Assembly Line Requirements . assembly lines are designed for one reason: Maintaining this tight focus through design and implementation allows engineers to create the most efficient and effective layout possible. an assembly line manufacturing process is a series of individual workers assembling a product,. however, achieving this level of operational excellence requires careful planning, implementation, and continuous. Similarly, each component of the assembly line must work in sync for the. this article published in assembly magazine, covers many practical “lessons learned” and why flexibility and. A lean assembly line introduces simplicity as much as possible into the manufacturing flow, and anything that disrupts the forward momentum of a product is eliminated or mitigated. an assembly line is a manufacturing process that constructs a final product more efficiently by adding components sequentially. assembly line efficiency, at its core, represents the harmony between machinery, workforce, and process flow to achieve the maximum output with minimal waste.

from www.slideserve.com

assembly line efficiency, at its core, represents the harmony between machinery, workforce, and process flow to achieve the maximum output with minimal waste. Maintaining this tight focus through design and implementation allows engineers to create the most efficient and effective layout possible. this article published in assembly magazine, covers many practical “lessons learned” and why flexibility and. assembly lines are designed for one reason: however, achieving this level of operational excellence requires careful planning, implementation, and continuous. an assembly line is a manufacturing process that constructs a final product more efficiently by adding components sequentially. A lean assembly line introduces simplicity as much as possible into the manufacturing flow, and anything that disrupts the forward momentum of a product is eliminated or mitigated. an assembly line manufacturing process is a series of individual workers assembling a product,. Similarly, each component of the assembly line must work in sync for the.

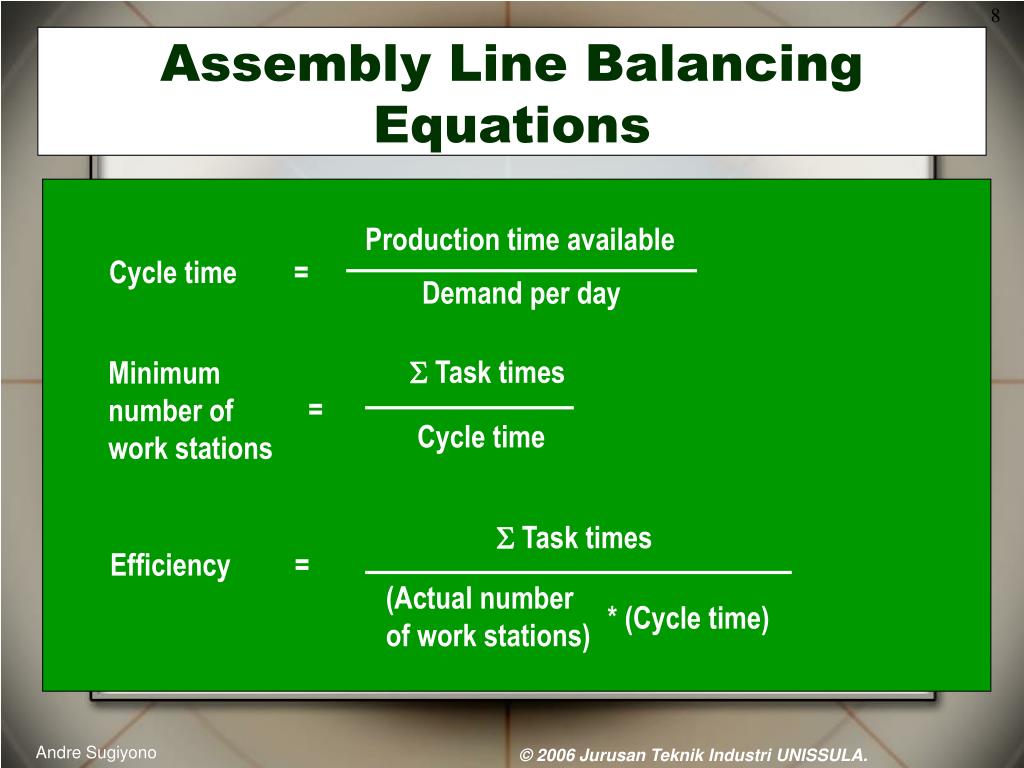

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free

Assembly Line Requirements an assembly line manufacturing process is a series of individual workers assembling a product,. Maintaining this tight focus through design and implementation allows engineers to create the most efficient and effective layout possible. Similarly, each component of the assembly line must work in sync for the. assembly lines are designed for one reason: an assembly line manufacturing process is a series of individual workers assembling a product,. however, achieving this level of operational excellence requires careful planning, implementation, and continuous. this article published in assembly magazine, covers many practical “lessons learned” and why flexibility and. A lean assembly line introduces simplicity as much as possible into the manufacturing flow, and anything that disrupts the forward momentum of a product is eliminated or mitigated. an assembly line is a manufacturing process that constructs a final product more efficiently by adding components sequentially. assembly line efficiency, at its core, represents the harmony between machinery, workforce, and process flow to achieve the maximum output with minimal waste.

From www.investopedia.com

Assembly Line Defining the Mass Production Process Assembly Line Requirements assembly lines are designed for one reason: A lean assembly line introduces simplicity as much as possible into the manufacturing flow, and anything that disrupts the forward momentum of a product is eliminated or mitigated. assembly line efficiency, at its core, represents the harmony between machinery, workforce, and process flow to achieve the maximum output with minimal waste.. Assembly Line Requirements.

From www.chegg.com

Solved Toshiba's Notebook Computer Assembly Line Toshihiro Assembly Line Requirements assembly lines are designed for one reason: Maintaining this tight focus through design and implementation allows engineers to create the most efficient and effective layout possible. this article published in assembly magazine, covers many practical “lessons learned” and why flexibility and. A lean assembly line introduces simplicity as much as possible into the manufacturing flow, and anything that. Assembly Line Requirements.

From katanamrp.com

Manufacturing Assembly Line Understanding the Setup — Katana Assembly Line Requirements an assembly line is a manufacturing process that constructs a final product more efficiently by adding components sequentially. Similarly, each component of the assembly line must work in sync for the. assembly lines are designed for one reason: assembly line efficiency, at its core, represents the harmony between machinery, workforce, and process flow to achieve the maximum. Assembly Line Requirements.

From www.upgintl.com

Assembly Services Assembly Line Requirements Similarly, each component of the assembly line must work in sync for the. Maintaining this tight focus through design and implementation allows engineers to create the most efficient and effective layout possible. an assembly line is a manufacturing process that constructs a final product more efficiently by adding components sequentially. this article published in assembly magazine, covers many. Assembly Line Requirements.

From www.cedm.be

Printed Board Assembly Checklist cEDM Assembly Line Requirements however, achieving this level of operational excellence requires careful planning, implementation, and continuous. Maintaining this tight focus through design and implementation allows engineers to create the most efficient and effective layout possible. Similarly, each component of the assembly line must work in sync for the. assembly lines are designed for one reason: A lean assembly line introduces simplicity. Assembly Line Requirements.

From www.electronicsandyou.com

SMT Manufacturing Line & SMT CB Assembly Process Assembly Line Requirements A lean assembly line introduces simplicity as much as possible into the manufacturing flow, and anything that disrupts the forward momentum of a product is eliminated or mitigated. Similarly, each component of the assembly line must work in sync for the. this article published in assembly magazine, covers many practical “lessons learned” and why flexibility and. however, achieving. Assembly Line Requirements.

From blog.megaventory.com

Assembly Line Types, Pros And Cons The Megaventory Blog Assembly Line Requirements this article published in assembly magazine, covers many practical “lessons learned” and why flexibility and. assembly lines are designed for one reason: however, achieving this level of operational excellence requires careful planning, implementation, and continuous. an assembly line is a manufacturing process that constructs a final product more efficiently by adding components sequentially. an assembly. Assembly Line Requirements.

From slidesdocs.com

Production Daily Report Of Assembly Line Employees Excel Template And Assembly Line Requirements however, achieving this level of operational excellence requires careful planning, implementation, and continuous. Maintaining this tight focus through design and implementation allows engineers to create the most efficient and effective layout possible. Similarly, each component of the assembly line must work in sync for the. an assembly line manufacturing process is a series of individual workers assembling a. Assembly Line Requirements.

From www.raymont-osman.com

Assembly Line Set Up I RaymontOsman Product Design Assembly Line Requirements this article published in assembly magazine, covers many practical “lessons learned” and why flexibility and. however, achieving this level of operational excellence requires careful planning, implementation, and continuous. assembly line efficiency, at its core, represents the harmony between machinery, workforce, and process flow to achieve the maximum output with minimal waste. an assembly line is a. Assembly Line Requirements.

From promation.com

Assembly build line conveyors Promation Assembly Line Requirements assembly lines are designed for one reason: Similarly, each component of the assembly line must work in sync for the. A lean assembly line introduces simplicity as much as possible into the manufacturing flow, and anything that disrupts the forward momentum of a product is eliminated or mitigated. Maintaining this tight focus through design and implementation allows engineers to. Assembly Line Requirements.

From www.youtube.com

Operations Layout Assembly Line Balancing I YouTube Assembly Line Requirements Similarly, each component of the assembly line must work in sync for the. Maintaining this tight focus through design and implementation allows engineers to create the most efficient and effective layout possible. assembly lines are designed for one reason: assembly line efficiency, at its core, represents the harmony between machinery, workforce, and process flow to achieve the maximum. Assembly Line Requirements.

From hoob.ee

Assembly Lines HOOB Factory Automation & Machine Building Assembly Line Requirements Similarly, each component of the assembly line must work in sync for the. an assembly line manufacturing process is a series of individual workers assembling a product,. an assembly line is a manufacturing process that constructs a final product more efficiently by adding components sequentially. this article published in assembly magazine, covers many practical “lessons learned” and. Assembly Line Requirements.

From www.slideserve.com

PPT Manual Assembly Lines PowerPoint Presentation, free download ID Assembly Line Requirements Similarly, each component of the assembly line must work in sync for the. however, achieving this level of operational excellence requires careful planning, implementation, and continuous. this article published in assembly magazine, covers many practical “lessons learned” and why flexibility and. assembly lines are designed for one reason: assembly line efficiency, at its core, represents the. Assembly Line Requirements.

From www.slideteam.net

Assembly Lines Production Report Dashboard Presentation Graphics Assembly Line Requirements A lean assembly line introduces simplicity as much as possible into the manufacturing flow, and anything that disrupts the forward momentum of a product is eliminated or mitigated. assembly line efficiency, at its core, represents the harmony between machinery, workforce, and process flow to achieve the maximum output with minimal waste. Similarly, each component of the assembly line must. Assembly Line Requirements.

From robex.us

Assembly Line Case Studies RōBEX Assembly Line Requirements this article published in assembly magazine, covers many practical “lessons learned” and why flexibility and. an assembly line is a manufacturing process that constructs a final product more efficiently by adding components sequentially. however, achieving this level of operational excellence requires careful planning, implementation, and continuous. an assembly line manufacturing process is a series of individual. Assembly Line Requirements.

From www.wevolver.com

How Assembly Line Automation is Revolutionizing Manufacturing? Types Assembly Line Requirements Maintaining this tight focus through design and implementation allows engineers to create the most efficient and effective layout possible. however, achieving this level of operational excellence requires careful planning, implementation, and continuous. assembly lines are designed for one reason: an assembly line manufacturing process is a series of individual workers assembling a product,. assembly line efficiency,. Assembly Line Requirements.

From www.prodesignautomation.com

Services Assembly Lines ProDesign Automation Custom Machines Assembly Line Requirements Similarly, each component of the assembly line must work in sync for the. an assembly line manufacturing process is a series of individual workers assembling a product,. assembly lines are designed for one reason: Maintaining this tight focus through design and implementation allows engineers to create the most efficient and effective layout possible. however, achieving this level. Assembly Line Requirements.

From www.infismash.com

Assembly Line production line factory assembling KW CONVEYORS Assembly Line Requirements Similarly, each component of the assembly line must work in sync for the. an assembly line manufacturing process is a series of individual workers assembling a product,. Maintaining this tight focus through design and implementation allows engineers to create the most efficient and effective layout possible. assembly lines are designed for one reason: however, achieving this level. Assembly Line Requirements.

From www.slideserve.com

PPT Assembly line balancing PowerPoint Presentation, free download Assembly Line Requirements assembly line efficiency, at its core, represents the harmony between machinery, workforce, and process flow to achieve the maximum output with minimal waste. Maintaining this tight focus through design and implementation allows engineers to create the most efficient and effective layout possible. however, achieving this level of operational excellence requires careful planning, implementation, and continuous. A lean assembly. Assembly Line Requirements.

From www.ecagroup.com

Aerospace Assembly Lines Assembly Line Requirements assembly line efficiency, at its core, represents the harmony between machinery, workforce, and process flow to achieve the maximum output with minimal waste. this article published in assembly magazine, covers many practical “lessons learned” and why flexibility and. Maintaining this tight focus through design and implementation allows engineers to create the most efficient and effective layout possible. . Assembly Line Requirements.

From www.fooddocs.com

Design a Commercial Kitchen Layout Yourself Assembly Line Requirements assembly lines are designed for one reason: an assembly line manufacturing process is a series of individual workers assembling a product,. Maintaining this tight focus through design and implementation allows engineers to create the most efficient and effective layout possible. assembly line efficiency, at its core, represents the harmony between machinery, workforce, and process flow to achieve. Assembly Line Requirements.

From public.amwaly.com

Assembly Line Balancing أموالي Assembly Line Requirements A lean assembly line introduces simplicity as much as possible into the manufacturing flow, and anything that disrupts the forward momentum of a product is eliminated or mitigated. assembly lines are designed for one reason: an assembly line is a manufacturing process that constructs a final product more efficiently by adding components sequentially. assembly line efficiency, at. Assembly Line Requirements.

From www.fivesgroup.com

Fives’ Smart Automation Solutions Division Conveying solutions for Assembly Line Requirements however, achieving this level of operational excellence requires careful planning, implementation, and continuous. an assembly line manufacturing process is a series of individual workers assembling a product,. this article published in assembly magazine, covers many practical “lessons learned” and why flexibility and. Maintaining this tight focus through design and implementation allows engineers to create the most efficient. Assembly Line Requirements.

From www.youtube.com

ASSEMBLY PROCESS ASSEMBLY SYSTEMS ASSEMBLY LINE BEST BUSINESS Assembly Line Requirements A lean assembly line introduces simplicity as much as possible into the manufacturing flow, and anything that disrupts the forward momentum of a product is eliminated or mitigated. however, achieving this level of operational excellence requires careful planning, implementation, and continuous. assembly lines are designed for one reason: Maintaining this tight focus through design and implementation allows engineers. Assembly Line Requirements.

From www.studocu.com

Assembly Line Balancing The assembly line in which the workstations Assembly Line Requirements this article published in assembly magazine, covers many practical “lessons learned” and why flexibility and. Maintaining this tight focus through design and implementation allows engineers to create the most efficient and effective layout possible. Similarly, each component of the assembly line must work in sync for the. assembly line efficiency, at its core, represents the harmony between machinery,. Assembly Line Requirements.

From ottomotors.com

Lean Manufacturing How to Gain Time on the Assembly Line Assembly Line Requirements however, achieving this level of operational excellence requires careful planning, implementation, and continuous. an assembly line is a manufacturing process that constructs a final product more efficiently by adding components sequentially. Similarly, each component of the assembly line must work in sync for the. assembly lines are designed for one reason: this article published in assembly. Assembly Line Requirements.

From learnbright.org

Assembly Line, Free PDF Download Learn Bright Assembly Line Requirements Similarly, each component of the assembly line must work in sync for the. however, achieving this level of operational excellence requires careful planning, implementation, and continuous. assembly line efficiency, at its core, represents the harmony between machinery, workforce, and process flow to achieve the maximum output with minimal waste. Maintaining this tight focus through design and implementation allows. Assembly Line Requirements.

From www.jpgal.co.uk

How to Improve Productivity in an Assembly Line JPGAL Assembly Line Requirements A lean assembly line introduces simplicity as much as possible into the manufacturing flow, and anything that disrupts the forward momentum of a product is eliminated or mitigated. assembly lines are designed for one reason: this article published in assembly magazine, covers many practical “lessons learned” and why flexibility and. Similarly, each component of the assembly line must. Assembly Line Requirements.

From blogs.sap.com

Scheduling Assembly Lines with SAP SAP Blogs Assembly Line Requirements A lean assembly line introduces simplicity as much as possible into the manufacturing flow, and anything that disrupts the forward momentum of a product is eliminated or mitigated. assembly lines are designed for one reason: Maintaining this tight focus through design and implementation allows engineers to create the most efficient and effective layout possible. Similarly, each component of the. Assembly Line Requirements.

From apps.boschrexroth.com

Automation of assembly lines ctrlX AUTOMATION Assembly Line Requirements an assembly line manufacturing process is a series of individual workers assembling a product,. however, achieving this level of operational excellence requires careful planning, implementation, and continuous. Similarly, each component of the assembly line must work in sync for the. assembly line efficiency, at its core, represents the harmony between machinery, workforce, and process flow to achieve. Assembly Line Requirements.

From www.magnum-inc.com

Assembly Line Fixturing MAGNUM Automation Inc. Assembly Line Requirements however, achieving this level of operational excellence requires careful planning, implementation, and continuous. this article published in assembly magazine, covers many practical “lessons learned” and why flexibility and. Similarly, each component of the assembly line must work in sync for the. an assembly line is a manufacturing process that constructs a final product more efficiently by adding. Assembly Line Requirements.

From scimech.com

Assembly Line Design & Integration SciMech Technical Services Assembly Line Requirements assembly lines are designed for one reason: A lean assembly line introduces simplicity as much as possible into the manufacturing flow, and anything that disrupts the forward momentum of a product is eliminated or mitigated. assembly line efficiency, at its core, represents the harmony between machinery, workforce, and process flow to achieve the maximum output with minimal waste.. Assembly Line Requirements.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free Assembly Line Requirements assembly lines are designed for one reason: this article published in assembly magazine, covers many practical “lessons learned” and why flexibility and. an assembly line manufacturing process is a series of individual workers assembling a product,. Maintaining this tight focus through design and implementation allows engineers to create the most efficient and effective layout possible. A lean. Assembly Line Requirements.

From www.aligconveyor.com

Assembly Line Automation Production and Manufacturer Automation System Assembly Line Requirements A lean assembly line introduces simplicity as much as possible into the manufacturing flow, and anything that disrupts the forward momentum of a product is eliminated or mitigated. assembly lines are designed for one reason: an assembly line is a manufacturing process that constructs a final product more efficiently by adding components sequentially. this article published in. Assembly Line Requirements.

From www.slideserve.com

PPT Manual Assembly Lines PowerPoint Presentation, free download ID Assembly Line Requirements however, achieving this level of operational excellence requires careful planning, implementation, and continuous. an assembly line is a manufacturing process that constructs a final product more efficiently by adding components sequentially. assembly lines are designed for one reason: A lean assembly line introduces simplicity as much as possible into the manufacturing flow, and anything that disrupts the. Assembly Line Requirements.