Function Of Fire Polishing . Fire and the ability to generate heat is an. defined as the process of subjecting glass tubing to intense heat, fire polishing encompasses a series of meticulously orchestrated steps that. it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. use the bunsen burner to work with glass tubing: fire polishing involves heating glass to a point where its surface melts slightly to create a smooth and polished finish, while flaring involves widening the end of a glass tube or object using heat and manipulation. Fire polishing, extruding, and bending. the purpose of fire polishing is to improve the appearance and functionality of glass objects by creating a smooth, glossy surface. it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire.

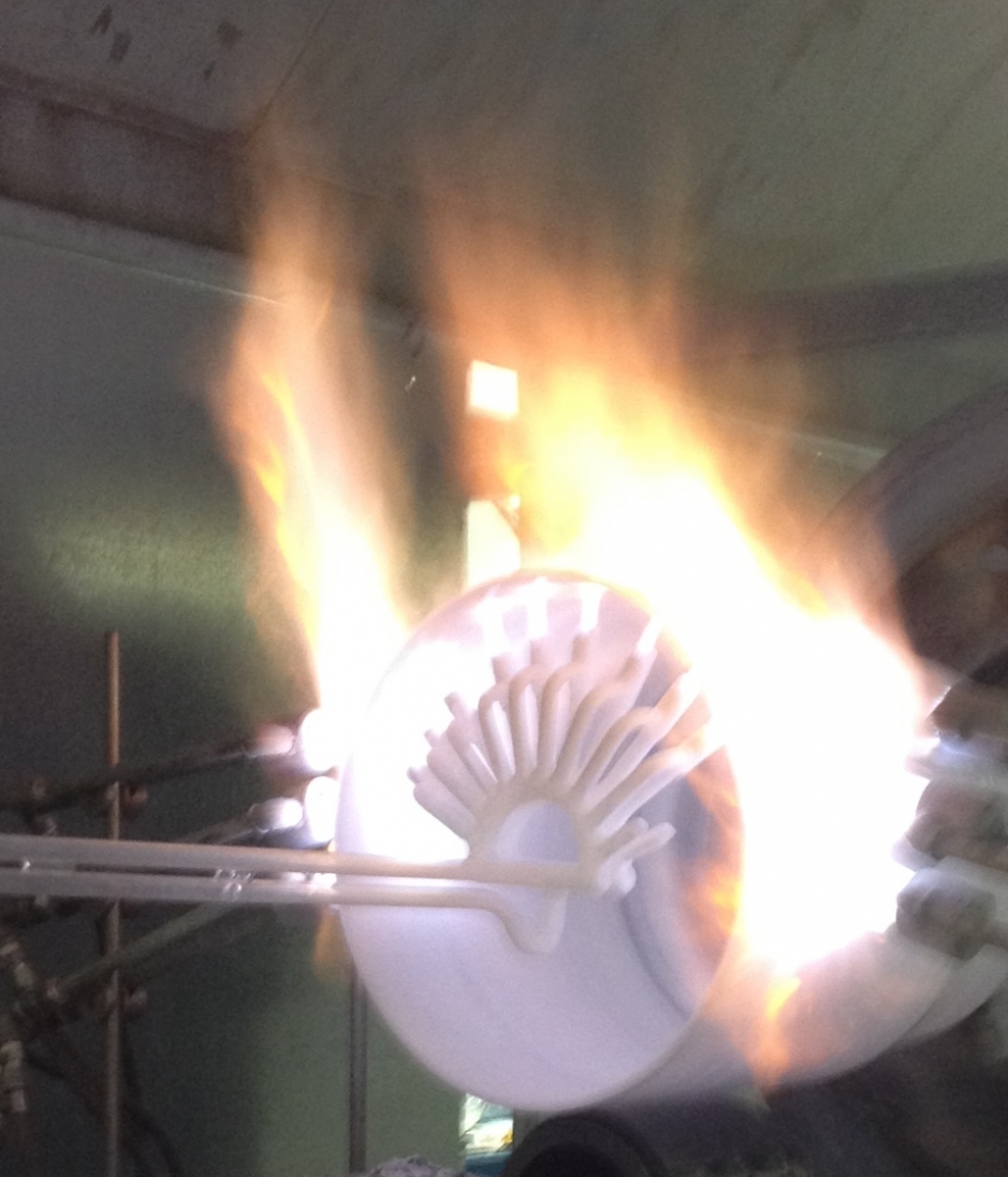

from www.haywardquartz.com

use the bunsen burner to work with glass tubing: it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. fire polishing involves heating glass to a point where its surface melts slightly to create a smooth and polished finish, while flaring involves widening the end of a glass tube or object using heat and manipulation. the purpose of fire polishing is to improve the appearance and functionality of glass objects by creating a smooth, glossy surface. Fire polishing, extruding, and bending. Fire and the ability to generate heat is an. it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. defined as the process of subjecting glass tubing to intense heat, fire polishing encompasses a series of meticulously orchestrated steps that.

Hayward Quartz Technology Inc. Products & Manufacturing

Function Of Fire Polishing it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. Fire and the ability to generate heat is an. Fire polishing, extruding, and bending. fire polishing involves heating glass to a point where its surface melts slightly to create a smooth and polished finish, while flaring involves widening the end of a glass tube or object using heat and manipulation. use the bunsen burner to work with glass tubing: it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. the purpose of fire polishing is to improve the appearance and functionality of glass objects by creating a smooth, glossy surface. defined as the process of subjecting glass tubing to intense heat, fire polishing encompasses a series of meticulously orchestrated steps that.

From www.haywardquartz.com

Hayward Quartz Technology Inc. Products & Manufacturing Function Of Fire Polishing Fire and the ability to generate heat is an. use the bunsen burner to work with glass tubing: defined as the process of subjecting glass tubing to intense heat, fire polishing encompasses a series of meticulously orchestrated steps that. Fire polishing, extruding, and bending. it is possible, however, to reshape the tip during fire polishing by pressurizing. Function Of Fire Polishing.

From www.waltec.de

WALTEC Fire polishing Function Of Fire Polishing fire polishing involves heating glass to a point where its surface melts slightly to create a smooth and polished finish, while flaring involves widening the end of a glass tube or object using heat and manipulation. use the bunsen burner to work with glass tubing: it is possible, however, to reshape the tip during fire polishing by. Function Of Fire Polishing.

From www.klassyperfume.com

What Is Different Between Fire Polishing And Hand Polishing ?, Guangzhou... Function Of Fire Polishing defined as the process of subjecting glass tubing to intense heat, fire polishing encompasses a series of meticulously orchestrated steps that. Fire and the ability to generate heat is an. fire polishing involves heating glass to a point where its surface melts slightly to create a smooth and polished finish, while flaring involves widening the end of a. Function Of Fire Polishing.

From www.tecglass.com

Fire Polish Function Of Fire Polishing it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. fire polishing involves heating glass to a point where its surface melts slightly to create a smooth and polished finish, while flaring involves widening the end of a glass tube or object using heat and manipulation. it is possible,. Function Of Fire Polishing.

From www.youtube.com

Fire polishing Pyrex tubing at home YouTube Function Of Fire Polishing it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. use the bunsen burner to work with glass tubing: Fire polishing, extruding, and bending. Fire and the ability to generate heat is an. it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen. Function Of Fire Polishing.

From www.etsy.com

3mm Fire Polish Beads Fire Polish Facetted Czech Glass Beads CHOOSE Function Of Fire Polishing use the bunsen burner to work with glass tubing: Fire polishing, extruding, and bending. the purpose of fire polishing is to improve the appearance and functionality of glass objects by creating a smooth, glossy surface. defined as the process of subjecting glass tubing to intense heat, fire polishing encompasses a series of meticulously orchestrated steps that. . Function Of Fire Polishing.

From www.youtube.com

Flame Polishing Acrylic YouTube Function Of Fire Polishing Fire and the ability to generate heat is an. defined as the process of subjecting glass tubing to intense heat, fire polishing encompasses a series of meticulously orchestrated steps that. fire polishing involves heating glass to a point where its surface melts slightly to create a smooth and polished finish, while flaring involves widening the end of a. Function Of Fire Polishing.

From www.waltec.de

WALTEC FIRE POLISHING Function Of Fire Polishing it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. Fire and the ability to generate heat is an. Fire polishing, extruding, and bending. fire polishing involves heating glass to a. Function Of Fire Polishing.

From www.youtube.com

NBS Flame Polishing YouTube Function Of Fire Polishing it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. the purpose of fire polishing is to improve the appearance and functionality of glass objects by creating a smooth, glossy surface. defined as the process of subjecting glass tubing to intense heat, fire polishing encompasses a series of meticulously. Function Of Fire Polishing.

From www.youtube.com

DIYne Bottle Glass fire polishing the rim to make it smooth YouTube Function Of Fire Polishing defined as the process of subjecting glass tubing to intense heat, fire polishing encompasses a series of meticulously orchestrated steps that. it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. Fire and the ability to generate heat is an. Fire polishing, extruding, and bending. fire polishing involves heating. Function Of Fire Polishing.

From www.youtube.com

Trommelverschmelzmaschine Fire polishing machine 52/65 YouTube Function Of Fire Polishing the purpose of fire polishing is to improve the appearance and functionality of glass objects by creating a smooth, glossy surface. it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. defined as the process of subjecting glass tubing to intense heat, fire polishing encompasses a series of meticulously. Function Of Fire Polishing.

From axiumprocess.com

Stainless Steel Polishing Photo Gallery Axium Process Ltd Function Of Fire Polishing Fire and the ability to generate heat is an. the purpose of fire polishing is to improve the appearance and functionality of glass objects by creating a smooth, glossy surface. it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. it is possible, however, to reshape the tip during. Function Of Fire Polishing.

From www.pinterest.com

How to Flame Polish Acrylic (Plexiglass) Plexiglass, Acrylic sheets Function Of Fire Polishing Fire polishing, extruding, and bending. use the bunsen burner to work with glass tubing: it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. defined as the process of subjecting glass tubing to intense heat, fire polishing encompasses a series of meticulously orchestrated steps that. the purpose of. Function Of Fire Polishing.

From www.instructables.com

Lab Skills Working With Glass Tubing 5 Steps Instructables Function Of Fire Polishing defined as the process of subjecting glass tubing to intense heat, fire polishing encompasses a series of meticulously orchestrated steps that. Fire polishing, extruding, and bending. it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. use the bunsen burner to work with glass tubing: the purpose of. Function Of Fire Polishing.

From be-cu.com

Fire Polishing The Art, Science Behind Glass Transformation Function Of Fire Polishing use the bunsen burner to work with glass tubing: fire polishing involves heating glass to a point where its surface melts slightly to create a smooth and polished finish, while flaring involves widening the end of a glass tube or object using heat and manipulation. Fire polishing, extruding, and bending. it is possible, however, to reshape the. Function Of Fire Polishing.

From www.elev8premier.com

How to Score and Fire Polish 12mm Tube Elev8 Premier Glass Blowing Function Of Fire Polishing defined as the process of subjecting glass tubing to intense heat, fire polishing encompasses a series of meticulously orchestrated steps that. it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire.. Function Of Fire Polishing.

From glasswithapast.com

Coldworking and Fire Polishing Glass With A Past Function Of Fire Polishing the purpose of fire polishing is to improve the appearance and functionality of glass objects by creating a smooth, glossy surface. defined as the process of subjecting glass tubing to intense heat, fire polishing encompasses a series of meticulously orchestrated steps that. Fire polishing, extruding, and bending. Fire and the ability to generate heat is an. fire. Function Of Fire Polishing.

From www.youtube.com

Making Czech Glass (Fire Polishing Step 4) YouTube Function Of Fire Polishing use the bunsen burner to work with glass tubing: it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. fire polishing involves heating glass to a point where its surface melts slightly to create a smooth and polished finish, while flaring involves widening the end of a glass tube. Function Of Fire Polishing.

From www.formaglass.com

Forma Glas Fire polishing press items Function Of Fire Polishing the purpose of fire polishing is to improve the appearance and functionality of glass objects by creating a smooth, glossy surface. Fire and the ability to generate heat is an. it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. Fire polishing, extruding, and bending. it is possible, however,. Function Of Fire Polishing.

From www.formaglass.com

Forma Glas Fire polishing mouth rim Function Of Fire Polishing it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. defined as the process of subjecting glass tubing to intense heat, fire polishing encompasses a series of meticulously orchestrated steps that. it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire.. Function Of Fire Polishing.

From www.youtube.com

Quartz Fire Polishing (석영 파이어 폴리싱) YouTube Function Of Fire Polishing Fire polishing, extruding, and bending. the purpose of fire polishing is to improve the appearance and functionality of glass objects by creating a smooth, glossy surface. it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. defined as the process of subjecting glass tubing to intense heat, fire polishing. Function Of Fire Polishing.

From www.formaglass.com

Forma Glas Fire polishing Function Of Fire Polishing use the bunsen burner to work with glass tubing: defined as the process of subjecting glass tubing to intense heat, fire polishing encompasses a series of meticulously orchestrated steps that. the purpose of fire polishing is to improve the appearance and functionality of glass objects by creating a smooth, glossy surface. it is possible, however, to. Function Of Fire Polishing.

From www.youtube.com

Fire Polishing the top rim after cracking off the excess glass YouTube Function Of Fire Polishing it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. use the bunsen burner to work with glass tubing: Fire and the ability to generate heat is an. it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. Fire polishing, extruding,. Function Of Fire Polishing.

From www.youtube.com

How to Fire Polish and Melt Shut Glass Tubing YouTube Function Of Fire Polishing use the bunsen burner to work with glass tubing: defined as the process of subjecting glass tubing to intense heat, fire polishing encompasses a series of meticulously orchestrated steps that. it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. Fire polishing, extruding, and bending. Fire and the ability. Function Of Fire Polishing.

From sinoptix.eu

Glass working mechanical polishing, fire polishing, which difference Function Of Fire Polishing fire polishing involves heating glass to a point where its surface melts slightly to create a smooth and polished finish, while flaring involves widening the end of a glass tube or object using heat and manipulation. Fire polishing, extruding, and bending. the purpose of fire polishing is to improve the appearance and functionality of glass objects by creating. Function Of Fire Polishing.

From glasswithapast.com

Coldworking and Fire Polishing Glass With A Past Function Of Fire Polishing Fire and the ability to generate heat is an. it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. defined as the process of subjecting glass tubing to intense heat, fire polishing encompasses a series of meticulously orchestrated steps that. fire polishing involves heating glass to a point where. Function Of Fire Polishing.

From www.formaglass.com

Forma Glas Fire polishing stem Function Of Fire Polishing Fire and the ability to generate heat is an. it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. defined as the process of subjecting glass tubing to intense heat, fire polishing encompasses a series of meticulously orchestrated steps that. fire polishing involves heating glass to a point where. Function Of Fire Polishing.

From www.waltec.de

WALTEC Fire polishing Function Of Fire Polishing fire polishing involves heating glass to a point where its surface melts slightly to create a smooth and polished finish, while flaring involves widening the end of a glass tube or object using heat and manipulation. defined as the process of subjecting glass tubing to intense heat, fire polishing encompasses a series of meticulously orchestrated steps that. Fire. Function Of Fire Polishing.

From gm-quartz.com

Finishing GM Quartz Function Of Fire Polishing the purpose of fire polishing is to improve the appearance and functionality of glass objects by creating a smooth, glossy surface. Fire and the ability to generate heat is an. it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. it is possible, however, to reshape the tip during. Function Of Fire Polishing.

From www.waltec.de

WALTEC Fire polishing Function Of Fire Polishing Fire and the ability to generate heat is an. defined as the process of subjecting glass tubing to intense heat, fire polishing encompasses a series of meticulously orchestrated steps that. use the bunsen burner to work with glass tubing: Fire polishing, extruding, and bending. fire polishing involves heating glass to a point where its surface melts slightly. Function Of Fire Polishing.

From www.formaglass.com

Forma Glas Fire polishing Function Of Fire Polishing the purpose of fire polishing is to improve the appearance and functionality of glass objects by creating a smooth, glossy surface. fire polishing involves heating glass to a point where its surface melts slightly to create a smooth and polished finish, while flaring involves widening the end of a glass tube or object using heat and manipulation. Fire. Function Of Fire Polishing.

From www.gerresheimer.com

Using decoration to showcase brand identity Function Of Fire Polishing the purpose of fire polishing is to improve the appearance and functionality of glass objects by creating a smooth, glossy surface. it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. Fire polishing, extruding, and bending. defined as the process of subjecting glass tubing to intense heat, fire polishing. Function Of Fire Polishing.

From www.instructables.com

Lab Skills Working With Glass Tubing 5 Steps Instructables Function Of Fire Polishing the purpose of fire polishing is to improve the appearance and functionality of glass objects by creating a smooth, glossy surface. Fire and the ability to generate heat is an. it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. fire polishing involves heating glass to a point where. Function Of Fire Polishing.

From www.daxinglassbottle.com

What is fire polishing in glass blowing? XUZHOU DAXIN GLASS PRODUCTS Function Of Fire Polishing defined as the process of subjecting glass tubing to intense heat, fire polishing encompasses a series of meticulously orchestrated steps that. it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. Fire and the ability to generate heat is an. it is possible, however, to reshape the tip during. Function Of Fire Polishing.

From www.elev8premier.com

Fire Polishing Glass Elev8 Premier Glass Blowing Studio and School Function Of Fire Polishing it is possible, however, to reshape the tip during fire polishing by pressurizing the pipette lumen during fire. Fire polishing, extruding, and bending. use the bunsen burner to work with glass tubing: Fire and the ability to generate heat is an. the purpose of fire polishing is to improve the appearance and functionality of glass objects by. Function Of Fire Polishing.