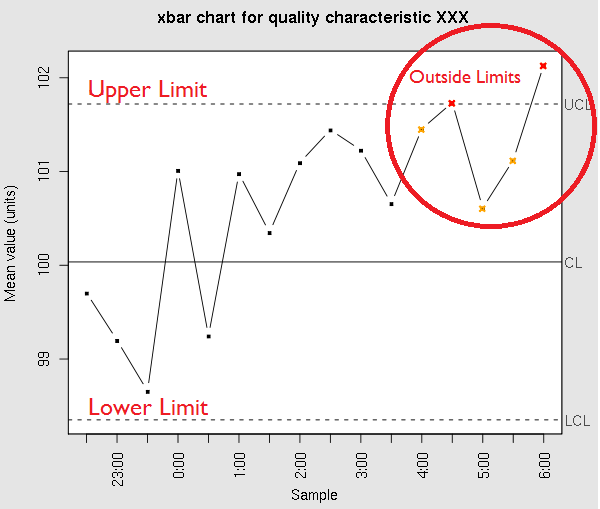

Process Control Limits Definition . Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process optimization. When you start a new control chart, the process may be out of control. If so, the control limits calculated from the first 20 points are conditional limits. These limits let you know when. They help in distinguishing between normal process variation (within. Control limits, also known as process control limits or specification limits, are statistical boundaries used in quality control to monitor and manage a process. These charts offer a visual representation of process performance over time, plotting measured data points to track variations, identify abnormalities, and discern trends. Control charts use upper and lower control limits, which are statistically derived boundaries. A control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. Control limits are the boundaries set on a control chart that indicate the acceptable range of variation for a process or measurement. When you have at least 20 sequential.

from www.statisticshowto.com

Control charts use upper and lower control limits, which are statistically derived boundaries. Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process optimization. These charts offer a visual representation of process performance over time, plotting measured data points to track variations, identify abnormalities, and discern trends. They help in distinguishing between normal process variation (within. If so, the control limits calculated from the first 20 points are conditional limits. A control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. These limits let you know when. Control limits, also known as process control limits or specification limits, are statistical boundaries used in quality control to monitor and manage a process. When you start a new control chart, the process may be out of control. When you have at least 20 sequential.

Statistical Process Control Statistics How To

Process Control Limits Definition Control charts use upper and lower control limits, which are statistically derived boundaries. Control charts use upper and lower control limits, which are statistically derived boundaries. When you have at least 20 sequential. These charts offer a visual representation of process performance over time, plotting measured data points to track variations, identify abnormalities, and discern trends. A control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. If so, the control limits calculated from the first 20 points are conditional limits. When you start a new control chart, the process may be out of control. Control limits, also known as process control limits or specification limits, are statistical boundaries used in quality control to monitor and manage a process. Control limits are the boundaries set on a control chart that indicate the acceptable range of variation for a process or measurement. Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process optimization. These limits let you know when. They help in distinguishing between normal process variation (within.

From www.six-sigma-material.com

Process Capability Indices Process Control Limits Definition Control limits are the boundaries set on a control chart that indicate the acceptable range of variation for a process or measurement. If so, the control limits calculated from the first 20 points are conditional limits. These charts offer a visual representation of process performance over time, plotting measured data points to track variations, identify abnormalities, and discern trends. They. Process Control Limits Definition.

From www.youtube.com

Control Limit Vs Specification Limit Difference between Control Process Control Limits Definition Control charts use upper and lower control limits, which are statistically derived boundaries. When you have at least 20 sequential. They help in distinguishing between normal process variation (within. Control limits, also known as process control limits or specification limits, are statistical boundaries used in quality control to monitor and manage a process. If so, the control limits calculated from. Process Control Limits Definition.

From www.presentationeze.com

Types of Control Charts Statistical Process Control.PresentationEZE Process Control Limits Definition Control limits, also known as process control limits or specification limits, are statistical boundaries used in quality control to monitor and manage a process. They help in distinguishing between normal process variation (within. When you start a new control chart, the process may be out of control. Control charts stand as a pivotal element in the realm of statistical process. Process Control Limits Definition.

From www.slideserve.com

PPT Process Control Charts PowerPoint Presentation, free download Process Control Limits Definition These charts offer a visual representation of process performance over time, plotting measured data points to track variations, identify abnormalities, and discern trends. If so, the control limits calculated from the first 20 points are conditional limits. When you have at least 20 sequential. Control limits are the boundaries set on a control chart that indicate the acceptable range of. Process Control Limits Definition.

From www.presentationeze.com

Statistical Process Control PresentationEZE Process Control Limits Definition These charts offer a visual representation of process performance over time, plotting measured data points to track variations, identify abnormalities, and discern trends. Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process optimization. These limits let you know when. A control chart displays process data by. Process Control Limits Definition.

From www.slideserve.com

PPT Statistical Process Control (SPC) PowerPoint Presentation, free Process Control Limits Definition These limits let you know when. Control charts use upper and lower control limits, which are statistically derived boundaries. Control limits are the boundaries set on a control chart that indicate the acceptable range of variation for a process or measurement. Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in. Process Control Limits Definition.

From www.slideserve.com

PPT Statistical Process Control PowerPoint Presentation, free Process Control Limits Definition Control limits, also known as process control limits or specification limits, are statistical boundaries used in quality control to monitor and manage a process. Control limits are the boundaries set on a control chart that indicate the acceptable range of variation for a process or measurement. Control charts stand as a pivotal element in the realm of statistical process control. Process Control Limits Definition.

From fr.slideshare.net

Control charts Process Control Limits Definition Control limits, also known as process control limits or specification limits, are statistical boundaries used in quality control to monitor and manage a process. These charts offer a visual representation of process performance over time, plotting measured data points to track variations, identify abnormalities, and discern trends. Control limits are the boundaries set on a control chart that indicate the. Process Control Limits Definition.

From www.latestquality.com

What Is the Difference Between Control Limits and Specification Limits Process Control Limits Definition Control limits, also known as process control limits or specification limits, are statistical boundaries used in quality control to monitor and manage a process. When you start a new control chart, the process may be out of control. These limits let you know when. They help in distinguishing between normal process variation (within. These charts offer a visual representation of. Process Control Limits Definition.

From nanohub.org

Resources Understanding Variation and Statistical Process Control Limits Definition A control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. If so, the control limits calculated from the first 20 points are conditional limits. Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management. Process Control Limits Definition.

From www.slideserve.com

PPT Chapter 4 PowerPoint Presentation, free download ID612427 Process Control Limits Definition Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process optimization. Control limits, also known as process control limits or specification limits, are statistical boundaries used in quality control to monitor and manage a process. Control charts use upper and lower control limits, which are statistically derived. Process Control Limits Definition.

From www.slideserve.com

PPT PROCESS CAPABILITY PowerPoint Presentation, free download ID Process Control Limits Definition These limits let you know when. Control limits are the boundaries set on a control chart that indicate the acceptable range of variation for a process or measurement. If so, the control limits calculated from the first 20 points are conditional limits. Control limits, also known as process control limits or specification limits, are statistical boundaries used in quality control. Process Control Limits Definition.

From thors.com

What is Statistical Distribution in SPC? Process Control Limits Definition These charts offer a visual representation of process performance over time, plotting measured data points to track variations, identify abnormalities, and discern trends. A control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. Control limits are the boundaries set on a control chart that indicate. Process Control Limits Definition.

From www.slideserve.com

PPT Process Control Charts PowerPoint Presentation, free download Process Control Limits Definition Control limits are the boundaries set on a control chart that indicate the acceptable range of variation for a process or measurement. When you have at least 20 sequential. These limits let you know when. When you start a new control chart, the process may be out of control. They help in distinguishing between normal process variation (within. If so,. Process Control Limits Definition.

From thors.com

Statistical Process Control (SPC) Basics Course Process Control Limits Definition Control limits are the boundaries set on a control chart that indicate the acceptable range of variation for a process or measurement. Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process optimization. These limits let you know when. Control charts use upper and lower control limits,. Process Control Limits Definition.

From www.slideserve.com

PPT Statistical Process Control PowerPoint Presentation, free Process Control Limits Definition Control limits are the boundaries set on a control chart that indicate the acceptable range of variation for a process or measurement. A control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. If so, the control limits calculated from the first 20 points are conditional. Process Control Limits Definition.

From www.slideserve.com

PPT Statistical Process Control (SPC) PowerPoint Presentation, free Process Control Limits Definition Control limits are the boundaries set on a control chart that indicate the acceptable range of variation for a process or measurement. These charts offer a visual representation of process performance over time, plotting measured data points to track variations, identify abnormalities, and discern trends. Control charts use upper and lower control limits, which are statistically derived boundaries. When you. Process Control Limits Definition.

From www.statisticshowto.com

Statistical Process Control Statistics How To Process Control Limits Definition When you have at least 20 sequential. These charts offer a visual representation of process performance over time, plotting measured data points to track variations, identify abnormalities, and discern trends. Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process optimization. These limits let you know when.. Process Control Limits Definition.

From www.vrogue.co

How To Calculate Statistical Process Control Limits vrogue.co Process Control Limits Definition Control limits are the boundaries set on a control chart that indicate the acceptable range of variation for a process or measurement. They help in distinguishing between normal process variation (within. Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process optimization. These limits let you know. Process Control Limits Definition.

From www.presentationeze.com

Types of Control Charts Statistical Process Control.PresentationEZE Process Control Limits Definition These limits let you know when. These charts offer a visual representation of process performance over time, plotting measured data points to track variations, identify abnormalities, and discern trends. Control limits, also known as process control limits or specification limits, are statistical boundaries used in quality control to monitor and manage a process. They help in distinguishing between normal process. Process Control Limits Definition.

From www.benchmarksixsigma.com

Control Limits vs Specification Limits We ask and you answer! The Process Control Limits Definition A control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. When you start a new control chart, the process may be out of control. If so, the control limits calculated from the first 20 points are conditional limits. These charts offer a visual representation of. Process Control Limits Definition.

From keydifference.in

Best 5 Difference Between Control Limits and Specification Limits Key Process Control Limits Definition Control charts use upper and lower control limits, which are statistically derived boundaries. These limits let you know when. Control limits, also known as process control limits or specification limits, are statistical boundaries used in quality control to monitor and manage a process. Control limits are the boundaries set on a control chart that indicate the acceptable range of variation. Process Control Limits Definition.

From www.slideserve.com

PPT PROCESS CAPABILITY PowerPoint Presentation, free download ID Process Control Limits Definition When you have at least 20 sequential. These charts offer a visual representation of process performance over time, plotting measured data points to track variations, identify abnormalities, and discern trends. They help in distinguishing between normal process variation (within. Control limits, also known as process control limits or specification limits, are statistical boundaries used in quality control to monitor and. Process Control Limits Definition.

From www.slideserve.com

PPT Statistical Process Control (SPC) PowerPoint Presentation, free Process Control Limits Definition Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process optimization. They help in distinguishing between normal process variation (within. These charts offer a visual representation of process performance over time, plotting measured data points to track variations, identify abnormalities, and discern trends. A control chart displays. Process Control Limits Definition.

From www.slideserve.com

PPT Control Chart (continued) PowerPoint Presentation, free download Process Control Limits Definition They help in distinguishing between normal process variation (within. A control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. Control charts use upper and lower control limits, which are statistically derived boundaries. When you have at least 20 sequential. Control limits are the boundaries set. Process Control Limits Definition.

From www.quality-assurance-solutions.com

Control Chart SPC, Control Charts and limits Process Control Limits Definition Control charts use upper and lower control limits, which are statistically derived boundaries. Control limits are the boundaries set on a control chart that indicate the acceptable range of variation for a process or measurement. If so, the control limits calculated from the first 20 points are conditional limits. When you start a new control chart, the process may be. Process Control Limits Definition.

From slideplayer.com

PROCESS CAPABILTY AND CONTROL CHARTS ppt download Process Control Limits Definition Control limits are the boundaries set on a control chart that indicate the acceptable range of variation for a process or measurement. They help in distinguishing between normal process variation (within. When you have at least 20 sequential. These limits let you know when. Control charts use upper and lower control limits, which are statistically derived boundaries. Control limits, also. Process Control Limits Definition.

From digestibledeming.substack.com

Control Charts by Christopher R Chapman Process Control Limits Definition A control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. These charts offer a visual representation of process performance over time, plotting measured data points to track variations, identify abnormalities, and discern trends. If so, the control limits calculated from the first 20 points are. Process Control Limits Definition.

From blog.kainexus.com

An Introduction to Process Behavior Charts Process Control Limits Definition They help in distinguishing between normal process variation (within. Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process optimization. When you have at least 20 sequential. These limits let you know when. Control limits, also known as process control limits or specification limits, are statistical boundaries. Process Control Limits Definition.

From www.slideserve.com

PPT Establish Critical Limits for each CCP (Task 8 / Principle 3 Process Control Limits Definition These limits let you know when. These charts offer a visual representation of process performance over time, plotting measured data points to track variations, identify abnormalities, and discern trends. Control limits are the boundaries set on a control chart that indicate the acceptable range of variation for a process or measurement. Control limits, also known as process control limits or. Process Control Limits Definition.

From www.youtube.com

What is Basic Process Control System? BPCS Industrial Automation Process Control Limits Definition Control charts use upper and lower control limits, which are statistically derived boundaries. If so, the control limits calculated from the first 20 points are conditional limits. Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process optimization. A control chart displays process data by time, along. Process Control Limits Definition.

From www.slideserve.com

PPT Chapter 5a Process Capability PowerPoint Presentation, free Process Control Limits Definition When you start a new control chart, the process may be out of control. Control limits are the boundaries set on a control chart that indicate the acceptable range of variation for a process or measurement. Control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process optimization.. Process Control Limits Definition.

From quality-one.com

SPC Statistical Process Control QualityOne Process Control Limits Definition They help in distinguishing between normal process variation (within. These charts offer a visual representation of process performance over time, plotting measured data points to track variations, identify abnormalities, and discern trends. Control charts use upper and lower control limits, which are statistically derived boundaries. Control charts stand as a pivotal element in the realm of statistical process control (spc),. Process Control Limits Definition.

From www.youtube.com

Statistical Process Control Overview and Basic Concepts What You Need Process Control Limits Definition These charts offer a visual representation of process performance over time, plotting measured data points to track variations, identify abnormalities, and discern trends. Control limits, also known as process control limits or specification limits, are statistical boundaries used in quality control to monitor and manage a process. When you have at least 20 sequential. Control limits are the boundaries set. Process Control Limits Definition.

From www.slideserve.com

PPT Statistical Process Control (SPC) PowerPoint Presentation, free Process Control Limits Definition Control limits are the boundaries set on a control chart that indicate the acceptable range of variation for a process or measurement. These charts offer a visual representation of process performance over time, plotting measured data points to track variations, identify abnormalities, and discern trends. When you start a new control chart, the process may be out of control. These. Process Control Limits Definition.