Control Valve Leak Test . Control valve leakage testing helps identify potential leaks that could affect process efficiency, product quality, and safety. This is sufficient time to allow quick visual observation of a. A, aa, a, b, c, cc, d, e, ee, f, g, and the rate a. For proper working of control valves, there are some tests that commonly include pressure tests (hydrostatic or shell tightness tests, seat/plug/packing leakage. Most valve internal leak testing is done with air for a relatively short duration, from a few seconds to a few minutes. By detecting and addressing leaks promptly, operators can minimize downtime, reduce environmental impact, and enhance overall operational reliability. Shell leakage tests are required for valves that are used in “full open” and “full closed” service, such as check, stop, and.

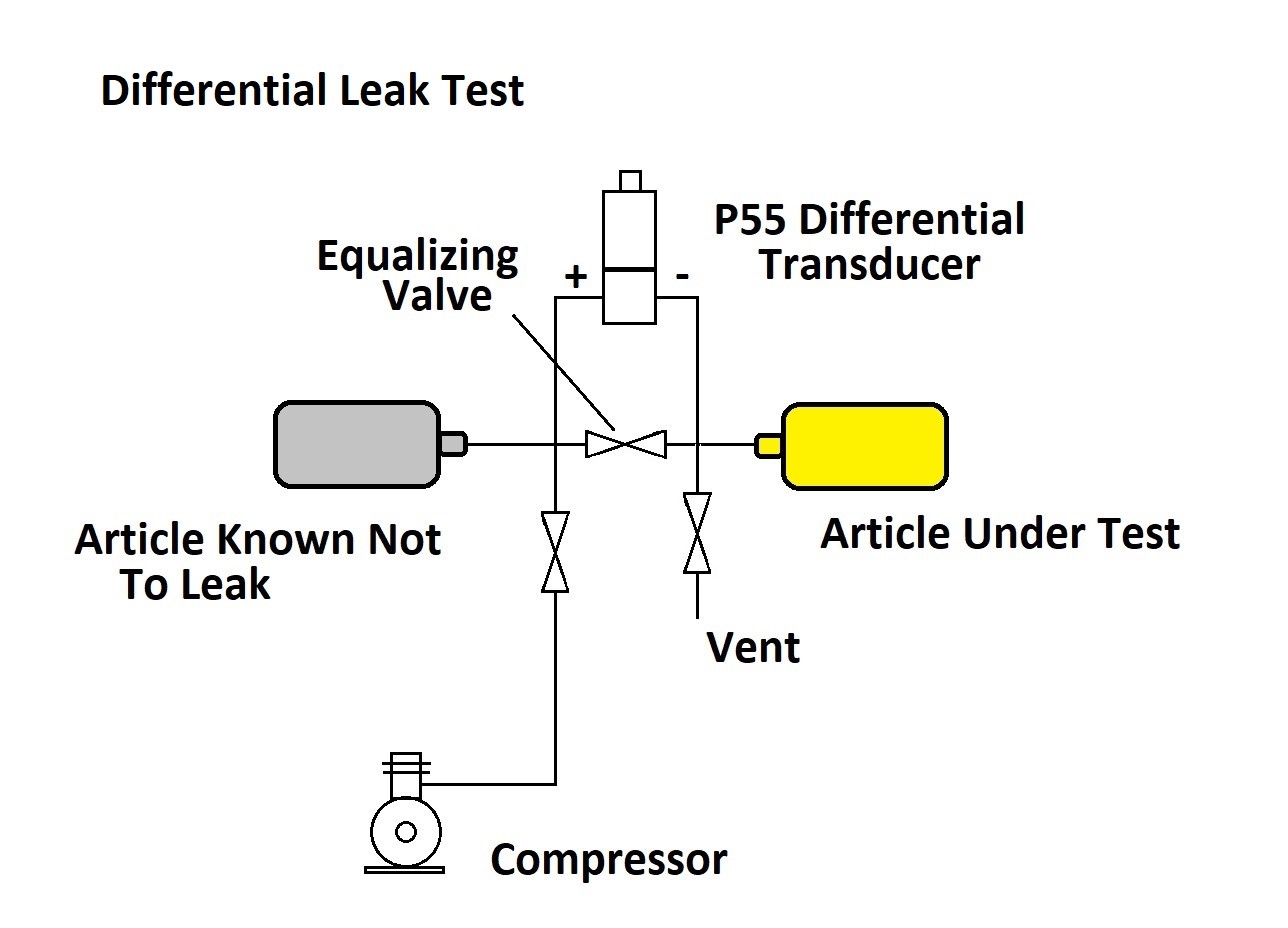

from www.validyne.com

This is sufficient time to allow quick visual observation of a. A, aa, a, b, c, cc, d, e, ee, f, g, and the rate a. Shell leakage tests are required for valves that are used in “full open” and “full closed” service, such as check, stop, and. For proper working of control valves, there are some tests that commonly include pressure tests (hydrostatic or shell tightness tests, seat/plug/packing leakage. By detecting and addressing leaks promptly, operators can minimize downtime, reduce environmental impact, and enhance overall operational reliability. Most valve internal leak testing is done with air for a relatively short duration, from a few seconds to a few minutes. Control valve leakage testing helps identify potential leaks that could affect process efficiency, product quality, and safety.

Leak Test using Pressure Sensors Validyne Engineering

Control Valve Leak Test By detecting and addressing leaks promptly, operators can minimize downtime, reduce environmental impact, and enhance overall operational reliability. This is sufficient time to allow quick visual observation of a. Shell leakage tests are required for valves that are used in “full open” and “full closed” service, such as check, stop, and. A, aa, a, b, c, cc, d, e, ee, f, g, and the rate a. Most valve internal leak testing is done with air for a relatively short duration, from a few seconds to a few minutes. By detecting and addressing leaks promptly, operators can minimize downtime, reduce environmental impact, and enhance overall operational reliability. For proper working of control valves, there are some tests that commonly include pressure tests (hydrostatic or shell tightness tests, seat/plug/packing leakage. Control valve leakage testing helps identify potential leaks that could affect process efficiency, product quality, and safety.

From fluidhandlingpro.com

Accuracy and Repeatability in Valve Leak Test Stands are Key to Space Control Valve Leak Test This is sufficient time to allow quick visual observation of a. Control valve leakage testing helps identify potential leaks that could affect process efficiency, product quality, and safety. By detecting and addressing leaks promptly, operators can minimize downtime, reduce environmental impact, and enhance overall operational reliability. For proper working of control valves, there are some tests that commonly include pressure. Control Valve Leak Test.

From www.youtube.com

Fisher Control valve leak test instrumentation YouTube Control Valve Leak Test A, aa, a, b, c, cc, d, e, ee, f, g, and the rate a. For proper working of control valves, there are some tests that commonly include pressure tests (hydrostatic or shell tightness tests, seat/plug/packing leakage. This is sufficient time to allow quick visual observation of a. Shell leakage tests are required for valves that are used in “full. Control Valve Leak Test.

From www.youtube.com

Ball Valve Leakage YouTube Control Valve Leak Test A, aa, a, b, c, cc, d, e, ee, f, g, and the rate a. Most valve internal leak testing is done with air for a relatively short duration, from a few seconds to a few minutes. For proper working of control valves, there are some tests that commonly include pressure tests (hydrostatic or shell tightness tests, seat/plug/packing leakage. By. Control Valve Leak Test.

From www.linkedin.com

A Comprehensive Comparison of Leak Testing Standards in Valve Industry Control Valve Leak Test Control valve leakage testing helps identify potential leaks that could affect process efficiency, product quality, and safety. This is sufficient time to allow quick visual observation of a. Shell leakage tests are required for valves that are used in “full open” and “full closed” service, such as check, stop, and. Most valve internal leak testing is done with air for. Control Valve Leak Test.

From www.electricalvolt.com

Control Valves Leakage Classifications Electrical Volt Control Valve Leak Test For proper working of control valves, there are some tests that commonly include pressure tests (hydrostatic or shell tightness tests, seat/plug/packing leakage. Control valve leakage testing helps identify potential leaks that could affect process efficiency, product quality, and safety. By detecting and addressing leaks promptly, operators can minimize downtime, reduce environmental impact, and enhance overall operational reliability. This is sufficient. Control Valve Leak Test.

From www.youtube.com

Internal leaks test control valve YouTube Control Valve Leak Test A, aa, a, b, c, cc, d, e, ee, f, g, and the rate a. For proper working of control valves, there are some tests that commonly include pressure tests (hydrostatic or shell tightness tests, seat/plug/packing leakage. Shell leakage tests are required for valves that are used in “full open” and “full closed” service, such as check, stop, and. Most. Control Valve Leak Test.

From paktechpoint.com

Troubleshooting Control Valve Seat Leakage PAKTECHPOINT Control Valve Leak Test This is sufficient time to allow quick visual observation of a. By detecting and addressing leaks promptly, operators can minimize downtime, reduce environmental impact, and enhance overall operational reliability. Control valve leakage testing helps identify potential leaks that could affect process efficiency, product quality, and safety. For proper working of control valves, there are some tests that commonly include pressure. Control Valve Leak Test.

From uniquevacuum.co.in

CONTROL VALVES LEAK TEST SYSTEMS Unique Vacuum Solutions Control Valve Leak Test By detecting and addressing leaks promptly, operators can minimize downtime, reduce environmental impact, and enhance overall operational reliability. Shell leakage tests are required for valves that are used in “full open” and “full closed” service, such as check, stop, and. This is sufficient time to allow quick visual observation of a. Control valve leakage testing helps identify potential leaks that. Control Valve Leak Test.

From instrumentationtools.com

Control Valves Leakage Classifications Instrumentation Tools Control Valve Leak Test By detecting and addressing leaks promptly, operators can minimize downtime, reduce environmental impact, and enhance overall operational reliability. For proper working of control valves, there are some tests that commonly include pressure tests (hydrostatic or shell tightness tests, seat/plug/packing leakage. Control valve leakage testing helps identify potential leaks that could affect process efficiency, product quality, and safety. A, aa, a,. Control Valve Leak Test.

From www.youtube.com

Control Valve Leakage Test By Positioner YouTube Control Valve Leak Test Control valve leakage testing helps identify potential leaks that could affect process efficiency, product quality, and safety. This is sufficient time to allow quick visual observation of a. A, aa, a, b, c, cc, d, e, ee, f, g, and the rate a. By detecting and addressing leaks promptly, operators can minimize downtime, reduce environmental impact, and enhance overall operational. Control Valve Leak Test.

From www.arotec-co.de

Inspection and Testing of a Control Valve Part 2 Arotec Control Valve Leak Test Control valve leakage testing helps identify potential leaks that could affect process efficiency, product quality, and safety. Shell leakage tests are required for valves that are used in “full open” and “full closed” service, such as check, stop, and. By detecting and addressing leaks promptly, operators can minimize downtime, reduce environmental impact, and enhance overall operational reliability. This is sufficient. Control Valve Leak Test.

From www.directindustry.com

Control valve leak test bench MIPA REVALVE Control Valve Leak Test Shell leakage tests are required for valves that are used in “full open” and “full closed” service, such as check, stop, and. A, aa, a, b, c, cc, d, e, ee, f, g, and the rate a. By detecting and addressing leaks promptly, operators can minimize downtime, reduce environmental impact, and enhance overall operational reliability. Most valve internal leak testing. Control Valve Leak Test.

From www.tqc.co.uk

Leak Testing & Pressure Testing Basic Principles of Leak Testing TQC Control Valve Leak Test Control valve leakage testing helps identify potential leaks that could affect process efficiency, product quality, and safety. Most valve internal leak testing is done with air for a relatively short duration, from a few seconds to a few minutes. For proper working of control valves, there are some tests that commonly include pressure tests (hydrostatic or shell tightness tests, seat/plug/packing. Control Valve Leak Test.

From industrial.dft-valves.com

DFT Valve Leak Test Infographic DFT® Inc Control Valve Leak Test This is sufficient time to allow quick visual observation of a. By detecting and addressing leaks promptly, operators can minimize downtime, reduce environmental impact, and enhance overall operational reliability. Shell leakage tests are required for valves that are used in “full open” and “full closed” service, such as check, stop, and. For proper working of control valves, there are some. Control Valve Leak Test.

From vdocuments.mx

QCP12 Valve Leak Test Procedure.pdf [PDF Document] Control Valve Leak Test Shell leakage tests are required for valves that are used in “full open” and “full closed” service, such as check, stop, and. This is sufficient time to allow quick visual observation of a. Control valve leakage testing helps identify potential leaks that could affect process efficiency, product quality, and safety. For proper working of control valves, there are some tests. Control Valve Leak Test.

From uniquevacuum.co.in

CONTROL VALVES LEAK TEST SYSTEMS Unique Vacuum Solutions Control Valve Leak Test For proper working of control valves, there are some tests that commonly include pressure tests (hydrostatic or shell tightness tests, seat/plug/packing leakage. Most valve internal leak testing is done with air for a relatively short duration, from a few seconds to a few minutes. A, aa, a, b, c, cc, d, e, ee, f, g, and the rate a. This. Control Valve Leak Test.

From www.validyne.com

Leak Test using Pressure Sensors Validyne Engineering Control Valve Leak Test A, aa, a, b, c, cc, d, e, ee, f, g, and the rate a. By detecting and addressing leaks promptly, operators can minimize downtime, reduce environmental impact, and enhance overall operational reliability. This is sufficient time to allow quick visual observation of a. Control valve leakage testing helps identify potential leaks that could affect process efficiency, product quality, and. Control Valve Leak Test.

From uniquevacuum.co.in

CONTROL VALVES LEAK TEST SYSTEMS Unique Vacuum Solutions Control Valve Leak Test For proper working of control valves, there are some tests that commonly include pressure tests (hydrostatic or shell tightness tests, seat/plug/packing leakage. Most valve internal leak testing is done with air for a relatively short duration, from a few seconds to a few minutes. Control valve leakage testing helps identify potential leaks that could affect process efficiency, product quality, and. Control Valve Leak Test.

From www.teknolab.info

Valves Leakage Testing Teknolab Control Valve Leak Test A, aa, a, b, c, cc, d, e, ee, f, g, and the rate a. Most valve internal leak testing is done with air for a relatively short duration, from a few seconds to a few minutes. For proper working of control valves, there are some tests that commonly include pressure tests (hydrostatic or shell tightness tests, seat/plug/packing leakage. By. Control Valve Leak Test.

From forumautomation.com

What is leakage class rating (Valve Design)? Valves Industrial Control Valve Leak Test Control valve leakage testing helps identify potential leaks that could affect process efficiency, product quality, and safety. A, aa, a, b, c, cc, d, e, ee, f, g, and the rate a. This is sufficient time to allow quick visual observation of a. Shell leakage tests are required for valves that are used in “full open” and “full closed” service,. Control Valve Leak Test.

From tfautomation.co.uk

Control Valve Leak Test & Vision Inspection to TF Automation Control Valve Leak Test This is sufficient time to allow quick visual observation of a. Shell leakage tests are required for valves that are used in “full open” and “full closed” service, such as check, stop, and. Most valve internal leak testing is done with air for a relatively short duration, from a few seconds to a few minutes. By detecting and addressing leaks. Control Valve Leak Test.

From forumautomation.com

What is leakage class rating (Valve Design)? Valves Industrial Control Valve Leak Test For proper working of control valves, there are some tests that commonly include pressure tests (hydrostatic or shell tightness tests, seat/plug/packing leakage. By detecting and addressing leaks promptly, operators can minimize downtime, reduce environmental impact, and enhance overall operational reliability. A, aa, a, b, c, cc, d, e, ee, f, g, and the rate a. Most valve internal leak testing. Control Valve Leak Test.

From www.youtube.com

Valve and Regulator Leak Detection Training YouTube Control Valve Leak Test Shell leakage tests are required for valves that are used in “full open” and “full closed” service, such as check, stop, and. For proper working of control valves, there are some tests that commonly include pressure tests (hydrostatic or shell tightness tests, seat/plug/packing leakage. A, aa, a, b, c, cc, d, e, ee, f, g, and the rate a. Control. Control Valve Leak Test.

From www.scribd.com

Valve Leak Test Procedure Leak Valve Control Valve Leak Test Control valve leakage testing helps identify potential leaks that could affect process efficiency, product quality, and safety. This is sufficient time to allow quick visual observation of a. Shell leakage tests are required for valves that are used in “full open” and “full closed” service, such as check, stop, and. A, aa, a, b, c, cc, d, e, ee, f,. Control Valve Leak Test.

From www.youtube.com

CYLINDER HEAD VALVES LEAK TEST. BEST WAY HOW TO FIND LEAKY VALVES BY Control Valve Leak Test For proper working of control valves, there are some tests that commonly include pressure tests (hydrostatic or shell tightness tests, seat/plug/packing leakage. A, aa, a, b, c, cc, d, e, ee, f, g, and the rate a. Shell leakage tests are required for valves that are used in “full open” and “full closed” service, such as check, stop, and. By. Control Valve Leak Test.

From www.slideserve.com

PPT ANNUAL SHUTDOWN MAINTENANCE OF FIELD INSTRUMENT IN PT ASAHIMAS Control Valve Leak Test Shell leakage tests are required for valves that are used in “full open” and “full closed” service, such as check, stop, and. This is sufficient time to allow quick visual observation of a. For proper working of control valves, there are some tests that commonly include pressure tests (hydrostatic or shell tightness tests, seat/plug/packing leakage. Control valve leakage testing helps. Control Valve Leak Test.

From diagramtrikoviwz.z13.web.core.windows.net

Double Check Valve Test Procedure Control Valve Leak Test By detecting and addressing leaks promptly, operators can minimize downtime, reduce environmental impact, and enhance overall operational reliability. This is sufficient time to allow quick visual observation of a. A, aa, a, b, c, cc, d, e, ee, f, g, and the rate a. For proper working of control valves, there are some tests that commonly include pressure tests (hydrostatic. Control Valve Leak Test.

From www.youtube.com

Control Valve Leakage Classes YouTube Control Valve Leak Test Shell leakage tests are required for valves that are used in “full open” and “full closed” service, such as check, stop, and. Most valve internal leak testing is done with air for a relatively short duration, from a few seconds to a few minutes. A, aa, a, b, c, cc, d, e, ee, f, g, and the rate a. For. Control Valve Leak Test.

From control.com

Valve Seat Leakage Basic Principles of Control Valves and Actuators Control Valve Leak Test This is sufficient time to allow quick visual observation of a. Control valve leakage testing helps identify potential leaks that could affect process efficiency, product quality, and safety. A, aa, a, b, c, cc, d, e, ee, f, g, and the rate a. Most valve internal leak testing is done with air for a relatively short duration, from a few. Control Valve Leak Test.

From www.vrogue.co

Instrumentation Control Valve Leakage Classifications vrogue.co Control Valve Leak Test For proper working of control valves, there are some tests that commonly include pressure tests (hydrostatic or shell tightness tests, seat/plug/packing leakage. Shell leakage tests are required for valves that are used in “full open” and “full closed” service, such as check, stop, and. Most valve internal leak testing is done with air for a relatively short duration, from a. Control Valve Leak Test.

From www.ebay.com

CONTROL VALVE LEAK RATE TEST STAND CALIBRATED eBay Control Valve Leak Test A, aa, a, b, c, cc, d, e, ee, f, g, and the rate a. Shell leakage tests are required for valves that are used in “full open” and “full closed” service, such as check, stop, and. For proper working of control valves, there are some tests that commonly include pressure tests (hydrostatic or shell tightness tests, seat/plug/packing leakage. Most. Control Valve Leak Test.

From www.automaticaeinstrumentacion.com

Cómo detectar e identificar patologías en las válvulas de control Control Valve Leak Test This is sufficient time to allow quick visual observation of a. Most valve internal leak testing is done with air for a relatively short duration, from a few seconds to a few minutes. By detecting and addressing leaks promptly, operators can minimize downtime, reduce environmental impact, and enhance overall operational reliability. Shell leakage tests are required for valves that are. Control Valve Leak Test.

From www.teknolab.info

Valves Leakage Testing Teknolab Control Valve Leak Test For proper working of control valves, there are some tests that commonly include pressure tests (hydrostatic or shell tightness tests, seat/plug/packing leakage. By detecting and addressing leaks promptly, operators can minimize downtime, reduce environmental impact, and enhance overall operational reliability. Shell leakage tests are required for valves that are used in “full open” and “full closed” service, such as check,. Control Valve Leak Test.

From instrumentationtools.com

Control Valve Stroke Test Procedure InstrumentationTools Control Valve Leak Test By detecting and addressing leaks promptly, operators can minimize downtime, reduce environmental impact, and enhance overall operational reliability. Most valve internal leak testing is done with air for a relatively short duration, from a few seconds to a few minutes. Control valve leakage testing helps identify potential leaks that could affect process efficiency, product quality, and safety. This is sufficient. Control Valve Leak Test.

From www.teknolab.info

Valves Leakage Testing Teknolab Control Valve Leak Test A, aa, a, b, c, cc, d, e, ee, f, g, and the rate a. Most valve internal leak testing is done with air for a relatively short duration, from a few seconds to a few minutes. By detecting and addressing leaks promptly, operators can minimize downtime, reduce environmental impact, and enhance overall operational reliability. Shell leakage tests are required. Control Valve Leak Test.