Jaw Coupling Advantages And Disadvantages . If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. The most standard fundamental jaw coupling spider is a spider constructed of solid nitrile butadiene (buna n) rubber (pictured at left). Compression type couplings offer advantages in four areas: Load capacity, torsional stiffness, safety, and easy installation.

from blog.naver.com

The most standard fundamental jaw coupling spider is a spider constructed of solid nitrile butadiene (buna n) rubber (pictured at left). Compression type couplings offer advantages in four areas: If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. Load capacity, torsional stiffness, safety, and easy installation. Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to.

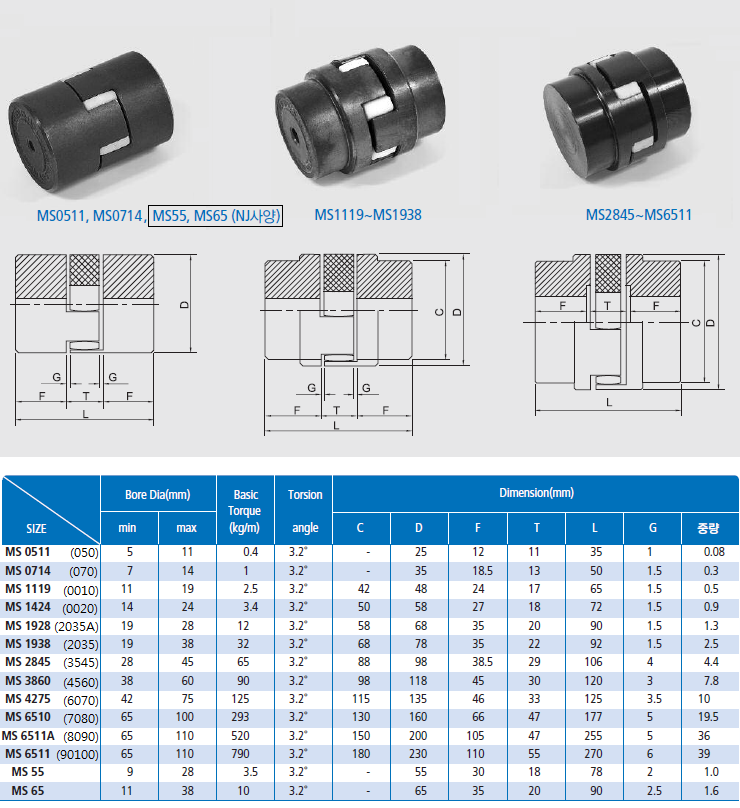

죠카플링 JAW COUPLING 네이버 블로그

Jaw Coupling Advantages And Disadvantages Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. Load capacity, torsional stiffness, safety, and easy installation. The most standard fundamental jaw coupling spider is a spider constructed of solid nitrile butadiene (buna n) rubber (pictured at left). If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. Compression type couplings offer advantages in four areas:

From www.rokeecoupling.com

Jaw Coupling Advantages And Disadvantages Rokee Jaw Coupling Advantages And Disadvantages The most standard fundamental jaw coupling spider is a spider constructed of solid nitrile butadiene (buna n) rubber (pictured at left). Compression type couplings offer advantages in four areas: Load capacity, torsional stiffness, safety, and easy installation. Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. If. Jaw Coupling Advantages And Disadvantages.

From www.rokeecoupling.com

Jaw Coupling Advantages And Disadvantages Rokee Jaw Coupling Advantages And Disadvantages Load capacity, torsional stiffness, safety, and easy installation. Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. The most standard fundamental jaw coupling spider is a spider constructed of solid nitrile butadiene (buna n) rubber (pictured at left). Compression type couplings offer advantages in four areas: If. Jaw Coupling Advantages And Disadvantages.

From www.rokee.com

Efficiency of Jaw Type Flexible Couplings Rokee Jaw Coupling Advantages And Disadvantages Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. Compression type couplings offer advantages in four areas: The most standard fundamental jaw coupling spider is a spider constructed of solid nitrile butadiene (buna n) rubber (pictured at left). If your equipment operates with varying shaft angles and. Jaw Coupling Advantages And Disadvantages.

From www.altramotion.com

L Jaw Couplings Jaw Coupling Advantages And Disadvantages Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. Compression type couplings offer advantages in four areas: The most standard fundamental jaw coupling spider is a spider constructed of solid nitrile butadiene (buna n) rubber (pictured at left). Load capacity, torsional stiffness, safety, and easy installation. If. Jaw Coupling Advantages And Disadvantages.

From www.pumpsandcouplings.com

Clamp Type Jaw Coupling JSCA Aluminum Pumps & Couplings Jaw Coupling Advantages And Disadvantages If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. The most standard fundamental jaw coupling spider is a spider constructed of solid nitrile butadiene (buna n) rubber (pictured at left). Compression type couplings offer advantages in four areas: Load capacity, torsional stiffness, safety, and easy installation. Made up. Jaw Coupling Advantages And Disadvantages.

From us.misumi-ec.com

TraditionalJawCoupling MISUMI Mech Lab Blog Jaw Coupling Advantages And Disadvantages The most standard fundamental jaw coupling spider is a spider constructed of solid nitrile butadiene (buna n) rubber (pictured at left). Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. Load capacity, torsional stiffness, safety, and easy installation. Compression type couplings offer advantages in four areas: If. Jaw Coupling Advantages And Disadvantages.

From www.mikipulley-us.com

Jaw & Spider Couplings Jaw Couplings Elastomer Couplings Jaw Coupling Advantages And Disadvantages Compression type couplings offer advantages in four areas: If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. The most standard fundamental jaw coupling spider is a spider constructed of solid nitrile butadiene (buna n) rubber (pictured at left). Made up of three components, two jaws and an elastomeric. Jaw Coupling Advantages And Disadvantages.

From www.youtube.com

Flexible jaw coupling ROTEX® SH with SPLIT hubs YouTube Jaw Coupling Advantages And Disadvantages Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. Load capacity, torsional stiffness, safety, and easy installation. The most standard fundamental jaw coupling spider is a spider constructed of solid nitrile butadiene (buna n) rubber (pictured at left). Compression type couplings offer advantages in four areas: If. Jaw Coupling Advantages And Disadvantages.

From www.scribd.com

Jaw Coupling Dimensions (Inches) PDF Machines Metalworking Jaw Coupling Advantages And Disadvantages Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. The most standard fundamental jaw coupling spider is a spider constructed of solid nitrile butadiene (buna n). Jaw Coupling Advantages And Disadvantages.

From www.rokeecoupling.com

Jaw Coupling Advantages And Disadvantages Rokee Jaw Coupling Advantages And Disadvantages Load capacity, torsional stiffness, safety, and easy installation. If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. Compression type couplings offer advantages in four areas: Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. The. Jaw Coupling Advantages And Disadvantages.

From jawcoupling.blogspot.com

How jaw coupling works? Jaw Coupling Advantages And Disadvantages The most standard fundamental jaw coupling spider is a spider constructed of solid nitrile butadiene (buna n) rubber (pictured at left). Compression type couplings offer advantages in four areas: If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. Made up of three components, two jaws and an elastomeric. Jaw Coupling Advantages And Disadvantages.

From blog.naver.com

죠카플링 JAW COUPLING 네이버 블로그 Jaw Coupling Advantages And Disadvantages The most standard fundamental jaw coupling spider is a spider constructed of solid nitrile butadiene (buna n) rubber (pictured at left). Compression type couplings offer advantages in four areas: If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. Load capacity, torsional stiffness, safety, and easy installation. Made up. Jaw Coupling Advantages And Disadvantages.

From www.sogears.com

Jaw coupling Jaw Coupling Advantages And Disadvantages Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. Load capacity, torsional stiffness, safety, and easy installation. Compression type couplings offer advantages in four areas: The. Jaw Coupling Advantages And Disadvantages.

From www.scribd.com

Jaw Coupling Machines Mechanical Engineering Jaw Coupling Advantages And Disadvantages Compression type couplings offer advantages in four areas: Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. Load capacity, torsional stiffness, safety, and easy installation. The. Jaw Coupling Advantages And Disadvantages.

From www.guardiancouplings.com

Curved Jaw Coupling Guardian Couplings Jaw Coupling Advantages And Disadvantages Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. Load capacity, torsional stiffness, safety, and easy installation. Compression type couplings offer advantages in four areas: The. Jaw Coupling Advantages And Disadvantages.

From faparts.net

Jaw Coupling Jaw Coupling Advantages And Disadvantages Compression type couplings offer advantages in four areas: Load capacity, torsional stiffness, safety, and easy installation. If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. The. Jaw Coupling Advantages And Disadvantages.

From exozsyupq.blob.core.windows.net

Lovejoy Coupling Advantages And Disadvantages at Patrick Whittenburg blog Jaw Coupling Advantages And Disadvantages Compression type couplings offer advantages in four areas: Load capacity, torsional stiffness, safety, and easy installation. Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. The. Jaw Coupling Advantages And Disadvantages.

From www.rototime.com

Jaw Coupling RotoTime Servo Gearbox, Stainless Gearbox, Bevel Jaw Coupling Advantages And Disadvantages Compression type couplings offer advantages in four areas: Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. The most standard fundamental jaw coupling spider is a spider constructed of solid nitrile butadiene (buna n) rubber (pictured at left). If your equipment operates with varying shaft angles and. Jaw Coupling Advantages And Disadvantages.

From www.tbwoods.com

LJaw Coupling CJaw Couplings TB Wood's Jaw Coupling Advantages And Disadvantages Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. The most standard fundamental jaw coupling spider is a spider constructed of solid nitrile butadiene (buna n) rubber (pictured at left). Load capacity, torsional stiffness, safety, and easy installation. If your equipment operates with varying shaft angles and. Jaw Coupling Advantages And Disadvantages.

From nobisindustrial.com

Solve Industrial Nobis Industrial Jaw Coupling Advantages And Disadvantages Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. Load capacity, torsional stiffness, safety, and easy installation. If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. The most standard fundamental jaw coupling spider is a. Jaw Coupling Advantages And Disadvantages.

From jingbang-fa.com

Flexible Shaft Coupling Jaw Shaft Collars,Shaft Coupling,Conveyor Jaw Coupling Advantages And Disadvantages Compression type couplings offer advantages in four areas: If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. The most standard fundamental jaw coupling spider is a spider constructed of solid nitrile butadiene (buna n) rubber (pictured at left). Load capacity, torsional stiffness, safety, and easy installation. Made up. Jaw Coupling Advantages And Disadvantages.

From conbear.com.au

Back to Basics How to select and install jaw couplings CBC Australia Jaw Coupling Advantages And Disadvantages Compression type couplings offer advantages in four areas: If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. Load capacity, torsional stiffness, safety, and easy installation. Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. The. Jaw Coupling Advantages And Disadvantages.

From www.hayescouplings.com

Hayes Original Jaw Couplings Hayes Manufacturing, Inc. Jaw Coupling Advantages And Disadvantages Compression type couplings offer advantages in four areas: If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. Load capacity, torsional stiffness, safety, and easy installation. The most standard fundamental jaw coupling spider is a spider constructed of solid nitrile butadiene (buna n) rubber (pictured at left). Made up. Jaw Coupling Advantages And Disadvantages.

From www.iqsdirectory.com

Quick Release Couplings Types, Benefits, Classifications, and Purpose Jaw Coupling Advantages And Disadvantages Load capacity, torsional stiffness, safety, and easy installation. Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. Compression type couplings offer advantages in four areas: The most standard fundamental jaw coupling spider is a spider constructed of solid nitrile butadiene (buna n) rubber (pictured at left). If. Jaw Coupling Advantages And Disadvantages.

From www.youtube.com

jaw coupling size calculation YouTube Jaw Coupling Advantages And Disadvantages If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. Load capacity, torsional stiffness, safety, and easy installation. Compression type couplings offer advantages in four areas: The most standard fundamental jaw coupling spider is a spider constructed of solid nitrile butadiene (buna n) rubber (pictured at left). Made up. Jaw Coupling Advantages And Disadvantages.

From www.rokeecoupling.com

Jaw Coupling Advantages And Disadvantages Rokee Jaw Coupling Advantages And Disadvantages If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. The most standard fundamental jaw coupling spider is a spider constructed of solid nitrile butadiene (buna n) rubber (pictured at left). Load capacity, torsional stiffness, safety, and easy installation. Made up of three components, two jaws and an elastomeric. Jaw Coupling Advantages And Disadvantages.

From www.youtube.com

Jaw Coupling Jaw Coupling Troubleshooting Problems and Remedies of Jaw Coupling Advantages And Disadvantages If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. Load capacity, torsional stiffness, safety, and easy installation. The most standard fundamental jaw coupling spider is a. Jaw Coupling Advantages And Disadvantages.

From www.thomasnet.com

Types of Shaft Couplings A Buying Guide Jaw Coupling Advantages And Disadvantages Compression type couplings offer advantages in four areas: The most standard fundamental jaw coupling spider is a spider constructed of solid nitrile butadiene (buna n) rubber (pictured at left). If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. Made up of three components, two jaws and an elastomeric. Jaw Coupling Advantages And Disadvantages.

From hxedqeuaz.blob.core.windows.net

Flexible Jaw Coupling at Leroy Patino blog Jaw Coupling Advantages And Disadvantages Compression type couplings offer advantages in four areas: If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. The most standard fundamental jaw coupling spider is a. Jaw Coupling Advantages And Disadvantages.

From www.grainger.com

TB WOOD'S Jaw Coupling Hub L190, 1 7/8 in Bore Dia., 1/2 in x 1/4 in Jaw Coupling Advantages And Disadvantages Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. Compression type couplings offer advantages in four areas: The most standard fundamental jaw coupling spider is a spider constructed of solid nitrile butadiene (buna n) rubber (pictured at left). Load capacity, torsional stiffness, safety, and easy installation. If. Jaw Coupling Advantages And Disadvantages.

From dokumen.tips

(PDF) ELASTOMERIC JAW TYPE COUPLINGS...Jaw Couplings Advantages Jaw Jaw Coupling Advantages And Disadvantages Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. Compression type couplings offer advantages in four areas: If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. The most standard fundamental jaw coupling spider is a. Jaw Coupling Advantages And Disadvantages.

From thietbickm.com.vn

Jaw coupling Jaw Coupling Advantages And Disadvantages Compression type couplings offer advantages in four areas: If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. Load capacity, torsional stiffness, safety, and easy installation. Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. The. Jaw Coupling Advantages And Disadvantages.

From www.youtube.com

Types Of Jaw Coupling Types of Love joy Coupling Jaw Coupling Types Jaw Coupling Advantages And Disadvantages Load capacity, torsional stiffness, safety, and easy installation. If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. The most standard fundamental jaw coupling spider is a spider constructed of solid nitrile butadiene (buna n) rubber (pictured at left). Made up of three components, two jaws and an elastomeric. Jaw Coupling Advantages And Disadvantages.

From marshward.com

JAW COUPLING "GAS" Jaw Coupling Advantages And Disadvantages Compression type couplings offer advantages in four areas: Load capacity, torsional stiffness, safety, and easy installation. The most standard fundamental jaw coupling spider is a spider constructed of solid nitrile butadiene (buna n) rubber (pictured at left). Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. If. Jaw Coupling Advantages And Disadvantages.

From www.linquip.com

What is Jaw Coupling? Working Principle & Size Chart Linquip Jaw Coupling Advantages And Disadvantages Made up of three components, two jaws and an elastomeric spider, jaw couplings operate in a single plane between two hubs to. Load capacity, torsional stiffness, safety, and easy installation. Compression type couplings offer advantages in four areas: If your equipment operates with varying shaft angles and needs to handle heavy loads, universal joints are likely the best option. The. Jaw Coupling Advantages And Disadvantages.