How To Identify Equipment Faults . Identifying the problem, planning a response, testing the solution, and resolving the issue. Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. Equipment failure is a common phenomenon in the industrial setting. By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive measures, and reduce the likelihood of equipment.

from www.slideserve.com

By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive measures, and reduce the likelihood of equipment. Identifying the problem, planning a response, testing the solution, and resolving the issue. Equipment failure is a common phenomenon in the industrial setting. It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance.

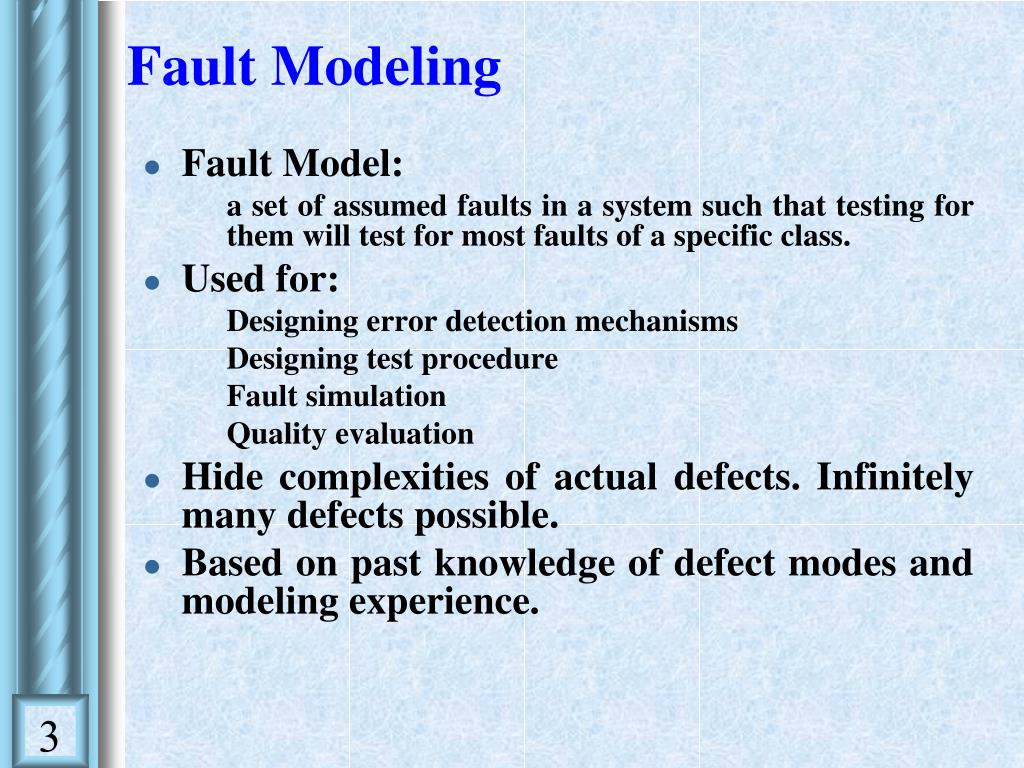

PPT 4. Fault Modeling PowerPoint Presentation, free download ID3471360

How To Identify Equipment Faults It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. Identifying the problem, planning a response, testing the solution, and resolving the issue. It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive measures, and reduce the likelihood of equipment. Equipment failure is a common phenomenon in the industrial setting.

From www.researchgate.net

Equipment fault separation diagram Download Scientific Diagram How To Identify Equipment Faults It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. Equipment failure is a common phenomenon in the industrial setting. Identifying the problem, planning a response, testing the solution, and resolving the issue. By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive measures,. How To Identify Equipment Faults.

From www.researchgate.net

Fault Management Lifecycle Download Scientific Diagram How To Identify Equipment Faults It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. Identifying the problem, planning a response, testing the solution, and resolving the issue. By conducting comprehensive fmea analysis, businesses can identify critical failure modes,. How To Identify Equipment Faults.

From www.nist.gov

Fault Detection and Diagnosis Research Data NIST How To Identify Equipment Faults It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. Equipment failure is a common phenomenon in the industrial setting. Identifying the problem, planning a response, testing the solution, and resolving the issue. By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive measures,. How To Identify Equipment Faults.

From www.youtube.com

TMG Radiodetection Fault Finding and TDR Tracing. YouTube How To Identify Equipment Faults Identifying the problem, planning a response, testing the solution, and resolving the issue. It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive measures, and reduce the likelihood of equipment. Equipment failure is a. How To Identify Equipment Faults.

From fantasticservicesgroup.com.au

Electrical Fault Finding Fantastic Services Melbourne How To Identify Equipment Faults It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. Identifying the problem, planning a response, testing the solution, and resolving the issue. Equipment failure is a common phenomenon in the industrial setting. By. How To Identify Equipment Faults.

From compliantsa.com.au

Fault Finding Compliant Electrical SA How To Identify Equipment Faults It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. Equipment failure is a common phenomenon in the industrial setting. By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive. How To Identify Equipment Faults.

From www.studyiq.com

Types of Faults, Causes, Types, Normal, Reverse, Diagram How To Identify Equipment Faults Equipment failure is a common phenomenon in the industrial setting. By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive measures, and reduce the likelihood of equipment. Identifying the problem, planning a response, testing the solution, and resolving the issue. Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. It can. How To Identify Equipment Faults.

From limblecmms.com

Fault Detection And Diagnostics In Equipment Maintenance How To Identify Equipment Faults It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. Equipment failure is a common phenomenon in the industrial setting. Identifying the problem, planning a response, testing the solution, and resolving the issue. Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. By. How To Identify Equipment Faults.

From rollyselectrical.com.au

How to Identify Electrical Faults How To Identify Equipment Faults Equipment failure is a common phenomenon in the industrial setting. Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. Identifying the problem, planning a response, testing the solution, and resolving the issue. By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive measures, and reduce the likelihood of equipment. It can. How To Identify Equipment Faults.

From www.liyuemachinery.com

Common Faults and Troubleshooting Henan Liyue Machinery Equipment Co How To Identify Equipment Faults Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. Equipment failure is a common phenomenon in the industrial setting. By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive measures, and reduce the likelihood of equipment. It can result in higher repair costs, production downtime, health and safety implications for workers,. How To Identify Equipment Faults.

From fiixsoftware.com

What Is Fault Tree Analysis (FTA)? Fiix How To Identify Equipment Faults By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive measures, and reduce the likelihood of equipment. Identifying the problem, planning a response, testing the solution, and resolving the issue. It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. Key indicators of equipment. How To Identify Equipment Faults.

From electricalguide360.com

What is an Electrical Fault? Definition, Types, Nature & Cause, its How To Identify Equipment Faults By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive measures, and reduce the likelihood of equipment. Equipment failure is a common phenomenon in the industrial setting. It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. Identifying the problem, planning a response, testing. How To Identify Equipment Faults.

From www.scribd.com

Identify faults in farm equipment and facilities using preventive How To Identify Equipment Faults Equipment failure is a common phenomenon in the industrial setting. Identifying the problem, planning a response, testing the solution, and resolving the issue. Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. By. How To Identify Equipment Faults.

From www.prettywired.co.uk

How to Identify Electrical Faults Pretty Wired How To Identify Equipment Faults Identifying the problem, planning a response, testing the solution, and resolving the issue. By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive measures, and reduce the likelihood of equipment. Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. It can result in higher repair costs, production downtime, health and safety. How To Identify Equipment Faults.

From bin95.com

Fault Finding Troubleshooting Examples How To Identify Equipment Faults Identifying the problem, planning a response, testing the solution, and resolving the issue. By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive measures, and reduce the likelihood of equipment. Equipment failure is a common phenomenon in the industrial setting. It can result in higher repair costs, production downtime, health and safety implications for workers, and. How To Identify Equipment Faults.

From www.researchgate.net

Fault Management to Identify Device Current and Fault Status Download How To Identify Equipment Faults Equipment failure is a common phenomenon in the industrial setting. Identifying the problem, planning a response, testing the solution, and resolving the issue. By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive measures, and reduce the likelihood of equipment. It can result in higher repair costs, production downtime, health and safety implications for workers, and. How To Identify Equipment Faults.

From www.r-e-v.co.uk

Fault Finding Rotating Equipment Verification How To Identify Equipment Faults Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. Equipment failure is a common phenomenon in the industrial setting. It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive. How To Identify Equipment Faults.

From www.youtube.com

Identify equipment faults YouTube How To Identify Equipment Faults Identifying the problem, planning a response, testing the solution, and resolving the issue. Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. Equipment failure is a common phenomenon in the industrial setting. It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. By. How To Identify Equipment Faults.

From firewize.com.au

Firewize What is a FAS Fault? How To Identify Equipment Faults Identifying the problem, planning a response, testing the solution, and resolving the issue. Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. Equipment failure is a common phenomenon in the industrial setting. By. How To Identify Equipment Faults.

From www.youtube.com

LESSON 8 IDENTIFY EQUIPMENT FAULTS AND TAKE APPROPRIATE ACTION Copy How To Identify Equipment Faults By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive measures, and reduce the likelihood of equipment. Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. Equipment failure is a common phenomenon in the industrial setting. Identifying the problem, planning a response, testing the solution, and resolving the issue. It can. How To Identify Equipment Faults.

From www.intechopen.com

RealTime Fault Detection and Diagnosis Using Intelligent Monitoring How To Identify Equipment Faults By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive measures, and reduce the likelihood of equipment. Equipment failure is a common phenomenon in the industrial setting. Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. It can result in higher repair costs, production downtime, health and safety implications for workers,. How To Identify Equipment Faults.

From www.slideserve.com

PPT 4. Fault Modeling PowerPoint Presentation, free download ID3471360 How To Identify Equipment Faults Identifying the problem, planning a response, testing the solution, and resolving the issue. It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. Equipment failure is a common phenomenon in the industrial setting. By. How To Identify Equipment Faults.

From www.researchgate.net

Fault identification flow chart Download Scientific Diagram How To Identify Equipment Faults Identifying the problem, planning a response, testing the solution, and resolving the issue. By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive measures, and reduce the likelihood of equipment. It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. Key indicators of equipment. How To Identify Equipment Faults.

From www.researchgate.net

Flow chart of equipment fault detection algorithm. Download How To Identify Equipment Faults Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive measures, and reduce the likelihood of equipment. It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. Equipment failure is. How To Identify Equipment Faults.

From www.youtube.com

Common Faults in Using Hand Tools YouTube How To Identify Equipment Faults Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. Equipment failure is a common phenomenon in the industrial setting. Identifying the problem, planning a response, testing the solution, and resolving the issue. It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. By. How To Identify Equipment Faults.

From limblecmms.com

Fault Detection And Diagnostics In Equipment Maintenance How To Identify Equipment Faults Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. Equipment failure is a common phenomenon in the industrial setting. Identifying the problem, planning a response, testing the solution, and resolving the issue. By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive measures, and reduce the likelihood of equipment. It can. How To Identify Equipment Faults.

From douglasbaseball.com

How To Report Kitchen Equipment Faults Within Equipment Fault Report How To Identify Equipment Faults By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive measures, and reduce the likelihood of equipment. Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. Equipment failure is a common phenomenon in the industrial setting. Identifying the problem, planning a response, testing the solution, and resolving the issue. It can. How To Identify Equipment Faults.

From testguy.net

Characteristics of Circuit Breaker Trip Curves and Coordination How To Identify Equipment Faults Identifying the problem, planning a response, testing the solution, and resolving the issue. By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive measures, and reduce the likelihood of equipment. It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. Equipment failure is a. How To Identify Equipment Faults.

From electrical-engineering-portal.com

Fault calculation methods for industrial and commercial power systems EEP How To Identify Equipment Faults It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive measures, and reduce the likelihood of equipment. Equipment failure is. How To Identify Equipment Faults.

From www.researchgate.net

Equipment fault diagnosis method based on machine learning. Download How To Identify Equipment Faults By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive measures, and reduce the likelihood of equipment. Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. Identifying the problem,. How To Identify Equipment Faults.

From www.diy.com

How to identify electrical faults Ideas & Advice DIY at B&Q How To Identify Equipment Faults Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. Identifying the problem, planning a response, testing the solution, and resolving the issue. It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. By conducting comprehensive fmea analysis, businesses can identify critical failure modes,. How To Identify Equipment Faults.

From www.electricalengineering.xyz

Types and Classification of Faults on Electrical Power Systems How To Identify Equipment Faults Equipment failure is a common phenomenon in the industrial setting. It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. Identifying the problem, planning a response, testing the solution, and resolving the issue. Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. By. How To Identify Equipment Faults.

From www.slideserve.com

PPT Key Terms and Concepts PowerPoint Presentation, free download How To Identify Equipment Faults By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive measures, and reduce the likelihood of equipment. Equipment failure is a common phenomenon in the industrial setting. It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. Key indicators of equipment defects include abnormal. How To Identify Equipment Faults.

From edukite.org

Machinery Fault Diagnosis and Signal Processing Edukite How To Identify Equipment Faults Key indicators of equipment defects include abnormal noises, vibrations, leaks, and fluctuations in performance. It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. Identifying the problem, planning a response, testing the solution, and resolving the issue. Equipment failure is a common phenomenon in the industrial setting. By. How To Identify Equipment Faults.

From ipasolutions.com.au

What Is Industrial Electrical Fault Finding How To Identify Equipment Faults By conducting comprehensive fmea analysis, businesses can identify critical failure modes, develop appropriate preventive measures, and reduce the likelihood of equipment. Identifying the problem, planning a response, testing the solution, and resolving the issue. It can result in higher repair costs, production downtime, health and safety implications for workers, and affect production and delivery of services. Key indicators of equipment. How To Identify Equipment Faults.