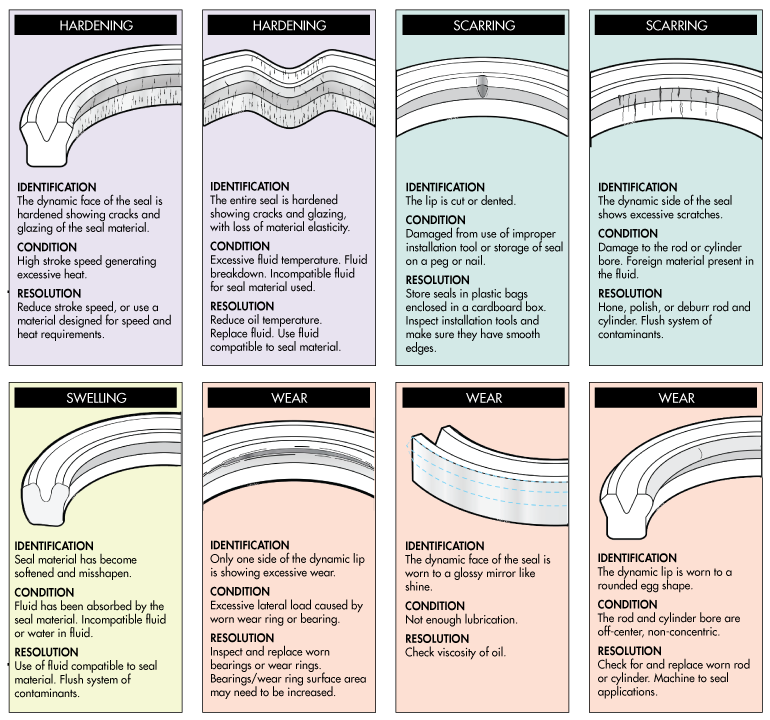

Hydraulic Cylinder Seal Failure The Main Causes . Seal failures can be caused by excessive heat, improper installation, contamination, and excessive pressure spikes, among other reasons. leaking seals lead to a loss of hydraulic pressure, reducing the cylinder’s performance. shown above and below are common examples of seal failures, and solutions on how to fix them. Inspect seals and gaskets regularly and replace them at the first sign of wear. Hardening results in cracks and loss of elasticity in seals, which ultimately leads to seal failure. Due to time of use or. To prevent hardening, reduce the stroke speed or temperature in the system if possible. Seals are critical in hydraulic cylinders,. when a hydraulic cylinder is not working, one of the first issues to look for is seal leakage. they react against the radial load caused by side loads acted upon the cylinder assembly.

from www.toparts.cc

shown above and below are common examples of seal failures, and solutions on how to fix them. leaking seals lead to a loss of hydraulic pressure, reducing the cylinder’s performance. when a hydraulic cylinder is not working, one of the first issues to look for is seal leakage. Inspect seals and gaskets regularly and replace them at the first sign of wear. Seals are critical in hydraulic cylinders,. Hardening results in cracks and loss of elasticity in seals, which ultimately leads to seal failure. Seal failures can be caused by excessive heat, improper installation, contamination, and excessive pressure spikes, among other reasons. Due to time of use or. To prevent hardening, reduce the stroke speed or temperature in the system if possible. they react against the radial load caused by side loads acted upon the cylinder assembly.

How to choose the right hydraulic cylinder seal kit

Hydraulic Cylinder Seal Failure The Main Causes leaking seals lead to a loss of hydraulic pressure, reducing the cylinder’s performance. shown above and below are common examples of seal failures, and solutions on how to fix them. Hardening results in cracks and loss of elasticity in seals, which ultimately leads to seal failure. they react against the radial load caused by side loads acted upon the cylinder assembly. To prevent hardening, reduce the stroke speed or temperature in the system if possible. leaking seals lead to a loss of hydraulic pressure, reducing the cylinder’s performance. when a hydraulic cylinder is not working, one of the first issues to look for is seal leakage. Inspect seals and gaskets regularly and replace them at the first sign of wear. Seals are critical in hydraulic cylinders,. Due to time of use or. Seal failures can be caused by excessive heat, improper installation, contamination, and excessive pressure spikes, among other reasons.

From www.dshseals.com

8 Common Reasons of Hydraulic Seals Failure and Solutions Hydraulic Cylinder Seal Failure The Main Causes Seals are critical in hydraulic cylinders,. Hardening results in cracks and loss of elasticity in seals, which ultimately leads to seal failure. when a hydraulic cylinder is not working, one of the first issues to look for is seal leakage. shown above and below are common examples of seal failures, and solutions on how to fix them. To. Hydraulic Cylinder Seal Failure The Main Causes.

From www.mechanical-knowledge.com

MECHANICAL SEALS FAILURE,CAUSES AND ITS REMEDIES Hydraulic Cylinder Seal Failure The Main Causes Due to time of use or. when a hydraulic cylinder is not working, one of the first issues to look for is seal leakage. Inspect seals and gaskets regularly and replace them at the first sign of wear. Seals are critical in hydraulic cylinders,. shown above and below are common examples of seal failures, and solutions on how. Hydraulic Cylinder Seal Failure The Main Causes.

From antares-global.com

The Primary Cause of Hydraulic System Failures Antares Engineering Services Hydraulic Cylinder Seal Failure The Main Causes Seals are critical in hydraulic cylinders,. To prevent hardening, reduce the stroke speed or temperature in the system if possible. Inspect seals and gaskets regularly and replace them at the first sign of wear. Seal failures can be caused by excessive heat, improper installation, contamination, and excessive pressure spikes, among other reasons. when a hydraulic cylinder is not working,. Hydraulic Cylinder Seal Failure The Main Causes.

From www.jxscmachine.com

9 Types Of Causes And Treatment Methods For Hydraulic System Failures JXSC Machine Hydraulic Cylinder Seal Failure The Main Causes Due to time of use or. To prevent hardening, reduce the stroke speed or temperature in the system if possible. they react against the radial load caused by side loads acted upon the cylinder assembly. Seal failures can be caused by excessive heat, improper installation, contamination, and excessive pressure spikes, among other reasons. when a hydraulic cylinder is. Hydraulic Cylinder Seal Failure The Main Causes.

From www.slideshare.net

The Top Causes of Seal Failure in Hydraulic Cylinders Hydraulic Cylinder Seal Failure The Main Causes they react against the radial load caused by side loads acted upon the cylinder assembly. Seal failures can be caused by excessive heat, improper installation, contamination, and excessive pressure spikes, among other reasons. when a hydraulic cylinder is not working, one of the first issues to look for is seal leakage. To prevent hardening, reduce the stroke speed. Hydraulic Cylinder Seal Failure The Main Causes.

From cylindersinc.com

9 Most Common Causes of Hydraulic Cylinder Failure Cylinders, Inc. Hydraulic Cylinder Seal Failure The Main Causes leaking seals lead to a loss of hydraulic pressure, reducing the cylinder’s performance. Inspect seals and gaskets regularly and replace them at the first sign of wear. Due to time of use or. To prevent hardening, reduce the stroke speed or temperature in the system if possible. shown above and below are common examples of seal failures, and. Hydraulic Cylinder Seal Failure The Main Causes.

From www.scribd.com

Mechanical Seals Failure,Causes and Its Remedies Bearing (Mechanical) Pump Hydraulic Cylinder Seal Failure The Main Causes Hardening results in cracks and loss of elasticity in seals, which ultimately leads to seal failure. they react against the radial load caused by side loads acted upon the cylinder assembly. leaking seals lead to a loss of hydraulic pressure, reducing the cylinder’s performance. when a hydraulic cylinder is not working, one of the first issues to. Hydraulic Cylinder Seal Failure The Main Causes.

From yorkpmh.com

Most Common Causes of Hydraulic Systems Failure YorkPMH Hydraulic Cylinder Seal Failure The Main Causes Hardening results in cracks and loss of elasticity in seals, which ultimately leads to seal failure. Seal failures can be caused by excessive heat, improper installation, contamination, and excessive pressure spikes, among other reasons. they react against the radial load caused by side loads acted upon the cylinder assembly. shown above and below are common examples of seal. Hydraulic Cylinder Seal Failure The Main Causes.

From rhkhydraulics.com

7 Common Causes Of Hydraulic Cylinder Failure Hydraulic Cylinder Seal Failure The Main Causes Due to time of use or. Seals are critical in hydraulic cylinders,. they react against the radial load caused by side loads acted upon the cylinder assembly. To prevent hardening, reduce the stroke speed or temperature in the system if possible. Inspect seals and gaskets regularly and replace them at the first sign of wear. shown above and. Hydraulic Cylinder Seal Failure The Main Causes.

From exovgcnjm.blob.core.windows.net

Mechanical Seal Failure Modes at Carol Anderson blog Hydraulic Cylinder Seal Failure The Main Causes they react against the radial load caused by side loads acted upon the cylinder assembly. shown above and below are common examples of seal failures, and solutions on how to fix them. Due to time of use or. Hardening results in cracks and loss of elasticity in seals, which ultimately leads to seal failure. Inspect seals and gaskets. Hydraulic Cylinder Seal Failure The Main Causes.

From www.liveabout.com

Symptoms of Master Cylinder Failure Hydraulic Cylinder Seal Failure The Main Causes when a hydraulic cylinder is not working, one of the first issues to look for is seal leakage. To prevent hardening, reduce the stroke speed or temperature in the system if possible. leaking seals lead to a loss of hydraulic pressure, reducing the cylinder’s performance. Due to time of use or. shown above and below are common. Hydraulic Cylinder Seal Failure The Main Causes.

From www.toparts.net

Common failures and analysis of hydraulic cylinder seals Hydraulic Cylinder Seal Failure The Main Causes when a hydraulic cylinder is not working, one of the first issues to look for is seal leakage. To prevent hardening, reduce the stroke speed or temperature in the system if possible. Hardening results in cracks and loss of elasticity in seals, which ultimately leads to seal failure. shown above and below are common examples of seal failures,. Hydraulic Cylinder Seal Failure The Main Causes.

From www.parjetseals.com

5 Common Causes of Hydraulic Seal Failure and Ways to prevent|Advanced Sealing Solution Provider Hydraulic Cylinder Seal Failure The Main Causes they react against the radial load caused by side loads acted upon the cylinder assembly. To prevent hardening, reduce the stroke speed or temperature in the system if possible. leaking seals lead to a loss of hydraulic pressure, reducing the cylinder’s performance. Hardening results in cracks and loss of elasticity in seals, which ultimately leads to seal failure.. Hydraulic Cylinder Seal Failure The Main Causes.

From www.youtube.com

Repair FAILED Hydraulic Cylinder Part 1 Making a New Barrel YouTube Hydraulic Cylinder Seal Failure The Main Causes Seal failures can be caused by excessive heat, improper installation, contamination, and excessive pressure spikes, among other reasons. To prevent hardening, reduce the stroke speed or temperature in the system if possible. Inspect seals and gaskets regularly and replace them at the first sign of wear. Due to time of use or. when a hydraulic cylinder is not working,. Hydraulic Cylinder Seal Failure The Main Causes.

From www.hydrauliccylindersinc.com

Top 4 Causes of Hydraulic Cylinder Failure Hydraulic Cylinders, Inc. Hydraulic Cylinder Seal Failure The Main Causes Seal failures can be caused by excessive heat, improper installation, contamination, and excessive pressure spikes, among other reasons. when a hydraulic cylinder is not working, one of the first issues to look for is seal leakage. Seals are critical in hydraulic cylinders,. leaking seals lead to a loss of hydraulic pressure, reducing the cylinder’s performance. Hardening results in. Hydraulic Cylinder Seal Failure The Main Causes.

From dxojwpdmy.blob.core.windows.net

How To Change A Hydraulic Cylinder Seal at Theodore Johnson blog Hydraulic Cylinder Seal Failure The Main Causes Due to time of use or. leaking seals lead to a loss of hydraulic pressure, reducing the cylinder’s performance. shown above and below are common examples of seal failures, and solutions on how to fix them. Seals are critical in hydraulic cylinders,. Hardening results in cracks and loss of elasticity in seals, which ultimately leads to seal failure.. Hydraulic Cylinder Seal Failure The Main Causes.

From www.toparts.cc

How to choose the right hydraulic cylinder seal kit Hydraulic Cylinder Seal Failure The Main Causes they react against the radial load caused by side loads acted upon the cylinder assembly. Seals are critical in hydraulic cylinders,. when a hydraulic cylinder is not working, one of the first issues to look for is seal leakage. Inspect seals and gaskets regularly and replace them at the first sign of wear. To prevent hardening, reduce the. Hydraulic Cylinder Seal Failure The Main Causes.

From exoehkkpk.blob.core.windows.net

Hydraulic Cylinder Piston Damage at Cornelius Cleary blog Hydraulic Cylinder Seal Failure The Main Causes Due to time of use or. they react against the radial load caused by side loads acted upon the cylinder assembly. Seal failures can be caused by excessive heat, improper installation, contamination, and excessive pressure spikes, among other reasons. when a hydraulic cylinder is not working, one of the first issues to look for is seal leakage. Hardening. Hydraulic Cylinder Seal Failure The Main Causes.

From gohydraulics.ca

Reasons of Hydraulic Cylinder Failure Hydraulic Cylinder Repair Hydraulic Cylinder Seal Failure The Main Causes Due to time of use or. shown above and below are common examples of seal failures, and solutions on how to fix them. Seal failures can be caused by excessive heat, improper installation, contamination, and excessive pressure spikes, among other reasons. leaking seals lead to a loss of hydraulic pressure, reducing the cylinder’s performance. Hardening results in cracks. Hydraulic Cylinder Seal Failure The Main Causes.

From innovationdiscoveries.space

Master Cylinder Failure Symptoms Clutch Hydraulic Cylinder Seal Failure The Main Causes To prevent hardening, reduce the stroke speed or temperature in the system if possible. Inspect seals and gaskets regularly and replace them at the first sign of wear. they react against the radial load caused by side loads acted upon the cylinder assembly. Seal failures can be caused by excessive heat, improper installation, contamination, and excessive pressure spikes, among. Hydraulic Cylinder Seal Failure The Main Causes.

From gohydraulics.ca

Reasons Behind Hydraulic Cylinder Failure Go Hydraulics Hydraulic Cylinder Seal Failure The Main Causes Seals are critical in hydraulic cylinders,. Due to time of use or. To prevent hardening, reduce the stroke speed or temperature in the system if possible. Inspect seals and gaskets regularly and replace them at the first sign of wear. shown above and below are common examples of seal failures, and solutions on how to fix them. they. Hydraulic Cylinder Seal Failure The Main Causes.

From cylindersinc.com

9 Most Common Causes of Hydraulic Cylinder Failure Cylinders, Inc. Hydraulic Cylinder Seal Failure The Main Causes leaking seals lead to a loss of hydraulic pressure, reducing the cylinder’s performance. Seals are critical in hydraulic cylinders,. To prevent hardening, reduce the stroke speed or temperature in the system if possible. Inspect seals and gaskets regularly and replace them at the first sign of wear. they react against the radial load caused by side loads acted. Hydraulic Cylinder Seal Failure The Main Causes.

From connect2local.com

5 Frequent Causes of Hydraulic Cylinder Failure LWG Finishing Hydraulic Cylinder Seal Failure The Main Causes Hardening results in cracks and loss of elasticity in seals, which ultimately leads to seal failure. Due to time of use or. Seal failures can be caused by excessive heat, improper installation, contamination, and excessive pressure spikes, among other reasons. Seals are critical in hydraulic cylinders,. they react against the radial load caused by side loads acted upon the. Hydraulic Cylinder Seal Failure The Main Causes.

From dokumen.tips

(PDF) Applied Failure Analysis Hydraulic Cylinder Seal Failure Analysis DOKUMEN.TIPS Hydraulic Cylinder Seal Failure The Main Causes Inspect seals and gaskets regularly and replace them at the first sign of wear. they react against the radial load caused by side loads acted upon the cylinder assembly. shown above and below are common examples of seal failures, and solutions on how to fix them. Hardening results in cracks and loss of elasticity in seals, which ultimately. Hydraulic Cylinder Seal Failure The Main Causes.

From www.choongngaiengineering.com

Symptoms of Hydraulic Cylinder Failure Hydraulic Cylinder Seal Failure The Main Causes Inspect seals and gaskets regularly and replace them at the first sign of wear. leaking seals lead to a loss of hydraulic pressure, reducing the cylinder’s performance. they react against the radial load caused by side loads acted upon the cylinder assembly. shown above and below are common examples of seal failures, and solutions on how to. Hydraulic Cylinder Seal Failure The Main Causes.

From www.millerhydraulic.com

Hydraulic Seal Failure Miller Hydraulic Hydraulic Cylinder Seal Failure The Main Causes when a hydraulic cylinder is not working, one of the first issues to look for is seal leakage. Seal failures can be caused by excessive heat, improper installation, contamination, and excessive pressure spikes, among other reasons. leaking seals lead to a loss of hydraulic pressure, reducing the cylinder’s performance. Hardening results in cracks and loss of elasticity in. Hydraulic Cylinder Seal Failure The Main Causes.

From www.sviinternational.com

Hydraulic Cylinder Seal Replacement Procedure SVI International, Inc. Hydraulic Cylinder Seal Failure The Main Causes Hardening results in cracks and loss of elasticity in seals, which ultimately leads to seal failure. Seal failures can be caused by excessive heat, improper installation, contamination, and excessive pressure spikes, among other reasons. To prevent hardening, reduce the stroke speed or temperature in the system if possible. Due to time of use or. Inspect seals and gaskets regularly and. Hydraulic Cylinder Seal Failure The Main Causes.

From www.peninsularcylinders.com

Testing Hydraulic Cylinder Goes Wrong Fire Erupts Hydraulic Cylinder Seal Failure The Main Causes they react against the radial load caused by side loads acted upon the cylinder assembly. Inspect seals and gaskets regularly and replace them at the first sign of wear. Hardening results in cracks and loss of elasticity in seals, which ultimately leads to seal failure. leaking seals lead to a loss of hydraulic pressure, reducing the cylinder’s performance.. Hydraulic Cylinder Seal Failure The Main Causes.

From www.selfgrowth.com

What are the Reasons why Hydraulic Cylinder Seals Often Fail? Hydraulic Cylinder Seal Failure The Main Causes they react against the radial load caused by side loads acted upon the cylinder assembly. leaking seals lead to a loss of hydraulic pressure, reducing the cylinder’s performance. To prevent hardening, reduce the stroke speed or temperature in the system if possible. Seal failures can be caused by excessive heat, improper installation, contamination, and excessive pressure spikes, among. Hydraulic Cylinder Seal Failure The Main Causes.

From www.quadfluiddynamics.com

3 Main Reasons Why Your Hydraulic Cylinder Seals Fail Prematurely Hydraulic Cylinder Seal Failure The Main Causes shown above and below are common examples of seal failures, and solutions on how to fix them. To prevent hardening, reduce the stroke speed or temperature in the system if possible. Inspect seals and gaskets regularly and replace them at the first sign of wear. when a hydraulic cylinder is not working, one of the first issues to. Hydraulic Cylinder Seal Failure The Main Causes.

From www.sealingandcontaminationtips.com

5 common failures of hydraulic cylinder seals Sealing & Contamination Control Tips Hydraulic Cylinder Seal Failure The Main Causes shown above and below are common examples of seal failures, and solutions on how to fix them. Seal failures can be caused by excessive heat, improper installation, contamination, and excessive pressure spikes, among other reasons. Hardening results in cracks and loss of elasticity in seals, which ultimately leads to seal failure. when a hydraulic cylinder is not working,. Hydraulic Cylinder Seal Failure The Main Causes.

From www.svks-rubberseal.com

What are the causes of the failure of hydraulic seals? KNOWLEDGE Tianjin SWKS Technology Hydraulic Cylinder Seal Failure The Main Causes Due to time of use or. shown above and below are common examples of seal failures, and solutions on how to fix them. when a hydraulic cylinder is not working, one of the first issues to look for is seal leakage. leaking seals lead to a loss of hydraulic pressure, reducing the cylinder’s performance. Hardening results in. Hydraulic Cylinder Seal Failure The Main Causes.

From www.powermotiontech.com

7 Common Failures of Hydraulic Seals Power & Motion Hydraulic Cylinder Seal Failure The Main Causes Due to time of use or. Seals are critical in hydraulic cylinders,. shown above and below are common examples of seal failures, and solutions on how to fix them. Seal failures can be caused by excessive heat, improper installation, contamination, and excessive pressure spikes, among other reasons. To prevent hardening, reduce the stroke speed or temperature in the system. Hydraulic Cylinder Seal Failure The Main Causes.

From www.newequipment.com

7 Common Failures of Hydraulic Seals New Equipment Digest Hydraulic Cylinder Seal Failure The Main Causes Seal failures can be caused by excessive heat, improper installation, contamination, and excessive pressure spikes, among other reasons. Seals are critical in hydraulic cylinders,. shown above and below are common examples of seal failures, and solutions on how to fix them. Due to time of use or. leaking seals lead to a loss of hydraulic pressure, reducing the. Hydraulic Cylinder Seal Failure The Main Causes.

From www.applerubber.com

The Most Common Causes of Hydraulic Seal Failure and How to Stop It Official Apple Rubber Blog Hydraulic Cylinder Seal Failure The Main Causes Seals are critical in hydraulic cylinders,. Inspect seals and gaskets regularly and replace them at the first sign of wear. Hardening results in cracks and loss of elasticity in seals, which ultimately leads to seal failure. they react against the radial load caused by side loads acted upon the cylinder assembly. Due to time of use or. To prevent. Hydraulic Cylinder Seal Failure The Main Causes.