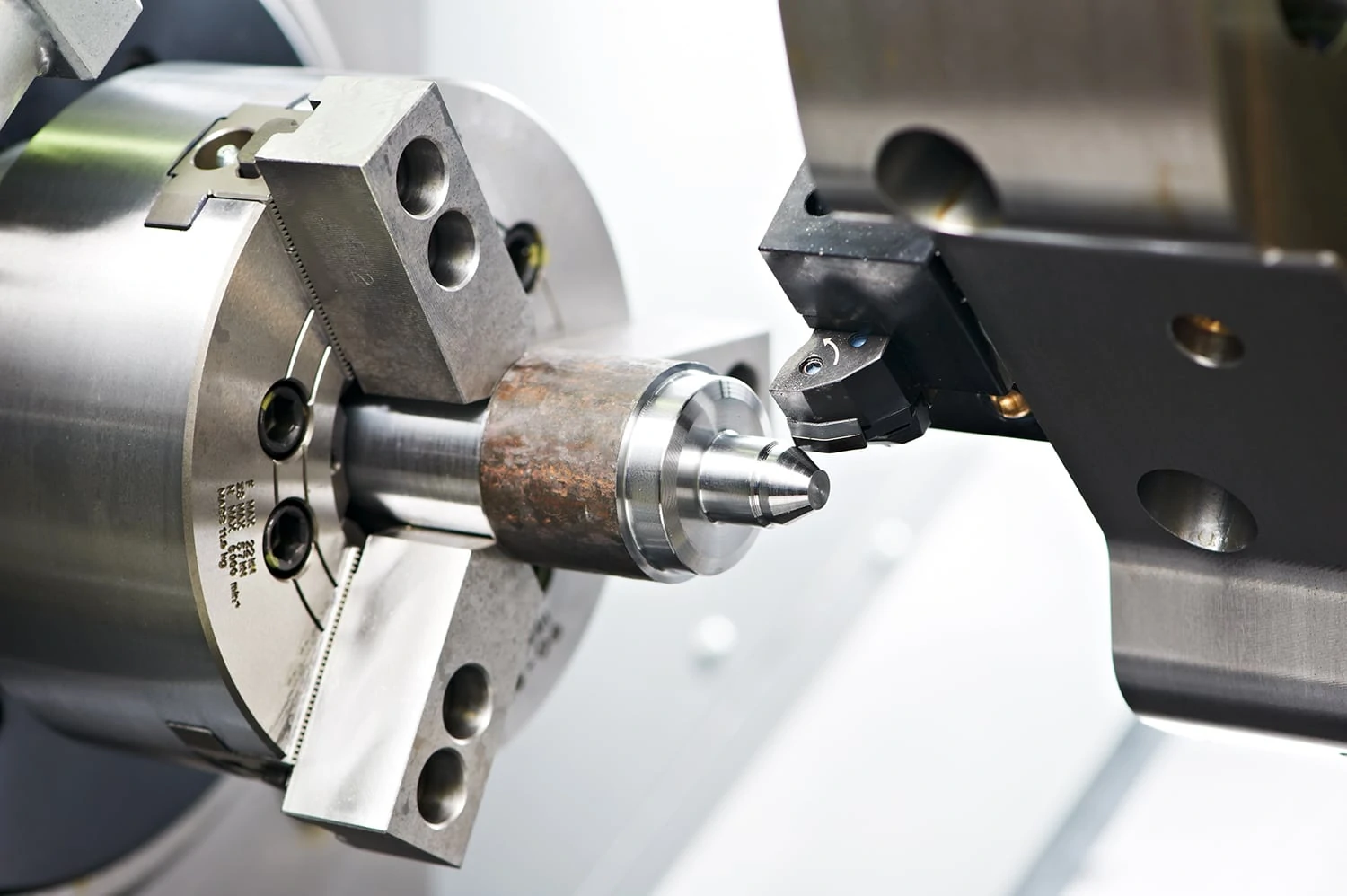

Work Holding Devices On A Lathe . Closely related terms are “jigs” and “fixtures.” a fixture holds your workpiece while it is being cut. work holding devices in lathe machine common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. this guide provides a comprehensive overview of the different work holding methods used on lathe machines, including chucks, collets,. These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations. Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw. It involves using various devices and methods to hold the workpiece in a fixed position and orientation while it is being machined. workholding plays a critical role in any machining process. workholding refers to any apparatus employed to securely grip your workpiece during its machining on the cnc machine. workholding in cnc machining refers to the practice of securing a workpiece against the forces generated during machining operations. one of the most popular ways to hold work on in a lathe is by using chucks or jaw chucks. chucks are probably the most widely adopted type of workholding device on the lathe. Here's an overview of the main workholding devices that every job shop should have. A jig holds the workpiece and also guides the cutter.

from dxooovlin.blob.core.windows.net

work holding devices in lathe machine common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. Closely related terms are “jigs” and “fixtures.” a fixture holds your workpiece while it is being cut. workholding in cnc machining refers to the practice of securing a workpiece against the forces generated during machining operations. A jig holds the workpiece and also guides the cutter. one of the most popular ways to hold work on in a lathe is by using chucks or jaw chucks. workholding refers to any apparatus employed to securely grip your workpiece during its machining on the cnc machine. workholding plays a critical role in any machining process. These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations. this guide provides a comprehensive overview of the different work holding methods used on lathe machines, including chucks, collets,. chucks are probably the most widely adopted type of workholding device on the lathe.

Methods Of Holding Work In Lathe Machine at Jerome Hedges blog

Work Holding Devices On A Lathe workholding refers to any apparatus employed to securely grip your workpiece during its machining on the cnc machine. A jig holds the workpiece and also guides the cutter. workholding in cnc machining refers to the practice of securing a workpiece against the forces generated during machining operations. chucks are probably the most widely adopted type of workholding device on the lathe. workholding refers to any apparatus employed to securely grip your workpiece during its machining on the cnc machine. Here's an overview of the main workholding devices that every job shop should have. this guide provides a comprehensive overview of the different work holding methods used on lathe machines, including chucks, collets,. These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations. Closely related terms are “jigs” and “fixtures.” a fixture holds your workpiece while it is being cut. workholding plays a critical role in any machining process. work holding devices in lathe machine common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw. one of the most popular ways to hold work on in a lathe is by using chucks or jaw chucks. It involves using various devices and methods to hold the workpiece in a fixed position and orientation while it is being machined.

From toolnotes.com

Lathe Workholding ToolNotes Work Holding Devices On A Lathe Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw. chucks are probably the most widely adopted type of workholding device on the lathe. one of the most popular ways to hold work on in a lathe is by using chucks or jaw chucks. These tools serve as work holding devices, each with specific. Work Holding Devices On A Lathe.

From toolnotes.com

Lathe Workholding ToolNotes Work Holding Devices On A Lathe workholding refers to any apparatus employed to securely grip your workpiece during its machining on the cnc machine. workholding in cnc machining refers to the practice of securing a workpiece against the forces generated during machining operations. Closely related terms are “jigs” and “fixtures.” a fixture holds your workpiece while it is being cut. Here's an overview of. Work Holding Devices On A Lathe.

From www.slideserve.com

PPT Work Holding and Tool Holding PowerPoint Presentation, free download ID5586120 Work Holding Devices On A Lathe Closely related terms are “jigs” and “fixtures.” a fixture holds your workpiece while it is being cut. one of the most popular ways to hold work on in a lathe is by using chucks or jaw chucks. These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations. . Work Holding Devices On A Lathe.

From www.youtube.com

4/7 Work holding Devices for Lathes Lathe Machine ASKAzad YouTube Work Holding Devices On A Lathe work holding devices in lathe machine common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw. workholding in cnc machining refers to the practice of securing a workpiece against the forces generated during machining operations. These tools serve. Work Holding Devices On A Lathe.

From www.youtube.com

Lathe Work Holding Devices Types Chucks Part1 YouTube Work Holding Devices On A Lathe workholding in cnc machining refers to the practice of securing a workpiece against the forces generated during machining operations. Closely related terms are “jigs” and “fixtures.” a fixture holds your workpiece while it is being cut. workholding plays a critical role in any machining process. A jig holds the workpiece and also guides the cutter. It involves using. Work Holding Devices On A Lathe.

From www.youtube.com

Lathe Work Holding Devices Types Of Chucks Part2 YouTube Work Holding Devices On A Lathe It involves using various devices and methods to hold the workpiece in a fixed position and orientation while it is being machined. Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw. Here's an overview of the main workholding devices that every job shop should have. A jig holds the workpiece and also guides the cutter.. Work Holding Devices On A Lathe.

From www.youtube.com

Work and Tool Holding in the Metal Lathe YouTube Work Holding Devices On A Lathe one of the most popular ways to hold work on in a lathe is by using chucks or jaw chucks. A jig holds the workpiece and also guides the cutter. It involves using various devices and methods to hold the workpiece in a fixed position and orientation while it is being machined. Closely related terms are “jigs” and “fixtures.”. Work Holding Devices On A Lathe.

From www.youtube.com

5 Work Holding Devices in Semi automatic Lathes Jaw Chucks and Collet Chucks I Their Working Work Holding Devices On A Lathe chucks are probably the most widely adopted type of workholding device on the lathe. These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations. It involves using various devices and methods to hold the workpiece in a fixed position and orientation while it is being machined. Chucks can. Work Holding Devices On A Lathe.

From www.youtube.com

Metal Lathe 121 Work Holding Intro, Safety, and Tool Force YouTube Work Holding Devices On A Lathe workholding in cnc machining refers to the practice of securing a workpiece against the forces generated during machining operations. These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations. this guide provides a comprehensive overview of the different work holding methods used on lathe machines, including chucks,. Work Holding Devices On A Lathe.

From www.slideshare.net

Work holding devices of lathe PPT Work Holding Devices On A Lathe chucks are probably the most widely adopted type of workholding device on the lathe. Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw. one of the most popular ways to hold work on in a lathe is by using chucks or jaw chucks. workholding in cnc machining refers to the practice of. Work Holding Devices On A Lathe.

From toolnotes.com

Lathe Workholding ToolNotes Work Holding Devices On A Lathe work holding devices in lathe machine common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. workholding in cnc machining refers to the practice of securing a workpiece against the forces generated during machining operations. These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece. Work Holding Devices On A Lathe.

From dxooovlin.blob.core.windows.net

Methods Of Holding Work In Lathe Machine at Jerome Hedges blog Work Holding Devices On A Lathe A jig holds the workpiece and also guides the cutter. workholding refers to any apparatus employed to securely grip your workpiece during its machining on the cnc machine. chucks are probably the most widely adopted type of workholding device on the lathe. Closely related terms are “jigs” and “fixtures.” a fixture holds your workpiece while it is being. Work Holding Devices On A Lathe.

From www.slideserve.com

PPT Introduction to the Lathe Machine PowerPoint Presentation, free download ID2263887 Work Holding Devices On A Lathe work holding devices in lathe machine common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw. chucks are probably the most widely adopted type of workholding device on the lathe. A jig holds the workpiece and also guides. Work Holding Devices On A Lathe.

From informacionpublica.svet.gob.gt

Work Holding Devices Of Capstan Lathe Types Of Chucks Work Holding Devices On A Lathe Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw. one of the most popular ways to hold work on in a lathe is by using chucks or jaw chucks. workholding in cnc machining refers to the practice of securing a workpiece against the forces generated during machining operations. workholding refers to any. Work Holding Devices On A Lathe.

From toolnotes.com

Lathe Workholding ToolNotes Work Holding Devices On A Lathe this guide provides a comprehensive overview of the different work holding methods used on lathe machines, including chucks, collets,. Closely related terms are “jigs” and “fixtures.” a fixture holds your workpiece while it is being cut. These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations. It involves. Work Holding Devices On A Lathe.

From news.thomasnet.com

Genius Vise Is Smartest New Workholding Device for Precision 5Axis Milling Work Holding Devices On A Lathe It involves using various devices and methods to hold the workpiece in a fixed position and orientation while it is being machined. work holding devices in lathe machine common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw. . Work Holding Devices On A Lathe.

From seisanzai-japan.com

Machining 08 What are work holding devices? Industry and Manufacturing News Archive Work Holding Devices On A Lathe workholding plays a critical role in any machining process. chucks are probably the most widely adopted type of workholding device on the lathe. this guide provides a comprehensive overview of the different work holding methods used on lathe machines, including chucks, collets,. A jig holds the workpiece and also guides the cutter. These tools serve as work. Work Holding Devices On A Lathe.

From www.youtube.com

Work and Tool Holding Devices for Lathes YouTube Work Holding Devices On A Lathe It involves using various devices and methods to hold the workpiece in a fixed position and orientation while it is being machined. workholding plays a critical role in any machining process. chucks are probably the most widely adopted type of workholding device on the lathe. Here's an overview of the main workholding devices that every job shop should. Work Holding Devices On A Lathe.

From www.youtube.com

Lathe Tutorial P 7 Work Holding YouTube Work Holding Devices On A Lathe workholding in cnc machining refers to the practice of securing a workpiece against the forces generated during machining operations. workholding plays a critical role in any machining process. chucks are probably the most widely adopted type of workholding device on the lathe. A jig holds the workpiece and also guides the cutter. this guide provides a. Work Holding Devices On A Lathe.

From informacionpublica.svet.gob.gt

Work Holding Devices In Lathe Machine Technology Work Holding Devices On A Lathe It involves using various devices and methods to hold the workpiece in a fixed position and orientation while it is being machined. one of the most popular ways to hold work on in a lathe is by using chucks or jaw chucks. this guide provides a comprehensive overview of the different work holding methods used on lathe machines,. Work Holding Devices On A Lathe.

From www.fastradius.com

Workholding for CNC Manufacturing Resources Fast Radius Work Holding Devices On A Lathe this guide provides a comprehensive overview of the different work holding methods used on lathe machines, including chucks, collets,. one of the most popular ways to hold work on in a lathe is by using chucks or jaw chucks. work holding devices in lathe machine common accessories for a lathe machine include chuck, face plate, lathe centers,. Work Holding Devices On A Lathe.

From www.hvrmagnet.com

Workholding for Lathe/Grinding/Milling/CNC Machining Centers Work Holding Devices On A Lathe one of the most popular ways to hold work on in a lathe is by using chucks or jaw chucks. workholding refers to any apparatus employed to securely grip your workpiece during its machining on the cnc machine. It involves using various devices and methods to hold the workpiece in a fixed position and orientation while it is. Work Holding Devices On A Lathe.

From toolnotes.com

Lathe Workholding ToolNotes Work Holding Devices On A Lathe workholding in cnc machining refers to the practice of securing a workpiece against the forces generated during machining operations. These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations. A jig holds the workpiece and also guides the cutter. It involves using various devices and methods to hold. Work Holding Devices On A Lathe.

From toolsonblog.blogspot.com

Work Holding Devices on Lathe Tools on Blog Work Holding Devices On A Lathe this guide provides a comprehensive overview of the different work holding methods used on lathe machines, including chucks, collets,. workholding refers to any apparatus employed to securely grip your workpiece during its machining on the cnc machine. These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations.. Work Holding Devices On A Lathe.

From www.mechical.com

Work Holding Devices in Lathe Machine and Their Types Work Holding Devices On A Lathe Closely related terms are “jigs” and “fixtures.” a fixture holds your workpiece while it is being cut. Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw. chucks are probably the most widely adopted type of workholding device on the lathe. These tools serve as work holding devices, each with specific functions in securing and. Work Holding Devices On A Lathe.

From slideplayer.com

Basic Mechanical Engineering 15ME101 Part2 Unit IVV ppt download Work Holding Devices On A Lathe work holding devices in lathe machine common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. Here's an overview of the main workholding devices that every job shop should have. one of the most popular ways to hold work on in a lathe is by using chucks or jaw chucks. A jig. Work Holding Devices On A Lathe.

From toolnotes.com

Lathe Workholding ToolNotes Work Holding Devices On A Lathe workholding plays a critical role in any machining process. A jig holds the workpiece and also guides the cutter. chucks are probably the most widely adopted type of workholding device on the lathe. workholding refers to any apparatus employed to securely grip your workpiece during its machining on the cnc machine. this guide provides a comprehensive. Work Holding Devices On A Lathe.

From www.slideserve.com

PPT Introduction to the Lathe Machine PowerPoint Presentation, free download ID2263887 Work Holding Devices On A Lathe A jig holds the workpiece and also guides the cutter. These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations. one of the most popular ways to hold work on in a lathe is by using chucks or jaw chucks. workholding refers to any apparatus employed to. Work Holding Devices On A Lathe.

From www.abmtools.com

Work Holding Devices ABM Tools Work Holding Devices On A Lathe workholding plays a critical role in any machining process. Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw. work holding devices in lathe machine common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. chucks are probably the most widely adopted type of workholding device on. Work Holding Devices On A Lathe.

From www.youtube.com

Work holding Devices for Lathes Lathe Machine A.S.K.Azad Mechanical Engineering YouTube Work Holding Devices On A Lathe this guide provides a comprehensive overview of the different work holding methods used on lathe machines, including chucks, collets,. Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw. Here's an overview of the main workholding devices that every job shop should have. work holding devices in lathe machine common accessories for a lathe. Work Holding Devices On A Lathe.

From www.scribd.com

27 Lathe Work Holding Devices Download Free PDF Tools Metalworking Work Holding Devices On A Lathe It involves using various devices and methods to hold the workpiece in a fixed position and orientation while it is being machined. work holding devices in lathe machine common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw. . Work Holding Devices On A Lathe.

From www.slideserve.com

PPT Introduction to the Lathe Machine PowerPoint Presentation ID2263887 Work Holding Devices On A Lathe this guide provides a comprehensive overview of the different work holding methods used on lathe machines, including chucks, collets,. Closely related terms are “jigs” and “fixtures.” a fixture holds your workpiece while it is being cut. A jig holds the workpiece and also guides the cutter. workholding refers to any apparatus employed to securely grip your workpiece during. Work Holding Devices On A Lathe.

From toolnotes.com

Lathe Workholding ToolNotes Work Holding Devices On A Lathe Closely related terms are “jigs” and “fixtures.” a fixture holds your workpiece while it is being cut. Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw. workholding in cnc machining refers to the practice of securing a workpiece against the forces generated during machining operations. work holding devices in lathe machine common accessories. Work Holding Devices On A Lathe.

From www.highlandwoodworking.com

Methods of Workholding for Woodturning Work Holding Devices On A Lathe workholding in cnc machining refers to the practice of securing a workpiece against the forces generated during machining operations. workholding plays a critical role in any machining process. chucks are probably the most widely adopted type of workholding device on the lathe. Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw. Closely. Work Holding Devices On A Lathe.

From toolnotes.com

Lathe Workholding ToolNotes Work Holding Devices On A Lathe Closely related terms are “jigs” and “fixtures.” a fixture holds your workpiece while it is being cut. this guide provides a comprehensive overview of the different work holding methods used on lathe machines, including chucks, collets,. chucks are probably the most widely adopted type of workholding device on the lathe. It involves using various devices and methods to. Work Holding Devices On A Lathe.