Measuring Countersink Angle . The first is to simply position and pull the trigger. You have the option to choose between units of length measurement. The diameter of ball 1 ( b 1 ) , the diameter of ball 2 ( b 2 ), and. Figure 2 shows the key variables involved: There are actually two ways to measure a countersink with fmt. The most common gages have a 90 o included angle on the gage plunger resulting in a 2:1 ratio between the taper diameter observed and the dial indicator rack travel. If we know the diameter of the countersink taper, we can use the depth that a gage ball that fits down into the countersink to compute the theoretical (unrounded) diameter of the countersink. Input the angle of the countersink, which is the. Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because the countersink angle. Two gage balls of different diameters are used to measure the countersink angle (θ). Input the diameter of the countersink hole at the surface. A countersink with a rounded or burred edge represents a measurement problem. The most common countersink angles are 82°, 90° or 100°.

from www.novacam.com

The most common countersink angles are 82°, 90° or 100°. The diameter of ball 1 ( b 1 ) , the diameter of ball 2 ( b 2 ), and. Input the diameter of the countersink hole at the surface. If we know the diameter of the countersink taper, we can use the depth that a gage ball that fits down into the countersink to compute the theoretical (unrounded) diameter of the countersink. Input the angle of the countersink, which is the. There are actually two ways to measure a countersink with fmt. The most common gages have a 90 o included angle on the gage plunger resulting in a 2:1 ratio between the taper diameter observed and the dial indicator rack travel. You have the option to choose between units of length measurement. Two gage balls of different diameters are used to measure the countersink angle (θ). A countersink with a rounded or burred edge represents a measurement problem.

3D countersink measurement noncontact and automated Novacam

Measuring Countersink Angle Two gage balls of different diameters are used to measure the countersink angle (θ). You have the option to choose between units of length measurement. A countersink with a rounded or burred edge represents a measurement problem. The first is to simply position and pull the trigger. If we know the diameter of the countersink taper, we can use the depth that a gage ball that fits down into the countersink to compute the theoretical (unrounded) diameter of the countersink. Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because the countersink angle. There are actually two ways to measure a countersink with fmt. Input the angle of the countersink, which is the. The most common gages have a 90 o included angle on the gage plunger resulting in a 2:1 ratio between the taper diameter observed and the dial indicator rack travel. Figure 2 shows the key variables involved: The most common countersink angles are 82°, 90° or 100°. The diameter of ball 1 ( b 1 ) , the diameter of ball 2 ( b 2 ), and. Input the diameter of the countersink hole at the surface. Two gage balls of different diameters are used to measure the countersink angle (θ).

From www.kristeel.com

Countersink Angle Gauge 60 to 120 Degrees Engineering Gauges Measuring Countersink Angle If we know the diameter of the countersink taper, we can use the depth that a gage ball that fits down into the countersink to compute the theoretical (unrounded) diameter of the countersink. There are actually two ways to measure a countersink with fmt. A countersink with a rounded or burred edge represents a measurement problem. Figure 2 shows the. Measuring Countersink Angle.

From www.walmart.com

Countersink Angle Gage 60°, 82°, 90°, 100°, 110°, and 120° Angles Measuring Countersink Angle You have the option to choose between units of length measurement. The most common gages have a 90 o included angle on the gage plunger resulting in a 2:1 ratio between the taper diameter observed and the dial indicator rack travel. The most common countersink angles are 82°, 90° or 100°. Input the diameter of the countersink hole at the. Measuring Countersink Angle.

From www.finepowertools.com

Countersink Angles Common Angles and Their Applications Measuring Countersink Angle You have the option to choose between units of length measurement. There are actually two ways to measure a countersink with fmt. Figure 2 shows the key variables involved: Two gage balls of different diameters are used to measure the countersink angle (θ). A countersink with a rounded or burred edge represents a measurement problem. Input the diameter of the. Measuring Countersink Angle.

From mathscinotes.com

Measuring Countersink Diameter Using Gage Balls Math Encounters Blog Measuring Countersink Angle The diameter of ball 1 ( b 1 ) , the diameter of ball 2 ( b 2 ), and. A countersink with a rounded or burred edge represents a measurement problem. You have the option to choose between units of length measurement. Input the diameter of the countersink hole at the surface. The first is to simply position and. Measuring Countersink Angle.

From www.reddit.com

Ur method measuring countersink diameters? (Caliper/pins?) r/Machinists Measuring Countersink Angle The diameter of ball 1 ( b 1 ) , the diameter of ball 2 ( b 2 ), and. If we know the diameter of the countersink taper, we can use the depth that a gage ball that fits down into the countersink to compute the theoretical (unrounded) diameter of the countersink. The most common countersink angles are 82°,. Measuring Countersink Angle.

From www.protoexpress.com

Countersink Holes in PCBs Sierra Circuits Measuring Countersink Angle Input the angle of the countersink, which is the. The most common countersink angles are 82°, 90° or 100°. The diameter of ball 1 ( b 1 ) , the diameter of ball 2 ( b 2 ), and. A countersink with a rounded or burred edge represents a measurement problem. The first is to simply position and pull the. Measuring Countersink Angle.

From www.penntoolco.com

SPI Countersink Angle Gage 137190 Penn Tool Co., Inc Measuring Countersink Angle The first is to simply position and pull the trigger. Input the diameter of the countersink hole at the surface. You have the option to choose between units of length measurement. The diameter of ball 1 ( b 1 ) , the diameter of ball 2 ( b 2 ), and. A countersink with a rounded or burred edge represents. Measuring Countersink Angle.

From www.mscdirect.com

SPI Countersink Gages; Minimum Measurement (Decimal Inch) 0.3610 Measuring Countersink Angle Two gage balls of different diameters are used to measure the countersink angle (θ). Input the angle of the countersink, which is the. The most common countersink angles are 82°, 90° or 100°. There are actually two ways to measure a countersink with fmt. The first is to simply position and pull the trigger. If we know the diameter of. Measuring Countersink Angle.

From www.mathscinotes.com

Measuring Countersink Diameter Using Gage Balls Math Encounters Blog Measuring Countersink Angle The most common countersink angles are 82°, 90° or 100°. Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because the countersink angle. Input the diameter of the countersink hole at the surface. There are actually two ways to measure a countersink with fmt. Two gage balls of different diameters are. Measuring Countersink Angle.

From forums.autodesk.com

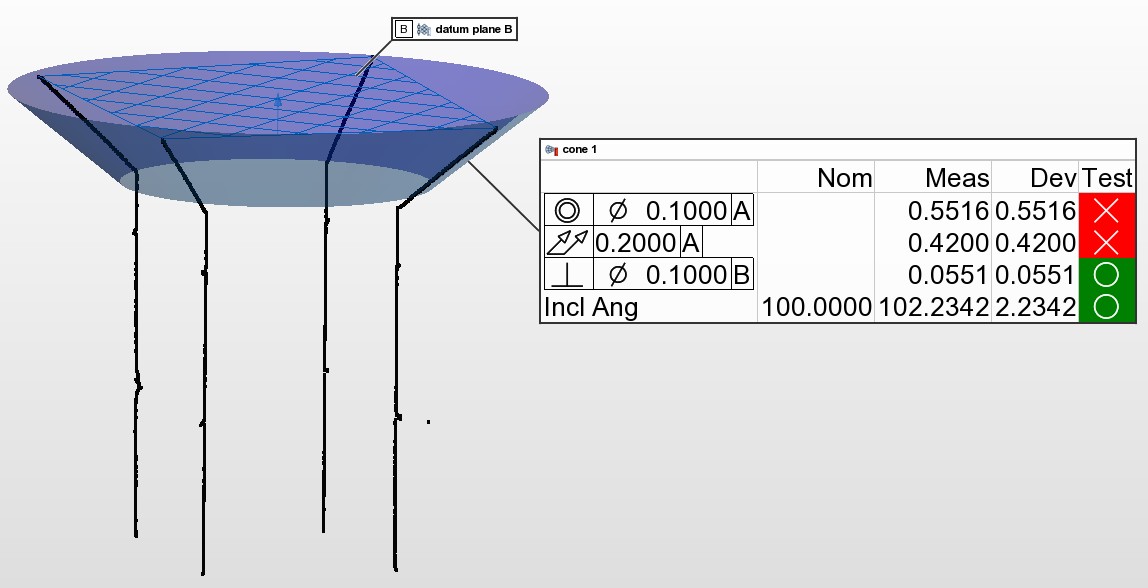

Measure a countersink angle? Autodesk Community Measuring Countersink Angle Two gage balls of different diameters are used to measure the countersink angle (θ). A countersink with a rounded or burred edge represents a measurement problem. If we know the diameter of the countersink taper, we can use the depth that a gage ball that fits down into the countersink to compute the theoretical (unrounded) diameter of the countersink. You. Measuring Countersink Angle.

From www.flexbar.com

30° Angle Countersink Gage (Capacity .360".560") — Flexbar Machine Measuring Countersink Angle Two gage balls of different diameters are used to measure the countersink angle (θ). The diameter of ball 1 ( b 1 ) , the diameter of ball 2 ( b 2 ), and. The most common countersink angles are 82°, 90° or 100°. You have the option to choose between units of length measurement. The most common gages have. Measuring Countersink Angle.

From www.walmart.com

Countersink Angle Gage 60°, 82°, 90°, 100°, 110°, and 120° Angles Measuring Countersink Angle A countersink with a rounded or burred edge represents a measurement problem. Figure 2 shows the key variables involved: You have the option to choose between units of length measurement. Input the angle of the countersink, which is the. The first is to simply position and pull the trigger. Note that in the case of the 90° countersink, this callout. Measuring Countersink Angle.

From www.penntoolco.com

Angle Countersink Gage Range 0.16 to 0.36", 82° 205310 Penn Tool Measuring Countersink Angle The most common countersink angles are 82°, 90° or 100°. Input the angle of the countersink, which is the. The first is to simply position and pull the trigger. Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because the countersink angle. A countersink with a rounded or burred edge represents. Measuring Countersink Angle.

From megadepot.com

Buy SPI 137190, Countersink Angle Gage Mega Depot Measuring Countersink Angle You have the option to choose between units of length measurement. Two gage balls of different diameters are used to measure the countersink angle (θ). Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because the countersink angle. The most common countersink angles are 82°, 90° or 100°. Figure 2 shows. Measuring Countersink Angle.

From www.mathscinotes.com

Measuring Countersink Angle Using Gage Balls Math Encounters Blog Measuring Countersink Angle Input the diameter of the countersink hole at the surface. There are actually two ways to measure a countersink with fmt. A countersink with a rounded or burred edge represents a measurement problem. The first is to simply position and pull the trigger. The most common countersink angles are 82°, 90° or 100°. Note that in the case of the. Measuring Countersink Angle.

From mathscinotes.com

Measuring Countersink Diameter Using Gage Balls Math Encounters Blog Measuring Countersink Angle The diameter of ball 1 ( b 1 ) , the diameter of ball 2 ( b 2 ), and. There are actually two ways to measure a countersink with fmt. Two gage balls of different diameters are used to measure the countersink angle (θ). Input the diameter of the countersink hole at the surface. A countersink with a rounded. Measuring Countersink Angle.

From www.threadcheck.com

Barcor 100° Countersink Gage .020" to .170" Range w/Digital Indicator Measuring Countersink Angle The most common gages have a 90 o included angle on the gage plunger resulting in a 2:1 ratio between the taper diameter observed and the dial indicator rack travel. Input the angle of the countersink, which is the. A countersink with a rounded or burred edge represents a measurement problem. You have the option to choose between units of. Measuring Countersink Angle.

From forums.autodesk.com

Measure a countersink angle? Autodesk Community Measuring Countersink Angle If we know the diameter of the countersink taper, we can use the depth that a gage ball that fits down into the countersink to compute the theoretical (unrounded) diameter of the countersink. You have the option to choose between units of length measurement. Two gage balls of different diameters are used to measure the countersink angle (θ). Input the. Measuring Countersink Angle.

From www.machinistguides.com

Spotfaces All About Machinist Guides Measuring Countersink Angle The most common gages have a 90 o included angle on the gage plunger resulting in a 2:1 ratio between the taper diameter observed and the dial indicator rack travel. Two gage balls of different diameters are used to measure the countersink angle (θ). A countersink with a rounded or burred edge represents a measurement problem. The first is to. Measuring Countersink Angle.

From engineersbible.com

Countersunk Hole Size for Machine Screw (ANSI Metric) Measuring Countersink Angle The diameter of ball 1 ( b 1 ) , the diameter of ball 2 ( b 2 ), and. A countersink with a rounded or burred edge represents a measurement problem. There are actually two ways to measure a countersink with fmt. Figure 2 shows the key variables involved: The most common countersink angles are 82°, 90° or 100°.. Measuring Countersink Angle.

From www.finepowertools.com

Countersink Angles Common Angles and Their Applications Measuring Countersink Angle A countersink with a rounded or burred edge represents a measurement problem. The first is to simply position and pull the trigger. There are actually two ways to measure a countersink with fmt. The diameter of ball 1 ( b 1 ) , the diameter of ball 2 ( b 2 ), and. Input the diameter of the countersink hole. Measuring Countersink Angle.

From www.indiamart.com

Countersink Angle Gauge at Rs 633/piece Angle Gauge in Tiruvannamalai Measuring Countersink Angle Two gage balls of different diameters are used to measure the countersink angle (θ). The first is to simply position and pull the trigger. Input the diameter of the countersink hole at the surface. Input the angle of the countersink, which is the. The most common gages have a 90 o included angle on the gage plunger resulting in a. Measuring Countersink Angle.

From www.ablcircuits.co.uk

PCB Hole Types Counterbore vs Countersink ABL Circuits Measuring Countersink Angle Input the angle of the countersink, which is the. The most common countersink angles are 82°, 90° or 100°. Figure 2 shows the key variables involved: The most common gages have a 90 o included angle on the gage plunger resulting in a 2:1 ratio between the taper diameter observed and the dial indicator rack travel. There are actually two. Measuring Countersink Angle.

From forums.autodesk.com

Measure a countersink angle? Autodesk Community Measuring Countersink Angle A countersink with a rounded or burred edge represents a measurement problem. The most common gages have a 90 o included angle on the gage plunger resulting in a 2:1 ratio between the taper diameter observed and the dial indicator rack travel. If we know the diameter of the countersink taper, we can use the depth that a gage ball. Measuring Countersink Angle.

From mathscinotes.com

Measuring Countersink Diameter Using Gage Balls Math Encounters Blog Measuring Countersink Angle Input the angle of the countersink, which is the. A countersink with a rounded or burred edge represents a measurement problem. Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because the countersink angle. The most common countersink angles are 82°, 90° or 100°. The most common gages have a 90. Measuring Countersink Angle.

From www.walmart.com

Countersink Angle Gage 60°, 82°, 90°, 100°, 110°, and 120° Angles Measuring Countersink Angle The first is to simply position and pull the trigger. Input the diameter of the countersink hole at the surface. Figure 2 shows the key variables involved: Two gage balls of different diameters are used to measure the countersink angle (θ). The most common countersink angles are 82°, 90° or 100°. Note that in the case of the 90° countersink,. Measuring Countersink Angle.

From www.mscdirect.com

SPI 110° Complementary Angle, Stainless Steel Angle Gage MSC Direct Measuring Countersink Angle The most common countersink angles are 82°, 90° or 100°. The first is to simply position and pull the trigger. There are actually two ways to measure a countersink with fmt. The diameter of ball 1 ( b 1 ) , the diameter of ball 2 ( b 2 ), and. Input the angle of the countersink, which is the.. Measuring Countersink Angle.

From www.novacam.com

3D countersink measurement noncontact and automated Novacam Measuring Countersink Angle The most common gages have a 90 o included angle on the gage plunger resulting in a 2:1 ratio between the taper diameter observed and the dial indicator rack travel. Input the angle of the countersink, which is the. You have the option to choose between units of length measurement. There are actually two ways to measure a countersink with. Measuring Countersink Angle.

From willrich.com

Starrett Countersink Gages Willrich Precision Instruments Measuring Countersink Angle The most common countersink angles are 82°, 90° or 100°. Figure 2 shows the key variables involved: Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because the countersink angle. Input the angle of the countersink, which is the. Input the diameter of the countersink hole at the surface. Two gage. Measuring Countersink Angle.

From www.cnccookbook.com

Countersink Depth Calculator [ Free Machinist Tool ] Measuring Countersink Angle Figure 2 shows the key variables involved: Two gage balls of different diameters are used to measure the countersink angle (θ). There are actually two ways to measure a countersink with fmt. If we know the diameter of the countersink taper, we can use the depth that a gage ball that fits down into the countersink to compute the theoretical. Measuring Countersink Angle.

From mathscinotes.com

Measuring Countersink Diameter Using Gage Balls Math Encounters Blog Measuring Countersink Angle Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because the countersink angle. The most common countersink angles are 82°, 90° or 100°. Two gage balls of different diameters are used to measure the countersink angle (θ). The diameter of ball 1 ( b 1 ) , the diameter of ball. Measuring Countersink Angle.

From willrich.com

Starrett Countersink Gages Willrich Precision Instruments Measuring Countersink Angle The most common gages have a 90 o included angle on the gage plunger resulting in a 2:1 ratio between the taper diameter observed and the dial indicator rack travel. Input the angle of the countersink, which is the. Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because the countersink. Measuring Countersink Angle.

From www.mathscinotes.com

Measuring Countersink Angle Using Gage Balls Math Encounters Blog Measuring Countersink Angle Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because the countersink angle. The first is to simply position and pull the trigger. There are actually two ways to measure a countersink with fmt. Two gage balls of different diameters are used to measure the countersink angle (θ). If we know. Measuring Countersink Angle.

From exoobudyf.blob.core.windows.net

Countersink Angle at David Jenkins blog Measuring Countersink Angle A countersink with a rounded or burred edge represents a measurement problem. If we know the diameter of the countersink taper, we can use the depth that a gage ball that fits down into the countersink to compute the theoretical (unrounded) diameter of the countersink. The first is to simply position and pull the trigger. Input the diameter of the. Measuring Countersink Angle.

From www.novacam.com

3D countersink measurement noncontact and automated Novacam Measuring Countersink Angle Figure 2 shows the key variables involved: A countersink with a rounded or burred edge represents a measurement problem. The first is to simply position and pull the trigger. If we know the diameter of the countersink taper, we can use the depth that a gage ball that fits down into the countersink to compute the theoretical (unrounded) diameter of. Measuring Countersink Angle.