What Are The Three Main Categories Of Waste In Lean . Originally there were seven wastes identified by taiichi ohno for the toyota production system. Lean principles emphasize the importance of continuous flow and aim to eliminate waiting to enhance overall operational efficiency. In lean thinking, the primary sources of waste are broken down into what we refer to as the 8 wastes of lean. The 8 wastes in lean manufacturing are: This article will explore the most common sources of waste in any organization. By the end of this article, you will have a clear understanding of each of the 8. The eight wastes of lean. Addressing the waste of waiting involves. We’ll also explore the benefits of identifying and eliminating waste, provide an example of how one organization approached this issue, and then present some best practices for undertaking this effort.

from insights.sei.cmu.edu

Lean principles emphasize the importance of continuous flow and aim to eliminate waiting to enhance overall operational efficiency. Addressing the waste of waiting involves. The eight wastes of lean. In lean thinking, the primary sources of waste are broken down into what we refer to as the 8 wastes of lean. By the end of this article, you will have a clear understanding of each of the 8. Originally there were seven wastes identified by taiichi ohno for the toyota production system. The 8 wastes in lean manufacturing are: We’ll also explore the benefits of identifying and eliminating waste, provide an example of how one organization approached this issue, and then present some best practices for undertaking this effort. This article will explore the most common sources of waste in any organization.

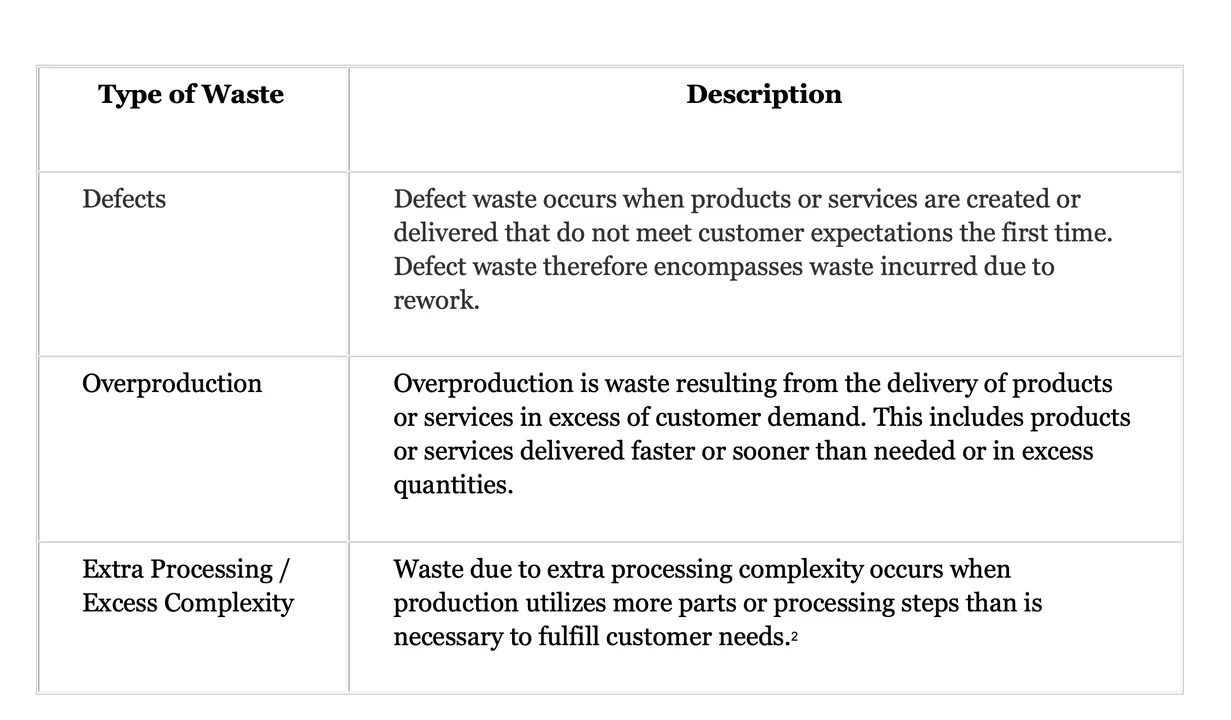

Lean Principles and Software Architecture Categories of Waste

What Are The Three Main Categories Of Waste In Lean By the end of this article, you will have a clear understanding of each of the 8. We’ll also explore the benefits of identifying and eliminating waste, provide an example of how one organization approached this issue, and then present some best practices for undertaking this effort. Lean principles emphasize the importance of continuous flow and aim to eliminate waiting to enhance overall operational efficiency. By the end of this article, you will have a clear understanding of each of the 8. Originally there were seven wastes identified by taiichi ohno for the toyota production system. In lean thinking, the primary sources of waste are broken down into what we refer to as the 8 wastes of lean. Addressing the waste of waiting involves. This article will explore the most common sources of waste in any organization. The eight wastes of lean. The 8 wastes in lean manufacturing are:

From sixsigmadsi.com

What Are The 8 Wastes of Lean? What Are The Three Main Categories Of Waste In Lean The 8 wastes in lean manufacturing are: Addressing the waste of waiting involves. Originally there were seven wastes identified by taiichi ohno for the toyota production system. In lean thinking, the primary sources of waste are broken down into what we refer to as the 8 wastes of lean. This article will explore the most common sources of waste in. What Are The Three Main Categories Of Waste In Lean.

From blog.unex.com

What is Lean Waste? [The 7 Wastes of Lean Manufacturing] What Are The Three Main Categories Of Waste In Lean In lean thinking, the primary sources of waste are broken down into what we refer to as the 8 wastes of lean. Originally there were seven wastes identified by taiichi ohno for the toyota production system. This article will explore the most common sources of waste in any organization. Addressing the waste of waiting involves. The eight wastes of lean.. What Are The Three Main Categories Of Waste In Lean.

From klargtcqg.blob.core.windows.net

What Are Examples Of Garbage at Daniel Reuter blog What Are The Three Main Categories Of Waste In Lean This article will explore the most common sources of waste in any organization. Originally there were seven wastes identified by taiichi ohno for the toyota production system. The eight wastes of lean. Addressing the waste of waiting involves. The 8 wastes in lean manufacturing are: We’ll also explore the benefits of identifying and eliminating waste, provide an example of how. What Are The Three Main Categories Of Waste In Lean.

From www.huimfg.com

8 Wastes of Lean Manufacturing Downtime Infographic What Are The Three Main Categories Of Waste In Lean We’ll also explore the benefits of identifying and eliminating waste, provide an example of how one organization approached this issue, and then present some best practices for undertaking this effort. Lean principles emphasize the importance of continuous flow and aim to eliminate waiting to enhance overall operational efficiency. In lean thinking, the primary sources of waste are broken down into. What Are The Three Main Categories Of Waste In Lean.

From www.creativesafetysupply.com

The 8 Wastes of Lean Poster (White) What Are The Three Main Categories Of Waste In Lean Lean principles emphasize the importance of continuous flow and aim to eliminate waiting to enhance overall operational efficiency. We’ll also explore the benefits of identifying and eliminating waste, provide an example of how one organization approached this issue, and then present some best practices for undertaking this effort. Addressing the waste of waiting involves. The eight wastes of lean. In. What Are The Three Main Categories Of Waste In Lean.

From www.lean.org

What are the 7 Wastes in Lean? Lean Enterprise Institute What Are The Three Main Categories Of Waste In Lean Originally there were seven wastes identified by taiichi ohno for the toyota production system. In lean thinking, the primary sources of waste are broken down into what we refer to as the 8 wastes of lean. The 8 wastes in lean manufacturing are: Lean principles emphasize the importance of continuous flow and aim to eliminate waiting to enhance overall operational. What Are The Three Main Categories Of Waste In Lean.

From www.nuweiqserv.com

Lean Tool Elimination Waste What Are The Three Main Categories Of Waste In Lean Addressing the waste of waiting involves. Originally there were seven wastes identified by taiichi ohno for the toyota production system. In lean thinking, the primary sources of waste are broken down into what we refer to as the 8 wastes of lean. We’ll also explore the benefits of identifying and eliminating waste, provide an example of how one organization approached. What Are The Three Main Categories Of Waste In Lean.

From flevy.com

Dump the Waste! What Are The Three Main Categories Of Waste In Lean Addressing the waste of waiting involves. We’ll also explore the benefits of identifying and eliminating waste, provide an example of how one organization approached this issue, and then present some best practices for undertaking this effort. By the end of this article, you will have a clear understanding of each of the 8. The 8 wastes in lean manufacturing are:. What Are The Three Main Categories Of Waste In Lean.

From insights.sei.cmu.edu

Lean Principles and Software Architecture Categories of Waste What Are The Three Main Categories Of Waste In Lean In lean thinking, the primary sources of waste are broken down into what we refer to as the 8 wastes of lean. We’ll also explore the benefits of identifying and eliminating waste, provide an example of how one organization approached this issue, and then present some best practices for undertaking this effort. This article will explore the most common sources. What Are The Three Main Categories Of Waste In Lean.

From affordablewastemanagement.co.uk

What are the three categories of food waste? Affordable Waste Management What Are The Three Main Categories Of Waste In Lean Addressing the waste of waiting involves. In lean thinking, the primary sources of waste are broken down into what we refer to as the 8 wastes of lean. The eight wastes of lean. By the end of this article, you will have a clear understanding of each of the 8. The 8 wastes in lean manufacturing are: Originally there were. What Are The Three Main Categories Of Waste In Lean.

From www.linkedin.com

7 Types of waste in Lean Manufacturing What Are The Three Main Categories Of Waste In Lean The 8 wastes in lean manufacturing are: We’ll also explore the benefits of identifying and eliminating waste, provide an example of how one organization approached this issue, and then present some best practices for undertaking this effort. Lean principles emphasize the importance of continuous flow and aim to eliminate waiting to enhance overall operational efficiency. By the end of this. What Are The Three Main Categories Of Waste In Lean.

From www.breval.co.in

Lean management Archives Breval Consulting Services What Are The Three Main Categories Of Waste In Lean This article will explore the most common sources of waste in any organization. Lean principles emphasize the importance of continuous flow and aim to eliminate waiting to enhance overall operational efficiency. We’ll also explore the benefits of identifying and eliminating waste, provide an example of how one organization approached this issue, and then present some best practices for undertaking this. What Are The Three Main Categories Of Waste In Lean.

From myleanbiz.com

The 8 Wastes Lean Poster MyLeanBusiness, Inc. What Are The Three Main Categories Of Waste In Lean This article will explore the most common sources of waste in any organization. Lean principles emphasize the importance of continuous flow and aim to eliminate waiting to enhance overall operational efficiency. We’ll also explore the benefits of identifying and eliminating waste, provide an example of how one organization approached this issue, and then present some best practices for undertaking this. What Are The Three Main Categories Of Waste In Lean.

From ceywlrpl.blob.core.windows.net

What Is Waste In Lean at Maxine Kaufman blog What Are The Three Main Categories Of Waste In Lean The eight wastes of lean. Addressing the waste of waiting involves. We’ll also explore the benefits of identifying and eliminating waste, provide an example of how one organization approached this issue, and then present some best practices for undertaking this effort. In lean thinking, the primary sources of waste are broken down into what we refer to as the 8. What Are The Three Main Categories Of Waste In Lean.

From www.slideshare.net

The 8 Types of WasteType What Are The Three Main Categories Of Waste In Lean Originally there were seven wastes identified by taiichi ohno for the toyota production system. The 8 wastes in lean manufacturing are: This article will explore the most common sources of waste in any organization. In lean thinking, the primary sources of waste are broken down into what we refer to as the 8 wastes of lean. Lean principles emphasize the. What Are The Three Main Categories Of Waste In Lean.

From klajgpfnm.blob.core.windows.net

Lean Supply Chain Management Examples at Norman blog What Are The Three Main Categories Of Waste In Lean In lean thinking, the primary sources of waste are broken down into what we refer to as the 8 wastes of lean. Lean principles emphasize the importance of continuous flow and aim to eliminate waiting to enhance overall operational efficiency. Originally there were seven wastes identified by taiichi ohno for the toyota production system. The eight wastes of lean. By. What Are The Three Main Categories Of Waste In Lean.

From ceywlrpl.blob.core.windows.net

What Is Waste In Lean at Maxine Kaufman blog What Are The Three Main Categories Of Waste In Lean This article will explore the most common sources of waste in any organization. The eight wastes of lean. Originally there were seven wastes identified by taiichi ohno for the toyota production system. By the end of this article, you will have a clear understanding of each of the 8. In lean thinking, the primary sources of waste are broken down. What Are The Three Main Categories Of Waste In Lean.

From mavink.com

Identifying Waste In Lean What Are The Three Main Categories Of Waste In Lean Addressing the waste of waiting involves. This article will explore the most common sources of waste in any organization. The 8 wastes in lean manufacturing are: In lean thinking, the primary sources of waste are broken down into what we refer to as the 8 wastes of lean. Originally there were seven wastes identified by taiichi ohno for the toyota. What Are The Three Main Categories Of Waste In Lean.

From taskoconsulting.com

Lean What Are The Three Main Categories Of Waste In Lean We’ll also explore the benefits of identifying and eliminating waste, provide an example of how one organization approached this issue, and then present some best practices for undertaking this effort. The 8 wastes in lean manufacturing are: Lean principles emphasize the importance of continuous flow and aim to eliminate waiting to enhance overall operational efficiency. This article will explore the. What Are The Three Main Categories Of Waste In Lean.

From www.fogwing.io

Guide On Lean Manufacturing Fogwing.io What Are The Three Main Categories Of Waste In Lean This article will explore the most common sources of waste in any organization. The 8 wastes in lean manufacturing are: Addressing the waste of waiting involves. Lean principles emphasize the importance of continuous flow and aim to eliminate waiting to enhance overall operational efficiency. In lean thinking, the primary sources of waste are broken down into what we refer to. What Are The Three Main Categories Of Waste In Lean.

From vienchibao.com

8 Forms of Waste (DOWNTIME) Lean Poster, for Business and Office Viễn What Are The Three Main Categories Of Waste In Lean Originally there were seven wastes identified by taiichi ohno for the toyota production system. Addressing the waste of waiting involves. The eight wastes of lean. By the end of this article, you will have a clear understanding of each of the 8. In lean thinking, the primary sources of waste are broken down into what we refer to as the. What Are The Three Main Categories Of Waste In Lean.

From loecvxvuq.blob.core.windows.net

What Are The Three Types Of Waste at Beau Lee blog What Are The Three Main Categories Of Waste In Lean The eight wastes of lean. In lean thinking, the primary sources of waste are broken down into what we refer to as the 8 wastes of lean. Originally there were seven wastes identified by taiichi ohno for the toyota production system. Lean principles emphasize the importance of continuous flow and aim to eliminate waiting to enhance overall operational efficiency. Addressing. What Are The Three Main Categories Of Waste In Lean.

From www.leanuk.org

Seven or Eight Wastes In Lean Thinking Lean Enterprise Academy What Are The Three Main Categories Of Waste In Lean By the end of this article, you will have a clear understanding of each of the 8. We’ll also explore the benefits of identifying and eliminating waste, provide an example of how one organization approached this issue, and then present some best practices for undertaking this effort. The eight wastes of lean. This article will explore the most common sources. What Are The Three Main Categories Of Waste In Lean.

From 1stcraft.com

Lean Manufacturing คืออะไร? โรงงานควรรู้อะไรบ้าง? Firstcraft What Are The Three Main Categories Of Waste In Lean The 8 wastes in lean manufacturing are: Lean principles emphasize the importance of continuous flow and aim to eliminate waiting to enhance overall operational efficiency. In lean thinking, the primary sources of waste are broken down into what we refer to as the 8 wastes of lean. Addressing the waste of waiting involves. By the end of this article, you. What Are The Three Main Categories Of Waste In Lean.

From ashwinmore.com

8 Waste in Lean Manufacturing Everything about Lean Six Sigma What Are The Three Main Categories Of Waste In Lean Originally there were seven wastes identified by taiichi ohno for the toyota production system. Lean principles emphasize the importance of continuous flow and aim to eliminate waiting to enhance overall operational efficiency. The eight wastes of lean. This article will explore the most common sources of waste in any organization. Addressing the waste of waiting involves. We’ll also explore the. What Are The Three Main Categories Of Waste In Lean.

From cexomsrk.blob.core.windows.net

What Is A Waste Reduction System at Ron Kivi blog What Are The Three Main Categories Of Waste In Lean Originally there were seven wastes identified by taiichi ohno for the toyota production system. This article will explore the most common sources of waste in any organization. We’ll also explore the benefits of identifying and eliminating waste, provide an example of how one organization approached this issue, and then present some best practices for undertaking this effort. The eight wastes. What Are The Three Main Categories Of Waste In Lean.

From www.pinterest.com

7 Types of Waste in Lean Manufacturing What Are The Three Main Categories Of Waste In Lean By the end of this article, you will have a clear understanding of each of the 8. The 8 wastes in lean manufacturing are: In lean thinking, the primary sources of waste are broken down into what we refer to as the 8 wastes of lean. Addressing the waste of waiting involves. We’ll also explore the benefits of identifying and. What Are The Three Main Categories Of Waste In Lean.

From design.udlvirtual.edu.pe

What Are The 5 Principles And 8 Wastes Of Lean Manufacturing Design Talk What Are The Three Main Categories Of Waste In Lean This article will explore the most common sources of waste in any organization. By the end of this article, you will have a clear understanding of each of the 8. The eight wastes of lean. The 8 wastes in lean manufacturing are: In lean thinking, the primary sources of waste are broken down into what we refer to as the. What Are The Three Main Categories Of Waste In Lean.

From www.youtube.com

Lean Concepts "8 Forms of Waste Cause & Effect How to Eliminate What Are The Three Main Categories Of Waste In Lean The 8 wastes in lean manufacturing are: In lean thinking, the primary sources of waste are broken down into what we refer to as the 8 wastes of lean. This article will explore the most common sources of waste in any organization. Lean principles emphasize the importance of continuous flow and aim to eliminate waiting to enhance overall operational efficiency.. What Are The Three Main Categories Of Waste In Lean.

From dxodlwpiv.blob.core.windows.net

What Are The Three Types Of Industrial Waste at Boyd Thornton blog What Are The Three Main Categories Of Waste In Lean The eight wastes of lean. Lean principles emphasize the importance of continuous flow and aim to eliminate waiting to enhance overall operational efficiency. By the end of this article, you will have a clear understanding of each of the 8. In lean thinking, the primary sources of waste are broken down into what we refer to as the 8 wastes. What Are The Three Main Categories Of Waste In Lean.

From www.altamira.ai

Lean Practices In Software Development Process Altamira What Are The Three Main Categories Of Waste In Lean The 8 wastes in lean manufacturing are: In lean thinking, the primary sources of waste are broken down into what we refer to as the 8 wastes of lean. Lean principles emphasize the importance of continuous flow and aim to eliminate waiting to enhance overall operational efficiency. Originally there were seven wastes identified by taiichi ohno for the toyota production. What Are The Three Main Categories Of Waste In Lean.

From mavink.com

7 Types Of Flow Lean What Are The Three Main Categories Of Waste In Lean In lean thinking, the primary sources of waste are broken down into what we refer to as the 8 wastes of lean. The 8 wastes in lean manufacturing are: Originally there were seven wastes identified by taiichi ohno for the toyota production system. Addressing the waste of waiting involves. This article will explore the most common sources of waste in. What Are The Three Main Categories Of Waste In Lean.

From esaola.com

مفهوم پسماند چیست و 5 دسته بندی اصلی پسماند کدام است؟ سائولا What Are The Three Main Categories Of Waste In Lean The 8 wastes in lean manufacturing are: By the end of this article, you will have a clear understanding of each of the 8. We’ll also explore the benefits of identifying and eliminating waste, provide an example of how one organization approached this issue, and then present some best practices for undertaking this effort. The eight wastes of lean. This. What Are The Three Main Categories Of Waste In Lean.

From www.amazon.com

7 Forms of Waste List Lean Poster 22" X 28" Peel and Stick What Are The Three Main Categories Of Waste In Lean In lean thinking, the primary sources of waste are broken down into what we refer to as the 8 wastes of lean. By the end of this article, you will have a clear understanding of each of the 8. The eight wastes of lean. Originally there were seven wastes identified by taiichi ohno for the toyota production system. We’ll also. What Are The Three Main Categories Of Waste In Lean.

From www.youtube.com

𝟴 𝗪𝗮𝘀𝘁𝗲𝘀 𝗼𝗳 𝗟𝗲𝗮𝗻 𝗠𝗮𝗻𝘂𝗳𝗮𝗰𝘁𝘂𝗿𝗶𝗻𝗴 [ Lean manufacturing wastes ] Lean What Are The Three Main Categories Of Waste In Lean Originally there were seven wastes identified by taiichi ohno for the toyota production system. The 8 wastes in lean manufacturing are: This article will explore the most common sources of waste in any organization. Addressing the waste of waiting involves. Lean principles emphasize the importance of continuous flow and aim to eliminate waiting to enhance overall operational efficiency. By the. What Are The Three Main Categories Of Waste In Lean.