Thread Engagement Ratio . If the value of j is greater than 1 then the length of engagement must be increased to at least. The thread engagement length is multiplied by a ratio of the shear areas and ultimate tensile strengths of the respective materials. Percent of thread engagement is based size of the mating hole compared to the fastener and how much the height of threads of the screw are engaged. For a steel nut member: For brass or cast iron threads, the minimum thread engagement should be 1.5 to 2.0 x the bolt’s or screw’s base nominal diameter. Le2 = minimum thread engagement. J = thread engagement ratio. This engineering calculator will determine the iso thread / fastener ratio and length requirements for an engineering requirement. It is commonly known that the minimum recommended thread engagement to make a strong connection for a component with a.

from www.autodesk.com

For brass or cast iron threads, the minimum thread engagement should be 1.5 to 2.0 x the bolt’s or screw’s base nominal diameter. Percent of thread engagement is based size of the mating hole compared to the fastener and how much the height of threads of the screw are engaged. J = thread engagement ratio. This engineering calculator will determine the iso thread / fastener ratio and length requirements for an engineering requirement. Le2 = minimum thread engagement. For a steel nut member: If the value of j is greater than 1 then the length of engagement must be increased to at least. It is commonly known that the minimum recommended thread engagement to make a strong connection for a component with a. The thread engagement length is multiplied by a ratio of the shear areas and ultimate tensile strengths of the respective materials.

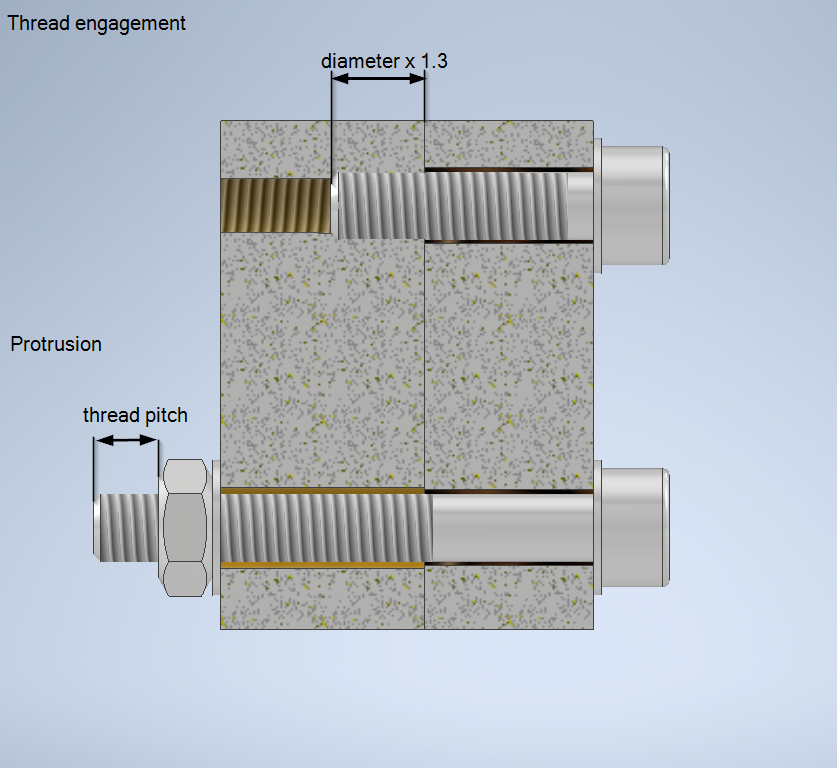

Minimum thread engagement and protrusion size in Inventor Bolted Connection

Thread Engagement Ratio Le2 = minimum thread engagement. If the value of j is greater than 1 then the length of engagement must be increased to at least. It is commonly known that the minimum recommended thread engagement to make a strong connection for a component with a. For a steel nut member: J = thread engagement ratio. Le2 = minimum thread engagement. For brass or cast iron threads, the minimum thread engagement should be 1.5 to 2.0 x the bolt’s or screw’s base nominal diameter. The thread engagement length is multiplied by a ratio of the shear areas and ultimate tensile strengths of the respective materials. Percent of thread engagement is based size of the mating hole compared to the fastener and how much the height of threads of the screw are engaged. This engineering calculator will determine the iso thread / fastener ratio and length requirements for an engineering requirement.

From mungfali.com

NPT Pipe Thread Engagement Chart Thread Engagement Ratio The thread engagement length is multiplied by a ratio of the shear areas and ultimate tensile strengths of the respective materials. J = thread engagement ratio. Le2 = minimum thread engagement. If the value of j is greater than 1 then the length of engagement must be increased to at least. This engineering calculator will determine the iso thread /. Thread Engagement Ratio.

From be-cu.com

A Guide To Thread TypesPractical Engineer's Guide Thread Engagement Ratio The thread engagement length is multiplied by a ratio of the shear areas and ultimate tensile strengths of the respective materials. Le2 = minimum thread engagement. This engineering calculator will determine the iso thread / fastener ratio and length requirements for an engineering requirement. For a steel nut member: For brass or cast iron threads, the minimum thread engagement should. Thread Engagement Ratio.

From www.slideshare.net

Minimum Bolt Thread Engagement with Respect to Various Material Stren… Thread Engagement Ratio For a steel nut member: It is commonly known that the minimum recommended thread engagement to make a strong connection for a component with a. For brass or cast iron threads, the minimum thread engagement should be 1.5 to 2.0 x the bolt’s or screw’s base nominal diameter. Le2 = minimum thread engagement. This engineering calculator will determine the iso. Thread Engagement Ratio.

From www.slideshare.net

Minimum Bolt Thread Engagement with Respect to Various Material Stren… Thread Engagement Ratio Le2 = minimum thread engagement. This engineering calculator will determine the iso thread / fastener ratio and length requirements for an engineering requirement. If the value of j is greater than 1 then the length of engagement must be increased to at least. The thread engagement length is multiplied by a ratio of the shear areas and ultimate tensile strengths. Thread Engagement Ratio.

From www.machiningdoctor.com

Metric Threads Dimensions, Classes & Formulas (full Guide) Thread Engagement Ratio If the value of j is greater than 1 then the length of engagement must be increased to at least. For a steel nut member: It is commonly known that the minimum recommended thread engagement to make a strong connection for a component with a. Percent of thread engagement is based size of the mating hole compared to the fastener. Thread Engagement Ratio.

From www.jcfasteners.com

Screw Thread Engagement J C Gupta & Sons Thread Engagement Ratio The thread engagement length is multiplied by a ratio of the shear areas and ultimate tensile strengths of the respective materials. J = thread engagement ratio. It is commonly known that the minimum recommended thread engagement to make a strong connection for a component with a. For a steel nut member: If the value of j is greater than 1. Thread Engagement Ratio.

From www.nord-lock.com

The Experts Thread engagement in a tapped hole NordLock Group Thread Engagement Ratio If the value of j is greater than 1 then the length of engagement must be increased to at least. This engineering calculator will determine the iso thread / fastener ratio and length requirements for an engineering requirement. J = thread engagement ratio. For a steel nut member: Le2 = minimum thread engagement. Percent of thread engagement is based size. Thread Engagement Ratio.

From mungfali.com

NPT Thread Chart Thread Engagement Ratio J = thread engagement ratio. The thread engagement length is multiplied by a ratio of the shear areas and ultimate tensile strengths of the respective materials. This engineering calculator will determine the iso thread / fastener ratio and length requirements for an engineering requirement. Percent of thread engagement is based size of the mating hole compared to the fastener and. Thread Engagement Ratio.

From staging.neilpatel.com

Twitter vs. Instagram Threads Performance Comparison Thread Engagement Ratio For a steel nut member: This engineering calculator will determine the iso thread / fastener ratio and length requirements for an engineering requirement. J = thread engagement ratio. It is commonly known that the minimum recommended thread engagement to make a strong connection for a component with a. If the value of j is greater than 1 then the length. Thread Engagement Ratio.

From www.scribd.com

METRIC THREAD.pdf Joining Tools Thread Engagement Ratio Percent of thread engagement is based size of the mating hole compared to the fastener and how much the height of threads of the screw are engaged. J = thread engagement ratio. It is commonly known that the minimum recommended thread engagement to make a strong connection for a component with a. Le2 = minimum thread engagement. This engineering calculator. Thread Engagement Ratio.

From www.apollointernational.in

National Pipe Thread NPT Thread Chart Apollo International Thread Engagement Ratio Percent of thread engagement is based size of the mating hole compared to the fastener and how much the height of threads of the screw are engaged. If the value of j is greater than 1 then the length of engagement must be increased to at least. This engineering calculator will determine the iso thread / fastener ratio and length. Thread Engagement Ratio.

From www.regalcuttingtools.com

Tapping Difficulties and Percent of Thread Regal Cutting Tools Thread Engagement Ratio Le2 = minimum thread engagement. It is commonly known that the minimum recommended thread engagement to make a strong connection for a component with a. J = thread engagement ratio. For a steel nut member: This engineering calculator will determine the iso thread / fastener ratio and length requirements for an engineering requirement. If the value of j is greater. Thread Engagement Ratio.

From www.slideserve.com

PPT Overview of VDI 2230 PowerPoint Presentation ID293640 Thread Engagement Ratio This engineering calculator will determine the iso thread / fastener ratio and length requirements for an engineering requirement. Le2 = minimum thread engagement. The thread engagement length is multiplied by a ratio of the shear areas and ultimate tensile strengths of the respective materials. J = thread engagement ratio. If the value of j is greater than 1 then the. Thread Engagement Ratio.

From mavink.com

Minimum Thread Engagement Chart Thread Engagement Ratio J = thread engagement ratio. For brass or cast iron threads, the minimum thread engagement should be 1.5 to 2.0 x the bolt’s or screw’s base nominal diameter. Percent of thread engagement is based size of the mating hole compared to the fastener and how much the height of threads of the screw are engaged. It is commonly known that. Thread Engagement Ratio.

From www.autodesk.com

Minimum thread engagement and protrusion size in Inventor Bolted Connection Thread Engagement Ratio For brass or cast iron threads, the minimum thread engagement should be 1.5 to 2.0 x the bolt’s or screw’s base nominal diameter. For a steel nut member: J = thread engagement ratio. The thread engagement length is multiplied by a ratio of the shear areas and ultimate tensile strengths of the respective materials. If the value of j is. Thread Engagement Ratio.

From instrumentationtubing.blogspot.com

Instrumentation Tubing and Their Connections 14.0 Threads Used For Thread Engagement Ratio The thread engagement length is multiplied by a ratio of the shear areas and ultimate tensile strengths of the respective materials. For brass or cast iron threads, the minimum thread engagement should be 1.5 to 2.0 x the bolt’s or screw’s base nominal diameter. Le2 = minimum thread engagement. J = thread engagement ratio. It is commonly known that the. Thread Engagement Ratio.

From www.mudgefasteners.com

Thread Pitch Charts Thread Engagement Ratio The thread engagement length is multiplied by a ratio of the shear areas and ultimate tensile strengths of the respective materials. For brass or cast iron threads, the minimum thread engagement should be 1.5 to 2.0 x the bolt’s or screw’s base nominal diameter. Le2 = minimum thread engagement. This engineering calculator will determine the iso thread / fastener ratio. Thread Engagement Ratio.

From www.youtube.com

Engineering Rule for bolt thread engagement (2 Solutions!!) YouTube Thread Engagement Ratio Le2 = minimum thread engagement. Percent of thread engagement is based size of the mating hole compared to the fastener and how much the height of threads of the screw are engaged. If the value of j is greater than 1 then the length of engagement must be increased to at least. For brass or cast iron threads, the minimum. Thread Engagement Ratio.

From www.slideshare.net

Minimum Bolt Thread Engagement with Respect to Various Material Stren… Thread Engagement Ratio If the value of j is greater than 1 then the length of engagement must be increased to at least. J = thread engagement ratio. The thread engagement length is multiplied by a ratio of the shear areas and ultimate tensile strengths of the respective materials. This engineering calculator will determine the iso thread / fastener ratio and length requirements. Thread Engagement Ratio.

From www.scribd.com

Minimum Thread Engagement Bolt Failure Chart Metric PDF Screw Thread Engagement Ratio J = thread engagement ratio. It is commonly known that the minimum recommended thread engagement to make a strong connection for a component with a. This engineering calculator will determine the iso thread / fastener ratio and length requirements for an engineering requirement. The thread engagement length is multiplied by a ratio of the shear areas and ultimate tensile strengths. Thread Engagement Ratio.

From www.forwardcontrolsdesign.com

On thread engagement Thread Engagement Ratio It is commonly known that the minimum recommended thread engagement to make a strong connection for a component with a. Percent of thread engagement is based size of the mating hole compared to the fastener and how much the height of threads of the screw are engaged. J = thread engagement ratio. For brass or cast iron threads, the minimum. Thread Engagement Ratio.

From pt.scribd.com

BSP Thread Chart Building Materials Mechanical Engineering Thread Engagement Ratio J = thread engagement ratio. Le2 = minimum thread engagement. It is commonly known that the minimum recommended thread engagement to make a strong connection for a component with a. This engineering calculator will determine the iso thread / fastener ratio and length requirements for an engineering requirement. Percent of thread engagement is based size of the mating hole compared. Thread Engagement Ratio.

From www.researchgate.net

Load displacement curve of one thread engagement length. Figure 17 Thread Engagement Ratio The thread engagement length is multiplied by a ratio of the shear areas and ultimate tensile strengths of the respective materials. For a steel nut member: Percent of thread engagement is based size of the mating hole compared to the fastener and how much the height of threads of the screw are engaged. For brass or cast iron threads, the. Thread Engagement Ratio.

From www.scribd.com

NPT Thread Dimensions Pipe (Fluid Conveyance) Machining Thread Engagement Ratio J = thread engagement ratio. Percent of thread engagement is based size of the mating hole compared to the fastener and how much the height of threads of the screw are engaged. For brass or cast iron threads, the minimum thread engagement should be 1.5 to 2.0 x the bolt’s or screw’s base nominal diameter. If the value of j. Thread Engagement Ratio.

From mungfali.com

NPT Thread Chart PDF Thread Engagement Ratio Le2 = minimum thread engagement. The thread engagement length is multiplied by a ratio of the shear areas and ultimate tensile strengths of the respective materials. J = thread engagement ratio. Percent of thread engagement is based size of the mating hole compared to the fastener and how much the height of threads of the screw are engaged. For brass. Thread Engagement Ratio.

From www.slideshare.net

Minimum Bolt Thread Engagement with Respect to Various Material Stren… Thread Engagement Ratio It is commonly known that the minimum recommended thread engagement to make a strong connection for a component with a. The thread engagement length is multiplied by a ratio of the shear areas and ultimate tensile strengths of the respective materials. If the value of j is greater than 1 then the length of engagement must be increased to at. Thread Engagement Ratio.

From rayb78.github.io

Npt Thread Chart Pdf Thread Engagement Ratio For a steel nut member: J = thread engagement ratio. If the value of j is greater than 1 then the length of engagement must be increased to at least. For brass or cast iron threads, the minimum thread engagement should be 1.5 to 2.0 x the bolt’s or screw’s base nominal diameter. It is commonly known that the minimum. Thread Engagement Ratio.

From engineerexcel.com

Thread Stripping Explained EngineerExcel Thread Engagement Ratio For a steel nut member: For brass or cast iron threads, the minimum thread engagement should be 1.5 to 2.0 x the bolt’s or screw’s base nominal diameter. If the value of j is greater than 1 then the length of engagement must be increased to at least. Percent of thread engagement is based size of the mating hole compared. Thread Engagement Ratio.

From www.scribd.com

NPT Thread Engagement PDF Metalworking Tools Thread Engagement Ratio For brass or cast iron threads, the minimum thread engagement should be 1.5 to 2.0 x the bolt’s or screw’s base nominal diameter. Le2 = minimum thread engagement. The thread engagement length is multiplied by a ratio of the shear areas and ultimate tensile strengths of the respective materials. If the value of j is greater than 1 then the. Thread Engagement Ratio.

From www.researchgate.net

Rectangular Test Plate (Dimensions in mm) Download Scientific Diagram Thread Engagement Ratio The thread engagement length is multiplied by a ratio of the shear areas and ultimate tensile strengths of the respective materials. Percent of thread engagement is based size of the mating hole compared to the fastener and how much the height of threads of the screw are engaged. J = thread engagement ratio. Le2 = minimum thread engagement. This engineering. Thread Engagement Ratio.

From www.zpag.net

American Standard Acme Screw Thread Dimensions Thread Engagement Ratio For brass or cast iron threads, the minimum thread engagement should be 1.5 to 2.0 x the bolt’s or screw’s base nominal diameter. The thread engagement length is multiplied by a ratio of the shear areas and ultimate tensile strengths of the respective materials. Le2 = minimum thread engagement. J = thread engagement ratio. Percent of thread engagement is based. Thread Engagement Ratio.

From www.slideshare.net

Minimum Bolt Thread Engagement with Respect to Various Material Stren… Thread Engagement Ratio J = thread engagement ratio. Le2 = minimum thread engagement. For a steel nut member: The thread engagement length is multiplied by a ratio of the shear areas and ultimate tensile strengths of the respective materials. Percent of thread engagement is based size of the mating hole compared to the fastener and how much the height of threads of the. Thread Engagement Ratio.

From punchlistzero.com

Pipe Thread Size Chart Punchlist Zero Thread Engagement Ratio This engineering calculator will determine the iso thread / fastener ratio and length requirements for an engineering requirement. For brass or cast iron threads, the minimum thread engagement should be 1.5 to 2.0 x the bolt’s or screw’s base nominal diameter. For a steel nut member: The thread engagement length is multiplied by a ratio of the shear areas and. Thread Engagement Ratio.

From inksterspartoftherock.blogspot.com

20 Unique Acme Thread Chart Thread Engagement Ratio Percent of thread engagement is based size of the mating hole compared to the fastener and how much the height of threads of the screw are engaged. J = thread engagement ratio. If the value of j is greater than 1 then the length of engagement must be increased to at least. For brass or cast iron threads, the minimum. Thread Engagement Ratio.

From aerobasegroup.com

Unified Thread Size Charts AeroBase Group, Inc. Thread Engagement Ratio Le2 = minimum thread engagement. It is commonly known that the minimum recommended thread engagement to make a strong connection for a component with a. This engineering calculator will determine the iso thread / fastener ratio and length requirements for an engineering requirement. J = thread engagement ratio. If the value of j is greater than 1 then the length. Thread Engagement Ratio.