What Is Ceramic Moulding Process . Discover how it's revolutionizing the production. Ceramic injection molding (cim) is a ceramic manufacturing process using injection molding technology to produce complex and intricate ceramic parts, especially for. Explore the intricate world of ceramic injection molding (cim), its process, advantages, applications, and its impact on manufacturing. 4 application of ceramic mold casting parts made from this process include impellers, complex cutting tools, plastic mold. In another branch of pim, ceramic or carbide materials are used as raw materials in a process called ceramic injection moulding (cim). • ceramic mould casting method uses a ceramic slurry prepared by mixing fine grained refractory powders of zircon ( zr sio4 ), alumina ( al2 o3 ), fused silica.

from www.youtube.com

• ceramic mould casting method uses a ceramic slurry prepared by mixing fine grained refractory powders of zircon ( zr sio4 ), alumina ( al2 o3 ), fused silica. In another branch of pim, ceramic or carbide materials are used as raw materials in a process called ceramic injection moulding (cim). Discover how it's revolutionizing the production. Ceramic injection molding (cim) is a ceramic manufacturing process using injection molding technology to produce complex and intricate ceramic parts, especially for. Explore the intricate world of ceramic injection molding (cim), its process, advantages, applications, and its impact on manufacturing. 4 application of ceramic mold casting parts made from this process include impellers, complex cutting tools, plastic mold.

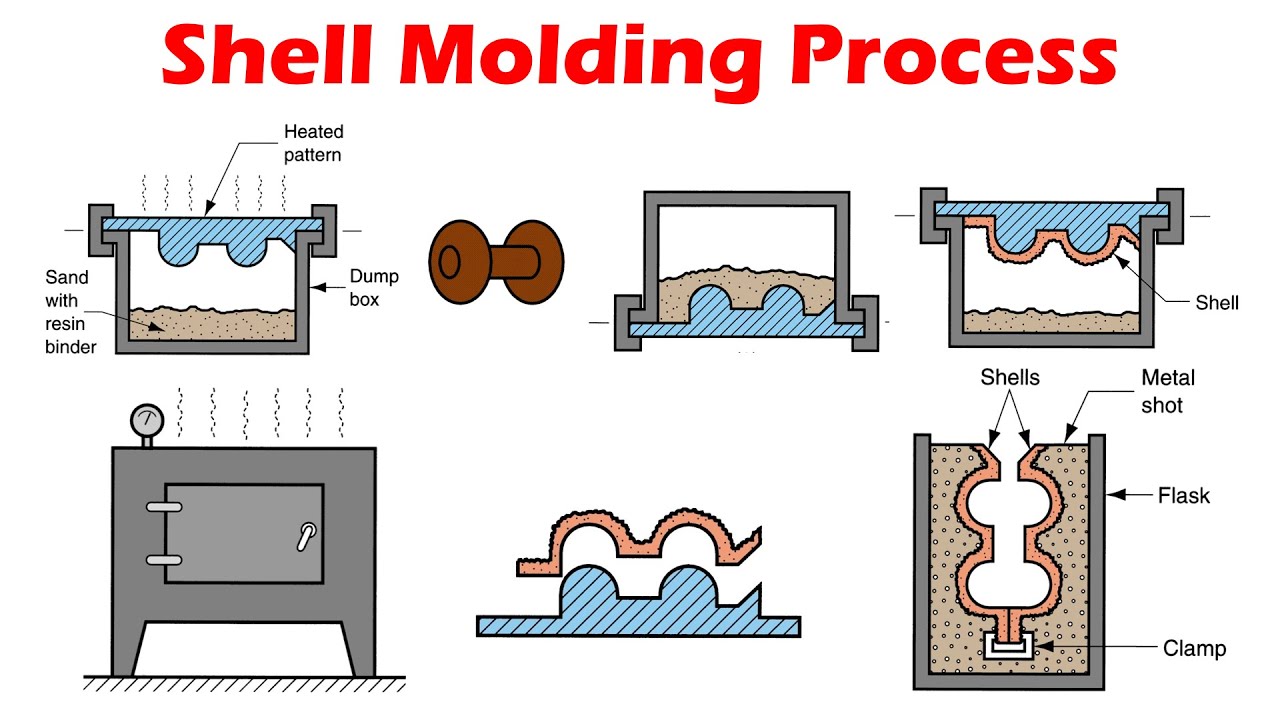

Shell Molding Expandable Mold Casting Processes YouTube

What Is Ceramic Moulding Process Ceramic injection molding (cim) is a ceramic manufacturing process using injection molding technology to produce complex and intricate ceramic parts, especially for. Explore the intricate world of ceramic injection molding (cim), its process, advantages, applications, and its impact on manufacturing. In another branch of pim, ceramic or carbide materials are used as raw materials in a process called ceramic injection moulding (cim). Discover how it's revolutionizing the production. Ceramic injection molding (cim) is a ceramic manufacturing process using injection molding technology to produce complex and intricate ceramic parts, especially for. 4 application of ceramic mold casting parts made from this process include impellers, complex cutting tools, plastic mold. • ceramic mould casting method uses a ceramic slurry prepared by mixing fine grained refractory powders of zircon ( zr sio4 ), alumina ( al2 o3 ), fused silica.

From www.youtube.com

Plaster Moulding Process Plaster Mould Casting Process ENGINEERING What Is Ceramic Moulding Process • ceramic mould casting method uses a ceramic slurry prepared by mixing fine grained refractory powders of zircon ( zr sio4 ), alumina ( al2 o3 ), fused silica. In another branch of pim, ceramic or carbide materials are used as raw materials in a process called ceramic injection moulding (cim). Explore the intricate world of ceramic injection molding (cim),. What Is Ceramic Moulding Process.

From www.youtube.com

Ceramic Injection Moulding Process Advanced Materials YouTube What Is Ceramic Moulding Process 4 application of ceramic mold casting parts made from this process include impellers, complex cutting tools, plastic mold. Discover how it's revolutionizing the production. Ceramic injection molding (cim) is a ceramic manufacturing process using injection molding technology to produce complex and intricate ceramic parts, especially for. In another branch of pim, ceramic or carbide materials are used as raw materials. What Is Ceramic Moulding Process.

From www.mecholic.com

What Is Meant By Shell Moulding? Process Of Shell Moulding What Is Ceramic Moulding Process In another branch of pim, ceramic or carbide materials are used as raw materials in a process called ceramic injection moulding (cim). Explore the intricate world of ceramic injection molding (cim), its process, advantages, applications, and its impact on manufacturing. Ceramic injection molding (cim) is a ceramic manufacturing process using injection molding technology to produce complex and intricate ceramic parts,. What Is Ceramic Moulding Process.

From www.researchgate.net

Major steps of the ceramic injectionmolding process combined with the What Is Ceramic Moulding Process 4 application of ceramic mold casting parts made from this process include impellers, complex cutting tools, plastic mold. Explore the intricate world of ceramic injection molding (cim), its process, advantages, applications, and its impact on manufacturing. • ceramic mould casting method uses a ceramic slurry prepared by mixing fine grained refractory powders of zircon ( zr sio4 ), alumina (. What Is Ceramic Moulding Process.

From www.open.edu

Ceramic mould casting OpenLearn Open University What Is Ceramic Moulding Process 4 application of ceramic mold casting parts made from this process include impellers, complex cutting tools, plastic mold. Explore the intricate world of ceramic injection molding (cim), its process, advantages, applications, and its impact on manufacturing. • ceramic mould casting method uses a ceramic slurry prepared by mixing fine grained refractory powders of zircon ( zr sio4 ), alumina (. What Is Ceramic Moulding Process.

From www.iqsdirectory.com

Compression Molding Process, Types of Molds, Features and Benefits What Is Ceramic Moulding Process Explore the intricate world of ceramic injection molding (cim), its process, advantages, applications, and its impact on manufacturing. Discover how it's revolutionizing the production. Ceramic injection molding (cim) is a ceramic manufacturing process using injection molding technology to produce complex and intricate ceramic parts, especially for. 4 application of ceramic mold casting parts made from this process include impellers, complex. What Is Ceramic Moulding Process.

From www.innovacera.com

What is ceramic injection molding (CIM)? INNOVACERA What Is Ceramic Moulding Process 4 application of ceramic mold casting parts made from this process include impellers, complex cutting tools, plastic mold. Explore the intricate world of ceramic injection molding (cim), its process, advantages, applications, and its impact on manufacturing. Discover how it's revolutionizing the production. Ceramic injection molding (cim) is a ceramic manufacturing process using injection molding technology to produce complex and intricate. What Is Ceramic Moulding Process.

From www.nano-di.com

Ceramic Injection Molding Nano Dimension What Is Ceramic Moulding Process 4 application of ceramic mold casting parts made from this process include impellers, complex cutting tools, plastic mold. • ceramic mould casting method uses a ceramic slurry prepared by mixing fine grained refractory powders of zircon ( zr sio4 ), alumina ( al2 o3 ), fused silica. In another branch of pim, ceramic or carbide materials are used as raw. What Is Ceramic Moulding Process.

From www.slideserve.com

PPT Processing of ceramics PowerPoint Presentation, free download What Is Ceramic Moulding Process Discover how it's revolutionizing the production. In another branch of pim, ceramic or carbide materials are used as raw materials in a process called ceramic injection moulding (cim). Explore the intricate world of ceramic injection molding (cim), its process, advantages, applications, and its impact on manufacturing. 4 application of ceramic mold casting parts made from this process include impellers, complex. What Is Ceramic Moulding Process.

From www.researchgate.net

Fabrication process of SiO 2 based ceramic molds. Download What Is Ceramic Moulding Process Ceramic injection molding (cim) is a ceramic manufacturing process using injection molding technology to produce complex and intricate ceramic parts, especially for. Explore the intricate world of ceramic injection molding (cim), its process, advantages, applications, and its impact on manufacturing. • ceramic mould casting method uses a ceramic slurry prepared by mixing fine grained refractory powders of zircon ( zr. What Is Ceramic Moulding Process.

From www.wundermold.com

Costs of Ceramic Injection Molding 🥇 Ceramic Injection Molding Companies What Is Ceramic Moulding Process Explore the intricate world of ceramic injection molding (cim), its process, advantages, applications, and its impact on manufacturing. In another branch of pim, ceramic or carbide materials are used as raw materials in a process called ceramic injection moulding (cim). • ceramic mould casting method uses a ceramic slurry prepared by mixing fine grained refractory powders of zircon ( zr. What Is Ceramic Moulding Process.

From www.xometry.com

Ceramic Mold Casting Definition, Importance, How It Works What Is Ceramic Moulding Process In another branch of pim, ceramic or carbide materials are used as raw materials in a process called ceramic injection moulding (cim). 4 application of ceramic mold casting parts made from this process include impellers, complex cutting tools, plastic mold. Explore the intricate world of ceramic injection molding (cim), its process, advantages, applications, and its impact on manufacturing. • ceramic. What Is Ceramic Moulding Process.

From www.researchgate.net

Process chain of ceramic injection molding to build a device What Is Ceramic Moulding Process Explore the intricate world of ceramic injection molding (cim), its process, advantages, applications, and its impact on manufacturing. • ceramic mould casting method uses a ceramic slurry prepared by mixing fine grained refractory powders of zircon ( zr sio4 ), alumina ( al2 o3 ), fused silica. Discover how it's revolutionizing the production. 4 application of ceramic mold casting parts. What Is Ceramic Moulding Process.

From ar.inspiredpencil.com

Ceramic Molding Techniques What Is Ceramic Moulding Process Ceramic injection molding (cim) is a ceramic manufacturing process using injection molding technology to produce complex and intricate ceramic parts, especially for. Explore the intricate world of ceramic injection molding (cim), its process, advantages, applications, and its impact on manufacturing. In another branch of pim, ceramic or carbide materials are used as raw materials in a process called ceramic injection. What Is Ceramic Moulding Process.

From machiningceramic.com

Ceramic Injection Molding Ceramic Mold Making Service What Is Ceramic Moulding Process • ceramic mould casting method uses a ceramic slurry prepared by mixing fine grained refractory powders of zircon ( zr sio4 ), alumina ( al2 o3 ), fused silica. Ceramic injection molding (cim) is a ceramic manufacturing process using injection molding technology to produce complex and intricate ceramic parts, especially for. 4 application of ceramic mold casting parts made from. What Is Ceramic Moulding Process.

From www.arptech.com.au

Injection Moulding Process Explained ArpTechBlog What Is Ceramic Moulding Process Explore the intricate world of ceramic injection molding (cim), its process, advantages, applications, and its impact on manufacturing. In another branch of pim, ceramic or carbide materials are used as raw materials in a process called ceramic injection moulding (cim). Ceramic injection molding (cim) is a ceramic manufacturing process using injection molding technology to produce complex and intricate ceramic parts,. What Is Ceramic Moulding Process.

From jackygao.com

Simple Guidance For You In Ceramic Items Process Part 2 Produce Clay What Is Ceramic Moulding Process Ceramic injection molding (cim) is a ceramic manufacturing process using injection molding technology to produce complex and intricate ceramic parts, especially for. In another branch of pim, ceramic or carbide materials are used as raw materials in a process called ceramic injection moulding (cim). 4 application of ceramic mold casting parts made from this process include impellers, complex cutting tools,. What Is Ceramic Moulding Process.

From www.mitalon.com

Advanced Technology Structural Industrial Ceramic Parts Mitalon What Is Ceramic Moulding Process Discover how it's revolutionizing the production. Explore the intricate world of ceramic injection molding (cim), its process, advantages, applications, and its impact on manufacturing. In another branch of pim, ceramic or carbide materials are used as raw materials in a process called ceramic injection moulding (cim). Ceramic injection molding (cim) is a ceramic manufacturing process using injection molding technology to. What Is Ceramic Moulding Process.

From www.indo-mim.com

Ceramic Injection Molding CIM parts manufacturer Ceramic Cores What Is Ceramic Moulding Process • ceramic mould casting method uses a ceramic slurry prepared by mixing fine grained refractory powders of zircon ( zr sio4 ), alumina ( al2 o3 ), fused silica. In another branch of pim, ceramic or carbide materials are used as raw materials in a process called ceramic injection moulding (cim). Discover how it's revolutionizing the production. 4 application of. What Is Ceramic Moulding Process.

From www.slideserve.com

PPT Metal Casting Processes PowerPoint Presentation, free download What Is Ceramic Moulding Process Explore the intricate world of ceramic injection molding (cim), its process, advantages, applications, and its impact on manufacturing. Ceramic injection molding (cim) is a ceramic manufacturing process using injection molding technology to produce complex and intricate ceramic parts, especially for. Discover how it's revolutionizing the production. • ceramic mould casting method uses a ceramic slurry prepared by mixing fine grained. What Is Ceramic Moulding Process.

From www.youtube.com

Injection Moulding Process Explained Polymer Matrix Composites What Is Ceramic Moulding Process 4 application of ceramic mold casting parts made from this process include impellers, complex cutting tools, plastic mold. In another branch of pim, ceramic or carbide materials are used as raw materials in a process called ceramic injection moulding (cim). Explore the intricate world of ceramic injection molding (cim), its process, advantages, applications, and its impact on manufacturing. Ceramic injection. What Is Ceramic Moulding Process.

From www.researchgate.net

Illustration of a ceramic mould assembly for casting a socketed bronze What Is Ceramic Moulding Process Explore the intricate world of ceramic injection molding (cim), its process, advantages, applications, and its impact on manufacturing. Discover how it's revolutionizing the production. In another branch of pim, ceramic or carbide materials are used as raw materials in a process called ceramic injection moulding (cim). Ceramic injection molding (cim) is a ceramic manufacturing process using injection molding technology to. What Is Ceramic Moulding Process.

From ceramicsmokeware.com

How slip casting and plaster molds work Ceramic Smokeware What Is Ceramic Moulding Process Discover how it's revolutionizing the production. • ceramic mould casting method uses a ceramic slurry prepared by mixing fine grained refractory powders of zircon ( zr sio4 ), alumina ( al2 o3 ), fused silica. 4 application of ceramic mold casting parts made from this process include impellers, complex cutting tools, plastic mold. Explore the intricate world of ceramic injection. What Is Ceramic Moulding Process.

From mungfali.com

Rotational Molding Process What Is Ceramic Moulding Process Explore the intricate world of ceramic injection molding (cim), its process, advantages, applications, and its impact on manufacturing. • ceramic mould casting method uses a ceramic slurry prepared by mixing fine grained refractory powders of zircon ( zr sio4 ), alumina ( al2 o3 ), fused silica. Discover how it's revolutionizing the production. Ceramic injection molding (cim) is a ceramic. What Is Ceramic Moulding Process.

From engineeringlearn.com

16 Types of Moulding [Explained with Complete Details] Engineering Learn What Is Ceramic Moulding Process 4 application of ceramic mold casting parts made from this process include impellers, complex cutting tools, plastic mold. Discover how it's revolutionizing the production. • ceramic mould casting method uses a ceramic slurry prepared by mixing fine grained refractory powders of zircon ( zr sio4 ), alumina ( al2 o3 ), fused silica. Explore the intricate world of ceramic injection. What Is Ceramic Moulding Process.

From www.youtube.com

Transfer Moulding Moulding with Polymers and Ceramics Production What Is Ceramic Moulding Process In another branch of pim, ceramic or carbide materials are used as raw materials in a process called ceramic injection moulding (cim). Discover how it's revolutionizing the production. • ceramic mould casting method uses a ceramic slurry prepared by mixing fine grained refractory powders of zircon ( zr sio4 ), alumina ( al2 o3 ), fused silica. Ceramic injection molding. What Is Ceramic Moulding Process.

From www.3erp.com

What is Injection Molding and How Does it Work Definition & Working What Is Ceramic Moulding Process Ceramic injection molding (cim) is a ceramic manufacturing process using injection molding technology to produce complex and intricate ceramic parts, especially for. 4 application of ceramic mold casting parts made from this process include impellers, complex cutting tools, plastic mold. Discover how it's revolutionizing the production. Explore the intricate world of ceramic injection molding (cim), its process, advantages, applications, and. What Is Ceramic Moulding Process.

From www.open.edu

Slipcasting OpenLearn Open University What Is Ceramic Moulding Process Explore the intricate world of ceramic injection molding (cim), its process, advantages, applications, and its impact on manufacturing. In another branch of pim, ceramic or carbide materials are used as raw materials in a process called ceramic injection moulding (cim). • ceramic mould casting method uses a ceramic slurry prepared by mixing fine grained refractory powders of zircon ( zr. What Is Ceramic Moulding Process.

From www.youtube.com

Shell Molding Expandable Mold Casting Processes YouTube What Is Ceramic Moulding Process Ceramic injection molding (cim) is a ceramic manufacturing process using injection molding technology to produce complex and intricate ceramic parts, especially for. Discover how it's revolutionizing the production. 4 application of ceramic mold casting parts made from this process include impellers, complex cutting tools, plastic mold. In another branch of pim, ceramic or carbide materials are used as raw materials. What Is Ceramic Moulding Process.

From themechanicalengineering.com

Injection Molding Definition, Construction, Working Process What Is Ceramic Moulding Process 4 application of ceramic mold casting parts made from this process include impellers, complex cutting tools, plastic mold. Discover how it's revolutionizing the production. In another branch of pim, ceramic or carbide materials are used as raw materials in a process called ceramic injection moulding (cim). • ceramic mould casting method uses a ceramic slurry prepared by mixing fine grained. What Is Ceramic Moulding Process.

From www.coorstek.com

Ceramic Injection Molding CoorsTek Technical Ceramics What Is Ceramic Moulding Process In another branch of pim, ceramic or carbide materials are used as raw materials in a process called ceramic injection moulding (cim). Discover how it's revolutionizing the production. 4 application of ceramic mold casting parts made from this process include impellers, complex cutting tools, plastic mold. Explore the intricate world of ceramic injection molding (cim), its process, advantages, applications, and. What Is Ceramic Moulding Process.

From startup-buzz.com

The Beginner’s Guide to Permanent Mold Casting Startup Buzz What Is Ceramic Moulding Process 4 application of ceramic mold casting parts made from this process include impellers, complex cutting tools, plastic mold. Discover how it's revolutionizing the production. Ceramic injection molding (cim) is a ceramic manufacturing process using injection molding technology to produce complex and intricate ceramic parts, especially for. Explore the intricate world of ceramic injection molding (cim), its process, advantages, applications, and. What Is Ceramic Moulding Process.

From www.researchgate.net

Slip casting steps [28] Download Scientific Diagram What Is Ceramic Moulding Process In another branch of pim, ceramic or carbide materials are used as raw materials in a process called ceramic injection moulding (cim). • ceramic mould casting method uses a ceramic slurry prepared by mixing fine grained refractory powders of zircon ( zr sio4 ), alumina ( al2 o3 ), fused silica. 4 application of ceramic mold casting parts made from. What Is Ceramic Moulding Process.

From www.youtube.com

The Basic Permanent Mold Casting Process YouTube What Is Ceramic Moulding Process In another branch of pim, ceramic or carbide materials are used as raw materials in a process called ceramic injection moulding (cim). Discover how it's revolutionizing the production. Ceramic injection molding (cim) is a ceramic manufacturing process using injection molding technology to produce complex and intricate ceramic parts, especially for. • ceramic mould casting method uses a ceramic slurry prepared. What Is Ceramic Moulding Process.

From www.sporvil.com

Everything you want to know about Ceramic Molds Molding 101 What Is Ceramic Moulding Process • ceramic mould casting method uses a ceramic slurry prepared by mixing fine grained refractory powders of zircon ( zr sio4 ), alumina ( al2 o3 ), fused silica. Ceramic injection molding (cim) is a ceramic manufacturing process using injection molding technology to produce complex and intricate ceramic parts, especially for. Explore the intricate world of ceramic injection molding (cim),. What Is Ceramic Moulding Process.