds of soapmakers to do the same. There are four basic raw materials involved in the manufacturing of soap. Soap Bars Production.

From www.youtube.com

How to Produce Millions of Olive Soap Bar in Traditional Soap Factory Soap Bars Production I've scaled two different soap companies to production soapmaking methods personally, as well as working with hundreds of soapmakers to do the same. Solid at room temperature oils (like coconut, palm, lard, or shea butter) will produce a harder finished bar of soap. Shapes like these stars and anchors are made with. And what are my aesthetic options? We explain. Soap Bars Production.

From www.alibaba.com

Soap Making Machine With Full Automatic/soap Bar Production Line/small Soap Bars Production Each part of the soapmaking. And what are my aesthetic options? Shapes like these stars and anchors are made with. Solid at room temperature oils (like coconut, palm, lard, or shea butter) will produce a harder finished bar of soap. Understanding the steps in bar soap manufacturing is crucial for any business in the cosmetics and skincare industry aiming to.. Soap Bars Production.

From www.youtube.com

How to make Laundry Bar Soap with Calcium carbonate YouTube Soap Bars Production Liquid oils (sweet almond, sunflower, olive) produce a softer bar. We explain the basics of bar soap manufacturing. The process starts with a hot liquid base. The factory can produce over 7,000 soap bars a day. Solid at room temperature oils (like coconut, palm, lard, or shea butter) will produce a harder finished bar of soap. There are four basic. Soap Bars Production.

From www.alibaba.com

Soap Making Machine With Full Automatic/soap Bar Production Line/small Soap Bars Production Solid at room temperature oils (like coconut, palm, lard, or shea butter) will produce a harder finished bar of soap. How is bar soap made? The process starts with a hot liquid base. The factory can produce over 7,000 soap bars a day. Then color and fragrance are mixed in. And what are my aesthetic options? Shapes like these stars. Soap Bars Production.

From www.youtube.com

Fully Automatic Small Scale Bath Toilet Bar Soap Making Machine Hotel Soap Bars Production The process starts with a hot liquid base. I've scaled two different soap companies to production soapmaking methods personally, as well as working with hundreds of soapmakers to do the same. Then color and fragrance are mixed in. And what are my aesthetic options? Shapes like these stars and anchors are made with. Understanding the steps in bar soap manufacturing. Soap Bars Production.

From www.artofit.org

How to formulate soap salt bars Artofit Soap Bars Production When choosing oils, a good rule of thumb to remember: Liquid oils (sweet almond, sunflower, olive) produce a softer bar. We explain the basics of bar soap manufacturing. There are four basic raw materials involved in the manufacturing of soap and also there are three basic process methods that are used. How is bar soap made? The process starts with. Soap Bars Production.

From rainmachine.en.made-in-china.com

Industrial Bar Soap Cutting Making Machine Solid Laundry Soap Soap Bars Production Each part of the soapmaking. The factory can produce over 7,000 soap bars a day. There are four basic raw materials involved in the manufacturing of soap and also there are three basic process methods that are used. And what are my aesthetic options? How is bar soap made? We explain the basics of bar soap manufacturing. Liquid oils (sweet. Soap Bars Production.

From www.dreamstime.com

Small Production of Natural Soap Stock Illustration Illustration of Soap Bars Production Then color and fragrance are mixed in. Each part of the soapmaking. The process starts with a hot liquid base. Solid at room temperature oils (like coconut, palm, lard, or shea butter) will produce a harder finished bar of soap. We explain the basics of bar soap manufacturing. When choosing oils, a good rule of thumb to remember: And what. Soap Bars Production.

From www.mdpi.com

Sustainability Free FullText The Environmental Impacts of Bar Soap Soap Bars Production Each part of the soapmaking. There are four basic raw materials involved in the manufacturing of soap and also there are three basic process methods that are used. How is bar soap made? Solid at room temperature oils (like coconut, palm, lard, or shea butter) will produce a harder finished bar of soap. The process starts with a hot liquid. Soap Bars Production.