Rockwell C Hardness Test Procedure . rockwell hardness test measures the permanent depth of indentation on a metal by applying a fixed load. The test indentations must be set in such a way that there is sufficient distance to the edge of the specimen and between the. it measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. Regular rockwell testing (e.g., c and b scales) and rockwell superficial testing. It offers direct readings without the need for secondary calculations and measurements, making it a straightforward and reliable part of the qa process. 1.1 these test methods cover the determination of the rockwell hardness and the rockwell superficial hardness of. the rockwell test is particularly suitable for measuring the hardness of hardened metals and alloys. rockwell testing falls into two categories:

from ourelabs.blogspot.com

rockwell hardness test measures the permanent depth of indentation on a metal by applying a fixed load. 1.1 these test methods cover the determination of the rockwell hardness and the rockwell superficial hardness of. it measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. the rockwell test is particularly suitable for measuring the hardness of hardened metals and alloys. rockwell testing falls into two categories: Regular rockwell testing (e.g., c and b scales) and rockwell superficial testing. It offers direct readings without the need for secondary calculations and measurements, making it a straightforward and reliable part of the qa process. The test indentations must be set in such a way that there is sufficient distance to the edge of the specimen and between the.

ROCKWELL HARDNESS TEST Ourengineeringlabs

Rockwell C Hardness Test Procedure The test indentations must be set in such a way that there is sufficient distance to the edge of the specimen and between the. The test indentations must be set in such a way that there is sufficient distance to the edge of the specimen and between the. the rockwell test is particularly suitable for measuring the hardness of hardened metals and alloys. it measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. rockwell hardness test measures the permanent depth of indentation on a metal by applying a fixed load. Regular rockwell testing (e.g., c and b scales) and rockwell superficial testing. 1.1 these test methods cover the determination of the rockwell hardness and the rockwell superficial hardness of. It offers direct readings without the need for secondary calculations and measurements, making it a straightforward and reliable part of the qa process. rockwell testing falls into two categories:

From westportcorp.com

Rockwell Hardness Testers In Stock and Ready to Ship WESTport Corp. Rockwell C Hardness Test Procedure rockwell hardness test measures the permanent depth of indentation on a metal by applying a fixed load. rockwell testing falls into two categories: the rockwell test is particularly suitable for measuring the hardness of hardened metals and alloys. The test indentations must be set in such a way that there is sufficient distance to the edge of. Rockwell C Hardness Test Procedure.

From www.titltest.com

Rockwell Hardness Tester Application Industry Rockwell C Hardness Test Procedure rockwell testing falls into two categories: rockwell hardness test measures the permanent depth of indentation on a metal by applying a fixed load. the rockwell test is particularly suitable for measuring the hardness of hardened metals and alloys. it measures the depth of penetration of an indenter on the material being tested, making it possible to. Rockwell C Hardness Test Procedure.

From www.youtube.com

ROCKWELL HARDNESS TEST HOW TO PERFORM ROCKWELL HARDNESS TEST Rockwell C Hardness Test Procedure the rockwell test is particularly suitable for measuring the hardness of hardened metals and alloys. Regular rockwell testing (e.g., c and b scales) and rockwell superficial testing. The test indentations must be set in such a way that there is sufficient distance to the edge of the specimen and between the. It offers direct readings without the need for. Rockwell C Hardness Test Procedure.

From www.tec-science.com

Rockwell hardness test tecscience Rockwell C Hardness Test Procedure it measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. rockwell hardness test measures the permanent depth of indentation on a metal by applying a fixed load. It offers direct readings without the need for secondary calculations and measurements, making it a straightforward and. Rockwell C Hardness Test Procedure.

From www.youtube.com

Types of hardness tester ? Rockwell hardness tester YouTube Rockwell C Hardness Test Procedure The test indentations must be set in such a way that there is sufficient distance to the edge of the specimen and between the. rockwell testing falls into two categories: it measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. Regular rockwell testing (e.g.,. Rockwell C Hardness Test Procedure.

From www.worldoftest.com

Rockwell Hardness Tester 101 Everything You Need to Know Qualitest Rockwell C Hardness Test Procedure rockwell hardness test measures the permanent depth of indentation on a metal by applying a fixed load. it measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. Regular rockwell testing (e.g., c and b scales) and rockwell superficial testing. the rockwell test is. Rockwell C Hardness Test Procedure.

From www.hardnessgauge.com

Rockwell Hardness Testing Hardness Tester Rockwell C Hardness Test Procedure 1.1 these test methods cover the determination of the rockwell hardness and the rockwell superficial hardness of. it measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. The test indentations must be set in such a way that there is sufficient distance to the edge. Rockwell C Hardness Test Procedure.

From www.yorksaw.com

Rockwell Hardness Guide What it is, How to Measure, & More Rockwell C Hardness Test Procedure rockwell hardness test measures the permanent depth of indentation on a metal by applying a fixed load. 1.1 these test methods cover the determination of the rockwell hardness and the rockwell superficial hardness of. rockwell testing falls into two categories: it measures the depth of penetration of an indenter on the material being tested, making it possible. Rockwell C Hardness Test Procedure.

From www.youtube.com

ROCKWELL HARDNESS TEST 3D ANIMATION ROCKWELL HARDNESS TEST Rockwell C Hardness Test Procedure it measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. the rockwell test is particularly suitable for measuring the hardness of hardened metals and alloys. It offers direct readings without the need for secondary calculations and measurements, making it a straightforward and reliable part. Rockwell C Hardness Test Procedure.

From www.educationalstuffs.in

STRENGTH OF MATERIALS Rockwell Hardness Test Rockwell C Hardness Test Procedure it measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. rockwell testing falls into two categories: Regular rockwell testing (e.g., c and b scales) and rockwell superficial testing. It offers direct readings without the need for secondary calculations and measurements, making it a straightforward. Rockwell C Hardness Test Procedure.

From www.tec-science.com

Rockwell hardness test tecscience Rockwell C Hardness Test Procedure rockwell hardness test measures the permanent depth of indentation on a metal by applying a fixed load. it measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. The test indentations must be set in such a way that there is sufficient distance to the. Rockwell C Hardness Test Procedure.

From www.slideshare.net

Rockwell hardnes testing Rockwell C Hardness Test Procedure 1.1 these test methods cover the determination of the rockwell hardness and the rockwell superficial hardness of. The test indentations must be set in such a way that there is sufficient distance to the edge of the specimen and between the. It offers direct readings without the need for secondary calculations and measurements, making it a straightforward and reliable part. Rockwell C Hardness Test Procedure.

From www.sinowon.com

durable rockwell hardness test procedure customized for small areas Rockwell C Hardness Test Procedure The test indentations must be set in such a way that there is sufficient distance to the edge of the specimen and between the. It offers direct readings without the need for secondary calculations and measurements, making it a straightforward and reliable part of the qa process. 1.1 these test methods cover the determination of the rockwell hardness and the. Rockwell C Hardness Test Procedure.

From www.scribd.com

Rockwell Hardness Test Rockwell C Hardness Test Procedure It offers direct readings without the need for secondary calculations and measurements, making it a straightforward and reliable part of the qa process. it measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. The test indentations must be set in such a way that there. Rockwell C Hardness Test Procedure.

From www.youtube.com

Rockwell hardness testing Experiment procedure YouTube Rockwell C Hardness Test Procedure rockwell testing falls into two categories: Regular rockwell testing (e.g., c and b scales) and rockwell superficial testing. 1.1 these test methods cover the determination of the rockwell hardness and the rockwell superficial hardness of. the rockwell test is particularly suitable for measuring the hardness of hardened metals and alloys. it measures the depth of penetration of. Rockwell C Hardness Test Procedure.

From www.slideshare.net

Rockwell hardnes testing Rockwell C Hardness Test Procedure the rockwell test is particularly suitable for measuring the hardness of hardened metals and alloys. It offers direct readings without the need for secondary calculations and measurements, making it a straightforward and reliable part of the qa process. 1.1 these test methods cover the determination of the rockwell hardness and the rockwell superficial hardness of. rockwell testing falls. Rockwell C Hardness Test Procedure.

From www.youtube.com

Rockwell Hardness test to find the BHN(Rockwell hardness number) of Rockwell C Hardness Test Procedure rockwell testing falls into two categories: the rockwell test is particularly suitable for measuring the hardness of hardened metals and alloys. The test indentations must be set in such a way that there is sufficient distance to the edge of the specimen and between the. 1.1 these test methods cover the determination of the rockwell hardness and the. Rockwell C Hardness Test Procedure.

From www.scribd.com

Rockwell Hardness Test Hardness Chemical Product Engineering Rockwell C Hardness Test Procedure It offers direct readings without the need for secondary calculations and measurements, making it a straightforward and reliable part of the qa process. rockwell testing falls into two categories: Regular rockwell testing (e.g., c and b scales) and rockwell superficial testing. the rockwell test is particularly suitable for measuring the hardness of hardened metals and alloys. it. Rockwell C Hardness Test Procedure.

From toolboxmagazine.com

Rockwell Hardness Testpage Toolbox MagazineHow Hard Should The Rockwell C Hardness Test Procedure rockwell hardness test measures the permanent depth of indentation on a metal by applying a fixed load. Regular rockwell testing (e.g., c and b scales) and rockwell superficial testing. it measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. the rockwell test is. Rockwell C Hardness Test Procedure.

From www.buehler.com

Rockwell Hardness Testing Buehler United Kingdom Metallography Rockwell C Hardness Test Procedure rockwell testing falls into two categories: 1.1 these test methods cover the determination of the rockwell hardness and the rockwell superficial hardness of. Regular rockwell testing (e.g., c and b scales) and rockwell superficial testing. The test indentations must be set in such a way that there is sufficient distance to the edge of the specimen and between the.. Rockwell C Hardness Test Procedure.

From www.youtube.com

Rockwell Hardness Tester (Rockwell hardness test procedure) YouTube Rockwell C Hardness Test Procedure the rockwell test is particularly suitable for measuring the hardness of hardened metals and alloys. Regular rockwell testing (e.g., c and b scales) and rockwell superficial testing. it measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. It offers direct readings without the need. Rockwell C Hardness Test Procedure.

From amesportablehardnesstesters.com

The Rockwell Metal Hardness Scales Explained Rockwell C Hardness Test Procedure it measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. Regular rockwell testing (e.g., c and b scales) and rockwell superficial testing. The test indentations must be set in such a way that there is sufficient distance to the edge of the specimen and between. Rockwell C Hardness Test Procedure.

From www.tec-science.com

Rockwell hardness test tecscience Rockwell C Hardness Test Procedure it measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. Regular rockwell testing (e.g., c and b scales) and rockwell superficial testing. It offers direct readings without the need for secondary calculations and measurements, making it a straightforward and reliable part of the qa process.. Rockwell C Hardness Test Procedure.

From www.researchgate.net

Rockwell C scale hardness test illustrated with change of force with Rockwell C Hardness Test Procedure it measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. rockwell testing falls into two categories: It offers direct readings without the need for secondary calculations and measurements, making it a straightforward and reliable part of the qa process. rockwell hardness test measures. Rockwell C Hardness Test Procedure.

From theconstructor.org

How To Perform Rockwell Hardness Test? The Constructor Rockwell C Hardness Test Procedure It offers direct readings without the need for secondary calculations and measurements, making it a straightforward and reliable part of the qa process. 1.1 these test methods cover the determination of the rockwell hardness and the rockwell superficial hardness of. The test indentations must be set in such a way that there is sufficient distance to the edge of the. Rockwell C Hardness Test Procedure.

From www.practicalmachinist.com

A Primer on Rockwell Hardness Testing Practical Machinist Practical Rockwell C Hardness Test Procedure Regular rockwell testing (e.g., c and b scales) and rockwell superficial testing. it measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. the rockwell test is particularly suitable for measuring the hardness of hardened metals and alloys. It offers direct readings without the need. Rockwell C Hardness Test Procedure.

From www.youtube.com

How it works... Rockwell hardness tester from Wilson YouTube Rockwell C Hardness Test Procedure The test indentations must be set in such a way that there is sufficient distance to the edge of the specimen and between the. it measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. 1.1 these test methods cover the determination of the rockwell hardness. Rockwell C Hardness Test Procedure.

From www.sinowon.com

quality rockwell hardness test procedure manufacturer for small areas Rockwell C Hardness Test Procedure It offers direct readings without the need for secondary calculations and measurements, making it a straightforward and reliable part of the qa process. rockwell testing falls into two categories: the rockwell test is particularly suitable for measuring the hardness of hardened metals and alloys. rockwell hardness test measures the permanent depth of indentation on a metal by. Rockwell C Hardness Test Procedure.

From www.sinowon.com

reliable rockwell hardness test procedure series for small areas Sinowon Rockwell C Hardness Test Procedure Regular rockwell testing (e.g., c and b scales) and rockwell superficial testing. the rockwell test is particularly suitable for measuring the hardness of hardened metals and alloys. rockwell hardness test measures the permanent depth of indentation on a metal by applying a fixed load. it measures the depth of penetration of an indenter on the material being. Rockwell C Hardness Test Procedure.

From hitestlab.com

Rockwell Hardness Test PT Hitestlab Rockwell C Hardness Test Procedure Regular rockwell testing (e.g., c and b scales) and rockwell superficial testing. The test indentations must be set in such a way that there is sufficient distance to the edge of the specimen and between the. 1.1 these test methods cover the determination of the rockwell hardness and the rockwell superficial hardness of. it measures the depth of penetration. Rockwell C Hardness Test Procedure.

From dxofglevr.blob.core.windows.net

Rockwell Hardness Tester Work Instruction at Danielle Rogers blog Rockwell C Hardness Test Procedure It offers direct readings without the need for secondary calculations and measurements, making it a straightforward and reliable part of the qa process. Regular rockwell testing (e.g., c and b scales) and rockwell superficial testing. the rockwell test is particularly suitable for measuring the hardness of hardened metals and alloys. The test indentations must be set in such a. Rockwell C Hardness Test Procedure.

From ourelabs.blogspot.com

ROCKWELL HARDNESS TEST Ourengineeringlabs Rockwell C Hardness Test Procedure rockwell hardness test measures the permanent depth of indentation on a metal by applying a fixed load. it measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. rockwell testing falls into two categories: 1.1 these test methods cover the determination of the rockwell. Rockwell C Hardness Test Procedure.

From mavink.com

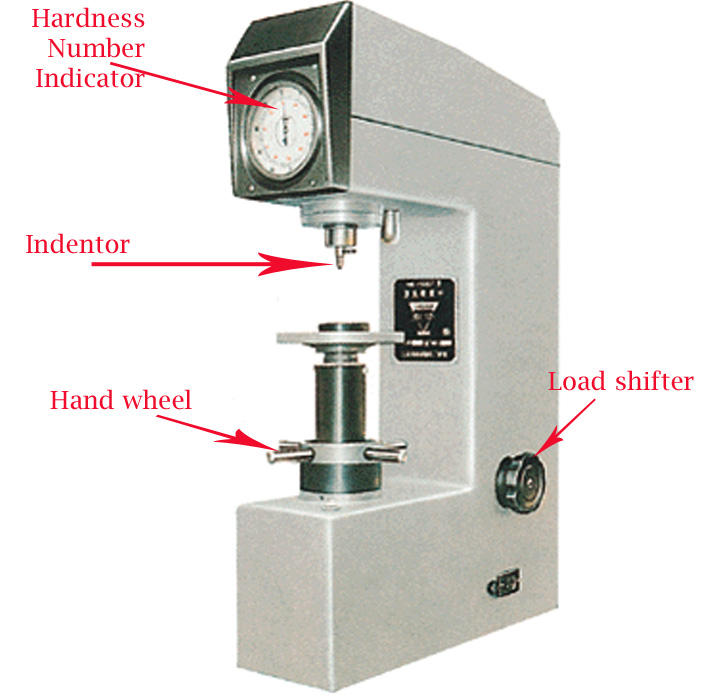

Rockwell Hardness Tester Diagram Rockwell C Hardness Test Procedure rockwell testing falls into two categories: rockwell hardness test measures the permanent depth of indentation on a metal by applying a fixed load. It offers direct readings without the need for secondary calculations and measurements, making it a straightforward and reliable part of the qa process. the rockwell test is particularly suitable for measuring the hardness of. Rockwell C Hardness Test Procedure.

From gbu-presnenskij.ru

Hardness Testing Methods Rockwell, Brinell And, 59 OFF Rockwell C Hardness Test Procedure rockwell hardness test measures the permanent depth of indentation on a metal by applying a fixed load. the rockwell test is particularly suitable for measuring the hardness of hardened metals and alloys. Regular rockwell testing (e.g., c and b scales) and rockwell superficial testing. It offers direct readings without the need for secondary calculations and measurements, making it. Rockwell C Hardness Test Procedure.

From www.sinowon.com

rockwell hardness test unit Rockwell Hardness Tester Sinowon Rockwell C Hardness Test Procedure the rockwell test is particularly suitable for measuring the hardness of hardened metals and alloys. rockwell hardness test measures the permanent depth of indentation on a metal by applying a fixed load. It offers direct readings without the need for secondary calculations and measurements, making it a straightforward and reliable part of the qa process. rockwell testing. Rockwell C Hardness Test Procedure.