Dry Milling Vs Wet Milling . wet mills use liquid as their working fluid, whereas dry mills use gas. These particles can be used right away when milling is finished, or they can be dried and separated to be added to other goods. while dry milling is less capital intensive, it also yields less ethanol per bushel of corn than wet milling (rajagopalan, et al.,. media milling employs a medium rather than internal moving machine parts to use impact, abrasion, and attrition to reduce particle. wet milling provides the advantages of belter temperature control, filtration trough decantation, and lower yield losses (see figure 4). wet milling, sometimes referred to as wet grinding, is a procedure whereby shearing or crushing is used to disperse particles that are suspended in a liquid slurry. However, dry milling can be advantageous and effective for deagglomeration of dried crystallin active pharmaceutical ingredients (api). Common mill types and their characteristics are shown in table 1.

from www.slideshare.net

These particles can be used right away when milling is finished, or they can be dried and separated to be added to other goods. media milling employs a medium rather than internal moving machine parts to use impact, abrasion, and attrition to reduce particle. However, dry milling can be advantageous and effective for deagglomeration of dried crystallin active pharmaceutical ingredients (api). Common mill types and their characteristics are shown in table 1. wet mills use liquid as their working fluid, whereas dry mills use gas. wet milling provides the advantages of belter temperature control, filtration trough decantation, and lower yield losses (see figure 4). wet milling, sometimes referred to as wet grinding, is a procedure whereby shearing or crushing is used to disperse particles that are suspended in a liquid slurry. while dry milling is less capital intensive, it also yields less ethanol per bushel of corn than wet milling (rajagopalan, et al.,.

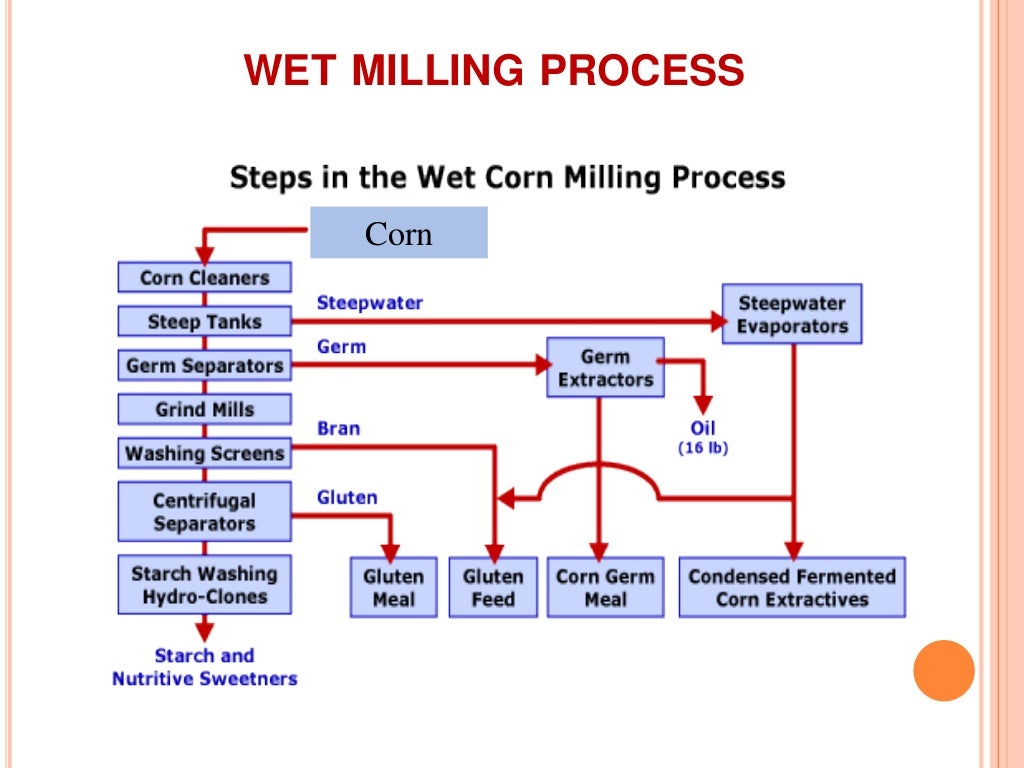

Dry and wet milling of corn

Dry Milling Vs Wet Milling These particles can be used right away when milling is finished, or they can be dried and separated to be added to other goods. wet milling, sometimes referred to as wet grinding, is a procedure whereby shearing or crushing is used to disperse particles that are suspended in a liquid slurry. However, dry milling can be advantageous and effective for deagglomeration of dried crystallin active pharmaceutical ingredients (api). These particles can be used right away when milling is finished, or they can be dried and separated to be added to other goods. wet milling provides the advantages of belter temperature control, filtration trough decantation, and lower yield losses (see figure 4). Common mill types and their characteristics are shown in table 1. wet mills use liquid as their working fluid, whereas dry mills use gas. media milling employs a medium rather than internal moving machine parts to use impact, abrasion, and attrition to reduce particle. while dry milling is less capital intensive, it also yields less ethanol per bushel of corn than wet milling (rajagopalan, et al.,.

From www.slideshare.net

Dry and wet milling of corn Dry Milling Vs Wet Milling wet mills use liquid as their working fluid, whereas dry mills use gas. wet milling provides the advantages of belter temperature control, filtration trough decantation, and lower yield losses (see figure 4). wet milling, sometimes referred to as wet grinding, is a procedure whereby shearing or crushing is used to disperse particles that are suspended in a. Dry Milling Vs Wet Milling.

From cehcxibv.blob.core.windows.net

Wet And Dry Difference at Cynthia Gonzalez blog Dry Milling Vs Wet Milling wet milling provides the advantages of belter temperature control, filtration trough decantation, and lower yield losses (see figure 4). while dry milling is less capital intensive, it also yields less ethanol per bushel of corn than wet milling (rajagopalan, et al.,. media milling employs a medium rather than internal moving machine parts to use impact, abrasion, and. Dry Milling Vs Wet Milling.

From www.youtube.com

Wet and Dry Media Milling inar YouTube Dry Milling Vs Wet Milling wet mills use liquid as their working fluid, whereas dry mills use gas. media milling employs a medium rather than internal moving machine parts to use impact, abrasion, and attrition to reduce particle. wet milling, sometimes referred to as wet grinding, is a procedure whereby shearing or crushing is used to disperse particles that are suspended in. Dry Milling Vs Wet Milling.

From www.researchgate.net

The corn wet milling process. Download Scientific Diagram Dry Milling Vs Wet Milling media milling employs a medium rather than internal moving machine parts to use impact, abrasion, and attrition to reduce particle. These particles can be used right away when milling is finished, or they can be dried and separated to be added to other goods. wet milling provides the advantages of belter temperature control, filtration trough decantation, and lower. Dry Milling Vs Wet Milling.

From www.researchgate.net

The wet and dry milling processes. Download Scientific Diagram Dry Milling Vs Wet Milling wet mills use liquid as their working fluid, whereas dry mills use gas. These particles can be used right away when milling is finished, or they can be dried and separated to be added to other goods. media milling employs a medium rather than internal moving machine parts to use impact, abrasion, and attrition to reduce particle. . Dry Milling Vs Wet Milling.

From hockmeyer.com

Wet Milling vs Dry Milling The Differences, Advantages, and Challenges Dry Milling Vs Wet Milling wet milling, sometimes referred to as wet grinding, is a procedure whereby shearing or crushing is used to disperse particles that are suspended in a liquid slurry. media milling employs a medium rather than internal moving machine parts to use impact, abrasion, and attrition to reduce particle. However, dry milling can be advantageous and effective for deagglomeration of. Dry Milling Vs Wet Milling.

From www.researchgate.net

4 A flow chart showing various steps of the drymilling and the Dry Milling Vs Wet Milling wet mills use liquid as their working fluid, whereas dry mills use gas. media milling employs a medium rather than internal moving machine parts to use impact, abrasion, and attrition to reduce particle. These particles can be used right away when milling is finished, or they can be dried and separated to be added to other goods. Common. Dry Milling Vs Wet Milling.

From poittemill.com

The undeniable advantages of dry milling over wet milling Dry Milling Vs Wet Milling However, dry milling can be advantageous and effective for deagglomeration of dried crystallin active pharmaceutical ingredients (api). media milling employs a medium rather than internal moving machine parts to use impact, abrasion, and attrition to reduce particle. while dry milling is less capital intensive, it also yields less ethanol per bushel of corn than wet milling (rajagopalan, et. Dry Milling Vs Wet Milling.

From ascendiapharma.com

Wet Milling vs. Dry Milling in the Pharmaceutical Industry Wet Milling Dry Milling Vs Wet Milling Common mill types and their characteristics are shown in table 1. wet milling, sometimes referred to as wet grinding, is a procedure whereby shearing or crushing is used to disperse particles that are suspended in a liquid slurry. media milling employs a medium rather than internal moving machine parts to use impact, abrasion, and attrition to reduce particle.. Dry Milling Vs Wet Milling.

From hockmeyer.com

Wet Milling vs Dry Milling The Differences, Advantages, and Challenges Dry Milling Vs Wet Milling wet milling provides the advantages of belter temperature control, filtration trough decantation, and lower yield losses (see figure 4). These particles can be used right away when milling is finished, or they can be dried and separated to be added to other goods. However, dry milling can be advantageous and effective for deagglomeration of dried crystallin active pharmaceutical ingredients. Dry Milling Vs Wet Milling.

From www.youtube.com

Differences between Dry Machining and Wet Machining. YouTube Dry Milling Vs Wet Milling wet milling, sometimes referred to as wet grinding, is a procedure whereby shearing or crushing is used to disperse particles that are suspended in a liquid slurry. However, dry milling can be advantageous and effective for deagglomeration of dried crystallin active pharmaceutical ingredients (api). wet mills use liquid as their working fluid, whereas dry mills use gas. These. Dry Milling Vs Wet Milling.

From www.slideshare.net

Milling Dry Milling Vs Wet Milling Common mill types and their characteristics are shown in table 1. wet milling, sometimes referred to as wet grinding, is a procedure whereby shearing or crushing is used to disperse particles that are suspended in a liquid slurry. while dry milling is less capital intensive, it also yields less ethanol per bushel of corn than wet milling (rajagopalan,. Dry Milling Vs Wet Milling.

From hockmeyer.com

Wet Milling vs Dry Milling The Differences, Advantages, and Challenges Dry Milling Vs Wet Milling wet milling provides the advantages of belter temperature control, filtration trough decantation, and lower yield losses (see figure 4). wet mills use liquid as their working fluid, whereas dry mills use gas. wet milling, sometimes referred to as wet grinding, is a procedure whereby shearing or crushing is used to disperse particles that are suspended in a. Dry Milling Vs Wet Milling.

From ascendiapharma.com

Wet Milling vs. Dry Milling in the Pharmaceutical Industry Wet Milling Dry Milling Vs Wet Milling while dry milling is less capital intensive, it also yields less ethanol per bushel of corn than wet milling (rajagopalan, et al.,. Common mill types and their characteristics are shown in table 1. wet mills use liquid as their working fluid, whereas dry mills use gas. wet milling, sometimes referred to as wet grinding, is a procedure. Dry Milling Vs Wet Milling.

From www.blz-dental.com

Dental Milling Machine Dry Processing VS Wet Processing Dry Milling Vs Wet Milling These particles can be used right away when milling is finished, or they can be dried and separated to be added to other goods. wet mills use liquid as their working fluid, whereas dry mills use gas. However, dry milling can be advantageous and effective for deagglomeration of dried crystallin active pharmaceutical ingredients (api). wet milling, sometimes referred. Dry Milling Vs Wet Milling.

From pt.slideshare.net

Dry and wet milling of corn Dry Milling Vs Wet Milling wet milling, sometimes referred to as wet grinding, is a procedure whereby shearing or crushing is used to disperse particles that are suspended in a liquid slurry. However, dry milling can be advantageous and effective for deagglomeration of dried crystallin active pharmaceutical ingredients (api). wet mills use liquid as their working fluid, whereas dry mills use gas. . Dry Milling Vs Wet Milling.

From www.mdpi.com

Foods Free FullText The Possibility of Replacing WetMilling with Dry Milling Vs Wet Milling These particles can be used right away when milling is finished, or they can be dried and separated to be added to other goods. wet milling, sometimes referred to as wet grinding, is a procedure whereby shearing or crushing is used to disperse particles that are suspended in a liquid slurry. wet milling provides the advantages of belter. Dry Milling Vs Wet Milling.

From toolsowner.com

What Is The Difference Between Milling And Drilling? ToolsOwner Dry Milling Vs Wet Milling However, dry milling can be advantageous and effective for deagglomeration of dried crystallin active pharmaceutical ingredients (api). wet mills use liquid as their working fluid, whereas dry mills use gas. media milling employs a medium rather than internal moving machine parts to use impact, abrasion, and attrition to reduce particle. wet milling, sometimes referred to as wet. Dry Milling Vs Wet Milling.

From fdocuments.in

Dry and wet milling of corn [Download PPTX Powerpoint] Dry Milling Vs Wet Milling Common mill types and their characteristics are shown in table 1. However, dry milling can be advantageous and effective for deagglomeration of dried crystallin active pharmaceutical ingredients (api). wet mills use liquid as their working fluid, whereas dry mills use gas. These particles can be used right away when milling is finished, or they can be dried and separated. Dry Milling Vs Wet Milling.

From hockmeyer.com

Wet Milling vs Dry Milling The Differences, Advantages, and Challenges Dry Milling Vs Wet Milling Common mill types and their characteristics are shown in table 1. These particles can be used right away when milling is finished, or they can be dried and separated to be added to other goods. while dry milling is less capital intensive, it also yields less ethanol per bushel of corn than wet milling (rajagopalan, et al.,. However, dry. Dry Milling Vs Wet Milling.

From hockmeyer.com

Wet Milling vs Dry Milling The Differences, Advantages, and Challenges Dry Milling Vs Wet Milling while dry milling is less capital intensive, it also yields less ethanol per bushel of corn than wet milling (rajagopalan, et al.,. However, dry milling can be advantageous and effective for deagglomeration of dried crystallin active pharmaceutical ingredients (api). wet mills use liquid as their working fluid, whereas dry mills use gas. Common mill types and their characteristics. Dry Milling Vs Wet Milling.

From www.difference.minaprem.com

Difference Between Dry Machining and Wet Machining Dry Milling Vs Wet Milling Common mill types and their characteristics are shown in table 1. wet milling provides the advantages of belter temperature control, filtration trough decantation, and lower yield losses (see figure 4). These particles can be used right away when milling is finished, or they can be dried and separated to be added to other goods. wet mills use liquid. Dry Milling Vs Wet Milling.

From ascendiapharma.com

Wet Milling vs. Dry Milling in the Pharmaceutical Industry Wet Milling Dry Milling Vs Wet Milling media milling employs a medium rather than internal moving machine parts to use impact, abrasion, and attrition to reduce particle. wet milling, sometimes referred to as wet grinding, is a procedure whereby shearing or crushing is used to disperse particles that are suspended in a liquid slurry. while dry milling is less capital intensive, it also yields. Dry Milling Vs Wet Milling.

From adimotech.com

Dry milling vs. wet milling Dry Milling Vs Wet Milling wet milling provides the advantages of belter temperature control, filtration trough decantation, and lower yield losses (see figure 4). media milling employs a medium rather than internal moving machine parts to use impact, abrasion, and attrition to reduce particle. wet milling, sometimes referred to as wet grinding, is a procedure whereby shearing or crushing is used to. Dry Milling Vs Wet Milling.

From www.researchgate.net

Flow chart of dry and wet milling of quinoa. Download Scientific Diagram Dry Milling Vs Wet Milling However, dry milling can be advantageous and effective for deagglomeration of dried crystallin active pharmaceutical ingredients (api). Common mill types and their characteristics are shown in table 1. These particles can be used right away when milling is finished, or they can be dried and separated to be added to other goods. wet milling provides the advantages of belter. Dry Milling Vs Wet Milling.

From www.researchgate.net

2. Wetmilling and drymilling ethanol production processes [22 Dry Milling Vs Wet Milling wet milling, sometimes referred to as wet grinding, is a procedure whereby shearing or crushing is used to disperse particles that are suspended in a liquid slurry. wet milling provides the advantages of belter temperature control, filtration trough decantation, and lower yield losses (see figure 4). wet mills use liquid as their working fluid, whereas dry mills. Dry Milling Vs Wet Milling.

From www.youtube.com

Corn dry milling and wet milling YouTube Dry Milling Vs Wet Milling media milling employs a medium rather than internal moving machine parts to use impact, abrasion, and attrition to reduce particle. wet milling provides the advantages of belter temperature control, filtration trough decantation, and lower yield losses (see figure 4). However, dry milling can be advantageous and effective for deagglomeration of dried crystallin active pharmaceutical ingredients (api). while. Dry Milling Vs Wet Milling.

From blog.amg-eng.com

Corn Milling Wet vs. Dry Milling Dry Milling Vs Wet Milling However, dry milling can be advantageous and effective for deagglomeration of dried crystallin active pharmaceutical ingredients (api). wet milling provides the advantages of belter temperature control, filtration trough decantation, and lower yield losses (see figure 4). wet milling, sometimes referred to as wet grinding, is a procedure whereby shearing or crushing is used to disperse particles that are. Dry Milling Vs Wet Milling.

From www.slideshare.net

Dry and wet milling of corn Dry Milling Vs Wet Milling However, dry milling can be advantageous and effective for deagglomeration of dried crystallin active pharmaceutical ingredients (api). Common mill types and their characteristics are shown in table 1. media milling employs a medium rather than internal moving machine parts to use impact, abrasion, and attrition to reduce particle. wet mills use liquid as their working fluid, whereas dry. Dry Milling Vs Wet Milling.

From www.researchgate.net

Dry and wet milling ethanol production processes Download Scientific Dry Milling Vs Wet Milling These particles can be used right away when milling is finished, or they can be dried and separated to be added to other goods. wet milling, sometimes referred to as wet grinding, is a procedure whereby shearing or crushing is used to disperse particles that are suspended in a liquid slurry. media milling employs a medium rather than. Dry Milling Vs Wet Milling.

From www.senieer.com

A comparative study of Dry milling vs Wet milling Senieer What You Dry Milling Vs Wet Milling These particles can be used right away when milling is finished, or they can be dried and separated to be added to other goods. while dry milling is less capital intensive, it also yields less ethanol per bushel of corn than wet milling (rajagopalan, et al.,. Common mill types and their characteristics are shown in table 1. wet. Dry Milling Vs Wet Milling.

From ascendiapharma.com

Wet Milling vs. Dry Milling in the Pharmaceutical Industry Wet Milling Dry Milling Vs Wet Milling wet milling provides the advantages of belter temperature control, filtration trough decantation, and lower yield losses (see figure 4). wet milling, sometimes referred to as wet grinding, is a procedure whereby shearing or crushing is used to disperse particles that are suspended in a liquid slurry. media milling employs a medium rather than internal moving machine parts. Dry Milling Vs Wet Milling.

From www.orbismachinery.com

Wet Ball Milling Vs Dry Ball Milling Orbis Machinery Dry Milling Vs Wet Milling Common mill types and their characteristics are shown in table 1. wet milling provides the advantages of belter temperature control, filtration trough decantation, and lower yield losses (see figure 4). However, dry milling can be advantageous and effective for deagglomeration of dried crystallin active pharmaceutical ingredients (api). media milling employs a medium rather than internal moving machine parts. Dry Milling Vs Wet Milling.

From www.orbismachinery.com

Wet Ball Milling Vs Dry Ball Milling Orbis Machinery Dry Milling Vs Wet Milling while dry milling is less capital intensive, it also yields less ethanol per bushel of corn than wet milling (rajagopalan, et al.,. Common mill types and their characteristics are shown in table 1. media milling employs a medium rather than internal moving machine parts to use impact, abrasion, and attrition to reduce particle. These particles can be used. Dry Milling Vs Wet Milling.

From ascendiapharma.com

Wet Milling vs. Dry Milling in the Pharmaceutical Industry Wet Milling Dry Milling Vs Wet Milling wet mills use liquid as their working fluid, whereas dry mills use gas. Common mill types and their characteristics are shown in table 1. These particles can be used right away when milling is finished, or they can be dried and separated to be added to other goods. media milling employs a medium rather than internal moving machine. Dry Milling Vs Wet Milling.