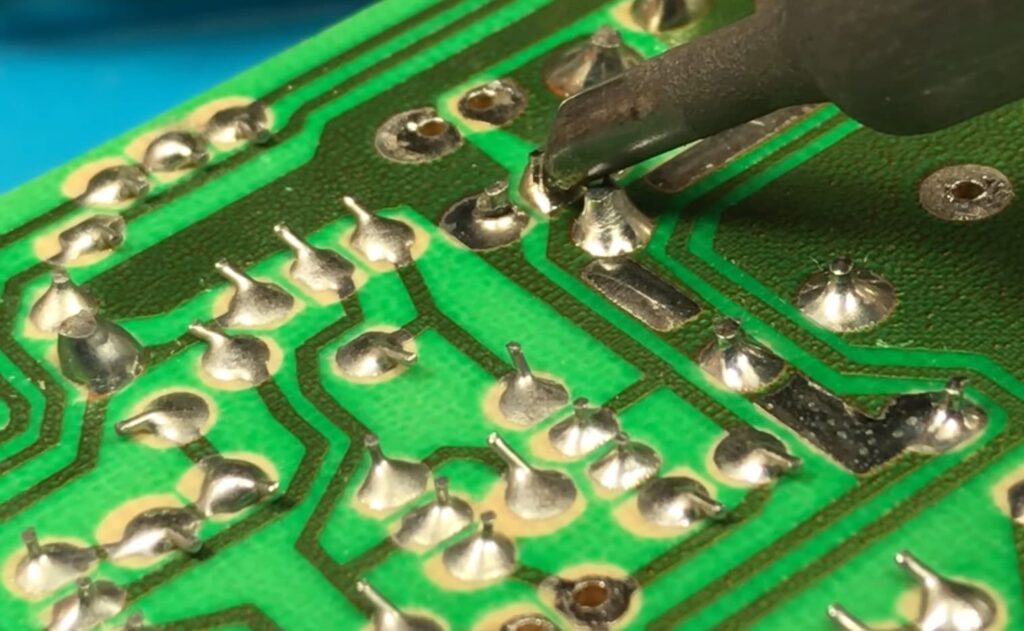

Grainy Solder Joint . When your solder joints cool down, if the period is a little slower, than the joint will have a less shiny look. Cold solder joints might have a grainy or granular appearance under close inspection. Some common ways to identify a dry solder joint include: If there is a visual clue, it's usually that the solder didn't wick into the joint properly. Cold solder joint is the sold ring defect in electronic industry which presents dull grainy appearance and lack of mechanical strength of soldered links and liable to cause circuit. It will look a little beaded up instead of having. A dry solder joint usually has a dull, grainy, or rough appearance, unlike a shiny and. How to identify dry solder joints? Externally the solder joints look good. A solder joint that has a rough, gritty appearance that is caused by the solder microstructure giving the. The leads had pulled out of the solder joint reveling a grainy texture with voids internally. If your solder joints are not shiny, but a have a duller finish, it is typically just the effect of having a coarse grainy structure in the solder joint.

from nerdytechy.com

Cold solder joints might have a grainy or granular appearance under close inspection. Some common ways to identify a dry solder joint include: A solder joint that has a rough, gritty appearance that is caused by the solder microstructure giving the. When your solder joints cool down, if the period is a little slower, than the joint will have a less shiny look. A dry solder joint usually has a dull, grainy, or rough appearance, unlike a shiny and. How to identify dry solder joints? Externally the solder joints look good. Cold solder joint is the sold ring defect in electronic industry which presents dull grainy appearance and lack of mechanical strength of soldered links and liable to cause circuit. If your solder joints are not shiny, but a have a duller finish, it is typically just the effect of having a coarse grainy structure in the solder joint. It will look a little beaded up instead of having.

What Is a Cold Solder Joint? NerdyTechy

Grainy Solder Joint The leads had pulled out of the solder joint reveling a grainy texture with voids internally. Cold solder joint is the sold ring defect in electronic industry which presents dull grainy appearance and lack of mechanical strength of soldered links and liable to cause circuit. If there is a visual clue, it's usually that the solder didn't wick into the joint properly. Some common ways to identify a dry solder joint include: The leads had pulled out of the solder joint reveling a grainy texture with voids internally. Cold solder joints might have a grainy or granular appearance under close inspection. Externally the solder joints look good. When your solder joints cool down, if the period is a little slower, than the joint will have a less shiny look. It will look a little beaded up instead of having. If your solder joints are not shiny, but a have a duller finish, it is typically just the effect of having a coarse grainy structure in the solder joint. A solder joint that has a rough, gritty appearance that is caused by the solder microstructure giving the. How to identify dry solder joints? A dry solder joint usually has a dull, grainy, or rough appearance, unlike a shiny and.

From resources.altium.com

Types of PCB Soldering and the Assembly Process Blog Altium Designer Grainy Solder Joint A solder joint that has a rough, gritty appearance that is caused by the solder microstructure giving the. Some common ways to identify a dry solder joint include: If there is a visual clue, it's usually that the solder didn't wick into the joint properly. Cold solder joints might have a grainy or granular appearance under close inspection. How to. Grainy Solder Joint.

From pcbassemblymanufacturing.com

Solder joint one basic lesson about PCB soldering Grainy Solder Joint Some common ways to identify a dry solder joint include: If there is a visual clue, it's usually that the solder didn't wick into the joint properly. The leads had pulled out of the solder joint reveling a grainy texture with voids internally. Cold solder joint is the sold ring defect in electronic industry which presents dull grainy appearance and. Grainy Solder Joint.

From rushpcb.com

What is a Solder Joint? RushPcb Grainy Solder Joint The leads had pulled out of the solder joint reveling a grainy texture with voids internally. When your solder joints cool down, if the period is a little slower, than the joint will have a less shiny look. It will look a little beaded up instead of having. If there is a visual clue, it's usually that the solder didn't. Grainy Solder Joint.

From www.researchgate.net

Procedure for assembling a single BGA structure solder joint by Grainy Solder Joint The leads had pulled out of the solder joint reveling a grainy texture with voids internally. Cold solder joint is the sold ring defect in electronic industry which presents dull grainy appearance and lack of mechanical strength of soldered links and liable to cause circuit. A solder joint that has a rough, gritty appearance that is caused by the solder. Grainy Solder Joint.

From www.pcbaaa.com

Understanding solder joint basics and techniques IBE Electronics Grainy Solder Joint Cold solder joints might have a grainy or granular appearance under close inspection. When your solder joints cool down, if the period is a little slower, than the joint will have a less shiny look. The leads had pulled out of the solder joint reveling a grainy texture with voids internally. How to identify dry solder joints? If your solder. Grainy Solder Joint.

From thesolderblog.blogspot.com

TheSolderBlog Lead Free Solder Grainy Solder Joint A dry solder joint usually has a dull, grainy, or rough appearance, unlike a shiny and. A solder joint that has a rough, gritty appearance that is caused by the solder microstructure giving the. How to identify dry solder joints? Externally the solder joints look good. It will look a little beaded up instead of having. Some common ways to. Grainy Solder Joint.

From www.researchgate.net

Actual solder joints with different bump shape in the study a barrel Grainy Solder Joint If there is a visual clue, it's usually that the solder didn't wick into the joint properly. The leads had pulled out of the solder joint reveling a grainy texture with voids internally. A dry solder joint usually has a dull, grainy, or rough appearance, unlike a shiny and. Some common ways to identify a dry solder joint include: A. Grainy Solder Joint.

From www.slideshare.net

How To Solder V3.5 Grainy Solder Joint A solder joint that has a rough, gritty appearance that is caused by the solder microstructure giving the. If there is a visual clue, it's usually that the solder didn't wick into the joint properly. Cold solder joints might have a grainy or granular appearance under close inspection. Externally the solder joints look good. Cold solder joint is the sold. Grainy Solder Joint.

From www.plumbersforums.net

Soldered Joints Rough / Grainy Finish at top of Joint (Lead free Solder Grainy Solder Joint Externally the solder joints look good. A dry solder joint usually has a dull, grainy, or rough appearance, unlike a shiny and. How to identify dry solder joints? A solder joint that has a rough, gritty appearance that is caused by the solder microstructure giving the. Some common ways to identify a dry solder joint include: Cold solder joints might. Grainy Solder Joint.

From www.plumbersforums.net

Soldered Joints Rough / Grainy Finish at top of Joint (Lead free Solder Grainy Solder Joint How to identify dry solder joints? Cold solder joint is the sold ring defect in electronic industry which presents dull grainy appearance and lack of mechanical strength of soldered links and liable to cause circuit. Externally the solder joints look good. It will look a little beaded up instead of having. A solder joint that has a rough, gritty appearance. Grainy Solder Joint.

From www.circuitbasics.com

Tips for Good Soldering Technique Circuit Basics Grainy Solder Joint If your solder joints are not shiny, but a have a duller finish, it is typically just the effect of having a coarse grainy structure in the solder joint. It will look a little beaded up instead of having. How to identify dry solder joints? The leads had pulled out of the solder joint reveling a grainy texture with voids. Grainy Solder Joint.

From www.nextpcb.com

Dry Solder Joints How to Identify and Fix Them? Grainy Solder Joint The leads had pulled out of the solder joint reveling a grainy texture with voids internally. A dry solder joint usually has a dull, grainy, or rough appearance, unlike a shiny and. If there is a visual clue, it's usually that the solder didn't wick into the joint properly. Externally the solder joints look good. Cold solder joints might have. Grainy Solder Joint.

From www.plumbersforums.net

Soldered Joints Rough / Grainy Finish at top of Joint (Lead free Solder Grainy Solder Joint It will look a little beaded up instead of having. A solder joint that has a rough, gritty appearance that is caused by the solder microstructure giving the. If your solder joints are not shiny, but a have a duller finish, it is typically just the effect of having a coarse grainy structure in the solder joint. How to identify. Grainy Solder Joint.

From www.electronicsandyou.com

Basic Soldering Guide How to Solder Electronic Components Grainy Solder Joint Some common ways to identify a dry solder joint include: A dry solder joint usually has a dull, grainy, or rough appearance, unlike a shiny and. When your solder joints cool down, if the period is a little slower, than the joint will have a less shiny look. Cold solder joint is the sold ring defect in electronic industry which. Grainy Solder Joint.

From www.raypcb.com

The Detailed Comparison of LeadFree and Lead Soldering Phenomenon of PCBs Grainy Solder Joint A solder joint that has a rough, gritty appearance that is caused by the solder microstructure giving the. Some common ways to identify a dry solder joint include: Externally the solder joints look good. A dry solder joint usually has a dull, grainy, or rough appearance, unlike a shiny and. Cold solder joints might have a grainy or granular appearance. Grainy Solder Joint.

From absolutepcbassembly.com

IPC JSTD001 Standard for Soldering Absolute Electronics Grainy Solder Joint The leads had pulled out of the solder joint reveling a grainy texture with voids internally. Cold solder joint is the sold ring defect in electronic industry which presents dull grainy appearance and lack of mechanical strength of soldered links and liable to cause circuit. It will look a little beaded up instead of having. A dry solder joint usually. Grainy Solder Joint.

From www.plumbersforums.net

Soldered Joints Rough / Grainy Finish at top of Joint (Lead free Solder Grainy Solder Joint A solder joint that has a rough, gritty appearance that is caused by the solder microstructure giving the. Some common ways to identify a dry solder joint include: It will look a little beaded up instead of having. How to identify dry solder joints? When your solder joints cool down, if the period is a little slower, than the joint. Grainy Solder Joint.

From www.pcba-manufacturers.com

Understanding Cold Solder Joints Causes, Identification and Solutions Grainy Solder Joint Some common ways to identify a dry solder joint include: Cold solder joint is the sold ring defect in electronic industry which presents dull grainy appearance and lack of mechanical strength of soldered links and liable to cause circuit. How to identify dry solder joints? The leads had pulled out of the solder joint reveling a grainy texture with voids. Grainy Solder Joint.

From morepcb.com

How to Solder Wire on Circuit Board Mastering the Basics MorePCB Grainy Solder Joint When your solder joints cool down, if the period is a little slower, than the joint will have a less shiny look. A solder joint that has a rough, gritty appearance that is caused by the solder microstructure giving the. Some common ways to identify a dry solder joint include: How to identify dry solder joints? The leads had pulled. Grainy Solder Joint.

From smt.iconnect007.com

Acceptance Testing Of LowAg Reflow Solder Alloys (Part 2) Grainy Solder Joint A dry solder joint usually has a dull, grainy, or rough appearance, unlike a shiny and. When your solder joints cool down, if the period is a little slower, than the joint will have a less shiny look. Externally the solder joints look good. How to identify dry solder joints? Cold solder joints might have a grainy or granular appearance. Grainy Solder Joint.

From www.youtube.com

How to Solder Properly 5 Soldering Joint Splices YouTube Grainy Solder Joint If your solder joints are not shiny, but a have a duller finish, it is typically just the effect of having a coarse grainy structure in the solder joint. Cold solder joint is the sold ring defect in electronic industry which presents dull grainy appearance and lack of mechanical strength of soldered links and liable to cause circuit. How to. Grainy Solder Joint.

From www.electronicsandyou.com

Cold Solder Joint Symptoms, Prevent, Repair and Fix Cold Solder Joint Grainy Solder Joint A dry solder joint usually has a dull, grainy, or rough appearance, unlike a shiny and. Cold solder joints might have a grainy or granular appearance under close inspection. It will look a little beaded up instead of having. Cold solder joint is the sold ring defect in electronic industry which presents dull grainy appearance and lack of mechanical strength. Grainy Solder Joint.

From www.researchgate.net

Solder joint of a shear test specimen after successive straining Grainy Solder Joint Cold solder joint is the sold ring defect in electronic industry which presents dull grainy appearance and lack of mechanical strength of soldered links and liable to cause circuit. A dry solder joint usually has a dull, grainy, or rough appearance, unlike a shiny and. Cold solder joints might have a grainy or granular appearance under close inspection. If there. Grainy Solder Joint.

From absolutepcbassembly.com

Cold Solder Joint Definitive Guide to Soldering Absolute Grainy Solder Joint When your solder joints cool down, if the period is a little slower, than the joint will have a less shiny look. A solder joint that has a rough, gritty appearance that is caused by the solder microstructure giving the. Externally the solder joints look good. If there is a visual clue, it's usually that the solder didn't wick into. Grainy Solder Joint.

From nerdytechy.com

What Is a Cold Solder Joint? NerdyTechy Grainy Solder Joint If your solder joints are not shiny, but a have a duller finish, it is typically just the effect of having a coarse grainy structure in the solder joint. The leads had pulled out of the solder joint reveling a grainy texture with voids internally. If there is a visual clue, it's usually that the solder didn't wick into the. Grainy Solder Joint.

From www.tayloredge.com

Tayloredge SMT Soldering Grainy Solder Joint If there is a visual clue, it's usually that the solder didn't wick into the joint properly. It will look a little beaded up instead of having. How to identify dry solder joints? If your solder joints are not shiny, but a have a duller finish, it is typically just the effect of having a coarse grainy structure in the. Grainy Solder Joint.

From www.pcbaaa.com

Cold solder joints Unraveling the hazards, causes, detection, repair Grainy Solder Joint It will look a little beaded up instead of having. Externally the solder joints look good. If your solder joints are not shiny, but a have a duller finish, it is typically just the effect of having a coarse grainy structure in the solder joint. If there is a visual clue, it's usually that the solder didn't wick into the. Grainy Solder Joint.

From www.youtube.com

Electronics Why does a cold solder joint appear grainy or dull? YouTube Grainy Solder Joint Cold solder joint is the sold ring defect in electronic industry which presents dull grainy appearance and lack of mechanical strength of soldered links and liable to cause circuit. When your solder joints cool down, if the period is a little slower, than the joint will have a less shiny look. If your solder joints are not shiny, but a. Grainy Solder Joint.

From www.electronicsandyou.com

Cold Solder Joint Symptoms, Prevent, Repair and Fix Cold Solder Joint Grainy Solder Joint It will look a little beaded up instead of having. If there is a visual clue, it's usually that the solder didn't wick into the joint properly. A dry solder joint usually has a dull, grainy, or rough appearance, unlike a shiny and. When your solder joints cool down, if the period is a little slower, than the joint will. Grainy Solder Joint.

From www.youtube.com

How to repair cold solder joint YouTube Grainy Solder Joint The leads had pulled out of the solder joint reveling a grainy texture with voids internally. A solder joint that has a rough, gritty appearance that is caused by the solder microstructure giving the. If there is a visual clue, it's usually that the solder didn't wick into the joint properly. Cold solder joint is the sold ring defect in. Grainy Solder Joint.

From nerdytechy.com

What Is a Cold Solder Joint? NerdyTechy Grainy Solder Joint Cold solder joints might have a grainy or granular appearance under close inspection. It will look a little beaded up instead of having. When your solder joints cool down, if the period is a little slower, than the joint will have a less shiny look. A dry solder joint usually has a dull, grainy, or rough appearance, unlike a shiny. Grainy Solder Joint.

From core-electronics.com.au

Soldering 101 Tutorial Australia Grainy Solder Joint If your solder joints are not shiny, but a have a duller finish, it is typically just the effect of having a coarse grainy structure in the solder joint. Cold solder joints might have a grainy or granular appearance under close inspection. The leads had pulled out of the solder joint reveling a grainy texture with voids internally. Externally the. Grainy Solder Joint.

From store.curiousinventor.com

Heat and Solder the Joint Curious Inventor Grainy Solder Joint When your solder joints cool down, if the period is a little slower, than the joint will have a less shiny look. A dry solder joint usually has a dull, grainy, or rough appearance, unlike a shiny and. Some common ways to identify a dry solder joint include: Cold solder joint is the sold ring defect in electronic industry which. Grainy Solder Joint.

From nerdytechy.com

What Is a Cold Solder Joint? NerdyTechy Grainy Solder Joint Some common ways to identify a dry solder joint include: How to identify dry solder joints? Cold solder joints might have a grainy or granular appearance under close inspection. When your solder joints cool down, if the period is a little slower, than the joint will have a less shiny look. It will look a little beaded up instead of. Grainy Solder Joint.

From www.digikey.co.uk

ROHS vs NonROHS Soldering Grainy Solder Joint A solder joint that has a rough, gritty appearance that is caused by the solder microstructure giving the. Some common ways to identify a dry solder joint include: Cold solder joints might have a grainy or granular appearance under close inspection. Cold solder joint is the sold ring defect in electronic industry which presents dull grainy appearance and lack of. Grainy Solder Joint.