Jic Vs Compression Fitting . They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. Jic (or joint industry council) fittings, defined by sae j514, are compression fittings machined with a 37 degree flare seating surface and parallel threads. Jic fittings adhere to the sae j514. The only difference between an and jic fittings is that an fittings are manufactured as per more stringent tolerances for military applications. Though these fittings are similar in. The acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads. While jic and an fittings share some similarities, several key differences set them apart: Jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications. Pros and cons of jic fittings. Jic fitting hydraulic connections are common in most fluid power systems. Flared fittings have long been used instead of pipe. Flared fittings are significantly superior to pipe fittings in terms of design and performance.

from www.qchydraulics.com

Pros and cons of jic fittings. Jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications. Jic fitting hydraulic connections are common in most fluid power systems. Jic fittings adhere to the sae j514. Flared fittings are significantly superior to pipe fittings in terms of design and performance. While jic and an fittings share some similarities, several key differences set them apart: Flared fittings have long been used instead of pipe. The acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads. They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. The only difference between an and jic fittings is that an fittings are manufactured as per more stringent tolerances for military applications.

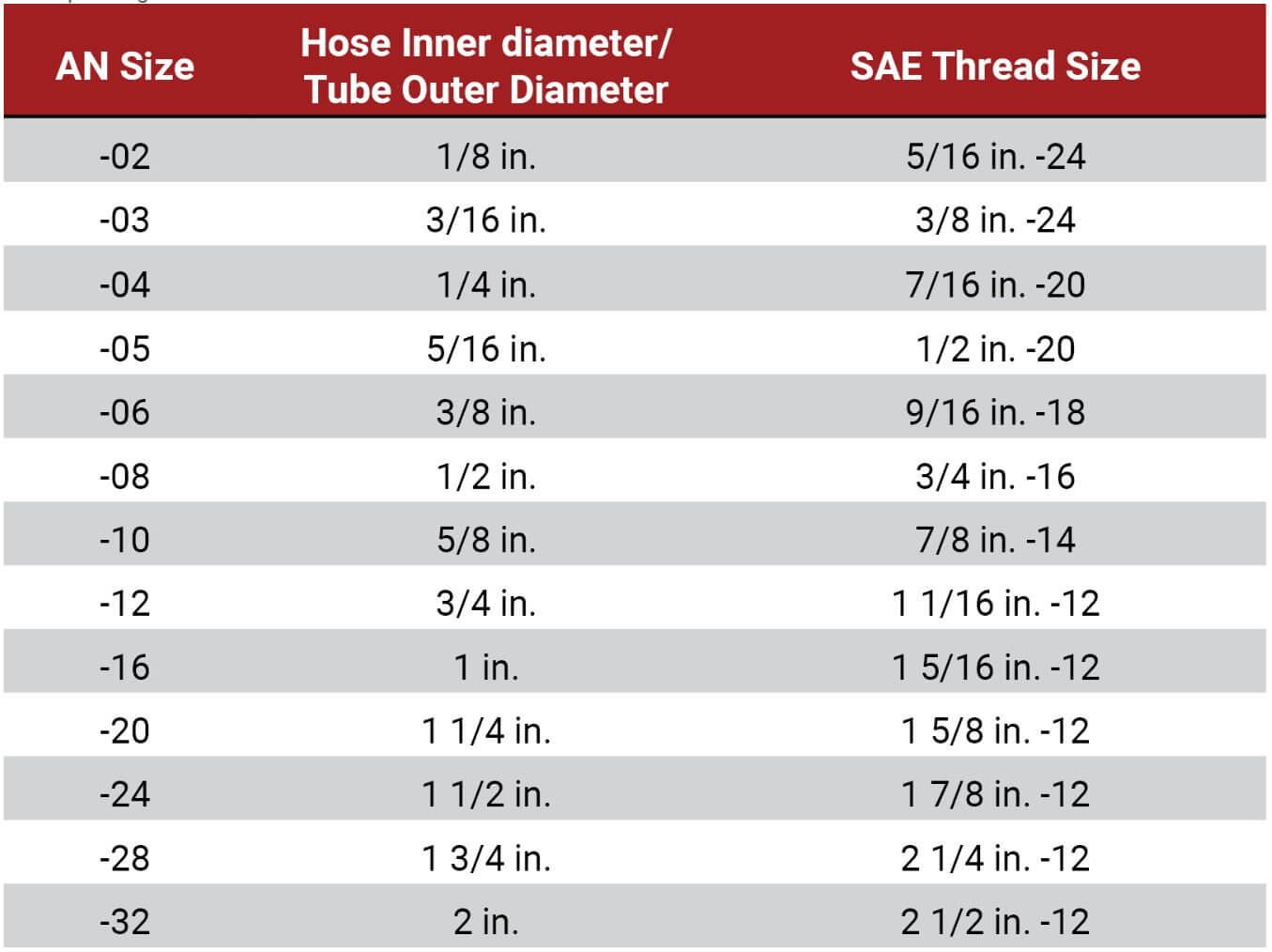

An Fitting Size Chart A guide To the right Size QC Hydraulics

Jic Vs Compression Fitting Jic fitting hydraulic connections are common in most fluid power systems. Jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications. Pros and cons of jic fittings. While jic and an fittings share some similarities, several key differences set them apart: Jic (or joint industry council) fittings, defined by sae j514, are compression fittings machined with a 37 degree flare seating surface and parallel threads. Flared fittings have long been used instead of pipe. The only difference between an and jic fittings is that an fittings are manufactured as per more stringent tolerances for military applications. Jic fitting hydraulic connections are common in most fluid power systems. Though these fittings are similar in. Flared fittings are significantly superior to pipe fittings in terms of design and performance. They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. The acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads. Jic fittings adhere to the sae j514. They are commonly manufactured in nickel alloys, brass, carbon & stainless steel.

From www.laikehydraulics.com

JIC vs SAE What's the Difference Jic Vs Compression Fitting Jic (or joint industry council) fittings, defined by sae j514, are compression fittings machined with a 37 degree flare seating surface and parallel threads. Jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications. Flared fittings are significantly superior to pipe fittings in terms of design and performance. While jic. Jic Vs Compression Fitting.

From my.eezee.sg

Rfs Stainless Steel SS316 Jic Hex Plug, 5/8 Male Jic, 37Degree Flared Jic Vs Compression Fitting They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. The only difference between an and jic fittings is that an fittings are manufactured as per more stringent tolerances for military applications. Jic (or joint industry council) fittings, defined by sae j514, are compression fittings machined with a 37 degree flare seating surface and parallel threads. Flared fittings. Jic Vs Compression Fitting.

From eezee.sg

Rfs Stainless Steel SS316 Jic Hex Plug, 3/4 Male Jic, 37Degree Flared Jic Vs Compression Fitting They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. Pros and cons of jic fittings. Jic fittings adhere to the sae j514. They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. Flared fittings have long been used instead of pipe. Jic (or joint industry council) fittings, defined by sae j514, are compression fittings machined. Jic Vs Compression Fitting.

From hydraulicfitting.cn

Swaged Hose Fittings VS Compression Fittings Sinopulse hydraulic Jic Vs Compression Fitting Pros and cons of jic fittings. Flared fittings are significantly superior to pipe fittings in terms of design and performance. They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. Though these fittings are similar in. The acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads.. Jic Vs Compression Fitting.

From www.jiayuanfitting.com

SAE thread JIC fitting size chart Knowledge Yuyao Jiayuan Hydraulic Jic Vs Compression Fitting While jic and an fittings share some similarities, several key differences set them apart: The only difference between an and jic fittings is that an fittings are manufactured as per more stringent tolerances for military applications. Though these fittings are similar in. Jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and. Jic Vs Compression Fitting.

From www.hidraflex.com

JIC male thread 3/4" JIC compression fitting for hose inner Ø 12,7 mm Jic Vs Compression Fitting Though these fittings are similar in. Pros and cons of jic fittings. While jic and an fittings share some similarities, several key differences set them apart: Jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications. Flared fittings have long been used instead of pipe. Jic fittings adhere to the. Jic Vs Compression Fitting.

From eezee.sg

Rfs Stainless Steel SS316 Jic 90Degree Male Elbow, 1" Jic X 1 Npt, 37 Jic Vs Compression Fitting Flared fittings are significantly superior to pipe fittings in terms of design and performance. They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. The only difference between an and jic fittings is that an fittings are manufactured as per more stringent tolerances for military applications. While jic and an fittings share some similarities, several key differences set. Jic Vs Compression Fitting.

From rubberandspecialties.com

JIC vs. SAE Flare Fittings Rubber & Specialties,Inc. Jic Vs Compression Fitting They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. Jic fitting hydraulic connections are common in most fluid power systems. While jic and an fittings share some similarities, several key differences set them apart: The acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads. The. Jic Vs Compression Fitting.

From hydraulicfitting.cn

JIC Fitting Sizes Overview Sinopulse hydraulic Jic Vs Compression Fitting The only difference between an and jic fittings is that an fittings are manufactured as per more stringent tolerances for military applications. Though these fittings are similar in. Flared fittings are significantly superior to pipe fittings in terms of design and performance. Pros and cons of jic fittings. They are commonly manufactured in nickel alloys, brass, carbon & stainless steel.. Jic Vs Compression Fitting.

From hydraulicfitting.cn

JIC vs SAE Flare Fittings Which is Better? Sinopulse hydraulic Jic Vs Compression Fitting Jic fittings adhere to the sae j514. Though these fittings are similar in. While jic and an fittings share some similarities, several key differences set them apart: The only difference between an and jic fittings is that an fittings are manufactured as per more stringent tolerances for military applications. They are commonly manufactured in nickel alloys, brass, carbon & stainless. Jic Vs Compression Fitting.

From www.rajdeepmetals.com

Stainless Steel JIC Fittings manufacturer India SAE Bulkhead Fitting Jic Vs Compression Fitting Jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications. Jic (or joint industry council) fittings, defined by sae j514, are compression fittings machined with a 37 degree flare seating surface and parallel threads. While jic and an fittings share some similarities, several key differences set them apart: Flared fittings. Jic Vs Compression Fitting.

From eezee.sg

Rfs Stainless Steel SS316 Jic 90Degree Union Elbow, 1 1/4", 37Degree Jic Vs Compression Fitting The acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads. Jic fittings adhere to the sae j514. Flared fittings are significantly superior to pipe fittings in terms of design and performance. They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. Jic fitting hydraulic connections are. Jic Vs Compression Fitting.

From greenbushfarmcom.blogspot.com

Jic Hydraulic Fitting Size Chart Jic Vs Compression Fitting They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. Flared fittings are significantly superior to pipe fittings in terms of design and performance. While jic and an fittings share some similarities, several key differences set them apart: Jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications.. Jic Vs Compression Fitting.

From eezee.sg

Rfs Stainless Steel SS316 Jic Male Connector, 5/16" Jic X 1/4 Npt, 37 Jic Vs Compression Fitting Jic fittings adhere to the sae j514. Jic (or joint industry council) fittings, defined by sae j514, are compression fittings machined with a 37 degree flare seating surface and parallel threads. The acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads. Jic and an fittings are both threaded. Jic Vs Compression Fitting.

From www.cntopa.com

JIC vs NPT Fittings The Ultimate Guide Topa Jic Vs Compression Fitting Jic fitting hydraulic connections are common in most fluid power systems. Flared fittings have long been used instead of pipe. Pros and cons of jic fittings. Though these fittings are similar in. Jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications. They are commonly manufactured in nickel alloys, brass,. Jic Vs Compression Fitting.

From www.triadtechnologies.com

JIC vs. AN Fittings A HeadtoHead Comparison Jic Vs Compression Fitting They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. Jic (or joint industry council) fittings, defined by sae j514, are compression fittings machined with a 37 degree flare seating surface and parallel threads. While jic and an fittings share some similarities, several key differences set them apart: Though these fittings are similar in. Flared fittings are significantly. Jic Vs Compression Fitting.

From www.qchydraulics.com

JIC fittings vs NPT fittings What's the Difference and Similarity QC Jic Vs Compression Fitting Jic fitting hydraulic connections are common in most fluid power systems. They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. Jic (or joint industry council) fittings, defined by sae j514, are compression fittings machined with a 37 degree flare seating surface and parallel threads. Though these fittings are similar in. They are commonly manufactured in nickel alloys,. Jic Vs Compression Fitting.

From www.qchydraulics.com

An Fitting Size Chart A guide To the right Size QC Hydraulics Jic Vs Compression Fitting Flared fittings are significantly superior to pipe fittings in terms of design and performance. They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. While jic and an fittings share some similarities, several key differences set them apart: Jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications.. Jic Vs Compression Fitting.

From eezee.sg

Rfs Stainless Steel SS316 Jic 90Degree Union Elbow, 1", 37Degree Jic Vs Compression Fitting Though these fittings are similar in. Jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications. Jic fittings adhere to the sae j514. Flared fittings have long been used instead of pipe. While jic and an fittings share some similarities, several key differences set them apart: They are commonly manufactured. Jic Vs Compression Fitting.

From fluiddrivecoupling.com

JIS vs JIC fitting standards Knowledge EVERPOWER GROUP CO., LTD. Jic Vs Compression Fitting Pros and cons of jic fittings. Though these fittings are similar in. Flared fittings have long been used instead of pipe. Jic (or joint industry council) fittings, defined by sae j514, are compression fittings machined with a 37 degree flare seating surface and parallel threads. The only difference between an and jic fittings is that an fittings are manufactured as. Jic Vs Compression Fitting.

From irontime-sales.com

FUI 1" 45° ELBOW JIC X JIC FEMALE SWIVEL COMPRESSION FITTING 65021616 Jic Vs Compression Fitting Jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications. The only difference between an and jic fittings is that an fittings are manufactured as per more stringent tolerances for military applications. Pros and cons of jic fittings. Jic fittings adhere to the sae j514. While jic and an fittings. Jic Vs Compression Fitting.

From eezee.sg

Rfs Stainless Steel SS316 Jic Hex Plug, 5/8 Male Jic, 37Degree Flared Jic Vs Compression Fitting Jic (or joint industry council) fittings, defined by sae j514, are compression fittings machined with a 37 degree flare seating surface and parallel threads. The only difference between an and jic fittings is that an fittings are manufactured as per more stringent tolerances for military applications. While jic and an fittings share some similarities, several key differences set them apart:. Jic Vs Compression Fitting.

From hydraxio.com

Understanding the Differences AN vs. JIC Fittings Hydraxio China SS Jic Vs Compression Fitting Flared fittings are significantly superior to pipe fittings in terms of design and performance. Flared fittings have long been used instead of pipe. They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. The acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads. Pros and cons. Jic Vs Compression Fitting.

From eezee.sg

Rfs Stainless Steel SS316 Jic Male Connector, 5/16" Jic X 1/4 Npt, 37 Jic Vs Compression Fitting The only difference between an and jic fittings is that an fittings are manufactured as per more stringent tolerances for military applications. Jic fitting hydraulic connections are common in most fluid power systems. They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. Flared fittings have long been used instead of pipe. Pros and cons of jic fittings.. Jic Vs Compression Fitting.

From fluidpowerjournal.com

Screwed on Right The Pros and Cons of JIC Hydraulic Fittings Fluid Jic Vs Compression Fitting They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. The acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads. Jic fitting hydraulic connections are common in most fluid power systems. Flared fittings have long been used instead of pipe. Jic and an fittings are both. Jic Vs Compression Fitting.

From www.youtube.com

Fittings 101 JIC YouTube Jic Vs Compression Fitting Jic (or joint industry council) fittings, defined by sae j514, are compression fittings machined with a 37 degree flare seating surface and parallel threads. Jic fittings adhere to the sae j514. Jic fitting hydraulic connections are common in most fluid power systems. They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. They are commonly manufactured in nickel. Jic Vs Compression Fitting.

From www.rhhardware.com

JIC vs AN Fitting Differences Yuyao Ruihua Hardware Factory Jic Vs Compression Fitting They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. Though these fittings are similar in. Jic fitting hydraulic connections are common in most fluid power systems. Pros and cons of jic fittings. Flared fittings are significantly superior to pipe fittings in terms of design and performance. Flared fittings have long been used instead of pipe. The only. Jic Vs Compression Fitting.

From www.laikehydraulics.com

NPT Fittings vs JIC Fittings Laike Jic Vs Compression Fitting Flared fittings have long been used instead of pipe. Flared fittings are significantly superior to pipe fittings in terms of design and performance. Though these fittings are similar in. Jic fitting hydraulic connections are common in most fluid power systems. Jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications.. Jic Vs Compression Fitting.

From eezee.sg

Rfs Stainless Steel SS316 Jic 90Degree Male Elbow, 1" Jic X 3/4 Npt Jic Vs Compression Fitting They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. Jic fittings adhere to the sae j514. While jic and an fittings share some similarities, several key differences set them apart: Jic (or joint industry council) fittings, defined by sae j514, are compression fittings machined with a 37 degree flare seating surface and parallel threads. The only difference. Jic Vs Compression Fitting.

From www.valvers.com

AN and JIC Fittings Jic Vs Compression Fitting The acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads. Jic (or joint industry council) fittings, defined by sae j514, are compression fittings machined with a 37 degree flare seating surface and parallel threads. Flared fittings are significantly superior to pipe fittings in terms of design and performance.. Jic Vs Compression Fitting.

From www.qchydraulics.com

flare vs compression fittings QC Hydraulics Jic Vs Compression Fitting They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. Flared fittings have long been used instead of pipe. Though these fittings are similar in. Jic fitting hydraulic connections are common in most fluid power systems. Jic fittings adhere to the sae j514. Pros and cons of jic fittings. They are commonly manufactured in nickel alloys, brass, carbon. Jic Vs Compression Fitting.

From eezee.sg

Rfs Stainless Steel SS316 Jic Male Connector, 1 1/2" Jic X 1 1/2 Npt Jic Vs Compression Fitting While jic and an fittings share some similarities, several key differences set them apart: Jic fittings adhere to the sae j514. Flared fittings have long been used instead of pipe. Jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications. They are commonly manufactured in nickel alloys, brass, carbon &. Jic Vs Compression Fitting.

From eezee.sg

Rfs Stainless Steel SS316 Bulkhead Union Jic Fitting, 3/8", 37Degree Jic Vs Compression Fitting Flared fittings are significantly superior to pipe fittings in terms of design and performance. Flared fittings have long been used instead of pipe. While jic and an fittings share some similarities, several key differences set them apart: Pros and cons of jic fittings. Jic fittings adhere to the sae j514. Jic and an fittings are both threaded fittings with a. Jic Vs Compression Fitting.

From www.besteflon.com

News What's the Difference Between AN and JIC Fittings? Jic Vs Compression Fitting Jic and an fittings are both threaded fittings with a flared end which are used in hydraulic and pneumatic applications. Jic fitting hydraulic connections are common in most fluid power systems. They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. Jic fittings adhere to the sae j514. Flared fittings have long been used instead of pipe. Though. Jic Vs Compression Fitting.

From www.cntopa.com

How to Identify Metric vs BSP Hydraulic Fittings Topa Blog Jic Vs Compression Fitting Pros and cons of jic fittings. The acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads. Jic fitting hydraulic connections are common in most fluid power systems. They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. Jic and an fittings are both threaded fittings with. Jic Vs Compression Fitting.