Barrel Of Oil Refining Process . Diesel fuel, another transportation fuel, is generally. Nearly half of every barrel of crude oil that goes into a typical u.s. Refinery will energy on the other end as gasoline. Figure 1.4 shows a typical distribution of products from a barrel of crude oil in a u.s. All refineries have three basic steps: Modern separation involves piping crude oil through hot furnaces. Depending on the size of the refinery, from 80,000 to 300,000+ barrels of crude oil. Distillation process separates the crude oil into boiling point fractions. The ability to obtain products like gasoline, asphalt, and propane from a. At our 15 refineries our throughput capacity of crude oil and other feedstocks is 3.2 million barrels per day.

from www.top-petroleum.com

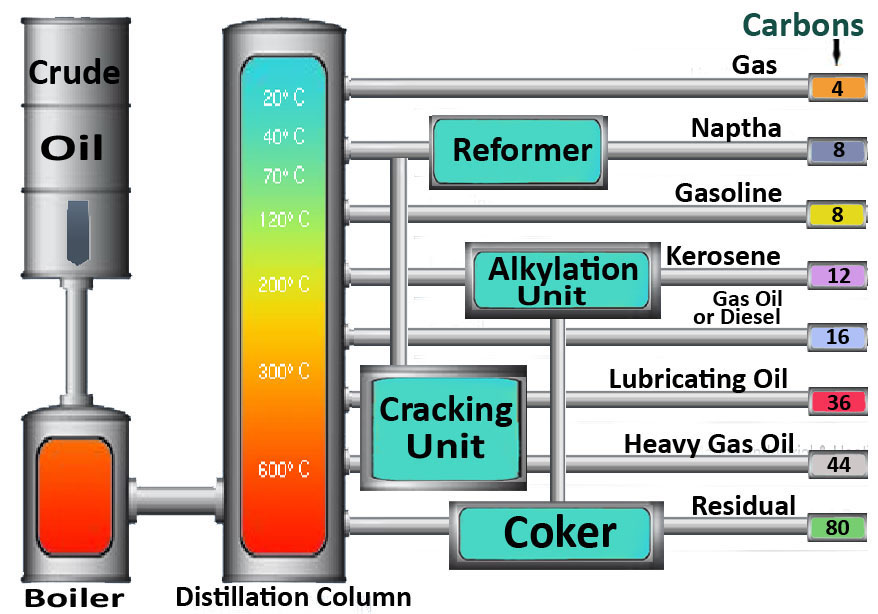

Modern separation involves piping crude oil through hot furnaces. Distillation process separates the crude oil into boiling point fractions. At our 15 refineries our throughput capacity of crude oil and other feedstocks is 3.2 million barrels per day. Figure 1.4 shows a typical distribution of products from a barrel of crude oil in a u.s. Diesel fuel, another transportation fuel, is generally. All refineries have three basic steps: Depending on the size of the refinery, from 80,000 to 300,000+ barrels of crude oil. Refinery will energy on the other end as gasoline. Nearly half of every barrel of crude oil that goes into a typical u.s. The ability to obtain products like gasoline, asphalt, and propane from a.

Top Petroleum Inc Suppliers and Sellers of Crude Oil, petroleum

Barrel Of Oil Refining Process Distillation process separates the crude oil into boiling point fractions. Refinery will energy on the other end as gasoline. At our 15 refineries our throughput capacity of crude oil and other feedstocks is 3.2 million barrels per day. Modern separation involves piping crude oil through hot furnaces. All refineries have three basic steps: Diesel fuel, another transportation fuel, is generally. Distillation process separates the crude oil into boiling point fractions. Depending on the size of the refinery, from 80,000 to 300,000+ barrels of crude oil. Figure 1.4 shows a typical distribution of products from a barrel of crude oil in a u.s. Nearly half of every barrel of crude oil that goes into a typical u.s. The ability to obtain products like gasoline, asphalt, and propane from a.

From passmyexams.co.uk

Crude Oil / Petroleum Easy exam revision notes for GSCE Chemistry Barrel Of Oil Refining Process Figure 1.4 shows a typical distribution of products from a barrel of crude oil in a u.s. At our 15 refineries our throughput capacity of crude oil and other feedstocks is 3.2 million barrels per day. All refineries have three basic steps: Refinery will energy on the other end as gasoline. Distillation process separates the crude oil into boiling point. Barrel Of Oil Refining Process.

From circuitwiringfrorn88.z21.web.core.windows.net

Crude Oil Refinery Process Flow Diagram Pdf Barrel Of Oil Refining Process Refinery will energy on the other end as gasoline. Diesel fuel, another transportation fuel, is generally. The ability to obtain products like gasoline, asphalt, and propane from a. At our 15 refineries our throughput capacity of crude oil and other feedstocks is 3.2 million barrels per day. Figure 1.4 shows a typical distribution of products from a barrel of crude. Barrel Of Oil Refining Process.

From www.researchgate.net

Generic Fractional Distillation in the Crude Oil Refining Process Barrel Of Oil Refining Process Refinery will energy on the other end as gasoline. Modern separation involves piping crude oil through hot furnaces. The ability to obtain products like gasoline, asphalt, and propane from a. Distillation process separates the crude oil into boiling point fractions. At our 15 refineries our throughput capacity of crude oil and other feedstocks is 3.2 million barrels per day. Nearly. Barrel Of Oil Refining Process.

From byjus.com

What is Petroleum? Petroleum Refining, Definition, Formation & Uses Barrel Of Oil Refining Process Refinery will energy on the other end as gasoline. The ability to obtain products like gasoline, asphalt, and propane from a. All refineries have three basic steps: Figure 1.4 shows a typical distribution of products from a barrel of crude oil in a u.s. At our 15 refineries our throughput capacity of crude oil and other feedstocks is 3.2 million. Barrel Of Oil Refining Process.

From www.crownoil.co.uk

Fractional Distillation of Crude Oil Refining Petroleum Products Barrel Of Oil Refining Process Modern separation involves piping crude oil through hot furnaces. Distillation process separates the crude oil into boiling point fractions. All refineries have three basic steps: Depending on the size of the refinery, from 80,000 to 300,000+ barrels of crude oil. Diesel fuel, another transportation fuel, is generally. The ability to obtain products like gasoline, asphalt, and propane from a. Refinery. Barrel Of Oil Refining Process.

From www.youtube.com

Petroleum refining processes explained simply YouTube Barrel Of Oil Refining Process Modern separation involves piping crude oil through hot furnaces. Figure 1.4 shows a typical distribution of products from a barrel of crude oil in a u.s. Diesel fuel, another transportation fuel, is generally. At our 15 refineries our throughput capacity of crude oil and other feedstocks is 3.2 million barrels per day. Nearly half of every barrel of crude oil. Barrel Of Oil Refining Process.

From www.horiba.com

Oil Refinery Improving Efficiency and Process Management HORIBA Barrel Of Oil Refining Process Distillation process separates the crude oil into boiling point fractions. Modern separation involves piping crude oil through hot furnaces. Nearly half of every barrel of crude oil that goes into a typical u.s. Refinery will energy on the other end as gasoline. Figure 1.4 shows a typical distribution of products from a barrel of crude oil in a u.s. Depending. Barrel Of Oil Refining Process.

From www.oiltanking.com

Oiltanking The Petroleum Refining Process Barrel Of Oil Refining Process Modern separation involves piping crude oil through hot furnaces. Diesel fuel, another transportation fuel, is generally. Distillation process separates the crude oil into boiling point fractions. The ability to obtain products like gasoline, asphalt, and propane from a. Nearly half of every barrel of crude oil that goes into a typical u.s. Refinery will energy on the other end as. Barrel Of Oil Refining Process.

From galvinconanstuart.blogspot.com

Petroleum Refinery Process Flow Diagram General Wiring Diagram Barrel Of Oil Refining Process The ability to obtain products like gasoline, asphalt, and propane from a. At our 15 refineries our throughput capacity of crude oil and other feedstocks is 3.2 million barrels per day. Diesel fuel, another transportation fuel, is generally. All refineries have three basic steps: Modern separation involves piping crude oil through hot furnaces. Figure 1.4 shows a typical distribution of. Barrel Of Oil Refining Process.

From eng.libretexts.org

2.2 The process of crude oil refining Engineering LibreTexts Barrel Of Oil Refining Process Diesel fuel, another transportation fuel, is generally. At our 15 refineries our throughput capacity of crude oil and other feedstocks is 3.2 million barrels per day. Depending on the size of the refinery, from 80,000 to 300,000+ barrels of crude oil. The ability to obtain products like gasoline, asphalt, and propane from a. Modern separation involves piping crude oil through. Barrel Of Oil Refining Process.

From www.pinterest.co.uk

Illustration of a crude oil refining. Stages of processing crude oil on Barrel Of Oil Refining Process Modern separation involves piping crude oil through hot furnaces. Diesel fuel, another transportation fuel, is generally. Nearly half of every barrel of crude oil that goes into a typical u.s. Distillation process separates the crude oil into boiling point fractions. Figure 1.4 shows a typical distribution of products from a barrel of crude oil in a u.s. Depending on the. Barrel Of Oil Refining Process.

From www.htoilmachine.com

What is the vegetable oil refining process? Edible Oil Expeller Machinery Barrel Of Oil Refining Process Depending on the size of the refinery, from 80,000 to 300,000+ barrels of crude oil. Distillation process separates the crude oil into boiling point fractions. Diesel fuel, another transportation fuel, is generally. Nearly half of every barrel of crude oil that goes into a typical u.s. All refineries have three basic steps: Figure 1.4 shows a typical distribution of products. Barrel Of Oil Refining Process.

From www.pinterest.com.au

Crude Oil Refining and Australia's Fuel Security Animated Infographic Barrel Of Oil Refining Process Depending on the size of the refinery, from 80,000 to 300,000+ barrels of crude oil. Figure 1.4 shows a typical distribution of products from a barrel of crude oil in a u.s. Distillation process separates the crude oil into boiling point fractions. At our 15 refineries our throughput capacity of crude oil and other feedstocks is 3.2 million barrels per. Barrel Of Oil Refining Process.

From www.enggstudy.com

Petroleum refining process in detail Barrel Of Oil Refining Process Figure 1.4 shows a typical distribution of products from a barrel of crude oil in a u.s. Nearly half of every barrel of crude oil that goes into a typical u.s. At our 15 refineries our throughput capacity of crude oil and other feedstocks is 3.2 million barrels per day. Depending on the size of the refinery, from 80,000 to. Barrel Of Oil Refining Process.

From www.vectorstock.com

Process of oil production and petrolium refining Vector Image Barrel Of Oil Refining Process Refinery will energy on the other end as gasoline. Depending on the size of the refinery, from 80,000 to 300,000+ barrels of crude oil. Figure 1.4 shows a typical distribution of products from a barrel of crude oil in a u.s. All refineries have three basic steps: The ability to obtain products like gasoline, asphalt, and propane from a. At. Barrel Of Oil Refining Process.

From www.vectorstock.com

Oil refinery process infographic crude Royalty Free Vector Barrel Of Oil Refining Process Modern separation involves piping crude oil through hot furnaces. Nearly half of every barrel of crude oil that goes into a typical u.s. The ability to obtain products like gasoline, asphalt, and propane from a. Distillation process separates the crude oil into boiling point fractions. Depending on the size of the refinery, from 80,000 to 300,000+ barrels of crude oil.. Barrel Of Oil Refining Process.

From mavink.com

Oil Refinery Process Flow Diagram Barrel Of Oil Refining Process The ability to obtain products like gasoline, asphalt, and propane from a. Modern separation involves piping crude oil through hot furnaces. All refineries have three basic steps: Distillation process separates the crude oil into boiling point fractions. Nearly half of every barrel of crude oil that goes into a typical u.s. At our 15 refineries our throughput capacity of crude. Barrel Of Oil Refining Process.

From ebrary.net

Downstream Operations Petroleum Refining of Crude Oil Into Useful Barrel Of Oil Refining Process Diesel fuel, another transportation fuel, is generally. Distillation process separates the crude oil into boiling point fractions. All refineries have three basic steps: Figure 1.4 shows a typical distribution of products from a barrel of crude oil in a u.s. Nearly half of every barrel of crude oil that goes into a typical u.s. At our 15 refineries our throughput. Barrel Of Oil Refining Process.

From igcsetuition.blogspot.com

O Level Chemistry Oil Refining Crude Oil Barrel Of Oil Refining Process Refinery will energy on the other end as gasoline. Distillation process separates the crude oil into boiling point fractions. Nearly half of every barrel of crude oil that goes into a typical u.s. Modern separation involves piping crude oil through hot furnaces. Depending on the size of the refinery, from 80,000 to 300,000+ barrels of crude oil. Diesel fuel, another. Barrel Of Oil Refining Process.

From canaryusa.com

Light on the Top, Heavy on the Bottom A Crude Oil Refinery Primer Barrel Of Oil Refining Process Depending on the size of the refinery, from 80,000 to 300,000+ barrels of crude oil. The ability to obtain products like gasoline, asphalt, and propane from a. At our 15 refineries our throughput capacity of crude oil and other feedstocks is 3.2 million barrels per day. Nearly half of every barrel of crude oil that goes into a typical u.s.. Barrel Of Oil Refining Process.

From www.vectorstock.com

Oil refinery process infographic crude Royalty Free Vector Barrel Of Oil Refining Process Distillation process separates the crude oil into boiling point fractions. Diesel fuel, another transportation fuel, is generally. Figure 1.4 shows a typical distribution of products from a barrel of crude oil in a u.s. The ability to obtain products like gasoline, asphalt, and propane from a. Modern separation involves piping crude oil through hot furnaces. Refinery will energy on the. Barrel Of Oil Refining Process.

From www.top-petroleum.com

Top Petroleum Inc Suppliers and Sellers of Crude Oil, petroleum Barrel Of Oil Refining Process Depending on the size of the refinery, from 80,000 to 300,000+ barrels of crude oil. Nearly half of every barrel of crude oil that goes into a typical u.s. Diesel fuel, another transportation fuel, is generally. Modern separation involves piping crude oil through hot furnaces. Figure 1.4 shows a typical distribution of products from a barrel of crude oil in. Barrel Of Oil Refining Process.

From science.howstuffworks.com

The Refining Process How Oil Refining Works HowStuffWorks Barrel Of Oil Refining Process Depending on the size of the refinery, from 80,000 to 300,000+ barrels of crude oil. At our 15 refineries our throughput capacity of crude oil and other feedstocks is 3.2 million barrels per day. Modern separation involves piping crude oil through hot furnaces. Figure 1.4 shows a typical distribution of products from a barrel of crude oil in a u.s.. Barrel Of Oil Refining Process.

From www.e-education.psu.edu

The process of crude oil refining EME 801 Energy Markets, Policy Barrel Of Oil Refining Process Figure 1.4 shows a typical distribution of products from a barrel of crude oil in a u.s. Nearly half of every barrel of crude oil that goes into a typical u.s. At our 15 refineries our throughput capacity of crude oil and other feedstocks is 3.2 million barrels per day. All refineries have three basic steps: The ability to obtain. Barrel Of Oil Refining Process.

From www.wermac.org

Fossils into Fuels Petroleum Refining Processes ExxonMobil Australia Barrel Of Oil Refining Process Diesel fuel, another transportation fuel, is generally. Figure 1.4 shows a typical distribution of products from a barrel of crude oil in a u.s. The ability to obtain products like gasoline, asphalt, and propane from a. Depending on the size of the refinery, from 80,000 to 300,000+ barrels of crude oil. All refineries have three basic steps: At our 15. Barrel Of Oil Refining Process.

From thepetrosolutions.com

Petroleum Refinery Process Barrel Of Oil Refining Process Nearly half of every barrel of crude oil that goes into a typical u.s. The ability to obtain products like gasoline, asphalt, and propane from a. Refinery will energy on the other end as gasoline. Distillation process separates the crude oil into boiling point fractions. Modern separation involves piping crude oil through hot furnaces. Diesel fuel, another transportation fuel, is. Barrel Of Oil Refining Process.

From schematicmanualwilliam.z13.web.core.windows.net

Oil And Gas Refinery Process Flow Diagram Barrel Of Oil Refining Process Depending on the size of the refinery, from 80,000 to 300,000+ barrels of crude oil. All refineries have three basic steps: Figure 1.4 shows a typical distribution of products from a barrel of crude oil in a u.s. Distillation process separates the crude oil into boiling point fractions. Refinery will energy on the other end as gasoline. Nearly half of. Barrel Of Oil Refining Process.

From jnuecheng.wordpress.com

The Procedure of Refining Quality Oil KMEC Barrel Of Oil Refining Process Distillation process separates the crude oil into boiling point fractions. At our 15 refineries our throughput capacity of crude oil and other feedstocks is 3.2 million barrels per day. Refinery will energy on the other end as gasoline. Depending on the size of the refinery, from 80,000 to 300,000+ barrels of crude oil. All refineries have three basic steps: Nearly. Barrel Of Oil Refining Process.

From www.americangeosciences.org

Oil Refining and Gas Processing American Geosciences Institute Barrel Of Oil Refining Process Figure 1.4 shows a typical distribution of products from a barrel of crude oil in a u.s. The ability to obtain products like gasoline, asphalt, and propane from a. Nearly half of every barrel of crude oil that goes into a typical u.s. Diesel fuel, another transportation fuel, is generally. All refineries have three basic steps: At our 15 refineries. Barrel Of Oil Refining Process.

From www.oceansplasticleanup.com

NAPHTHA Barrel Of Oil Refining Process Refinery will energy on the other end as gasoline. The ability to obtain products like gasoline, asphalt, and propane from a. At our 15 refineries our throughput capacity of crude oil and other feedstocks is 3.2 million barrels per day. Depending on the size of the refinery, from 80,000 to 300,000+ barrels of crude oil. Nearly half of every barrel. Barrel Of Oil Refining Process.

From mavink.com

Life Cycle Of Crude Oil Barrel Barrel Of Oil Refining Process At our 15 refineries our throughput capacity of crude oil and other feedstocks is 3.2 million barrels per day. Distillation process separates the crude oil into boiling point fractions. Nearly half of every barrel of crude oil that goes into a typical u.s. Depending on the size of the refinery, from 80,000 to 300,000+ barrels of crude oil. The ability. Barrel Of Oil Refining Process.

From www.visualcapitalist.com

Infographic What Can Be Made from One Barrel of Oil? Barrel Of Oil Refining Process All refineries have three basic steps: Refinery will energy on the other end as gasoline. Distillation process separates the crude oil into boiling point fractions. Depending on the size of the refinery, from 80,000 to 300,000+ barrels of crude oil. Diesel fuel, another transportation fuel, is generally. At our 15 refineries our throughput capacity of crude oil and other feedstocks. Barrel Of Oil Refining Process.

From u.osu.edu

Step 3 Refinement Crude Oil Commodity Chain Barrel Of Oil Refining Process Distillation process separates the crude oil into boiling point fractions. Refinery will energy on the other end as gasoline. Figure 1.4 shows a typical distribution of products from a barrel of crude oil in a u.s. At our 15 refineries our throughput capacity of crude oil and other feedstocks is 3.2 million barrels per day. Depending on the size of. Barrel Of Oil Refining Process.

From ektinteractive.com

Oil 101 Refinery Processes Downstream Oil and Gas Barrel Of Oil Refining Process Refinery will energy on the other end as gasoline. Diesel fuel, another transportation fuel, is generally. The ability to obtain products like gasoline, asphalt, and propane from a. Distillation process separates the crude oil into boiling point fractions. Modern separation involves piping crude oil through hot furnaces. Nearly half of every barrel of crude oil that goes into a typical. Barrel Of Oil Refining Process.

From www.ektinteractive.com

Oil 101 Refining Downstream Oil and Gas Barrel Of Oil Refining Process At our 15 refineries our throughput capacity of crude oil and other feedstocks is 3.2 million barrels per day. Distillation process separates the crude oil into boiling point fractions. Depending on the size of the refinery, from 80,000 to 300,000+ barrels of crude oil. All refineries have three basic steps: Diesel fuel, another transportation fuel, is generally. Figure 1.4 shows. Barrel Of Oil Refining Process.