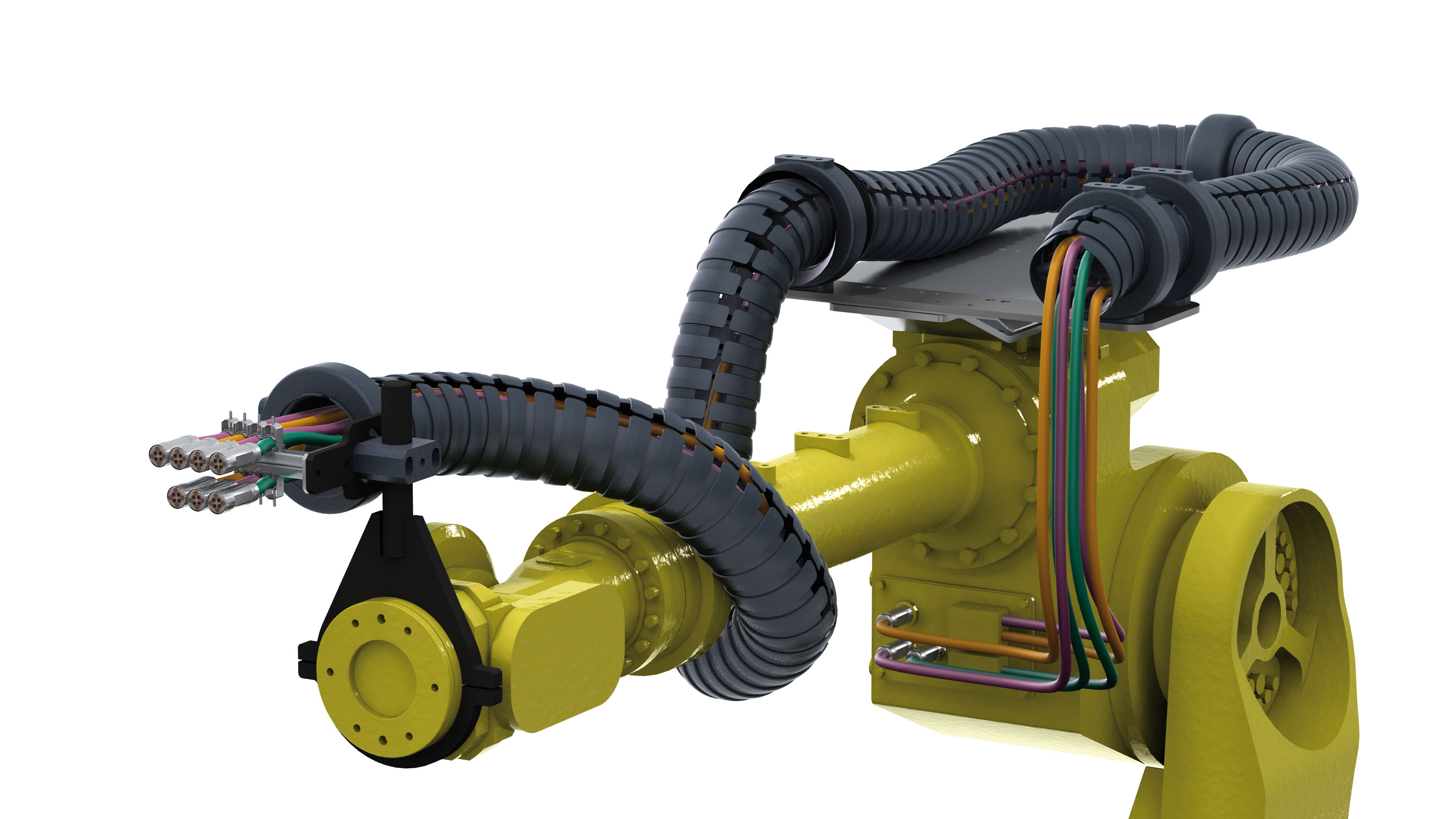

Robotic Arm Cable Management . There are a number of things you can do to optimize robotic cable management. Good cable management ensures that your robots perform optimally, reduces the risk of unexpected breakdowns, and extends the lifespan. What’s in a cable anyway? Because robots are autonomous, the robot could break a cable before you even have time to realize or react. It’s available in three sizes 36, 52 and 70 mm. Cables that link the robot tool to the robot controller generally have two functions: Approach to cable management is a best practice that robotics engineers and integrators can apply. You need to be proactive with your robot cable management. There are a number of things you can do to optimize robotic cable management. Why robot cable protection is so important Unlike with other types of cable routing, robot cabling problems are hard to fix on the fly. Transmitting electricity, and establishing communications between the devices. Here’s how to do proper cable management on your robot. It centers on designing cable management systems. The sixth axis to the.

from www.designworldonline.com

There are a number of things you can do to optimize robotic cable management. Unlike with other types of cable routing, robot cabling problems are hard to fix on the fly. The sixth axis to the. Why robot cable protection is so important Good cable management ensures that your robots perform optimally, reduces the risk of unexpected breakdowns, and extends the lifespan. What’s in a cable anyway? It centers on designing cable management systems. Approach to cable management is a best practice that robotics engineers and integrators can apply. Cables that link the robot tool to the robot controller generally have two functions: Our cable saver™ solution eliminates downtime, loss of revenue, expensive cable and hose replacement costs, maintenance labour costs.

Motion systems application examples Cables

Robotic Arm Cable Management There are a number of things you can do to optimize robotic cable management. There are a number of things you can do to optimize robotic cable management. Approach to cable management is a best practice that robotics engineers and integrators can apply. You need to be proactive with your robot cable management. Because robots are autonomous, the robot could break a cable before you even have time to realize or react. It’s available in three sizes 36, 52 and 70 mm. Why robot cable protection is so important What’s in a cable anyway? Transmitting electricity, and establishing communications between the devices. The sixth axis to the. There are a number of things you can do to optimize robotic cable management. Unlike with other types of cable routing, robot cabling problems are hard to fix on the fly. Our cable saver™ solution eliminates downtime, loss of revenue, expensive cable and hose replacement costs, maintenance labour costs. Good cable management ensures that your robots perform optimally, reduces the risk of unexpected breakdowns, and extends the lifespan. Here’s how to do proper cable management on your robot. Cables that link the robot tool to the robot controller generally have two functions:

From markforged.com

Robot Arm Cable Management with 3D Printers Farason Robotic Arm Cable Management Here’s how to do proper cable management on your robot. Why robot cable protection is so important Unlike with other types of cable routing, robot cabling problems are hard to fix on the fly. There are a number of things you can do to optimize robotic cable management. There are a number of things you can do to optimize robotic. Robotic Arm Cable Management.

From www.youtube.com

CPS RoboWay® simple and reliable solution for robotic cables and Robotic Arm Cable Management Good cable management ensures that your robots perform optimally, reduces the risk of unexpected breakdowns, and extends the lifespan. Here’s how to do proper cable management on your robot. Approach to cable management is a best practice that robotics engineers and integrators can apply. Cables that link the robot tool to the robot controller generally have two functions: There are. Robotic Arm Cable Management.

From www.automationmag.com

igus debuts cable management kit for any cobot arm Manufacturing Robotic Arm Cable Management Cables that link the robot tool to the robot controller generally have two functions: Good cable management ensures that your robots perform optimally, reduces the risk of unexpected breakdowns, and extends the lifespan. It centers on designing cable management systems. The sixth axis to the. Unlike with other types of cable routing, robot cabling problems are hard to fix on. Robotic Arm Cable Management.

From news.mit.edu

Letting robots manipulate cables MIT News Massachusetts Institute Robotic Arm Cable Management Because robots are autonomous, the robot could break a cable before you even have time to realize or react. Good cable management ensures that your robots perform optimally, reduces the risk of unexpected breakdowns, and extends the lifespan. There are a number of things you can do to optimize robotic cable management. Here’s how to do proper cable management on. Robotic Arm Cable Management.

From designsolutionsmag.co.uk

Video The different options for Robot cable management Design Solutions Robotic Arm Cable Management It’s available in three sizes 36, 52 and 70 mm. The sixth axis to the. Transmitting electricity, and establishing communications between the devices. Our cable saver™ solution eliminates downtime, loss of revenue, expensive cable and hose replacement costs, maintenance labour costs. Here’s how to do proper cable management on your robot. You need to be proactive with your robot cable. Robotic Arm Cable Management.

From www.essentracomponents.com

What is robotic cable management? Essentra Components UK Robotic Arm Cable Management Cables that link the robot tool to the robot controller generally have two functions: Why robot cable protection is so important There are a number of things you can do to optimize robotic cable management. Because robots are autonomous, the robot could break a cable before you even have time to realize or react. Our cable saver™ solution eliminates downtime,. Robotic Arm Cable Management.

From www.techbriefs.com

The Less is More Approach to Robotic Cable Management Tech Briefs Robotic Arm Cable Management Transmitting electricity, and establishing communications between the devices. Here’s how to do proper cable management on your robot. Good cable management ensures that your robots perform optimally, reduces the risk of unexpected breakdowns, and extends the lifespan. There are a number of things you can do to optimize robotic cable management. There are a number of things you can do. Robotic Arm Cable Management.

From www.youtube.com

CiRA CORE collaborative robotic arms for door locks cables Robotic Arm Cable Management It’s available in three sizes 36, 52 and 70 mm. Why robot cable protection is so important The sixth axis to the. Good cable management ensures that your robots perform optimally, reduces the risk of unexpected breakdowns, and extends the lifespan. It centers on designing cable management systems. Our cable saver™ solution eliminates downtime, loss of revenue, expensive cable and. Robotic Arm Cable Management.

From www.youtube.com

triflex® R Robot Cable Management Retraction Systems (1m) YouTube Robotic Arm Cable Management There are a number of things you can do to optimize robotic cable management. The sixth axis to the. There are a number of things you can do to optimize robotic cable management. Approach to cable management is a best practice that robotics engineers and integrators can apply. You need to be proactive with your robot cable management. Why robot. Robotic Arm Cable Management.

From www.techbriefs.com

The Less is More Approach to Robotic Cable Management Tech Briefs Robotic Arm Cable Management Because robots are autonomous, the robot could break a cable before you even have time to realize or react. Our cable saver™ solution eliminates downtime, loss of revenue, expensive cable and hose replacement costs, maintenance labour costs. Transmitting electricity, and establishing communications between the devices. What’s in a cable anyway? It’s available in three sizes 36, 52 and 70 mm.. Robotic Arm Cable Management.

From www.shgongboshi.com

Cable Management Collaborative Robot Arm BN UNI KIT FLEX FOR UR5 / UR10 Robotic Arm Cable Management Transmitting electricity, and establishing communications between the devices. Unlike with other types of cable routing, robot cabling problems are hard to fix on the fly. There are a number of things you can do to optimize robotic cable management. Why robot cable protection is so important What’s in a cable anyway? There are a number of things you can do. Robotic Arm Cable Management.

From www.shgongboshi.com

Cable Management Collaborative Robot Arm BN UNI KIT FLEX FOR UR5 / UR10 Robotic Arm Cable Management You need to be proactive with your robot cable management. There are a number of things you can do to optimize robotic cable management. Here’s how to do proper cable management on your robot. Good cable management ensures that your robots perform optimally, reduces the risk of unexpected breakdowns, and extends the lifespan. The sixth axis to the. Why robot. Robotic Arm Cable Management.

From reikuna.com

Cable Saver™ Kit Reiku North America Robotic Arm Cable Management Because robots are autonomous, the robot could break a cable before you even have time to realize or react. Our cable saver™ solution eliminates downtime, loss of revenue, expensive cable and hose replacement costs, maintenance labour costs. There are a number of things you can do to optimize robotic cable management. Unlike with other types of cable routing, robot cabling. Robotic Arm Cable Management.

From www.igus.com

What to Look for When Specifying a Robot Cable Robotic Arm Cable Management It’s available in three sizes 36, 52 and 70 mm. There are a number of things you can do to optimize robotic cable management. The sixth axis to the. Cables that link the robot tool to the robot controller generally have two functions: Approach to cable management is a best practice that robotics engineers and integrators can apply. Good cable. Robotic Arm Cable Management.

From www.automate.org

Robotic Cable Management Tips Robotic Arm Cable Management Unlike with other types of cable routing, robot cabling problems are hard to fix on the fly. Because robots are autonomous, the robot could break a cable before you even have time to realize or react. There are a number of things you can do to optimize robotic cable management. There are a number of things you can do to. Robotic Arm Cable Management.

From www.roboticstomorrow.com

The Less is More Approach to Robotic Cable Management RoboticsTomorrow Robotic Arm Cable Management You need to be proactive with your robot cable management. It’s available in three sizes 36, 52 and 70 mm. Cables that link the robot tool to the robot controller generally have two functions: What’s in a cable anyway? Here’s how to do proper cable management on your robot. Why robot cable protection is so important Our cable saver™ solution. Robotic Arm Cable Management.

From hackaday.io

Gallery Cable Six Axis Robotic Arm Hackaday.io Robotic Arm Cable Management There are a number of things you can do to optimize robotic cable management. It centers on designing cable management systems. Why robot cable protection is so important Good cable management ensures that your robots perform optimally, reduces the risk of unexpected breakdowns, and extends the lifespan. There are a number of things you can do to optimize robotic cable. Robotic Arm Cable Management.

From www.designworldonline.com

Robotic Cable Management Made Easy Robotic Arm Cable Management Because robots are autonomous, the robot could break a cable before you even have time to realize or react. There are a number of things you can do to optimize robotic cable management. You need to be proactive with your robot cable management. Cables that link the robot tool to the robot controller generally have two functions: Why robot cable. Robotic Arm Cable Management.

From www.researchgate.net

Developed cabledriven robotic manipulator. Download Scientific Diagram Robotic Arm Cable Management What’s in a cable anyway? Why robot cable protection is so important Our cable saver™ solution eliminates downtime, loss of revenue, expensive cable and hose replacement costs, maintenance labour costs. Good cable management ensures that your robots perform optimally, reduces the risk of unexpected breakdowns, and extends the lifespan. It’s available in three sizes 36, 52 and 70 mm. You. Robotic Arm Cable Management.

From www.shgongboshi.com

Cable Management Collaborative Robot Arm BN UNI KIT FLEX FOR UR5 / UR10 Robotic Arm Cable Management The sixth axis to the. There are a number of things you can do to optimize robotic cable management. Because robots are autonomous, the robot could break a cable before you even have time to realize or react. You need to be proactive with your robot cable management. Good cable management ensures that your robots perform optimally, reduces the risk. Robotic Arm Cable Management.

From www.youtube.com

Prototype cabledriven robot arm YouTube Robotic Arm Cable Management What’s in a cable anyway? Good cable management ensures that your robots perform optimally, reduces the risk of unexpected breakdowns, and extends the lifespan. There are a number of things you can do to optimize robotic cable management. The sixth axis to the. There are a number of things you can do to optimize robotic cable management. Why robot cable. Robotic Arm Cable Management.

From www.shgongboshi.com

Cable Management Collaborative Robot Arm BN UNI KIT FLEX FOR UR5 / UR10 Robotic Arm Cable Management Here’s how to do proper cable management on your robot. What’s in a cable anyway? Approach to cable management is a best practice that robotics engineers and integrators can apply. Our cable saver™ solution eliminates downtime, loss of revenue, expensive cable and hose replacement costs, maintenance labour costs. Unlike with other types of cable routing, robot cabling problems are hard. Robotic Arm Cable Management.

From www.automate.org

Robot Cable Management / Dress Components Automation Products Robotic Arm Cable Management It centers on designing cable management systems. Here’s how to do proper cable management on your robot. There are a number of things you can do to optimize robotic cable management. The sixth axis to the. Transmitting electricity, and establishing communications between the devices. Good cable management ensures that your robots perform optimally, reduces the risk of unexpected breakdowns, and. Robotic Arm Cable Management.

From www.shgongboshi.com

Multi Dimensionally Cable Driven Robot Arm , Smart Robotic Arm FAUDE C Robotic Arm Cable Management Approach to cable management is a best practice that robotics engineers and integrators can apply. There are a number of things you can do to optimize robotic cable management. Here’s how to do proper cable management on your robot. Transmitting electricity, and establishing communications between the devices. Unlike with other types of cable routing, robot cabling problems are hard to. Robotic Arm Cable Management.

From cobotdepot.com

Igus Cable Management Kits UR Robot Cobot Depot Robotic Arm Cable Management Approach to cable management is a best practice that robotics engineers and integrators can apply. Why robot cable protection is so important Cables that link the robot tool to the robot controller generally have two functions: The sixth axis to the. There are a number of things you can do to optimize robotic cable management. Transmitting electricity, and establishing communications. Robotic Arm Cable Management.

From www.designworldonline.com

Motion systems application examples Cables Robotic Arm Cable Management Why robot cable protection is so important You need to be proactive with your robot cable management. Our cable saver™ solution eliminates downtime, loss of revenue, expensive cable and hose replacement costs, maintenance labour costs. It centers on designing cable management systems. Cables that link the robot tool to the robot controller generally have two functions: Transmitting electricity, and establishing. Robotic Arm Cable Management.

From www.roboticstomorrow.com

The Less is More Approach to Robotic Cable Management RoboticsTomorrow Robotic Arm Cable Management You need to be proactive with your robot cable management. There are a number of things you can do to optimize robotic cable management. Good cable management ensures that your robots perform optimally, reduces the risk of unexpected breakdowns, and extends the lifespan. The sixth axis to the. Approach to cable management is a best practice that robotics engineers and. Robotic Arm Cable Management.

From www.shgongboshi.com

Cable Management Collaborative Robot Arm BN UNI KIT FLEX FOR UR5 / UR10 Robotic Arm Cable Management Transmitting electricity, and establishing communications between the devices. You need to be proactive with your robot cable management. Here’s how to do proper cable management on your robot. The sixth axis to the. It centers on designing cable management systems. It’s available in three sizes 36, 52 and 70 mm. What’s in a cable anyway? Approach to cable management is. Robotic Arm Cable Management.

From murrplastik.com

Flexible Holding System for Collaborative Robots Murrplastik Robotic Arm Cable Management Good cable management ensures that your robots perform optimally, reduces the risk of unexpected breakdowns, and extends the lifespan. The sixth axis to the. What’s in a cable anyway? Why robot cable protection is so important Approach to cable management is a best practice that robotics engineers and integrators can apply. There are a number of things you can do. Robotic Arm Cable Management.

From www.youtube.com

How to install an igus triflex RSE cable management system on a six Robotic Arm Cable Management Here’s how to do proper cable management on your robot. It’s available in three sizes 36, 52 and 70 mm. It centers on designing cable management systems. There are a number of things you can do to optimize robotic cable management. What’s in a cable anyway? Why robot cable protection is so important Our cable saver™ solution eliminates downtime, loss. Robotic Arm Cable Management.

From directory.howtorobot.com

Robotic Cable Management Equipment (Hardware) Robotic Arm Cable Management What’s in a cable anyway? Good cable management ensures that your robots perform optimally, reduces the risk of unexpected breakdowns, and extends the lifespan. Unlike with other types of cable routing, robot cabling problems are hard to fix on the fly. Transmitting electricity, and establishing communications between the devices. There are a number of things you can do to optimize. Robotic Arm Cable Management.

From info.panelshop.com

Robotic Cable Management Best Practices Robotic Arm Cable Management Our cable saver™ solution eliminates downtime, loss of revenue, expensive cable and hose replacement costs, maintenance labour costs. Why robot cable protection is so important What’s in a cable anyway? There are a number of things you can do to optimize robotic cable management. It’s available in three sizes 36, 52 and 70 mm. Unlike with other types of cable. Robotic Arm Cable Management.

From www.youtube.com

6 DOF Alloy Robotic Arm Kit Cable Connection YouTube Robotic Arm Cable Management Why robot cable protection is so important It’s available in three sizes 36, 52 and 70 mm. You need to be proactive with your robot cable management. It centers on designing cable management systems. There are a number of things you can do to optimize robotic cable management. Cables that link the robot tool to the robot controller generally have. Robotic Arm Cable Management.

From www.youtube.com

[First Demo] BMArm (Biomuscular cabledriven arm) force control Robotic Arm Cable Management Transmitting electricity, and establishing communications between the devices. Why robot cable protection is so important Here’s how to do proper cable management on your robot. There are a number of things you can do to optimize robotic cable management. Our cable saver™ solution eliminates downtime, loss of revenue, expensive cable and hose replacement costs, maintenance labour costs. Cables that link. Robotic Arm Cable Management.

From medium.com

Robotic cable management system — LAPP by Laapstore Medium Robotic Arm Cable Management There are a number of things you can do to optimize robotic cable management. Cables that link the robot tool to the robot controller generally have two functions: Good cable management ensures that your robots perform optimally, reduces the risk of unexpected breakdowns, and extends the lifespan. Transmitting electricity, and establishing communications between the devices. The sixth axis to the.. Robotic Arm Cable Management.