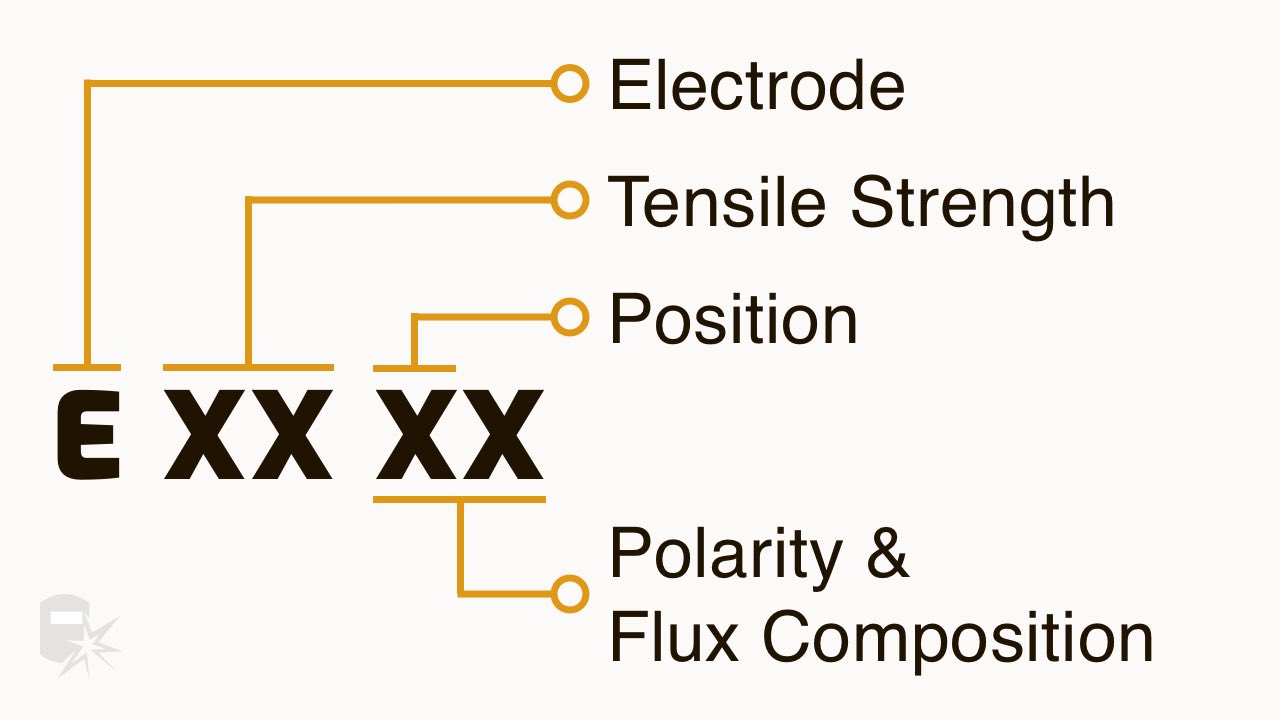

What Does E6013 Welding Rod Meaning . E 6010 and e 6011 replace e 6013 whenever the electrode is not available or whenever the welder prefers faster solidification. It has excellent arc stability and produces smooth, clean welds with minimal spatter. The classification of e6013 represents its tensile strength, position, and intended use. The e6011 and e6013 are comparable in tensile strength, welding positions, and current types. 6013 has high titanic electrode coats, which serve primarily for designing shallow penetration. The e6013 welding rod is a widely used electrode in the welding industry. E 6013 is the common electrode used for sheet metal welding; The most typical use of e6013 welding rods is in sheet metal welding. Understanding the e6013 welding rod.

from joiuzvmhk.blob.core.windows.net

The most typical use of e6013 welding rods is in sheet metal welding. The e6013 welding rod is a widely used electrode in the welding industry. The e6011 and e6013 are comparable in tensile strength, welding positions, and current types. E 6010 and e 6011 replace e 6013 whenever the electrode is not available or whenever the welder prefers faster solidification. Understanding the e6013 welding rod. 6013 has high titanic electrode coats, which serve primarily for designing shallow penetration. The classification of e6013 represents its tensile strength, position, and intended use. It has excellent arc stability and produces smooth, clean welds with minimal spatter. E 6013 is the common electrode used for sheet metal welding;

E6013 Welding Rod Meaning at Stephanie Horton blog

What Does E6013 Welding Rod Meaning The most typical use of e6013 welding rods is in sheet metal welding. It has excellent arc stability and produces smooth, clean welds with minimal spatter. E 6010 and e 6011 replace e 6013 whenever the electrode is not available or whenever the welder prefers faster solidification. The e6013 welding rod is a widely used electrode in the welding industry. 6013 has high titanic electrode coats, which serve primarily for designing shallow penetration. The most typical use of e6013 welding rods is in sheet metal welding. The classification of e6013 represents its tensile strength, position, and intended use. The e6011 and e6013 are comparable in tensile strength, welding positions, and current types. E 6013 is the common electrode used for sheet metal welding; Understanding the e6013 welding rod.

From www.amazon.co.uk

Weld Right General Purpose E6013 6013 Arc Welding Electrodes Rods 1.6mm What Does E6013 Welding Rod Meaning E 6013 is the common electrode used for sheet metal welding; The e6011 and e6013 are comparable in tensile strength, welding positions, and current types. Understanding the e6013 welding rod. It has excellent arc stability and produces smooth, clean welds with minimal spatter. E 6010 and e 6011 replace e 6013 whenever the electrode is not available or whenever the. What Does E6013 Welding Rod Meaning.

From www.oceanproperty.co.th

Welding Electrode TypesWelding Rod Number Meaning, 59 OFF What Does E6013 Welding Rod Meaning E 6013 is the common electrode used for sheet metal welding; Understanding the e6013 welding rod. The most typical use of e6013 welding rods is in sheet metal welding. The e6011 and e6013 are comparable in tensile strength, welding positions, and current types. The classification of e6013 represents its tensile strength, position, and intended use. It has excellent arc stability. What Does E6013 Welding Rod Meaning.

From shopee.ph

Welding Rod Mild Steel E6013 Standard and Premium ELECTROWELD per What Does E6013 Welding Rod Meaning E 6013 is the common electrode used for sheet metal welding; The most typical use of e6013 welding rods is in sheet metal welding. 6013 has high titanic electrode coats, which serve primarily for designing shallow penetration. The e6013 welding rod is a widely used electrode in the welding industry. The classification of e6013 represents its tensile strength, position, and. What Does E6013 Welding Rod Meaning.

From www.katariyasteel.com

E6013 Welding Rod Manufacturer, Supplier In Qatar What Does E6013 Welding Rod Meaning 6013 has high titanic electrode coats, which serve primarily for designing shallow penetration. It has excellent arc stability and produces smooth, clean welds with minimal spatter. The e6013 welding rod is a widely used electrode in the welding industry. Understanding the e6013 welding rod. E 6010 and e 6011 replace e 6013 whenever the electrode is not available or whenever. What Does E6013 Welding Rod Meaning.

From shopee.ph

FUJIWELD Welding Rod E6011 / E6012 / E6013 / E7018 (PER KILO) Shopee What Does E6013 Welding Rod Meaning It has excellent arc stability and produces smooth, clean welds with minimal spatter. The e6011 and e6013 are comparable in tensile strength, welding positions, and current types. Understanding the e6013 welding rod. E 6010 and e 6011 replace e 6013 whenever the electrode is not available or whenever the welder prefers faster solidification. E 6013 is the common electrode used. What Does E6013 Welding Rod Meaning.

From atelier-yuwa.ciao.jp

Nihon Welding Rod 6013 atelieryuwa.ciao.jp What Does E6013 Welding Rod Meaning The most typical use of e6013 welding rods is in sheet metal welding. The e6013 welding rod is a widely used electrode in the welding industry. Understanding the e6013 welding rod. 6013 has high titanic electrode coats, which serve primarily for designing shallow penetration. E 6013 is the common electrode used for sheet metal welding; E 6010 and e 6011. What Does E6013 Welding Rod Meaning.

From loepezzws.blob.core.windows.net

Rb Welding Rod Meaning at Joan Duhart blog What Does E6013 Welding Rod Meaning E 6010 and e 6011 replace e 6013 whenever the electrode is not available or whenever the welder prefers faster solidification. It has excellent arc stability and produces smooth, clean welds with minimal spatter. E 6013 is the common electrode used for sheet metal welding; 6013 has high titanic electrode coats, which serve primarily for designing shallow penetration. The e6011. What Does E6013 Welding Rod Meaning.

From materialwelding.com

E6013 Electrode Specification, meaning, with actual MTC What Does E6013 Welding Rod Meaning The e6011 and e6013 are comparable in tensile strength, welding positions, and current types. It has excellent arc stability and produces smooth, clean welds with minimal spatter. E 6013 is the common electrode used for sheet metal welding; The classification of e6013 represents its tensile strength, position, and intended use. Understanding the e6013 welding rod. E 6010 and e 6011. What Does E6013 Welding Rod Meaning.

From primeweld.com

Guide To Welding Rods and Electrodes PrimeWeld What Does E6013 Welding Rod Meaning E 6010 and e 6011 replace e 6013 whenever the electrode is not available or whenever the welder prefers faster solidification. The e6013 welding rod is a widely used electrode in the welding industry. Understanding the e6013 welding rod. The most typical use of e6013 welding rods is in sheet metal welding. E 6013 is the common electrode used for. What Does E6013 Welding Rod Meaning.

From shopee.ph

Welding Rod 6013 6011 Welding Electrode 1/8 3.2mm 3/32 2.5mm 1 KILO What Does E6013 Welding Rod Meaning 6013 has high titanic electrode coats, which serve primarily for designing shallow penetration. It has excellent arc stability and produces smooth, clean welds with minimal spatter. The most typical use of e6013 welding rods is in sheet metal welding. E 6010 and e 6011 replace e 6013 whenever the electrode is not available or whenever the welder prefers faster solidification.. What Does E6013 Welding Rod Meaning.

From www.kingsofwelding.com

6010 vs 6011 vs 6013 vs 7018 vs 7024 Welding Rods Kings of Welding What Does E6013 Welding Rod Meaning The e6011 and e6013 are comparable in tensile strength, welding positions, and current types. The most typical use of e6013 welding rods is in sheet metal welding. Understanding the e6013 welding rod. It has excellent arc stability and produces smooth, clean welds with minimal spatter. E 6010 and e 6011 replace e 6013 whenever the electrode is not available or. What Does E6013 Welding Rod Meaning.

From www.weldingcity.com

1/8" x 14" WeldingCity® E6013 Carbon Steel Stick Welding Electrode Rods What Does E6013 Welding Rod Meaning The most typical use of e6013 welding rods is in sheet metal welding. The e6013 welding rod is a widely used electrode in the welding industry. Understanding the e6013 welding rod. It has excellent arc stability and produces smooth, clean welds with minimal spatter. The classification of e6013 represents its tensile strength, position, and intended use. The e6011 and e6013. What Does E6013 Welding Rod Meaning.

From www.globalsources.com

Buy Wholesale China Aws E6013 Low Hydrogen Factory Price Tingxing What Does E6013 Welding Rod Meaning The most typical use of e6013 welding rods is in sheet metal welding. E 6010 and e 6011 replace e 6013 whenever the electrode is not available or whenever the welder prefers faster solidification. Understanding the e6013 welding rod. The classification of e6013 represents its tensile strength, position, and intended use. It has excellent arc stability and produces smooth, clean. What Does E6013 Welding Rod Meaning.

From www.oceanproperty.co.th

Welding Electrode TypesWelding Rod Number Meaning, 57 OFF What Does E6013 Welding Rod Meaning 6013 has high titanic electrode coats, which serve primarily for designing shallow penetration. The most typical use of e6013 welding rods is in sheet metal welding. The classification of e6013 represents its tensile strength, position, and intended use. E 6013 is the common electrode used for sheet metal welding; It has excellent arc stability and produces smooth, clean welds with. What Does E6013 Welding Rod Meaning.

From www.lazada.com.ph

WIPWELD Welding Rod Electrode E6013 [GENCORD 1/8" 3.2mm] (1 KILO, 1kg What Does E6013 Welding Rod Meaning The most typical use of e6013 welding rods is in sheet metal welding. E 6010 and e 6011 replace e 6013 whenever the electrode is not available or whenever the welder prefers faster solidification. The e6011 and e6013 are comparable in tensile strength, welding positions, and current types. E 6013 is the common electrode used for sheet metal welding; Understanding. What Does E6013 Welding Rod Meaning.

From weldingintro.com

What Is 6013 Welding Rod Used For (All You Need To Know) What Does E6013 Welding Rod Meaning Understanding the e6013 welding rod. E 6013 is the common electrode used for sheet metal welding; 6013 has high titanic electrode coats, which serve primarily for designing shallow penetration. The e6011 and e6013 are comparable in tensile strength, welding positions, and current types. E 6010 and e 6011 replace e 6013 whenever the electrode is not available or whenever the. What Does E6013 Welding Rod Meaning.

From weldingpros.net

Stick Welding Rod Charts and Calculator Amps, Sizes, Types What Does E6013 Welding Rod Meaning The most typical use of e6013 welding rods is in sheet metal welding. E 6013 is the common electrode used for sheet metal welding; The e6013 welding rod is a widely used electrode in the welding industry. E 6010 and e 6011 replace e 6013 whenever the electrode is not available or whenever the welder prefers faster solidification. The e6011. What Does E6013 Welding Rod Meaning.

From beginnerweldingguide.com

What Is a 6013 Welding Rod Used For? Beginner Welding Guide What Does E6013 Welding Rod Meaning The e6011 and e6013 are comparable in tensile strength, welding positions, and current types. 6013 has high titanic electrode coats, which serve primarily for designing shallow penetration. The classification of e6013 represents its tensile strength, position, and intended use. Understanding the e6013 welding rod. The e6013 welding rod is a widely used electrode in the welding industry. It has excellent. What Does E6013 Welding Rod Meaning.

From weldguru.com

Welding Rod Numbers Explained What Do They Mean? What Does E6013 Welding Rod Meaning It has excellent arc stability and produces smooth, clean welds with minimal spatter. E 6010 and e 6011 replace e 6013 whenever the electrode is not available or whenever the welder prefers faster solidification. The classification of e6013 represents its tensile strength, position, and intended use. E 6013 is the common electrode used for sheet metal welding; The e6011 and. What Does E6013 Welding Rod Meaning.

From www.ebay.co.uk

Mild Steel E6013 ARC Welding Electrodes Rods 1.6 / 2.0 / 2.5mm / 3.2mm What Does E6013 Welding Rod Meaning The classification of e6013 represents its tensile strength, position, and intended use. The most typical use of e6013 welding rods is in sheet metal welding. It has excellent arc stability and produces smooth, clean welds with minimal spatter. Understanding the e6013 welding rod. The e6013 welding rod is a widely used electrode in the welding industry. 6013 has high titanic. What Does E6013 Welding Rod Meaning.

From loepezzws.blob.core.windows.net

Rb Welding Rod Meaning at Joan Duhart blog What Does E6013 Welding Rod Meaning The e6011 and e6013 are comparable in tensile strength, welding positions, and current types. E 6010 and e 6011 replace e 6013 whenever the electrode is not available or whenever the welder prefers faster solidification. E 6013 is the common electrode used for sheet metal welding; It has excellent arc stability and produces smooth, clean welds with minimal spatter. Understanding. What Does E6013 Welding Rod Meaning.

From ebcastworld.com

High Quality 6013 Welding Rod Carbon Steel E6013 Welding Rod ,6013 What Does E6013 Welding Rod Meaning The e6013 welding rod is a widely used electrode in the welding industry. 6013 has high titanic electrode coats, which serve primarily for designing shallow penetration. The classification of e6013 represents its tensile strength, position, and intended use. E 6013 is the common electrode used for sheet metal welding; E 6010 and e 6011 replace e 6013 whenever the electrode. What Does E6013 Welding Rod Meaning.

From www.katariyasteel.com

E6013 Welding Rod Manufacturer, Supplier In Mexico What Does E6013 Welding Rod Meaning E 6010 and e 6011 replace e 6013 whenever the electrode is not available or whenever the welder prefers faster solidification. The most typical use of e6013 welding rods is in sheet metal welding. 6013 has high titanic electrode coats, which serve primarily for designing shallow penetration. Understanding the e6013 welding rod. The e6013 welding rod is a widely used. What Does E6013 Welding Rod Meaning.

From weldinghero.en.made-in-china.com

Factory Price Welding Electrode Welding Rod E6013 E7018 E7016 E6010 What Does E6013 Welding Rod Meaning 6013 has high titanic electrode coats, which serve primarily for designing shallow penetration. The most typical use of e6013 welding rods is in sheet metal welding. The classification of e6013 represents its tensile strength, position, and intended use. The e6011 and e6013 are comparable in tensile strength, welding positions, and current types. The e6013 welding rod is a widely used. What Does E6013 Welding Rod Meaning.

From www.globalsources.com

Buy Wholesale China Aws E6013 Low Hydrogen Factory Price Tingxing What Does E6013 Welding Rod Meaning The most typical use of e6013 welding rods is in sheet metal welding. The e6011 and e6013 are comparable in tensile strength, welding positions, and current types. The e6013 welding rod is a widely used electrode in the welding industry. The classification of e6013 represents its tensile strength, position, and intended use. E 6010 and e 6011 replace e 6013. What Does E6013 Welding Rod Meaning.

From shopee.com.my

(30PCS) 12 2.5MM GOLDEN BRIDGE E6013 WELDING ROD WELDING ELECTRODES What Does E6013 Welding Rod Meaning Understanding the e6013 welding rod. It has excellent arc stability and produces smooth, clean welds with minimal spatter. E 6010 and e 6011 replace e 6013 whenever the electrode is not available or whenever the welder prefers faster solidification. The e6013 welding rod is a widely used electrode in the welding industry. E 6013 is the common electrode used for. What Does E6013 Welding Rod Meaning.

From www.machineryoffers.com

ABS AWS E6013 China Welding Rod Brand E6013 6013 Welding Rod Price 2 What Does E6013 Welding Rod Meaning The e6013 welding rod is a widely used electrode in the welding industry. It has excellent arc stability and produces smooth, clean welds with minimal spatter. Understanding the e6013 welding rod. The classification of e6013 represents its tensile strength, position, and intended use. E 6010 and e 6011 replace e 6013 whenever the electrode is not available or whenever the. What Does E6013 Welding Rod Meaning.

From joijuxamw.blob.core.windows.net

Best Welding Rods For Cast Steel at Ray Connell blog What Does E6013 Welding Rod Meaning The classification of e6013 represents its tensile strength, position, and intended use. Understanding the e6013 welding rod. It has excellent arc stability and produces smooth, clean welds with minimal spatter. E 6010 and e 6011 replace e 6013 whenever the electrode is not available or whenever the welder prefers faster solidification. The most typical use of e6013 welding rods is. What Does E6013 Welding Rod Meaning.

From www.rightwell.com.my

ESAB Welding Electrode 6013 Mild Steel What Does E6013 Welding Rod Meaning E 6010 and e 6011 replace e 6013 whenever the electrode is not available or whenever the welder prefers faster solidification. 6013 has high titanic electrode coats, which serve primarily for designing shallow penetration. It has excellent arc stability and produces smooth, clean welds with minimal spatter. The most typical use of e6013 welding rods is in sheet metal welding.. What Does E6013 Welding Rod Meaning.

From www.youtube.com

WHAT IS WELDING ELECTRODE E 6013 , ELECTRODE SPECIFICATION ( IN HINDI What Does E6013 Welding Rod Meaning The most typical use of e6013 welding rods is in sheet metal welding. The e6011 and e6013 are comparable in tensile strength, welding positions, and current types. It has excellent arc stability and produces smooth, clean welds with minimal spatter. E 6010 and e 6011 replace e 6013 whenever the electrode is not available or whenever the welder prefers faster. What Does E6013 Welding Rod Meaning.

From thetigwelder.com

6011 Vs 6013 Welding Rods The Tig Welder What Does E6013 Welding Rod Meaning The most typical use of e6013 welding rods is in sheet metal welding. The classification of e6013 represents its tensile strength, position, and intended use. The e6013 welding rod is a widely used electrode in the welding industry. Understanding the e6013 welding rod. It has excellent arc stability and produces smooth, clean welds with minimal spatter. E 6010 and e. What Does E6013 Welding Rod Meaning.

From joiuzvmhk.blob.core.windows.net

E6013 Welding Rod Meaning at Stephanie Horton blog What Does E6013 Welding Rod Meaning It has excellent arc stability and produces smooth, clean welds with minimal spatter. E 6013 is the common electrode used for sheet metal welding; The e6013 welding rod is a widely used electrode in the welding industry. The most typical use of e6013 welding rods is in sheet metal welding. Understanding the e6013 welding rod. The e6011 and e6013 are. What Does E6013 Welding Rod Meaning.

From klakefequ.blob.core.windows.net

What Is Electrode Size In Welding at John Gilchrist blog What Does E6013 Welding Rod Meaning E 6010 and e 6011 replace e 6013 whenever the electrode is not available or whenever the welder prefers faster solidification. It has excellent arc stability and produces smooth, clean welds with minimal spatter. The e6013 welding rod is a widely used electrode in the welding industry. The classification of e6013 represents its tensile strength, position, and intended use. E. What Does E6013 Welding Rod Meaning.

From www.electroweld.com.au

Cigweld Welding Rods Blogs Electroweld What Does E6013 Welding Rod Meaning E 6013 is the common electrode used for sheet metal welding; The most typical use of e6013 welding rods is in sheet metal welding. Understanding the e6013 welding rod. The e6011 and e6013 are comparable in tensile strength, welding positions, and current types. The classification of e6013 represents its tensile strength, position, and intended use. The e6013 welding rod is. What Does E6013 Welding Rod Meaning.

From cnatlantic.en.made-in-china.com

Atlantic Aws E6013 Welding Rods / 6013 Famous Brand Welding Electrodes What Does E6013 Welding Rod Meaning It has excellent arc stability and produces smooth, clean welds with minimal spatter. Understanding the e6013 welding rod. The most typical use of e6013 welding rods is in sheet metal welding. The e6011 and e6013 are comparable in tensile strength, welding positions, and current types. The classification of e6013 represents its tensile strength, position, and intended use. The e6013 welding. What Does E6013 Welding Rod Meaning.