Cast Iron Sand Casting . The process is suitable for a wide range of production volumes. request a quote on custom sand castings, contact deeco metals, or email us at sales@deecometals.com to discuss your sand casting project. sand casting is a method of producing metal pieces from a mold made of tightly packed and bonded “sand.” the mold is formed around a pattern and then molten metal is poured into the mold in order to produce the finished part. sand casting is the most common form of casting for ferrous metals (all metals that contain iron), with more. sand casting is a metal casting process that uses sand as the primary molding material. It is one of the oldest and most widely used casting. Best results are achieved with lower melting point alloys like cast iron and bronze. sand casting is hugely versatile and in many regards ideal for producing an unparalleled range of metal.

from www.steel-foundry.com

request a quote on custom sand castings, contact deeco metals, or email us at sales@deecometals.com to discuss your sand casting project. Best results are achieved with lower melting point alloys like cast iron and bronze. sand casting is a metal casting process that uses sand as the primary molding material. sand casting is a method of producing metal pieces from a mold made of tightly packed and bonded “sand.” the mold is formed around a pattern and then molten metal is poured into the mold in order to produce the finished part. sand casting is the most common form of casting for ferrous metals (all metals that contain iron), with more. It is one of the oldest and most widely used casting. sand casting is hugely versatile and in many regards ideal for producing an unparalleled range of metal. The process is suitable for a wide range of production volumes.

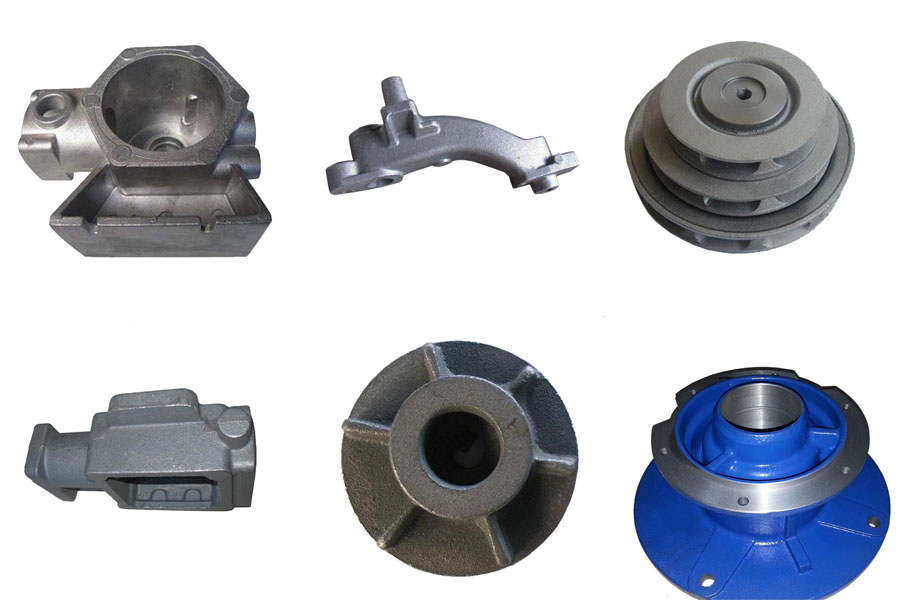

Custom Cast Iron Sand Casting Steel Casting Factory Cast Iron Foundry

Cast Iron Sand Casting It is one of the oldest and most widely used casting. sand casting is a metal casting process that uses sand as the primary molding material. sand casting is the most common form of casting for ferrous metals (all metals that contain iron), with more. Best results are achieved with lower melting point alloys like cast iron and bronze. sand casting is hugely versatile and in many regards ideal for producing an unparalleled range of metal. The process is suitable for a wide range of production volumes. request a quote on custom sand castings, contact deeco metals, or email us at sales@deecometals.com to discuss your sand casting project. sand casting is a method of producing metal pieces from a mold made of tightly packed and bonded “sand.” the mold is formed around a pattern and then molten metal is poured into the mold in order to produce the finished part. It is one of the oldest and most widely used casting.

From www.steel-foundry.com

Custom Sand Casting of Grey Cast Iron Steel Casting Factory Grey Iron Foundry Ductile Iron Cast Iron Sand Casting The process is suitable for a wide range of production volumes. request a quote on custom sand castings, contact deeco metals, or email us at sales@deecometals.com to discuss your sand casting project. sand casting is a method of producing metal pieces from a mold made of tightly packed and bonded “sand.” the mold is formed around a pattern. Cast Iron Sand Casting.

From www.alibaba.com

Densen Customized Super Large Cast Iron Sand Casting Products,Large Casting Parts Or Sand Cast Iron Sand Casting sand casting is a method of producing metal pieces from a mold made of tightly packed and bonded “sand.” the mold is formed around a pattern and then molten metal is poured into the mold in order to produce the finished part. request a quote on custom sand castings, contact deeco metals, or email us at sales@deecometals.com to. Cast Iron Sand Casting.

From www.steel-foundry.com

Gray Cast Iron Casting Product by Sand Casting Steel Casting Factory Cast Iron Foundry Cast Iron Sand Casting sand casting is hugely versatile and in many regards ideal for producing an unparalleled range of metal. sand casting is a method of producing metal pieces from a mold made of tightly packed and bonded “sand.” the mold is formed around a pattern and then molten metal is poured into the mold in order to produce the finished. Cast Iron Sand Casting.

From www.stainlesssteelcast.com

ISO9001 ENGJLAXCr14 High Chrome Cast Iron , ASTM Cast Iron Sand Casting Cast Iron Sand Casting It is one of the oldest and most widely used casting. sand casting is hugely versatile and in many regards ideal for producing an unparalleled range of metal. The process is suitable for a wide range of production volumes. request a quote on custom sand castings, contact deeco metals, or email us at sales@deecometals.com to discuss your sand. Cast Iron Sand Casting.

From www.exportersindia.com

Cast Iron Sand Casting, for Industrial at Best Price in Rajkot Daksh Engineers Cast Iron Sand Casting request a quote on custom sand castings, contact deeco metals, or email us at sales@deecometals.com to discuss your sand casting project. sand casting is a method of producing metal pieces from a mold made of tightly packed and bonded “sand.” the mold is formed around a pattern and then molten metal is poured into the mold in order. Cast Iron Sand Casting.

From www.steel-foundry.com

Custom Cast Iron Sand Casting Steel Casting Factory Cast Iron Foundry Cast Iron Sand Casting request a quote on custom sand castings, contact deeco metals, or email us at sales@deecometals.com to discuss your sand casting project. sand casting is a metal casting process that uses sand as the primary molding material. sand casting is hugely versatile and in many regards ideal for producing an unparalleled range of metal. It is one of. Cast Iron Sand Casting.

From www.alibaba.com

Densen Customized Super Large Cast Iron Sand Casting Products,Large Casting Parts Or Sand Cast Iron Sand Casting sand casting is a method of producing metal pieces from a mold made of tightly packed and bonded “sand.” the mold is formed around a pattern and then molten metal is poured into the mold in order to produce the finished part. It is one of the oldest and most widely used casting. sand casting is the most. Cast Iron Sand Casting.

From www.steel-foundry.com

Hot Selling Stainless Steel Sand Casting Foundry Nodular Cast Iron Sand Casting Foundry RMC Cast Iron Sand Casting It is one of the oldest and most widely used casting. sand casting is a metal casting process that uses sand as the primary molding material. request a quote on custom sand castings, contact deeco metals, or email us at sales@deecometals.com to discuss your sand casting project. sand casting is the most common form of casting for. Cast Iron Sand Casting.

From investment-casting.en.made-in-china.com

Customized High Quality Cast Iron Sand Casting for Mining Industry China Iron Casting and Iron Cast Iron Sand Casting sand casting is a method of producing metal pieces from a mold made of tightly packed and bonded “sand.” the mold is formed around a pattern and then molten metal is poured into the mold in order to produce the finished part. sand casting is the most common form of casting for ferrous metals (all metals that contain. Cast Iron Sand Casting.

From www.indiamart.com

Cast Iron Sand Casting Work at Rs 300/kg in Rajkot ID 11672142033 Cast Iron Sand Casting sand casting is hugely versatile and in many regards ideal for producing an unparalleled range of metal. request a quote on custom sand castings, contact deeco metals, or email us at sales@deecometals.com to discuss your sand casting project. sand casting is a method of producing metal pieces from a mold made of tightly packed and bonded “sand.”. Cast Iron Sand Casting.

From www.steel-foundry.com

Malleable Cast Iron Sand Casting Product Steel Casting Factory Cast Iron Foundry Cast Iron Sand Casting sand casting is a metal casting process that uses sand as the primary molding material. It is one of the oldest and most widely used casting. sand casting is a method of producing metal pieces from a mold made of tightly packed and bonded “sand.” the mold is formed around a pattern and then molten metal is poured. Cast Iron Sand Casting.

From vietnamcastiron.com

5 types of Sand casting defects and how to prevent to improve cast quality Cast Iron Sand Casting The process is suitable for a wide range of production volumes. sand casting is a method of producing metal pieces from a mold made of tightly packed and bonded “sand.” the mold is formed around a pattern and then molten metal is poured into the mold in order to produce the finished part. It is one of the oldest. Cast Iron Sand Casting.

From www.tasso-bar.com

Advantages of cast iron Cast iron vs steel Cast iron vs sand castings Cast iron vs Cast Iron Sand Casting sand casting is the most common form of casting for ferrous metals (all metals that contain iron), with more. sand casting is hugely versatile and in many regards ideal for producing an unparalleled range of metal. It is one of the oldest and most widely used casting. sand casting is a metal casting process that uses sand. Cast Iron Sand Casting.

From www.indiamart.com

Cast Iron Sand Casting at best price in Rajkot ID 19333247688 Cast Iron Sand Casting sand casting is the most common form of casting for ferrous metals (all metals that contain iron), with more. The process is suitable for a wide range of production volumes. request a quote on custom sand castings, contact deeco metals, or email us at sales@deecometals.com to discuss your sand casting project. sand casting is a method of. Cast Iron Sand Casting.

From www.steel-foundry.com

Malleable Cast Iron Sand Casting Product Steel Casting Factory Cast Iron Foundry Cast Iron Sand Casting sand casting is the most common form of casting for ferrous metals (all metals that contain iron), with more. sand casting is hugely versatile and in many regards ideal for producing an unparalleled range of metal. The process is suitable for a wide range of production volumes. It is one of the oldest and most widely used casting.. Cast Iron Sand Casting.

From www.indiamart.com

Cast Iron Sand Casting at best price in Coimbatore by Senthur Industries ID 21552944033 Cast Iron Sand Casting sand casting is a metal casting process that uses sand as the primary molding material. It is one of the oldest and most widely used casting. request a quote on custom sand castings, contact deeco metals, or email us at sales@deecometals.com to discuss your sand casting project. sand casting is the most common form of casting for. Cast Iron Sand Casting.

From www.metals-casting.com

High Strength OEM Gray Cast Iron Sand Casting Cast Iron Sand Casting sand casting is hugely versatile and in many regards ideal for producing an unparalleled range of metal. sand casting is a method of producing metal pieces from a mold made of tightly packed and bonded “sand.” the mold is formed around a pattern and then molten metal is poured into the mold in order to produce the finished. Cast Iron Sand Casting.

From www.steel-foundry.com

Ductile Cast Iron Sand Castings Steel Casting Factory Cast Iron Foundry Cast Iron Sand Casting sand casting is a method of producing metal pieces from a mold made of tightly packed and bonded “sand.” the mold is formed around a pattern and then molten metal is poured into the mold in order to produce the finished part. The process is suitable for a wide range of production volumes. It is one of the oldest. Cast Iron Sand Casting.

From www.steel-foundry.com

Gray Cast Iron Casting Product by Sand Casting Steel Casting Factory Cast Iron Foundry Cast Iron Sand Casting sand casting is a method of producing metal pieces from a mold made of tightly packed and bonded “sand.” the mold is formed around a pattern and then molten metal is poured into the mold in order to produce the finished part. request a quote on custom sand castings, contact deeco metals, or email us at sales@deecometals.com to. Cast Iron Sand Casting.

From www.alibaba.com

Densen Customized Super Large Cast Iron Sand Casting Products,Large Casting Parts Or Sand Cast Iron Sand Casting sand casting is hugely versatile and in many regards ideal for producing an unparalleled range of metal. sand casting is the most common form of casting for ferrous metals (all metals that contain iron), with more. The process is suitable for a wide range of production volumes. It is one of the oldest and most widely used casting.. Cast Iron Sand Casting.

From www.weld2cast.com

Sand Casting Weld2Cast Cast Iron Sand Casting sand casting is the most common form of casting for ferrous metals (all metals that contain iron), with more. sand casting is a method of producing metal pieces from a mold made of tightly packed and bonded “sand.” the mold is formed around a pattern and then molten metal is poured into the mold in order to produce. Cast Iron Sand Casting.

From www.ruicicasting.com

Supply Ductile Iron GGG50 Hot Resin Large Cast Iron Metal Sand Casting Factory Quotes Dalian Cast Iron Sand Casting sand casting is a method of producing metal pieces from a mold made of tightly packed and bonded “sand.” the mold is formed around a pattern and then molten metal is poured into the mold in order to produce the finished part. It is one of the oldest and most widely used casting. sand casting is hugely versatile. Cast Iron Sand Casting.

From www.steel-foundry.com

Custom Cast Iron Sand Casting Steel Casting Factory Cast Iron Foundry Cast Iron Sand Casting It is one of the oldest and most widely used casting. sand casting is a method of producing metal pieces from a mold made of tightly packed and bonded “sand.” the mold is formed around a pattern and then molten metal is poured into the mold in order to produce the finished part. sand casting is the most. Cast Iron Sand Casting.

From www.steel-foundry.com

Custom Gray Cast Iron Sand Casting Steel Casting Factory Grey Iron Foundry Ductile Iron Cast Iron Sand Casting sand casting is a metal casting process that uses sand as the primary molding material. request a quote on custom sand castings, contact deeco metals, or email us at sales@deecometals.com to discuss your sand casting project. sand casting is a method of producing metal pieces from a mold made of tightly packed and bonded “sand.” the mold. Cast Iron Sand Casting.

From www.steel-foundry.com

Gray Cast Iron Sand Casting Product Steel Casting Factory Cast Iron Foundry Cast Iron Sand Casting sand casting is the most common form of casting for ferrous metals (all metals that contain iron), with more. sand casting is a method of producing metal pieces from a mold made of tightly packed and bonded “sand.” the mold is formed around a pattern and then molten metal is poured into the mold in order to produce. Cast Iron Sand Casting.

From www.directindustry.com

Castiron sand casting ZS Industries Co., Ltd aluminum / copper / agriculture Cast Iron Sand Casting sand casting is a method of producing metal pieces from a mold made of tightly packed and bonded “sand.” the mold is formed around a pattern and then molten metal is poured into the mold in order to produce the finished part. The process is suitable for a wide range of production volumes. sand casting is the most. Cast Iron Sand Casting.

From metals-casting.com

Ductile cast iron sand casting foundry Cast Iron Sand Casting sand casting is hugely versatile and in many regards ideal for producing an unparalleled range of metal. request a quote on custom sand castings, contact deeco metals, or email us at sales@deecometals.com to discuss your sand casting project. sand casting is a metal casting process that uses sand as the primary molding material. sand casting is. Cast Iron Sand Casting.

From www.alibaba.com

Densen Customized Super Large Cast Iron Sand Casting Products,Large Casting Parts Or Sand Cast Iron Sand Casting request a quote on custom sand castings, contact deeco metals, or email us at sales@deecometals.com to discuss your sand casting project. sand casting is a metal casting process that uses sand as the primary molding material. The process is suitable for a wide range of production volumes. sand casting is the most common form of casting for. Cast Iron Sand Casting.

From www.newayprecision.com

Cast Iron Cast Iron Sand Casting It is one of the oldest and most widely used casting. Best results are achieved with lower melting point alloys like cast iron and bronze. request a quote on custom sand castings, contact deeco metals, or email us at sales@deecometals.com to discuss your sand casting project. sand casting is hugely versatile and in many regards ideal for producing. Cast Iron Sand Casting.

From www.onallcylinders.com

Cast System An Inside Look at Edelbrock's Foundry and Casting Techniques OnAllCylinders Cast Iron Sand Casting The process is suitable for a wide range of production volumes. Best results are achieved with lower melting point alloys like cast iron and bronze. sand casting is a metal casting process that uses sand as the primary molding material. sand casting is the most common form of casting for ferrous metals (all metals that contain iron), with. Cast Iron Sand Casting.

From www.isaacbutterworth.co.uk

Sand Casting Isaac Butterworth (Iron Founders) Ltd. Cast Iron Sand Casting sand casting is the most common form of casting for ferrous metals (all metals that contain iron), with more. Best results are achieved with lower melting point alloys like cast iron and bronze. request a quote on custom sand castings, contact deeco metals, or email us at sales@deecometals.com to discuss your sand casting project. sand casting is. Cast Iron Sand Casting.

From www.iqsdirectory.com

Sand Casting Construction, Types, Applications, and Advantages Cast Iron Sand Casting sand casting is a metal casting process that uses sand as the primary molding material. sand casting is the most common form of casting for ferrous metals (all metals that contain iron), with more. Best results are achieved with lower melting point alloys like cast iron and bronze. sand casting is a method of producing metal pieces. Cast Iron Sand Casting.

From www.metals-casting.com

High Strength OEM Gray Cast Iron Sand Casting Cast Iron Sand Casting sand casting is hugely versatile and in many regards ideal for producing an unparalleled range of metal. sand casting is a metal casting process that uses sand as the primary molding material. The process is suitable for a wide range of production volumes. sand casting is the most common form of casting for ferrous metals (all metals. Cast Iron Sand Casting.

From www.steel-foundry.com

Resin Coated Sand Casting of Nodular Cast Iron Steel Casting Factory Grey Iron Foundry Cast Iron Sand Casting sand casting is a metal casting process that uses sand as the primary molding material. sand casting is a method of producing metal pieces from a mold made of tightly packed and bonded “sand.” the mold is formed around a pattern and then molten metal is poured into the mold in order to produce the finished part. . Cast Iron Sand Casting.

From www.weld2cast.com

Sand Casting Weld2Cast Cast Iron Sand Casting The process is suitable for a wide range of production volumes. sand casting is the most common form of casting for ferrous metals (all metals that contain iron), with more. sand casting is a method of producing metal pieces from a mold made of tightly packed and bonded “sand.” the mold is formed around a pattern and then. Cast Iron Sand Casting.