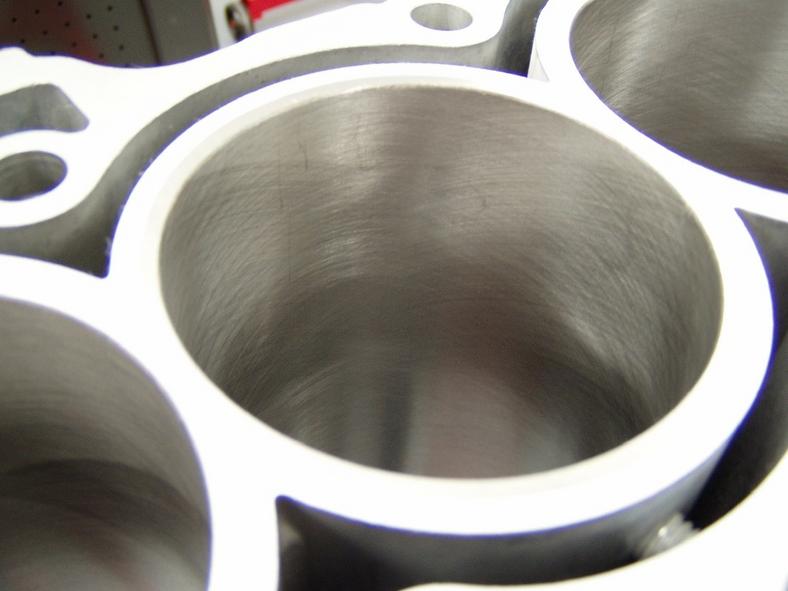

Engine Sleeve Honing . Straight sleeves seat against the base of the cylinder bore and require a press fit to stay in place while flanged. Dry sleeves come in two basic styles: Learn how an engine rebuilder and automotive machine shop used ball hones for deburring and surface finishing. To hone or not to hone? Follow along using the transcript. One way to ensure good heat transfer between the sleeve and block is to lightly hone the block with #280 grit stones after the hole has been bored. After installation, check the inside diameter of each sleeve at several locations, especially at the top and bottom to check for.

from www.performanceracingengine.com

Follow along using the transcript. Learn how an engine rebuilder and automotive machine shop used ball hones for deburring and surface finishing. To hone or not to hone? After installation, check the inside diameter of each sleeve at several locations, especially at the top and bottom to check for. Straight sleeves seat against the base of the cylinder bore and require a press fit to stay in place while flanged. Dry sleeves come in two basic styles: One way to ensure good heat transfer between the sleeve and block is to lightly hone the block with #280 grit stones after the hole has been bored.

Rottler H85 AX Diamond Cylinder Honing IL,MO,IA,KY,IN

Engine Sleeve Honing Learn how an engine rebuilder and automotive machine shop used ball hones for deburring and surface finishing. After installation, check the inside diameter of each sleeve at several locations, especially at the top and bottom to check for. Dry sleeves come in two basic styles: To hone or not to hone? One way to ensure good heat transfer between the sleeve and block is to lightly hone the block with #280 grit stones after the hole has been bored. Follow along using the transcript. Learn how an engine rebuilder and automotive machine shop used ball hones for deburring and surface finishing. Straight sleeves seat against the base of the cylinder bore and require a press fit to stay in place while flanged.

From www.masterparts.com

Cylinder Sleeves Auto Parts Masterparts Engine Sleeve Honing After installation, check the inside diameter of each sleeve at several locations, especially at the top and bottom to check for. Straight sleeves seat against the base of the cylinder bore and require a press fit to stay in place while flanged. One way to ensure good heat transfer between the sleeve and block is to lightly hone the block. Engine Sleeve Honing.

From www.hotrod.com

How to Sleeve An Engine Block Hot Rod Network Engine Sleeve Honing One way to ensure good heat transfer between the sleeve and block is to lightly hone the block with #280 grit stones after the hole has been bored. Learn how an engine rebuilder and automotive machine shop used ball hones for deburring and surface finishing. To hone or not to hone? After installation, check the inside diameter of each sleeve. Engine Sleeve Honing.

From www.performanceracingengine.com

Rottler H85 AX Diamond Cylinder Honing IL,MO,IA,KY,IN Engine Sleeve Honing To hone or not to hone? One way to ensure good heat transfer between the sleeve and block is to lightly hone the block with #280 grit stones after the hole has been bored. Learn how an engine rebuilder and automotive machine shop used ball hones for deburring and surface finishing. Straight sleeves seat against the base of the cylinder. Engine Sleeve Honing.

From www.amazon.com

EWK 2" to 7" 3 Stones Engine Cylinder Hone Tool Adjustable Engine Sleeve Honing Dry sleeves come in two basic styles: Learn how an engine rebuilder and automotive machine shop used ball hones for deburring and surface finishing. To hone or not to hone? After installation, check the inside diameter of each sleeve at several locations, especially at the top and bottom to check for. One way to ensure good heat transfer between the. Engine Sleeve Honing.

From www.larryspower.com

Larry's Auto Machine Engine Packages Sleeves Engine Sleeve Honing Learn how an engine rebuilder and automotive machine shop used ball hones for deburring and surface finishing. Dry sleeves come in two basic styles: After installation, check the inside diameter of each sleeve at several locations, especially at the top and bottom to check for. One way to ensure good heat transfer between the sleeve and block is to lightly. Engine Sleeve Honing.

From www.hotrod.com

Cylinder Honing Honed For Speed Hot Rod Network Engine Sleeve Honing Learn how an engine rebuilder and automotive machine shop used ball hones for deburring and surface finishing. Straight sleeves seat against the base of the cylinder bore and require a press fit to stay in place while flanged. Dry sleeves come in two basic styles: One way to ensure good heat transfer between the sleeve and block is to lightly. Engine Sleeve Honing.

From www.rlengines.com

Cylinder Honing Engine Block Cylinder FinishingMA,CT,RI,NH,VT,ME,NY,NJ Engine Sleeve Honing One way to ensure good heat transfer between the sleeve and block is to lightly hone the block with #280 grit stones after the hole has been bored. Follow along using the transcript. Dry sleeves come in two basic styles: Straight sleeves seat against the base of the cylinder bore and require a press fit to stay in place while. Engine Sleeve Honing.

From www.youtube.com

Sleeve removal Pakistani Technique tractor restoration sleeves Engine Sleeve Honing Dry sleeves come in two basic styles: Follow along using the transcript. After installation, check the inside diameter of each sleeve at several locations, especially at the top and bottom to check for. Learn how an engine rebuilder and automotive machine shop used ball hones for deburring and surface finishing. Straight sleeves seat against the base of the cylinder bore. Engine Sleeve Honing.

From www.youtube.com

LT1 engine build Honing cylinders to fix scoring marks during assembly Engine Sleeve Honing After installation, check the inside diameter of each sleeve at several locations, especially at the top and bottom to check for. Follow along using the transcript. Learn how an engine rebuilder and automotive machine shop used ball hones for deburring and surface finishing. Straight sleeves seat against the base of the cylinder bore and require a press fit to stay. Engine Sleeve Honing.

From www.enginelabs.com

Video Aftermarket Engine Sleeve Basics Engine Sleeve Honing Dry sleeves come in two basic styles: Learn how an engine rebuilder and automotive machine shop used ball hones for deburring and surface finishing. To hone or not to hone? After installation, check the inside diameter of each sleeve at several locations, especially at the top and bottom to check for. Follow along using the transcript. One way to ensure. Engine Sleeve Honing.

From www.supercheapauto.com.au

How To Hone an Engine Cylinder Engine Sleeve Honing Dry sleeves come in two basic styles: Learn how an engine rebuilder and automotive machine shop used ball hones for deburring and surface finishing. One way to ensure good heat transfer between the sleeve and block is to lightly hone the block with #280 grit stones after the hole has been bored. Follow along using the transcript. To hone or. Engine Sleeve Honing.

From www.enginebuildermag.com

Liners and Sleeves Engine Builder Magazine Engine Sleeve Honing Dry sleeves come in two basic styles: Straight sleeves seat against the base of the cylinder bore and require a press fit to stay in place while flanged. After installation, check the inside diameter of each sleeve at several locations, especially at the top and bottom to check for. One way to ensure good heat transfer between the sleeve and. Engine Sleeve Honing.

From classicautoadvisors.com

Classic Car Sleeving an Engine Classic Auto Advisors Engine Sleeve Honing One way to ensure good heat transfer between the sleeve and block is to lightly hone the block with #280 grit stones after the hole has been bored. To hone or not to hone? Straight sleeves seat against the base of the cylinder bore and require a press fit to stay in place while flanged. Learn how an engine rebuilder. Engine Sleeve Honing.

From www.youtube.com

Block Sleeve Honing YouTube Engine Sleeve Honing One way to ensure good heat transfer between the sleeve and block is to lightly hone the block with #280 grit stones after the hole has been bored. After installation, check the inside diameter of each sleeve at several locations, especially at the top and bottom to check for. To hone or not to hone? Dry sleeves come in two. Engine Sleeve Honing.

From comingsooncars.com

Basic Guidelines You Need Know About Cylinder Sleeves Coming Soon Cars Engine Sleeve Honing After installation, check the inside diameter of each sleeve at several locations, especially at the top and bottom to check for. Straight sleeves seat against the base of the cylinder bore and require a press fit to stay in place while flanged. Dry sleeves come in two basic styles: Follow along using the transcript. One way to ensure good heat. Engine Sleeve Honing.

From www.performanceracingengine.com

Engine_Block_Cylinder_Honing Engine Sleeve Honing Dry sleeves come in two basic styles: To hone or not to hone? Learn how an engine rebuilder and automotive machine shop used ball hones for deburring and surface finishing. Follow along using the transcript. One way to ensure good heat transfer between the sleeve and block is to lightly hone the block with #280 grit stones after the hole. Engine Sleeve Honing.

From motormission.com

High Performance Engine Cylinder Boring and Torque Plate Honing Motor Engine Sleeve Honing Learn how an engine rebuilder and automotive machine shop used ball hones for deburring and surface finishing. Dry sleeves come in two basic styles: Straight sleeves seat against the base of the cylinder bore and require a press fit to stay in place while flanged. One way to ensure good heat transfer between the sleeve and block is to lightly. Engine Sleeve Honing.

From www.hotrod.com

How to Sleeve An Engine Block Hot Rod Network Engine Sleeve Honing Straight sleeves seat against the base of the cylinder bore and require a press fit to stay in place while flanged. One way to ensure good heat transfer between the sleeve and block is to lightly hone the block with #280 grit stones after the hole has been bored. To hone or not to hone? Learn how an engine rebuilder. Engine Sleeve Honing.

From prorace-engineering.co.uk

Cylinder Rebore & Hone (Per Cylinder) ProRace Engineering Engine Sleeve Honing Dry sleeves come in two basic styles: Straight sleeves seat against the base of the cylinder bore and require a press fit to stay in place while flanged. Follow along using the transcript. One way to ensure good heat transfer between the sleeve and block is to lightly hone the block with #280 grit stones after the hole has been. Engine Sleeve Honing.

From www.performanceracingengine.com

Rottler H85 AX Diamond Cylinder Honing IL,MO,IA,KY,IN Engine Sleeve Honing To hone or not to hone? One way to ensure good heat transfer between the sleeve and block is to lightly hone the block with #280 grit stones after the hole has been bored. Straight sleeves seat against the base of the cylinder bore and require a press fit to stay in place while flanged. Dry sleeves come in two. Engine Sleeve Honing.

From www.hondatwins.net

Replace cylinder sleeves or bore / hone Engine Sleeve Honing One way to ensure good heat transfer between the sleeve and block is to lightly hone the block with #280 grit stones after the hole has been bored. After installation, check the inside diameter of each sleeve at several locations, especially at the top and bottom to check for. Follow along using the transcript. Dry sleeves come in two basic. Engine Sleeve Honing.

From www.reddit.com

Do I need to hone these cylinder sleeves? They were bored by a machine Engine Sleeve Honing Learn how an engine rebuilder and automotive machine shop used ball hones for deburring and surface finishing. One way to ensure good heat transfer between the sleeve and block is to lightly hone the block with #280 grit stones after the hole has been bored. Straight sleeves seat against the base of the cylinder bore and require a press fit. Engine Sleeve Honing.

From www.youtube.com

How To HONE AN ENGINE CYLINDER YouTube Engine Sleeve Honing Straight sleeves seat against the base of the cylinder bore and require a press fit to stay in place while flanged. One way to ensure good heat transfer between the sleeve and block is to lightly hone the block with #280 grit stones after the hole has been bored. Learn how an engine rebuilder and automotive machine shop used ball. Engine Sleeve Honing.

From www.hotrod.com

How to Sleeve An Engine Block Hot Rod Network Engine Sleeve Honing One way to ensure good heat transfer between the sleeve and block is to lightly hone the block with #280 grit stones after the hole has been bored. To hone or not to hone? Follow along using the transcript. After installation, check the inside diameter of each sleeve at several locations, especially at the top and bottom to check for.. Engine Sleeve Honing.

From www.enginelabs.com

Honing At Home Chucking Up A Ball Hone And Testing The Results Engine Sleeve Honing Follow along using the transcript. Straight sleeves seat against the base of the cylinder bore and require a press fit to stay in place while flanged. To hone or not to hone? After installation, check the inside diameter of each sleeve at several locations, especially at the top and bottom to check for. One way to ensure good heat transfer. Engine Sleeve Honing.

From rdcmachineandmotorsport.com

Cylinder bore/hone, sleeve installation RDCM&M Engine Sleeve Honing To hone or not to hone? Learn how an engine rebuilder and automotive machine shop used ball hones for deburring and surface finishing. One way to ensure good heat transfer between the sleeve and block is to lightly hone the block with #280 grit stones after the hole has been bored. Straight sleeves seat against the base of the cylinder. Engine Sleeve Honing.

From www.youtube.com

Engine Rebuild 101 Part 4 Cylinder Honing YouTube Engine Sleeve Honing Learn how an engine rebuilder and automotive machine shop used ball hones for deburring and surface finishing. To hone or not to hone? Dry sleeves come in two basic styles: Straight sleeves seat against the base of the cylinder bore and require a press fit to stay in place while flanged. Follow along using the transcript. After installation, check the. Engine Sleeve Honing.

From www.mech4study.com

What is Honing, its Process Parameter, Types and its Advantages Engine Sleeve Honing Dry sleeves come in two basic styles: To hone or not to hone? Follow along using the transcript. One way to ensure good heat transfer between the sleeve and block is to lightly hone the block with #280 grit stones after the hole has been bored. After installation, check the inside diameter of each sleeve at several locations, especially at. Engine Sleeve Honing.

From www.hotrod.com

Add Darton Sleeves to 2011andUp Shelby GT500 Engine Block Hot Rod Engine Sleeve Honing One way to ensure good heat transfer between the sleeve and block is to lightly hone the block with #280 grit stones after the hole has been bored. To hone or not to hone? After installation, check the inside diameter of each sleeve at several locations, especially at the top and bottom to check for. Follow along using the transcript.. Engine Sleeve Honing.

From wesengines.com.au

Wes Engines Services Tour Wes Race Engines Engine Sleeve Honing One way to ensure good heat transfer between the sleeve and block is to lightly hone the block with #280 grit stones after the hole has been bored. Learn how an engine rebuilder and automotive machine shop used ball hones for deburring and surface finishing. To hone or not to hone? After installation, check the inside diameter of each sleeve. Engine Sleeve Honing.

From www.hotrod.com

How to Sleeve An Engine Block Hot Rod Network Engine Sleeve Honing Learn how an engine rebuilder and automotive machine shop used ball hones for deburring and surface finishing. Straight sleeves seat against the base of the cylinder bore and require a press fit to stay in place while flanged. Follow along using the transcript. After installation, check the inside diameter of each sleeve at several locations, especially at the top and. Engine Sleeve Honing.

From www.cromwell.co.uk

Kennedy 4in1 Cylinder Honing Tool Set 5032930K Cromwell Tools Engine Sleeve Honing Straight sleeves seat against the base of the cylinder bore and require a press fit to stay in place while flanged. Follow along using the transcript. One way to ensure good heat transfer between the sleeve and block is to lightly hone the block with #280 grit stones after the hole has been bored. To hone or not to hone?. Engine Sleeve Honing.

From www.rlengines.com

Cylinder Honing Engine Block Cylinder FinishingMA,CT,RI,NH,VT,ME,NY,NJ Engine Sleeve Honing Learn how an engine rebuilder and automotive machine shop used ball hones for deburring and surface finishing. Follow along using the transcript. One way to ensure good heat transfer between the sleeve and block is to lightly hone the block with #280 grit stones after the hole has been bored. After installation, check the inside diameter of each sleeve at. Engine Sleeve Honing.

From rdcmachineandmotorsport.com

Cylinder bore/hone, sleeve installation RDCM&M Engine Sleeve Honing Learn how an engine rebuilder and automotive machine shop used ball hones for deburring and surface finishing. Follow along using the transcript. Straight sleeves seat against the base of the cylinder bore and require a press fit to stay in place while flanged. Dry sleeves come in two basic styles: One way to ensure good heat transfer between the sleeve. Engine Sleeve Honing.

From www.youtube.com

Engine Sleeve Replacement Complete Engine Repairing and Restoration Engine Sleeve Honing To hone or not to hone? After installation, check the inside diameter of each sleeve at several locations, especially at the top and bottom to check for. Dry sleeves come in two basic styles: One way to ensure good heat transfer between the sleeve and block is to lightly hone the block with #280 grit stones after the hole has. Engine Sleeve Honing.