Tool Design Procedure . Tool design is a comprehensive process involving the creation and refinement of tools, methods, and techniques aimed at enhancing manufacturing efficiency and productivity. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced methods like cad/cam. Cutting tool design requires an understanding of the application difficulties that can be encountered during the machining process,. Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. Whether it’s a lathe, milling machine, or a cnc (computer numerical. This intricate process encompasses the design of various tools, including jigs, fixtures, and other accessories. High quantity and quality parts require proper tooling. Tooling, also known as a mold, refers to the negative cavity space where molten plastic resin is injected to create a part. Tool design ensures that the right tool is used for the job, reducing waste and increasing productivity.

from gsmib.com

Whether it’s a lathe, milling machine, or a cnc (computer numerical. Tool design is a comprehensive process involving the creation and refinement of tools, methods, and techniques aimed at enhancing manufacturing efficiency and productivity. Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. Tooling, also known as a mold, refers to the negative cavity space where molten plastic resin is injected to create a part. Tool design ensures that the right tool is used for the job, reducing waste and increasing productivity. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced methods like cad/cam. High quantity and quality parts require proper tooling. Cutting tool design requires an understanding of the application difficulties that can be encountered during the machining process,. This intricate process encompasses the design of various tools, including jigs, fixtures, and other accessories.

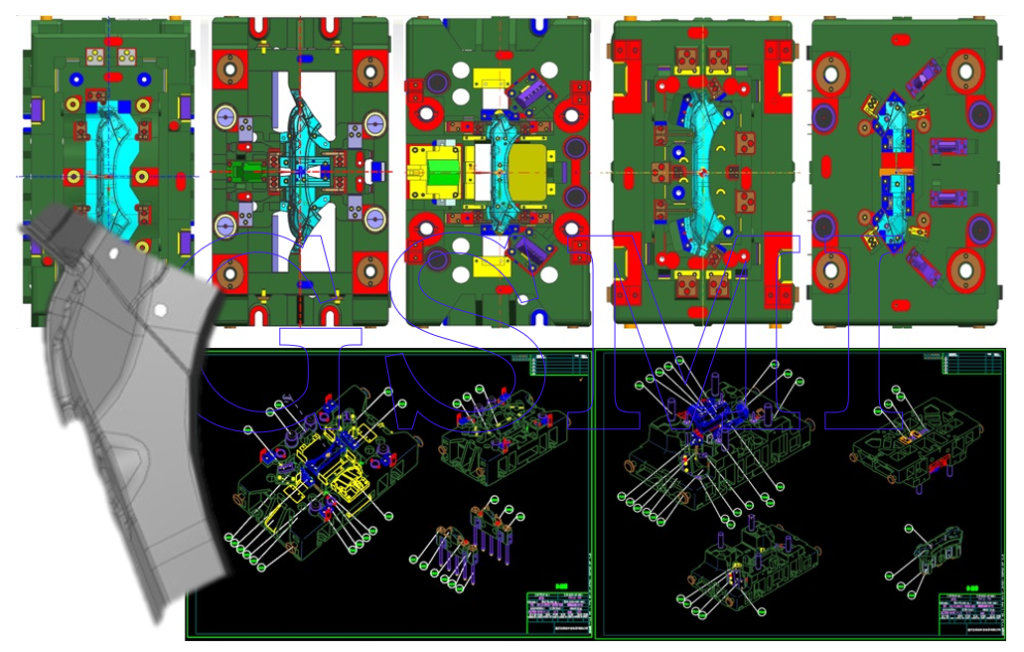

Casting Automatic Line Tool Design STAMPING DIES&TOOL

Tool Design Procedure High quantity and quality parts require proper tooling. Tooling, also known as a mold, refers to the negative cavity space where molten plastic resin is injected to create a part. Cutting tool design requires an understanding of the application difficulties that can be encountered during the machining process,. This intricate process encompasses the design of various tools, including jigs, fixtures, and other accessories. Tool design ensures that the right tool is used for the job, reducing waste and increasing productivity. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced methods like cad/cam. Whether it’s a lathe, milling machine, or a cnc (computer numerical. Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. High quantity and quality parts require proper tooling. Tool design is a comprehensive process involving the creation and refinement of tools, methods, and techniques aimed at enhancing manufacturing efficiency and productivity.

From asana.com

Process Documentation A HowTo Guide With Examples • Asana Tool Design Procedure Tool design ensures that the right tool is used for the job, reducing waste and increasing productivity. This intricate process encompasses the design of various tools, including jigs, fixtures, and other accessories. Whether it’s a lathe, milling machine, or a cnc (computer numerical. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced methods like cad/cam. Tool. Tool Design Procedure.

From www.vecteezy.com

creative tools design process 3d illustration 23363170 PNG Tool Design Procedure Explore manufacturing tool design with us, covering essentials from cutting tools to advanced methods like cad/cam. High quantity and quality parts require proper tooling. Cutting tool design requires an understanding of the application difficulties that can be encountered during the machining process,. Tool design ensures that the right tool is used for the job, reducing waste and increasing productivity. This. Tool Design Procedure.

From learnmechanical.com

What is Machine Design? Its Definitions, Classification, Methods, & Procedures (PDF) Learn Tool Design Procedure High quantity and quality parts require proper tooling. Cutting tool design requires an understanding of the application difficulties that can be encountered during the machining process,. This intricate process encompasses the design of various tools, including jigs, fixtures, and other accessories. Whether it’s a lathe, milling machine, or a cnc (computer numerical. Tool design is a comprehensive process involving the. Tool Design Procedure.

From www.conceptdraw.com

How to Create an Audit Flowchart Using ConceptDraw PRO Internal Audit Process Audit Process Tool Design Procedure Whether it’s a lathe, milling machine, or a cnc (computer numerical. Tool design is a comprehensive process involving the creation and refinement of tools, methods, and techniques aimed at enhancing manufacturing efficiency and productivity. Tooling, also known as a mold, refers to the negative cavity space where molten plastic resin is injected to create a part. Explore manufacturing tool design. Tool Design Procedure.

From www.scribd.com

Form Tool Design PROCEDURES PDF Wear Stress (Mechanics) Tool Design Procedure Tooling, also known as a mold, refers to the negative cavity space where molten plastic resin is injected to create a part. High quantity and quality parts require proper tooling. This intricate process encompasses the design of various tools, including jigs, fixtures, and other accessories. Cutting tool design requires an understanding of the application difficulties that can be encountered during. Tool Design Procedure.

From www.academia.edu

(PDF) Reconfigurable Machine Tools Design Methodologies and Measuring Reconfigurability for Tool Design Procedure Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. Tool design is a comprehensive process involving the creation and refinement of tools, methods, and techniques aimed at enhancing manufacturing efficiency and productivity. This intricate process encompasses the design of various tools, including jigs, fixtures, and other accessories. Cutting tool design requires. Tool Design Procedure.

From www.lmat-uk.com

Process simulation Material characterisation Software Resin Flow Tool design Tool Design Procedure Cutting tool design requires an understanding of the application difficulties that can be encountered during the machining process,. Tool design ensures that the right tool is used for the job, reducing waste and increasing productivity. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced methods like cad/cam. This intricate process encompasses the design of various tools,. Tool Design Procedure.

From www.decipherzone.com

Software Design Process and Tools Tool Design Procedure Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. Whether it’s a lathe, milling machine, or a cnc (computer numerical. This intricate process encompasses the design of various tools, including jigs, fixtures, and other accessories. Cutting tool design requires an understanding of the application difficulties that can be encountered during the. Tool Design Procedure.

From www.researchgate.net

The Result Of Tool Design Download Scientific Diagram Tool Design Procedure Tool design ensures that the right tool is used for the job, reducing waste and increasing productivity. Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. Whether it’s a lathe, milling machine, or a cnc (computer numerical. High quantity and quality parts require proper tooling. Tool design is a comprehensive process. Tool Design Procedure.

From www.mdpi.com

Heritage Free FullText Virtual Reality Applied to Heritage in Higher Education—Validation Tool Design Procedure High quantity and quality parts require proper tooling. Cutting tool design requires an understanding of the application difficulties that can be encountered during the machining process,. This intricate process encompasses the design of various tools, including jigs, fixtures, and other accessories. Tool design ensures that the right tool is used for the job, reducing waste and increasing productivity. Whether it’s. Tool Design Procedure.

From www.predictiveanalyticstoday.com

Guidelines for Preparing Standard Operating Procedures in 2024 Reviews, Features, Pricing Tool Design Procedure High quantity and quality parts require proper tooling. Whether it’s a lathe, milling machine, or a cnc (computer numerical. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced methods like cad/cam. Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. Cutting tool design requires an understanding of. Tool Design Procedure.

From www.aplyon.com

ISO 13485 Design and Development Procedures Tool Design Procedure Tooling, also known as a mold, refers to the negative cavity space where molten plastic resin is injected to create a part. Cutting tool design requires an understanding of the application difficulties that can be encountered during the machining process,. High quantity and quality parts require proper tooling. Explore manufacturing tool design with us, covering essentials from cutting tools to. Tool Design Procedure.

From www.researchgate.net

clinching tools design procedure [66]. Download Scientific Diagram Tool Design Procedure High quantity and quality parts require proper tooling. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced methods like cad/cam. This intricate process encompasses the design of various tools, including jigs, fixtures, and other accessories. Whether it’s a lathe, milling machine, or a cnc (computer numerical. Tooling, also known as a mold, refers to the negative. Tool Design Procedure.

From www.nexpcb.com

One Picture to Understand the Structure of an Injection Mold Tool Design Procedure Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. Tooling, also known as a mold, refers to the negative cavity space where molten plastic resin is injected to create a part. Cutting tool design requires an understanding of the application difficulties that can be encountered during the machining process,. Whether it’s. Tool Design Procedure.

From klariti.com

How to Write Better Business Processes Designs (with sample template) Tool Design Procedure Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. Cutting tool design requires an understanding of the application difficulties that can be encountered during the machining process,. Tool design ensures that the right tool is used for the job, reducing waste and increasing productivity. High quantity and quality parts require proper. Tool Design Procedure.

From www.techyv.com

Top 10 Design Tools Tool Design Procedure High quantity and quality parts require proper tooling. Tool design ensures that the right tool is used for the job, reducing waste and increasing productivity. Cutting tool design requires an understanding of the application difficulties that can be encountered during the machining process,. This intricate process encompasses the design of various tools, including jigs, fixtures, and other accessories. Tool design. Tool Design Procedure.

From venngage.com

15+ Best Standard Operating Procedure Checklist Templates Tool Design Procedure Explore manufacturing tool design with us, covering essentials from cutting tools to advanced methods like cad/cam. Tooling, also known as a mold, refers to the negative cavity space where molten plastic resin is injected to create a part. Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. Tool design ensures that. Tool Design Procedure.

From www.pinterest.com

Design Parameters in press tools design Tool design, Design development, Design Tool Design Procedure Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. Whether it’s a lathe, milling machine, or a cnc (computer numerical. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced methods like cad/cam. Tool design ensures that the right tool is used for the job, reducing waste and. Tool Design Procedure.

From www.youtube.com

Tool Engineering Imp. Que. Solution 9 Characteristics of form tools & Types of tools YouTube Tool Design Procedure Tool design ensures that the right tool is used for the job, reducing waste and increasing productivity. Tooling, also known as a mold, refers to the negative cavity space where molten plastic resin is injected to create a part. Whether it’s a lathe, milling machine, or a cnc (computer numerical. Tool design in machine tooling is the art and science. Tool Design Procedure.

From nbplastics.com

Tool Design Injection Molding Services New Berlin Plastics Tool Design Procedure Explore manufacturing tool design with us, covering essentials from cutting tools to advanced methods like cad/cam. High quantity and quality parts require proper tooling. Tooling, also known as a mold, refers to the negative cavity space where molten plastic resin is injected to create a part. Tool design ensures that the right tool is used for the job, reducing waste. Tool Design Procedure.

From www.openlawlab.com

Design Process Tools for Synthesis in System Design Open Law Lab Tool Design Procedure High quantity and quality parts require proper tooling. Cutting tool design requires an understanding of the application difficulties that can be encountered during the machining process,. Tool design ensures that the right tool is used for the job, reducing waste and increasing productivity. Tooling, also known as a mold, refers to the negative cavity space where molten plastic resin is. Tool Design Procedure.

From www.scribd.com

Introduction To Tool Design PDF Machine Tool Tool Design Procedure Tool design ensures that the right tool is used for the job, reducing waste and increasing productivity. Tooling, also known as a mold, refers to the negative cavity space where molten plastic resin is injected to create a part. This intricate process encompasses the design of various tools, including jigs, fixtures, and other accessories. Cutting tool design requires an understanding. Tool Design Procedure.

From www.sunstrong.com

Tool Design SIL Tool Design Procedure Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. Tool design is a comprehensive process involving the creation and refinement of tools, methods, and techniques aimed at enhancing manufacturing efficiency and productivity. High quantity and quality parts require proper tooling. Explore manufacturing tool design with us, covering essentials from cutting tools. Tool Design Procedure.

From www.youtube.com

Press Tools7 Compound Die vs Progressive Die Comparison, Bending Terminologies & Design Tool Design Procedure Tool design ensures that the right tool is used for the job, reducing waste and increasing productivity. Tooling, also known as a mold, refers to the negative cavity space where molten plastic resin is injected to create a part. Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. Whether it’s a. Tool Design Procedure.

From venngage.com

5 Stages for Managing a Project Process Infographic Template Venngage Tool Design Procedure This intricate process encompasses the design of various tools, including jigs, fixtures, and other accessories. Cutting tool design requires an understanding of the application difficulties that can be encountered during the machining process,. Tooling, also known as a mold, refers to the negative cavity space where molten plastic resin is injected to create a part. Tool design in machine tooling. Tool Design Procedure.

From accountinguide.com

Audit Procedures Types Assertions Accountinguide Tool Design Procedure High quantity and quality parts require proper tooling. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced methods like cad/cam. This intricate process encompasses the design of various tools, including jigs, fixtures, and other accessories. Tooling, also known as a mold, refers to the negative cavity space where molten plastic resin is injected to create a. Tool Design Procedure.

From www.designveloper.com

How to Organize Design Files That Help to Save Time? Tool Design Procedure Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. This intricate process encompasses the design of various tools, including jigs, fixtures, and other accessories. Cutting tool design requires an understanding of the application difficulties that can be encountered during the machining process,. Explore manufacturing tool design with us, covering essentials from. Tool Design Procedure.

From www.lmat-uk.com

Tool design LMAT Together we makes tools better Tool Design Procedure Tooling, also known as a mold, refers to the negative cavity space where molten plastic resin is injected to create a part. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced methods like cad/cam. Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. High quantity and quality. Tool Design Procedure.

From www.slideserve.com

PPT Layout Tools And Procedures PowerPoint Presentation, free download ID485350 Tool Design Procedure High quantity and quality parts require proper tooling. Tool design is a comprehensive process involving the creation and refinement of tools, methods, and techniques aimed at enhancing manufacturing efficiency and productivity. Cutting tool design requires an understanding of the application difficulties that can be encountered during the machining process,. Explore manufacturing tool design with us, covering essentials from cutting tools. Tool Design Procedure.

From www.the-3rddimension.com

The 3rd Dimension Tool Design Tool Design Procedure Tooling, also known as a mold, refers to the negative cavity space where molten plastic resin is injected to create a part. High quantity and quality parts require proper tooling. Tool design ensures that the right tool is used for the job, reducing waste and increasing productivity. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced. Tool Design Procedure.

From www.researchgate.net

1. Structural design procedure of HSC Download Scientific Diagram Tool Design Procedure This intricate process encompasses the design of various tools, including jigs, fixtures, and other accessories. Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced methods like cad/cam. Tool design ensures that the right tool is used for the. Tool Design Procedure.

From www.predictiveanalyticstoday.com

Top Standard Operating Procedures (SOP) Software Tool Design Procedure High quantity and quality parts require proper tooling. Tool design ensures that the right tool is used for the job, reducing waste and increasing productivity. This intricate process encompasses the design of various tools, including jigs, fixtures, and other accessories. Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. Whether it’s. Tool Design Procedure.

From www.openlawlab.com

Design Process Tools for Synthesis in System Design Open Law Lab Tool Design Procedure Explore manufacturing tool design with us, covering essentials from cutting tools to advanced methods like cad/cam. Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. Tool design is a comprehensive process involving the creation and refinement of tools, methods, and techniques aimed at enhancing manufacturing efficiency and productivity. Tooling, also known. Tool Design Procedure.

From gsmib.com

Casting Automatic Line Tool Design STAMPING DIES&TOOL Tool Design Procedure Tool design ensures that the right tool is used for the job, reducing waste and increasing productivity. Tooling, also known as a mold, refers to the negative cavity space where molten plastic resin is injected to create a part. This intricate process encompasses the design of various tools, including jigs, fixtures, and other accessories. Cutting tool design requires an understanding. Tool Design Procedure.

From www.gateinc.com

SOP Development — GATE, Inc. Oil & Gas Engineering Tool Design Procedure Tool design is a comprehensive process involving the creation and refinement of tools, methods, and techniques aimed at enhancing manufacturing efficiency and productivity. Tooling, also known as a mold, refers to the negative cavity space where molten plastic resin is injected to create a part. Tool design ensures that the right tool is used for the job, reducing waste and. Tool Design Procedure.