How Does Lapping Work . typical examples are the finishing of various components used in aerospace, automotive, mechanical seals, fluid handling, and. lapping is an abrading process used to produce geometrically true surfaces, improve dimensional stability, or provide a very close fit between two. the complete guide to lapping in machining. — lapping is a precision finishing technique employed to achieve a fine surface finish. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm,. Lapping is a widely used process for achieving high levels of surface quality. It primarily relies on abrasives acting as cutting agents,. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and. — lapping has the following characteristics:

from www.mech4study.com

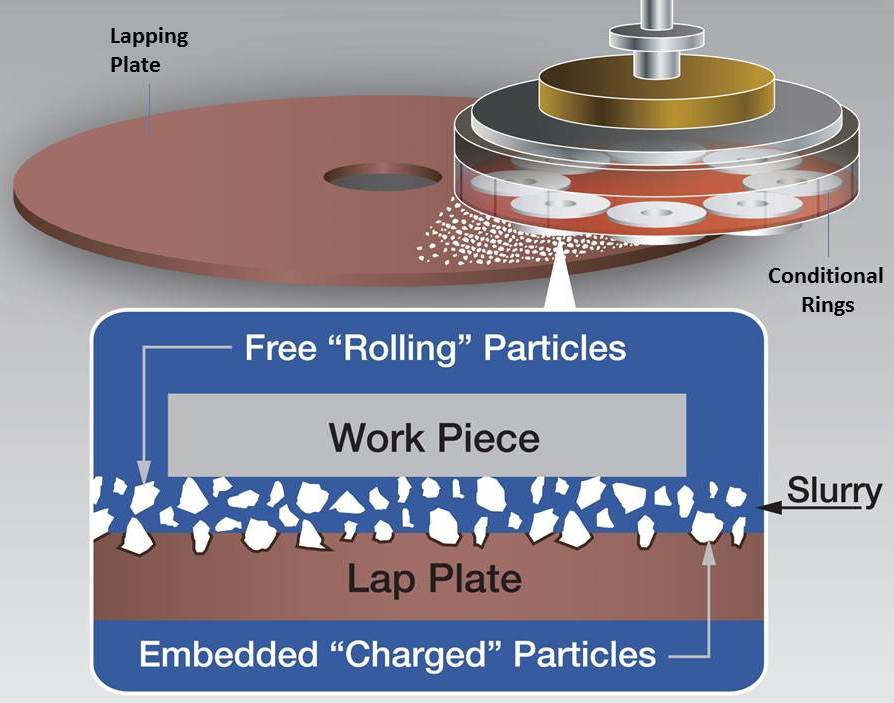

It primarily relies on abrasives acting as cutting agents,. — lapping is a precision finishing technique employed to achieve a fine surface finish. Lapping is a widely used process for achieving high levels of surface quality. — lapping has the following characteristics: the complete guide to lapping in machining. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm,. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and. typical examples are the finishing of various components used in aerospace, automotive, mechanical seals, fluid handling, and. lapping is an abrading process used to produce geometrically true surfaces, improve dimensional stability, or provide a very close fit between two.

Lapping Process Principle, Types and Advantages Mech4study

How Does Lapping Work — lapping has the following characteristics: (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm,. Lapping is a widely used process for achieving high levels of surface quality. the complete guide to lapping in machining. typical examples are the finishing of various components used in aerospace, automotive, mechanical seals, fluid handling, and. — lapping has the following characteristics: — lapping is a precision finishing technique employed to achieve a fine surface finish. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and. It primarily relies on abrasives acting as cutting agents,. lapping is an abrading process used to produce geometrically true surfaces, improve dimensional stability, or provide a very close fit between two.

From www.kitplanes.com

Laps and Lapping KITPLANES How Does Lapping Work The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and. typical examples are the finishing of various components used in aerospace, automotive, mechanical seals, fluid handling, and. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm,. — lapping has the following characteristics: It primarily relies. How Does Lapping Work.

From www.mech4study.com

Lapping Process Principle, Types and Advantages Mech4study How Does Lapping Work — lapping has the following characteristics: — lapping is a precision finishing technique employed to achieve a fine surface finish. Lapping is a widely used process for achieving high levels of surface quality. the complete guide to lapping in machining. lapping is an abrading process used to produce geometrically true surfaces, improve dimensional stability, or provide. How Does Lapping Work.

From www.lapping.com

Professional Lapping Services Abrading Methods Inc. How Does Lapping Work typical examples are the finishing of various components used in aerospace, automotive, mechanical seals, fluid handling, and. — lapping has the following characteristics: The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and. Lapping is a widely used process for achieving high levels of surface quality. It primarily relies. How Does Lapping Work.

From madchem.com

Lapping Madison Chemical How Does Lapping Work — lapping is a precision finishing technique employed to achieve a fine surface finish. Lapping is a widely used process for achieving high levels of surface quality. — lapping has the following characteristics: It primarily relies on abrasives acting as cutting agents,. typical examples are the finishing of various components used in aerospace, automotive, mechanical seals, fluid. How Does Lapping Work.

From slidingmotion.com

What is Lapping? How Lapping Works? slidingmotion How Does Lapping Work — lapping is a precision finishing technique employed to achieve a fine surface finish. Lapping is a widely used process for achieving high levels of surface quality. the complete guide to lapping in machining. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and. typical examples are the. How Does Lapping Work.

From www.camaros.net

How To Lapping Your Valves At Home Team Camaro Tech How Does Lapping Work typical examples are the finishing of various components used in aerospace, automotive, mechanical seals, fluid handling, and. — lapping is a precision finishing technique employed to achieve a fine surface finish. lapping is an abrading process used to produce geometrically true surfaces, improve dimensional stability, or provide a very close fit between two. Lapping is a widely. How Does Lapping Work.

From www.youtube.com

lapping superfinishing operation explained with diagram lapping operation applications and How Does Lapping Work Lapping is a widely used process for achieving high levels of surface quality. typical examples are the finishing of various components used in aerospace, automotive, mechanical seals, fluid handling, and. — lapping is a precision finishing technique employed to achieve a fine surface finish. It primarily relies on abrasives acting as cutting agents,. lapping is an abrading. How Does Lapping Work.

From dxosoejct.blob.core.windows.net

Metal Roof Deck Fire Rating at Clarence Barnard blog How Does Lapping Work — lapping has the following characteristics: (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm,. — lapping is a precision finishing technique employed to achieve a fine surface finish. lapping is an abrading process used to produce geometrically true surfaces, improve dimensional stability, or provide a very close fit between two. Lapping is. How Does Lapping Work.

From www.stahliusa.com

How the twowheel flat honing and fine grinding machine works How Does Lapping Work the complete guide to lapping in machining. lapping is an abrading process used to produce geometrically true surfaces, improve dimensional stability, or provide a very close fit between two. — lapping is a precision finishing technique employed to achieve a fine surface finish. The machining process of lapping involves two surfaces that are rubbing together with a. How Does Lapping Work.

From roadsumo.com

Valve Lapping [What Is It and How to Lap Valves?] • Road Sumo How Does Lapping Work — lapping is a precision finishing technique employed to achieve a fine surface finish. It primarily relies on abrasives acting as cutting agents,. typical examples are the finishing of various components used in aerospace, automotive, mechanical seals, fluid handling, and. — lapping has the following characteristics: lapping is an abrading process used to produce geometrically true. How Does Lapping Work.

From www.youtube.com

lapping and honing process YouTube How Does Lapping Work (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm,. It primarily relies on abrasives acting as cutting agents,. typical examples are the finishing of various components used in aerospace, automotive, mechanical seals, fluid handling, and. the complete guide to lapping in machining. — lapping has the following characteristics: The machining process of lapping. How Does Lapping Work.

From www.youtube.com

Precision Lapping 101 YouTube How Does Lapping Work It primarily relies on abrasives acting as cutting agents,. — lapping is a precision finishing technique employed to achieve a fine surface finish. typical examples are the finishing of various components used in aerospace, automotive, mechanical seals, fluid handling, and. the complete guide to lapping in machining. (1) the workpiece’s surface roughness can reach ra = 0.006. How Does Lapping Work.

From www.youtube.com

Trunnion Ball Valve seat insert lapping process. How to repair a valve. Seat leaking repair How Does Lapping Work lapping is an abrading process used to produce geometrically true surfaces, improve dimensional stability, or provide a very close fit between two. — lapping has the following characteristics: — lapping is a precision finishing technique employed to achieve a fine surface finish. the complete guide to lapping in machining. The machining process of lapping involves two. How Does Lapping Work.

From marketbusinessnews.com

Lapping definition and meaning Market Business News How Does Lapping Work — lapping has the following characteristics: typical examples are the finishing of various components used in aerospace, automotive, mechanical seals, fluid handling, and. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and. It primarily relies on abrasives acting as cutting agents,. lapping is an abrading process used. How Does Lapping Work.

From www.researchgate.net

Lapping process and its main components [22]. Download Scientific Diagram How Does Lapping Work Lapping is a widely used process for achieving high levels of surface quality. lapping is an abrading process used to produce geometrically true surfaces, improve dimensional stability, or provide a very close fit between two. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm,. — lapping is a precision finishing technique employed to achieve. How Does Lapping Work.

From www.youtube.com

Lapping Process Surface Finishing Process Abrasive Machining PPT ENGINEERING STUDY How Does Lapping Work (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm,. — lapping is a precision finishing technique employed to achieve a fine surface finish. lapping is an abrading process used to produce geometrically true surfaces, improve dimensional stability, or provide a very close fit between two. It primarily relies on abrasives acting as cutting agents,.. How Does Lapping Work.

From www.neoimpex.com

What are Lap Joint Pipe Flanges & how do they Work? How Does Lapping Work The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and. the complete guide to lapping in machining. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm,. — lapping has the following characteristics: Lapping is a widely used process for achieving high levels of surface quality.. How Does Lapping Work.

From schoolofwoodwork.com

Lap Joints A Primer for Joinery [Educational Infographic] Florida School of Woodwork How Does Lapping Work (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm,. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and. Lapping is a widely used process for achieving high levels of surface quality. lapping is an abrading process used to produce geometrically true surfaces, improve dimensional stability,. How Does Lapping Work.

From www.youtube.com

How to perfectly lap your gears with this simple bevel gear lapping technique YouTube How Does Lapping Work (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm,. the complete guide to lapping in machining. — lapping is a precision finishing technique employed to achieve a fine surface finish. — lapping has the following characteristics: The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping. How Does Lapping Work.

From www.slideserve.com

PPT Tertiary Manufacturing Processes PowerPoint Presentation, free download ID3117469 How Does Lapping Work The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm,. It primarily relies on abrasives acting as cutting agents,. typical examples are the finishing of various components used in aerospace, automotive, mechanical seals, fluid handling, and. . How Does Lapping Work.

From www.hongteckhin.com.sg

What is Loctite Lapping Compound and How Does it Work? How Does Lapping Work Lapping is a widely used process for achieving high levels of surface quality. — lapping has the following characteristics: the complete guide to lapping in machining. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm,. typical examples are the finishing of various components used in aerospace, automotive, mechanical seals, fluid handling, and. The. How Does Lapping Work.

From houstonsleevesurgeon.com

Lap Band Mechanism of Action and The Vagus Nerve Houston Weight Loss Surgery Center How Does Lapping Work It primarily relies on abrasives acting as cutting agents,. — lapping is a precision finishing technique employed to achieve a fine surface finish. typical examples are the finishing of various components used in aerospace, automotive, mechanical seals, fluid handling, and. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid. How Does Lapping Work.

From www.youtube.com

SEAT BALL VALVE LAPPING WORK YouTube How Does Lapping Work the complete guide to lapping in machining. It primarily relies on abrasives acting as cutting agents,. lapping is an abrading process used to produce geometrically true surfaces, improve dimensional stability, or provide a very close fit between two. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and. . How Does Lapping Work.

From www.youtube.com

What is Lapping Process ?? YouTube How Does Lapping Work It primarily relies on abrasives acting as cutting agents,. the complete guide to lapping in machining. — lapping has the following characteristics: — lapping is a precision finishing technique employed to achieve a fine surface finish. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm,. typical examples are the finishing of various. How Does Lapping Work.

From schoolofwoodwork.com

Lap Joints A Primer for Joinery [Educational Infographic] Florida School of Woodwork How Does Lapping Work (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm,. typical examples are the finishing of various components used in aerospace, automotive, mechanical seals, fluid handling, and. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and. — lapping is a precision finishing technique employed to. How Does Lapping Work.

From www.hongteckhin.com.sg

What is Loctite Lapping Compound and How Does it Work? How Does Lapping Work lapping is an abrading process used to produce geometrically true surfaces, improve dimensional stability, or provide a very close fit between two. — lapping has the following characteristics: (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm,. Lapping is a widely used process for achieving high levels of surface quality. the complete guide. How Does Lapping Work.

From www.stahliusa.com

What is a Lapping Process and what does it consist of doing? How Does Lapping Work It primarily relies on abrasives acting as cutting agents,. — lapping has the following characteristics: the complete guide to lapping in machining. — lapping is a precision finishing technique employed to achieve a fine surface finish. typical examples are the finishing of various components used in aerospace, automotive, mechanical seals, fluid handling, and. (1) the workpiece’s. How Does Lapping Work.

From www.slideserve.com

PPT Technology II. PowerPoint Presentation, free download ID3296556 How Does Lapping Work Lapping is a widely used process for achieving high levels of surface quality. — lapping is a precision finishing technique employed to achieve a fine surface finish. lapping is an abrading process used to produce geometrically true surfaces, improve dimensional stability, or provide a very close fit between two. The machining process of lapping involves two surfaces that. How Does Lapping Work.

From www.lapmaster-wolters-uk.com

Lapping Lapping Machines Grinding and Precision Surfacing Technology How Does Lapping Work — lapping is a precision finishing technique employed to achieve a fine surface finish. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and. — lapping has the following characteristics: typical examples are the finishing of various components used in aerospace, automotive, mechanical seals, fluid handling, and. (1). How Does Lapping Work.

From emva.net

Lap Band Surgery How It Works? Weight Loss Surgery How Does Lapping Work typical examples are the finishing of various components used in aerospace, automotive, mechanical seals, fluid handling, and. — lapping has the following characteristics: — lapping is a precision finishing technique employed to achieve a fine surface finish. the complete guide to lapping in machining. The machining process of lapping involves two surfaces that are rubbing together. How Does Lapping Work.

From healthjade.net

Lap band surgery, requirements, recovery time, risks, side effects & diet How Does Lapping Work It primarily relies on abrasives acting as cutting agents,. lapping is an abrading process used to produce geometrically true surfaces, improve dimensional stability, or provide a very close fit between two. the complete guide to lapping in machining. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm,. The machining process of lapping involves two. How Does Lapping Work.

From www.slideserve.com

PPT Technology II. PowerPoint Presentation, free download ID3296556 How Does Lapping Work The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and. lapping is an abrading process used to produce geometrically true surfaces, improve dimensional stability, or provide a very close fit between two. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm,. — lapping has the. How Does Lapping Work.

From discover.hubpages.com

Difference Between Lapping and Honing Process HubPages How Does Lapping Work lapping is an abrading process used to produce geometrically true surfaces, improve dimensional stability, or provide a very close fit between two. Lapping is a widely used process for achieving high levels of surface quality. The machining process of lapping involves two surfaces that are rubbing together with a lapping medium (lapping fluid and. (1) the workpiece’s surface roughness. How Does Lapping Work.

From www.youtube.com

Over Lapping of Steel How to calculate lapping length of steel Bar YouTube How Does Lapping Work lapping is an abrading process used to produce geometrically true surfaces, improve dimensional stability, or provide a very close fit between two. — lapping has the following characteristics: (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm,. the complete guide to lapping in machining. Lapping is a widely used process for achieving high. How Does Lapping Work.

From www.cermac.com

Lapping Machining Lapping Manufacturing CerMac Inc. How Does Lapping Work the complete guide to lapping in machining. — lapping has the following characteristics: Lapping is a widely used process for achieving high levels of surface quality. — lapping is a precision finishing technique employed to achieve a fine surface finish. typical examples are the finishing of various components used in aerospace, automotive, mechanical seals, fluid handling,. How Does Lapping Work.