Plastic Extrusion Defects . Extrusion mold design, raw materials choice, and manufacturing process. One extrusion line suddenly started making tubing with surface. A troubleshooting timeline helped a tubing processor to isolate the source of a processing problem. In the polymer extrusion process, these defects usually come from three primary sources: The technique of extruding plastic may result in a number of extrusion defects, which can manifest themselves at various points. High extrusion speed can stretch the material beyond its. Polymer extrusion defects may appear from a single cause or a commutative cause of multiple factors. The introduction, by russ gould, covers the basics. Inadequate material heating, leading to brittle extrusion. We have discussed the most critical polymer extrusion defects in the. Which are normally occurring in plastic extrusion process are due to three main causes: In extrusion products, defects due to processing include, poor understanding of the processing method, use of inadequate or old. Rapid cooling, causing material contraction at different rates. Mould design, material selection, and processing.

from www.slideserve.com

One extrusion line suddenly started making tubing with surface. Rapid cooling, causing material contraction at different rates. Inadequate material heating, leading to brittle extrusion. We have discussed the most critical polymer extrusion defects in the. The introduction, by russ gould, covers the basics. The technique of extruding plastic may result in a number of extrusion defects, which can manifest themselves at various points. Which are normally occurring in plastic extrusion process are due to three main causes: High extrusion speed can stretch the material beyond its. A troubleshooting timeline helped a tubing processor to isolate the source of a processing problem. Extrusion mold design, raw materials choice, and manufacturing process.

PPT Chapter 15 PowerPoint Presentation, free download ID24756

Plastic Extrusion Defects In extrusion products, defects due to processing include, poor understanding of the processing method, use of inadequate or old. The technique of extruding plastic may result in a number of extrusion defects, which can manifest themselves at various points. Rapid cooling, causing material contraction at different rates. Mould design, material selection, and processing. A troubleshooting timeline helped a tubing processor to isolate the source of a processing problem. In extrusion products, defects due to processing include, poor understanding of the processing method, use of inadequate or old. Extrusion mold design, raw materials choice, and manufacturing process. Polymer extrusion defects may appear from a single cause or a commutative cause of multiple factors. In the polymer extrusion process, these defects usually come from three primary sources: High extrusion speed can stretch the material beyond its. One extrusion line suddenly started making tubing with surface. The introduction, by russ gould, covers the basics. We have discussed the most critical polymer extrusion defects in the. Inadequate material heating, leading to brittle extrusion. Which are normally occurring in plastic extrusion process are due to three main causes:

From www.slideshare.net

PLASTIC DEFECTS Plastic Extrusion Defects In the polymer extrusion process, these defects usually come from three primary sources: Which are normally occurring in plastic extrusion process are due to three main causes: Extrusion mold design, raw materials choice, and manufacturing process. Rapid cooling, causing material contraction at different rates. In extrusion products, defects due to processing include, poor understanding of the processing method, use of. Plastic Extrusion Defects.

From www.researchgate.net

Streaks due to extrusion surface defects. (a) Profile of an anodized Plastic Extrusion Defects The introduction, by russ gould, covers the basics. We have discussed the most critical polymer extrusion defects in the. One extrusion line suddenly started making tubing with surface. In the polymer extrusion process, these defects usually come from three primary sources: Polymer extrusion defects may appear from a single cause or a commutative cause of multiple factors. Which are normally. Plastic Extrusion Defects.

From www.coursehero.com

[Solved] Discuss the defects in products which have produced using the Plastic Extrusion Defects We have discussed the most critical polymer extrusion defects in the. One extrusion line suddenly started making tubing with surface. In the polymer extrusion process, these defects usually come from three primary sources: A troubleshooting timeline helped a tubing processor to isolate the source of a processing problem. Which are normally occurring in plastic extrusion process are due to three. Plastic Extrusion Defects.

From www.researchgate.net

Material extrusion defect types (a) deformed edges (DE)(b Plastic Extrusion Defects One extrusion line suddenly started making tubing with surface. Rapid cooling, causing material contraction at different rates. The technique of extruding plastic may result in a number of extrusion defects, which can manifest themselves at various points. In the polymer extrusion process, these defects usually come from three primary sources: In extrusion products, defects due to processing include, poor understanding. Plastic Extrusion Defects.

From www.researchgate.net

Modes of deformation associated to endtoend joining of PVC tubes by Plastic Extrusion Defects Inadequate material heating, leading to brittle extrusion. One extrusion line suddenly started making tubing with surface. A troubleshooting timeline helped a tubing processor to isolate the source of a processing problem. In the polymer extrusion process, these defects usually come from three primary sources: Rapid cooling, causing material contraction at different rates. Which are normally occurring in plastic extrusion process. Plastic Extrusion Defects.

From www.scribd.com

Defect Definitions Extrusion Sheet Metal Plastic Extrusion Defects In the polymer extrusion process, these defects usually come from three primary sources: Inadequate material heating, leading to brittle extrusion. In extrusion products, defects due to processing include, poor understanding of the processing method, use of inadequate or old. Extrusion mold design, raw materials choice, and manufacturing process. One extrusion line suddenly started making tubing with surface. Mould design, material. Plastic Extrusion Defects.

From www.researchgate.net

(a) Extrusion Process, (b) Common Defects in Extrusion, (i) Central Plastic Extrusion Defects Mould design, material selection, and processing. Extrusion mold design, raw materials choice, and manufacturing process. Rapid cooling, causing material contraction at different rates. Which are normally occurring in plastic extrusion process are due to three main causes: The introduction, by russ gould, covers the basics. In the polymer extrusion process, these defects usually come from three primary sources: A troubleshooting. Plastic Extrusion Defects.

From slidetodoc.com

ENT 244 Manufacturing Engineering Processes Metal Extrusion Process Plastic Extrusion Defects The technique of extruding plastic may result in a number of extrusion defects, which can manifest themselves at various points. Mould design, material selection, and processing. In the polymer extrusion process, these defects usually come from three primary sources: A troubleshooting timeline helped a tubing processor to isolate the source of a processing problem. Polymer extrusion defects may appear from. Plastic Extrusion Defects.

From seashorerubber.com

Extrusion Defects The Most Critical Reasons You Should Know Plastic Extrusion Defects Inadequate material heating, leading to brittle extrusion. In extrusion products, defects due to processing include, poor understanding of the processing method, use of inadequate or old. The technique of extruding plastic may result in a number of extrusion defects, which can manifest themselves at various points. Extrusion mold design, raw materials choice, and manufacturing process. Polymer extrusion defects may appear. Plastic Extrusion Defects.

From materean.com

Names of coating/surface defects Paul Wu's Blog Plastic Extrusion Defects The introduction, by russ gould, covers the basics. Extrusion mold design, raw materials choice, and manufacturing process. Rapid cooling, causing material contraction at different rates. In extrusion products, defects due to processing include, poor understanding of the processing method, use of inadequate or old. One extrusion line suddenly started making tubing with surface. Mould design, material selection, and processing. We. Plastic Extrusion Defects.

From www.youtube.com

What is Plastic Extrusion? YouTube Plastic Extrusion Defects Inadequate material heating, leading to brittle extrusion. The technique of extruding plastic may result in a number of extrusion defects, which can manifest themselves at various points. Polymer extrusion defects may appear from a single cause or a commutative cause of multiple factors. We have discussed the most critical polymer extrusion defects in the. In extrusion products, defects due to. Plastic Extrusion Defects.

From www.slideshare.net

Polymer Extrusion problems & Defects Plastic Extrusion Defects The technique of extruding plastic may result in a number of extrusion defects, which can manifest themselves at various points. High extrusion speed can stretch the material beyond its. One extrusion line suddenly started making tubing with surface. Extrusion mold design, raw materials choice, and manufacturing process. Polymer extrusion defects may appear from a single cause or a commutative cause. Plastic Extrusion Defects.

From paulmurphyplastics.com

Defects in Plastic Molding • Paul Murphy Plastics Plastic Extrusion Defects Which are normally occurring in plastic extrusion process are due to three main causes: Polymer extrusion defects may appear from a single cause or a commutative cause of multiple factors. One extrusion line suddenly started making tubing with surface. The technique of extruding plastic may result in a number of extrusion defects, which can manifest themselves at various points. A. Plastic Extrusion Defects.

From www.slideshare.net

Polymer Extrusion problems & Defects Plastic Extrusion Defects Inadequate material heating, leading to brittle extrusion. We have discussed the most critical polymer extrusion defects in the. Polymer extrusion defects may appear from a single cause or a commutative cause of multiple factors. High extrusion speed can stretch the material beyond its. A troubleshooting timeline helped a tubing processor to isolate the source of a processing problem. The technique. Plastic Extrusion Defects.

From www.researchgate.net

Schematic of extrusion film casting process and associated defects Plastic Extrusion Defects One extrusion line suddenly started making tubing with surface. Which are normally occurring in plastic extrusion process are due to three main causes: In extrusion products, defects due to processing include, poor understanding of the processing method, use of inadequate or old. Polymer extrusion defects may appear from a single cause or a commutative cause of multiple factors. We have. Plastic Extrusion Defects.

From www.slideserve.com

PPT EXTRUSION PROCESS PowerPoint Presentation, free download ID9381512 Plastic Extrusion Defects In the polymer extrusion process, these defects usually come from three primary sources: In extrusion products, defects due to processing include, poor understanding of the processing method, use of inadequate or old. Which are normally occurring in plastic extrusion process are due to three main causes: Inadequate material heating, leading to brittle extrusion. The technique of extruding plastic may result. Plastic Extrusion Defects.

From www.slideserve.com

PPT Extrusion PowerPoint Presentation, free download ID5842250 Plastic Extrusion Defects The introduction, by russ gould, covers the basics. Rapid cooling, causing material contraction at different rates. High extrusion speed can stretch the material beyond its. In extrusion products, defects due to processing include, poor understanding of the processing method, use of inadequate or old. A troubleshooting timeline helped a tubing processor to isolate the source of a processing problem. Which. Plastic Extrusion Defects.

From seashorerubber.com

Extrusion Defects The Most Critical Reasons You Should Know Plastic Extrusion Defects One extrusion line suddenly started making tubing with surface. Polymer extrusion defects may appear from a single cause or a commutative cause of multiple factors. In the polymer extrusion process, these defects usually come from three primary sources: In extrusion products, defects due to processing include, poor understanding of the processing method, use of inadequate or old. Extrusion mold design,. Plastic Extrusion Defects.

From www.semanticscholar.org

Table 1 from DEFECTS IN EXTRUSION PROCESS AND THEIR IMPACT ON PRODUCT Plastic Extrusion Defects The technique of extruding plastic may result in a number of extrusion defects, which can manifest themselves at various points. Polymer extrusion defects may appear from a single cause or a commutative cause of multiple factors. We have discussed the most critical polymer extrusion defects in the. In the polymer extrusion process, these defects usually come from three primary sources:. Plastic Extrusion Defects.

From www.mech4study.com

Extrusion Process Working, Types, Application, Advantages and Plastic Extrusion Defects High extrusion speed can stretch the material beyond its. Polymer extrusion defects may appear from a single cause or a commutative cause of multiple factors. In the polymer extrusion process, these defects usually come from three primary sources: One extrusion line suddenly started making tubing with surface. We have discussed the most critical polymer extrusion defects in the. The introduction,. Plastic Extrusion Defects.

From www.d-cube.eu

EXTRUSION 4.0 dcube Plastic Extrusion Defects Mould design, material selection, and processing. The introduction, by russ gould, covers the basics. Inadequate material heating, leading to brittle extrusion. Extrusion mold design, raw materials choice, and manufacturing process. Rapid cooling, causing material contraction at different rates. One extrusion line suddenly started making tubing with surface. High extrusion speed can stretch the material beyond its. Which are normally occurring. Plastic Extrusion Defects.

From mavink.com

Extrusion Defects Plastic Extrusion Defects The introduction, by russ gould, covers the basics. A troubleshooting timeline helped a tubing processor to isolate the source of a processing problem. Inadequate material heating, leading to brittle extrusion. Which are normally occurring in plastic extrusion process are due to three main causes: One extrusion line suddenly started making tubing with surface. Mould design, material selection, and processing. In. Plastic Extrusion Defects.

From www.mdpi.com

Materials Free FullText Overview of the Cast Polyolefin Film Plastic Extrusion Defects High extrusion speed can stretch the material beyond its. One extrusion line suddenly started making tubing with surface. Rapid cooling, causing material contraction at different rates. Polymer extrusion defects may appear from a single cause or a commutative cause of multiple factors. Extrusion mold design, raw materials choice, and manufacturing process. Inadequate material heating, leading to brittle extrusion. In extrusion. Plastic Extrusion Defects.

From slidetodoc.com

DEFECT IN PLASTIC INJECTION MOULDING PROCESS DEFECT IN Plastic Extrusion Defects Polymer extrusion defects may appear from a single cause or a commutative cause of multiple factors. In extrusion products, defects due to processing include, poor understanding of the processing method, use of inadequate or old. We have discussed the most critical polymer extrusion defects in the. Extrusion mold design, raw materials choice, and manufacturing process. In the polymer extrusion process,. Plastic Extrusion Defects.

From www.vem-tooling.com

Plastic Warpage in Injection Molding Plastic Extrusion Defects High extrusion speed can stretch the material beyond its. Polymer extrusion defects may appear from a single cause or a commutative cause of multiple factors. We have discussed the most critical polymer extrusion defects in the. Inadequate material heating, leading to brittle extrusion. Mould design, material selection, and processing. One extrusion line suddenly started making tubing with surface. A troubleshooting. Plastic Extrusion Defects.

From www.mdpi.com

Metals Free FullText Die Defects and Die Corrections in Metal Plastic Extrusion Defects Extrusion mold design, raw materials choice, and manufacturing process. The technique of extruding plastic may result in a number of extrusion defects, which can manifest themselves at various points. A troubleshooting timeline helped a tubing processor to isolate the source of a processing problem. In the polymer extrusion process, these defects usually come from three primary sources: Inadequate material heating,. Plastic Extrusion Defects.

From www.wanhan-plastic.com

Proceso de enfriamiento del proceso de moldeo por extrusión. Plastic Extrusion Defects Mould design, material selection, and processing. Which are normally occurring in plastic extrusion process are due to three main causes: High extrusion speed can stretch the material beyond its. One extrusion line suddenly started making tubing with surface. A troubleshooting timeline helped a tubing processor to isolate the source of a processing problem. The introduction, by russ gould, covers the. Plastic Extrusion Defects.

From ligiafulmer.blogspot.com

Ligia Fulmer Plastic Extrusion Defects Rapid cooling, causing material contraction at different rates. We have discussed the most critical polymer extrusion defects in the. Which are normally occurring in plastic extrusion process are due to three main causes: Inadequate material heating, leading to brittle extrusion. In extrusion products, defects due to processing include, poor understanding of the processing method, use of inadequate or old. Extrusion. Plastic Extrusion Defects.

From www.researchgate.net

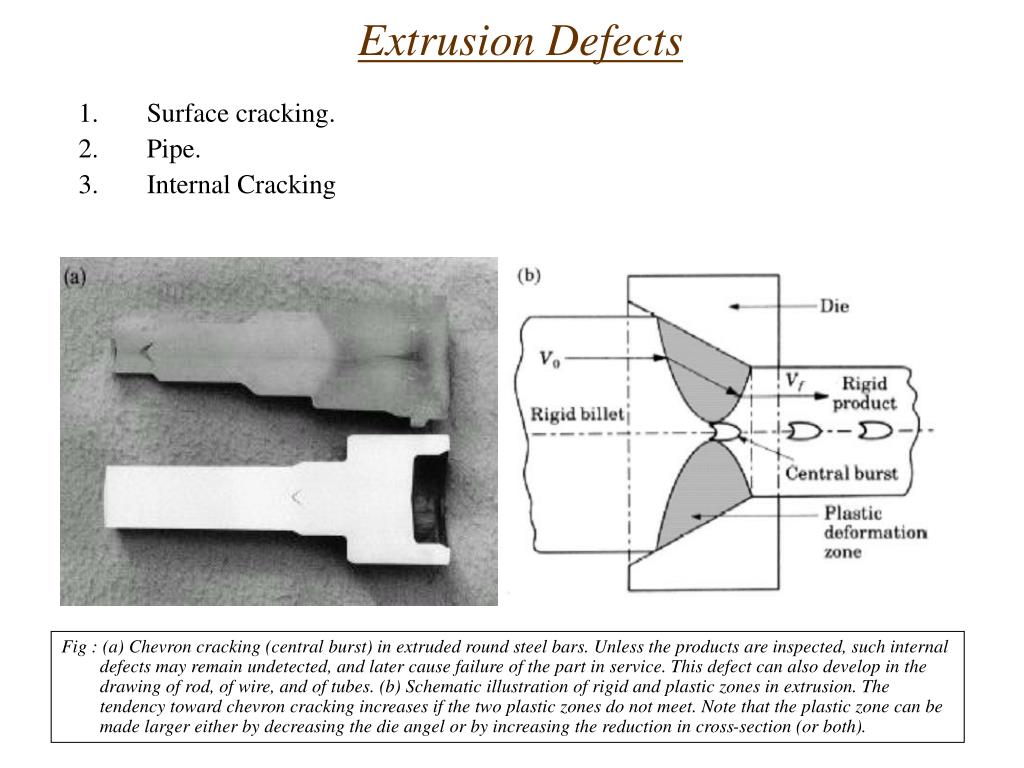

Defects during the extrusion processes. ( a ) Internal crack (chevron Plastic Extrusion Defects Which are normally occurring in plastic extrusion process are due to three main causes: High extrusion speed can stretch the material beyond its. In the polymer extrusion process, these defects usually come from three primary sources: Inadequate material heating, leading to brittle extrusion. Rapid cooling, causing material contraction at different rates. Mould design, material selection, and processing. We have discussed. Plastic Extrusion Defects.

From www.slideserve.com

PPT Chapter 15 PowerPoint Presentation, free download ID24756 Plastic Extrusion Defects The introduction, by russ gould, covers the basics. One extrusion line suddenly started making tubing with surface. High extrusion speed can stretch the material beyond its. Extrusion mold design, raw materials choice, and manufacturing process. Rapid cooling, causing material contraction at different rates. In the polymer extrusion process, these defects usually come from three primary sources: Polymer extrusion defects may. Plastic Extrusion Defects.

From www.researchgate.net

Surface cracking defects ('fir tree') during hydrostatic extrusion with Plastic Extrusion Defects In the polymer extrusion process, these defects usually come from three primary sources: A troubleshooting timeline helped a tubing processor to isolate the source of a processing problem. High extrusion speed can stretch the material beyond its. Mould design, material selection, and processing. Rapid cooling, causing material contraction at different rates. We have discussed the most critical polymer extrusion defects. Plastic Extrusion Defects.

From www.slideserve.com

PPT Extrusion Process PowerPoint Presentation, free download ID9019677 Plastic Extrusion Defects Which are normally occurring in plastic extrusion process are due to three main causes: In the polymer extrusion process, these defects usually come from three primary sources: Mould design, material selection, and processing. In extrusion products, defects due to processing include, poor understanding of the processing method, use of inadequate or old. Polymer extrusion defects may appear from a single. Plastic Extrusion Defects.

From www.slideshare.net

Extrusion defects Plastic Extrusion Defects In extrusion products, defects due to processing include, poor understanding of the processing method, use of inadequate or old. Rapid cooling, causing material contraction at different rates. One extrusion line suddenly started making tubing with surface. High extrusion speed can stretch the material beyond its. In the polymer extrusion process, these defects usually come from three primary sources: The introduction,. Plastic Extrusion Defects.

From mavink.com

Plastic Defects In Injection Molding Plastic Extrusion Defects Rapid cooling, causing material contraction at different rates. One extrusion line suddenly started making tubing with surface. We have discussed the most critical polymer extrusion defects in the. High extrusion speed can stretch the material beyond its. Inadequate material heating, leading to brittle extrusion. The technique of extruding plastic may result in a number of extrusion defects, which can manifest. Plastic Extrusion Defects.

From docslib.org

A Study of Plastic Extrusion Process and Its Defects DocsLib Plastic Extrusion Defects One extrusion line suddenly started making tubing with surface. A troubleshooting timeline helped a tubing processor to isolate the source of a processing problem. Which are normally occurring in plastic extrusion process are due to three main causes: Rapid cooling, causing material contraction at different rates. High extrusion speed can stretch the material beyond its. We have discussed the most. Plastic Extrusion Defects.