Bin Tracking Meaning . Native netsuite offers simple inventory. A bin tracking system can be designed by manufacturers to identify their containers using rfid technology. A warehouse management system (wms) makes it much easier to gain traceability throughout your warehouse. It is used to keep a running tally of the items in stock, as well as the dates and. Typically only a single sku is stored in each bin. This allows them to provide a complete and accurate view of their bin infrastructure to. Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. Bin tracking, from orchid systems, allows you to track items stored in multiple bins within a sage 300 inventory control location. Warehouse management solutions can track software along every part of its journey within the warehouse down to the bin level.

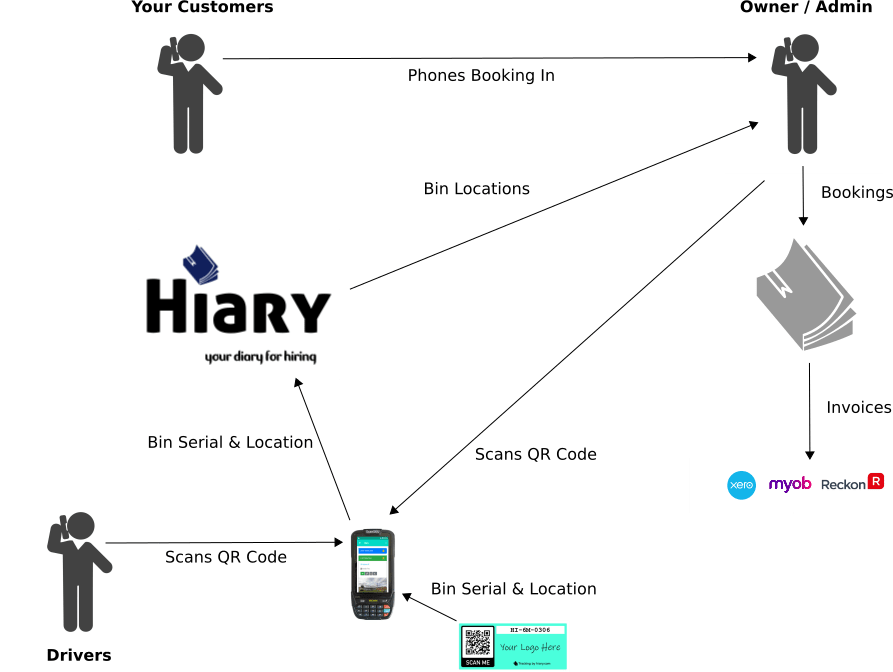

from hiary.com

Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. A bin tracking system can be designed by manufacturers to identify their containers using rfid technology. Warehouse management solutions can track software along every part of its journey within the warehouse down to the bin level. Bin tracking, from orchid systems, allows you to track items stored in multiple bins within a sage 300 inventory control location. Native netsuite offers simple inventory. This allows them to provide a complete and accurate view of their bin infrastructure to. It is used to keep a running tally of the items in stock, as well as the dates and. Typically only a single sku is stored in each bin. A warehouse management system (wms) makes it much easier to gain traceability throughout your warehouse.

Bin Tracking That Will Help Your Bin Manager Get More From Your Bins

Bin Tracking Meaning It is used to keep a running tally of the items in stock, as well as the dates and. Native netsuite offers simple inventory. Typically only a single sku is stored in each bin. A warehouse management system (wms) makes it much easier to gain traceability throughout your warehouse. Warehouse management solutions can track software along every part of its journey within the warehouse down to the bin level. It is used to keep a running tally of the items in stock, as well as the dates and. Bin tracking, from orchid systems, allows you to track items stored in multiple bins within a sage 300 inventory control location. A bin tracking system can be designed by manufacturers to identify their containers using rfid technology. Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. This allows them to provide a complete and accurate view of their bin infrastructure to.

From www.smh.com.au

Video GPS bin tracking to reduce waste Bin Tracking Meaning Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. Warehouse management solutions can track software along every part of its journey within the warehouse down to the bin level. A warehouse management system (wms) makes it much easier to gain traceability throughout your warehouse. A bin tracking system can be designed by manufacturers to. Bin Tracking Meaning.

From www.orchid.systems

Bin Tracking Orchid Systems Sage 300 Addons Bin Tracking Meaning This allows them to provide a complete and accurate view of their bin infrastructure to. It is used to keep a running tally of the items in stock, as well as the dates and. Native netsuite offers simple inventory. Typically only a single sku is stored in each bin. Bin level inventory is when each individual aisle, rack, shelf, and. Bin Tracking Meaning.

From ttconsultants.com

Smart Bins Innovating Waste Segregation & Sustainability Bin Tracking Meaning Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. It is used to keep a running tally of the items in stock, as well as the dates and. This allows them to provide a complete and accurate view of their bin infrastructure to. A bin tracking system can be designed by manufacturers to identify. Bin Tracking Meaning.

From za-marketplace.sage.com

Bin Tracking SAGE South Africa Marketplace Bin Tracking Meaning Warehouse management solutions can track software along every part of its journey within the warehouse down to the bin level. Typically only a single sku is stored in each bin. Bin tracking, from orchid systems, allows you to track items stored in multiple bins within a sage 300 inventory control location. Native netsuite offers simple inventory. Bin level inventory is. Bin Tracking Meaning.

From www.databit.com.sg

Bin Tracking Sage 300 ACCPAC ASIA Authorized Partner Bin Tracking Meaning A bin tracking system can be designed by manufacturers to identify their containers using rfid technology. This allows them to provide a complete and accurate view of their bin infrastructure to. Typically only a single sku is stored in each bin. Bin tracking, from orchid systems, allows you to track items stored in multiple bins within a sage 300 inventory. Bin Tracking Meaning.

From hiary.com

Bin Tracking That Will Help Your Bin Manager Get More From Your Bins Bin Tracking Meaning This allows them to provide a complete and accurate view of their bin infrastructure to. Warehouse management solutions can track software along every part of its journey within the warehouse down to the bin level. A bin tracking system can be designed by manufacturers to identify their containers using rfid technology. Native netsuite offers simple inventory. Bin level inventory is. Bin Tracking Meaning.

From www.panatrack.com

Bin Tracking with Put Away for PanatrackerGP Panatrack Bin Tracking Meaning A bin tracking system can be designed by manufacturers to identify their containers using rfid technology. It is used to keep a running tally of the items in stock, as well as the dates and. This allows them to provide a complete and accurate view of their bin infrastructure to. Native netsuite offers simple inventory. Typically only a single sku. Bin Tracking Meaning.

From www.orchid.systems

Bin Tracking Orchid Systems Sage 300 Addons Bin Tracking Meaning Native netsuite offers simple inventory. Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. A bin tracking system can be designed by manufacturers to identify their containers using rfid technology. Typically only a single sku is stored in each bin. It is used to keep a running tally of the items in stock, as. Bin Tracking Meaning.

From wlius.com

RFID Waste Management Fleet GPS Tracking & Telematics Bin Tracking Meaning It is used to keep a running tally of the items in stock, as well as the dates and. Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. Warehouse management solutions can track software along every part of its journey within the warehouse down to the bin level. Bin tracking, from orchid systems, allows. Bin Tracking Meaning.

From docs.kivalogic.com

Bin Tracking for Reclaimable Materials Kiva Logic Knowledge Base Bin Tracking Meaning Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. A warehouse management system (wms) makes it much easier to gain traceability throughout your warehouse. Warehouse management solutions can track software along every part of its journey within the warehouse down to the bin level. A bin tracking system can be designed by manufacturers to. Bin Tracking Meaning.

From www.yumpu.com

Bin TrackingLetter Single Layout.cdr ACCUDART Bin Tracking Meaning Warehouse management solutions can track software along every part of its journey within the warehouse down to the bin level. Typically only a single sku is stored in each bin. Bin tracking, from orchid systems, allows you to track items stored in multiple bins within a sage 300 inventory control location. This allows them to provide a complete and accurate. Bin Tracking Meaning.

From evreka.co

Why Container & Bin Tracking Is Important › Evreka Bin Tracking Meaning A bin tracking system can be designed by manufacturers to identify their containers using rfid technology. Typically only a single sku is stored in each bin. Bin tracking, from orchid systems, allows you to track items stored in multiple bins within a sage 300 inventory control location. It is used to keep a running tally of the items in stock,. Bin Tracking Meaning.

From telitek.ca

Waste Bin and Truck Tracking System — Telitek Bin Tracking Meaning Bin tracking, from orchid systems, allows you to track items stored in multiple bins within a sage 300 inventory control location. This allows them to provide a complete and accurate view of their bin infrastructure to. A warehouse management system (wms) makes it much easier to gain traceability throughout your warehouse. A bin tracking system can be designed by manufacturers. Bin Tracking Meaning.

From www.investopedia.com

TwoBin Inventory Control Definition, How It Works, and Example Bin Tracking Meaning Native netsuite offers simple inventory. Typically only a single sku is stored in each bin. Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. A bin tracking system can be designed by manufacturers to identify their containers using rfid technology. It is used to keep a running tally of the items in stock, as. Bin Tracking Meaning.

From docs.kivalogic.com

Bin Tracking for Reclaimable Materials Kiva Logic Knowledge Base Bin Tracking Meaning It is used to keep a running tally of the items in stock, as well as the dates and. A warehouse management system (wms) makes it much easier to gain traceability throughout your warehouse. Native netsuite offers simple inventory. Warehouse management solutions can track software along every part of its journey within the warehouse down to the bin level. Bin. Bin Tracking Meaning.

From telitek.ca

Waste Bin and Truck Tracking System — Telitek Bin Tracking Meaning Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. A bin tracking system can be designed by manufacturers to identify their containers using rfid technology. Native netsuite offers simple inventory. Warehouse management solutions can track software along every part of its journey within the warehouse down to the bin level. A warehouse management system. Bin Tracking Meaning.

From realha.us.to

Tableau Bins Create Bins in Tableau with just 3 Steps! DataFlair Bin Tracking Meaning Warehouse management solutions can track software along every part of its journey within the warehouse down to the bin level. A bin tracking system can be designed by manufacturers to identify their containers using rfid technology. A warehouse management system (wms) makes it much easier to gain traceability throughout your warehouse. Bin level inventory is when each individual aisle, rack,. Bin Tracking Meaning.

From wlius.com

RFID Waste Management Fleet GPS Tracking & Telematics Bin Tracking Meaning Native netsuite offers simple inventory. This allows them to provide a complete and accurate view of their bin infrastructure to. A warehouse management system (wms) makes it much easier to gain traceability throughout your warehouse. Typically only a single sku is stored in each bin. It is used to keep a running tally of the items in stock, as well. Bin Tracking Meaning.

From thetagfactory.com

Waste Management TheTagFactory Bin Tracking Meaning Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. Bin tracking, from orchid systems, allows you to track items stored in multiple bins within a sage 300 inventory control location. Warehouse management solutions can track software along every part of its journey within the warehouse down to the bin level. Native netsuite offers simple. Bin Tracking Meaning.

From docs.kivalogic.com

Bin Tracking for Reclaimable Materials Kiva Logic Knowledge Base Bin Tracking Meaning Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. Typically only a single sku is stored in each bin. A warehouse management system (wms) makes it much easier to gain traceability throughout your warehouse. It is used to keep a running tally of the items in stock, as well as the dates and. Warehouse. Bin Tracking Meaning.

From www.youtube.com

RFID waste management system; RFID garbage tracking; RFID garbage bin Bin Tracking Meaning A bin tracking system can be designed by manufacturers to identify their containers using rfid technology. It is used to keep a running tally of the items in stock, as well as the dates and. A warehouse management system (wms) makes it much easier to gain traceability throughout your warehouse. Bin level inventory is when each individual aisle, rack, shelf,. Bin Tracking Meaning.

From www.youtube.com

BinTracks overview video Bin Tracks visit to learn more Bin Tracking Meaning Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. Typically only a single sku is stored in each bin. A warehouse management system (wms) makes it much easier to gain traceability throughout your warehouse. It is used to keep a running tally of the items in stock, as well as the dates and. This. Bin Tracking Meaning.

From joikwqdhc.blob.core.windows.net

Bin Card Accounting Meaning at Monica Wells blog Bin Tracking Meaning This allows them to provide a complete and accurate view of their bin infrastructure to. It is used to keep a running tally of the items in stock, as well as the dates and. A warehouse management system (wms) makes it much easier to gain traceability throughout your warehouse. Warehouse management solutions can track software along every part of its. Bin Tracking Meaning.

From www.abr.com

Asset Tracking & Management AB&R® (American Barcode and RFID) Bin Tracking Meaning Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. A warehouse management system (wms) makes it much easier to gain traceability throughout your warehouse. A bin tracking system can be designed by manufacturers to identify their containers using rfid technology. This allows them to provide a complete and accurate view of their bin infrastructure. Bin Tracking Meaning.

From telitek.ca

Waste Bin and Truck Tracking System — Telitek Bin Tracking Meaning A bin tracking system can be designed by manufacturers to identify their containers using rfid technology. It is used to keep a running tally of the items in stock, as well as the dates and. Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. Bin tracking, from orchid systems, allows you to track items. Bin Tracking Meaning.

From www.youtube.com

Bin Tracking YouTube Bin Tracking Meaning It is used to keep a running tally of the items in stock, as well as the dates and. Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. Bin tracking, from orchid systems, allows you to track items stored in multiple bins within a sage 300 inventory control location. Typically only a single sku. Bin Tracking Meaning.

From docs.kivalogic.com

Bin Tracking for Reclaimable Materials Kiva Logic Knowledge Base Bin Tracking Meaning Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. Typically only a single sku is stored in each bin. Bin tracking, from orchid systems, allows you to track items stored in multiple bins within a sage 300 inventory control location. Native netsuite offers simple inventory. Warehouse management solutions can track software along every part. Bin Tracking Meaning.

From ctrlnet.co.za

Bin Tracking and Interlocking Consulting Bin Tracking Meaning A bin tracking system can be designed by manufacturers to identify their containers using rfid technology. This allows them to provide a complete and accurate view of their bin infrastructure to. It is used to keep a running tally of the items in stock, as well as the dates and. Warehouse management solutions can track software along every part of. Bin Tracking Meaning.

From www.pinterest.co.uk

*GPS Bin Tracking Devices Locate and Monitor Skip Bins* Tracking Bin Tracking Meaning Native netsuite offers simple inventory. This allows them to provide a complete and accurate view of their bin infrastructure to. A bin tracking system can be designed by manufacturers to identify their containers using rfid technology. Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. A warehouse management system (wms) makes it much easier. Bin Tracking Meaning.

From www.digitalmatter.com

GPS Bin Tracker Solutions BatteryPowered GPS Bintracker Bin Tracking Meaning Bin tracking, from orchid systems, allows you to track items stored in multiple bins within a sage 300 inventory control location. It is used to keep a running tally of the items in stock, as well as the dates and. A bin tracking system can be designed by manufacturers to identify their containers using rfid technology. A warehouse management system. Bin Tracking Meaning.

From help.orchid.systems

Bin Tracking Customized Forms Bin Tracking Meaning This allows them to provide a complete and accurate view of their bin infrastructure to. Typically only a single sku is stored in each bin. A warehouse management system (wms) makes it much easier to gain traceability throughout your warehouse. Warehouse management solutions can track software along every part of its journey within the warehouse down to the bin level.. Bin Tracking Meaning.

From www.digitalmatter.com

Waste Management GPS Tracking Devices Digital Matter Bin Tracking Meaning Bin tracking, from orchid systems, allows you to track items stored in multiple bins within a sage 300 inventory control location. Typically only a single sku is stored in each bin. A bin tracking system can be designed by manufacturers to identify their containers using rfid technology. Warehouse management solutions can track software along every part of its journey within. Bin Tracking Meaning.

From docs.kivalogic.com

Bin Tracking for Reclaimable Materials Kiva Logic Knowledge Base Bin Tracking Meaning A bin tracking system can be designed by manufacturers to identify their containers using rfid technology. A warehouse management system (wms) makes it much easier to gain traceability throughout your warehouse. Bin tracking, from orchid systems, allows you to track items stored in multiple bins within a sage 300 inventory control location. Typically only a single sku is stored in. Bin Tracking Meaning.

From sisko.co.za

SISKO Farm management Bin Tracking Meaning Typically only a single sku is stored in each bin. This allows them to provide a complete and accurate view of their bin infrastructure to. A bin tracking system can be designed by manufacturers to identify their containers using rfid technology. Native netsuite offers simple inventory. Bin tracking, from orchid systems, allows you to track items stored in multiple bins. Bin Tracking Meaning.